Abstract

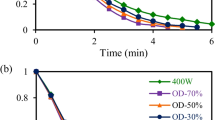

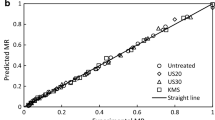

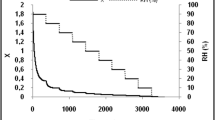

This aim of this study was aimed to evaluate the impact of HHP (high hydrostatic pressure) pre-treatment on the drying behavior of cashew slices, water adsorption isotherms, on extraction kinetic of total phenolic compounds (TPC) and antioxidant activity (AA). The drying kinetics were performed for cashew slices without pre-treatment (control) and pre-treated with 200 MPa (HHP1), 350 MPa (HHP2) and 500 MPa (HHP3) at a temperature of 70 °C in an electric oven (1200 W). Drying kinetics experimental data were fitted using empirical and diffusive models (third type boundary condition). The kinetics of ultrasound-assisted (40 kHz and 132 W) extraction of total phenolic compounds (TPCs) were realized and was determined AA (ABTS• + , DPPH• and FRAP) and water adsorption isotherms. The application of pressure 500 MPa (HHP3) provided an increase in the moisture transport process, a higher drying rate and shorter process time (40%). The effective diffusivity ranged from 1.2546 × 10–8 m2 min−1 (control) to 3.2045 × 10–8 m2 min−1 (HHP3). The extraction of TPC he was higher in the time of 180 min, emphasis for HHP3 who presented 154.48 mg GAE 100 g−1. Higher retention percentages AA by the three methods were observed for the slices pre-treated (HHP3) and the adsorption isotherms which presented characteristic of the type II curves. Therefore, the results of this study provide information for the potential application of HHP as a drying pre- treatment.

Graphical Abstract

Similar content being viewed by others

Data availability

Research data are not shared.

References

T.L. Honorato, M.C. Rabelo, L.R.B. Gonçalves, G.A.S. Pinto, S. Rodrigues, Fermentation of cashew apple juice to produce high added value products. World. J. Microbiol. Biotechnol. 23(10), 1409–1415 (2007). https://doi.org/10.1007/s11274-007-9381-z

T. Prommajak, N. Leksawasdi, N. Rattanapanone, Biotechnological valorization of cashew apple: a review. Chiang Mai. Univ. J. Nat. Sci. 13(2), 159–182 (2014). https://doi.org/10.12982/CMUJNS.2014.0029

C.S. Tamiello-Rosa, T.M. Cantu-Jungles, M. Iacomini, L.M. Cordeiro, Pectins from cashew apple fruit (Anacardium occidentale): extraction and chemical characterization. Carbohyd. Res. 483(107752), 1–6 (2019). https://doi.org/10.1016/j.carres.2019.107752

E.F. Souza, M.R. Furtado, C.W. Carvalho, O. Freitas-Silva, L.M. Gottschalk, Production and characterization of Gluconacetobacter xylinus bacterial cellulose using cashew apple juice and soybean molasses. Int. J. Biol. Macromol. 146, 285–289 (2020). https://doi.org/10.1016/j.ijbiomac.2019.12.180

H. Rajkumar, N.D. Ganesan, Effects of freeze-drying process on the production of cashew apple powder: Determination of bioactive compounds and fruit powder properties. J. Food Process. Preserv. 45(6), e15466 (2021). https://doi.org/10.1111/jfpp.15466

J.P. Gouveia, R.S. de Moura, F.D.A. Almeida, A.M.D.V. Oliveira, M.M.D. Silva, Avaliação da cinética de secagem de caju mediante um planejamento experimental. Rev. Bras. de Eng. Agríc. e Ambient. 6, 471–474 (2002). https://doi.org/10.1590/S1415-43662002000300015

P.M. Azoubel, Â.A. El-Aouar, R.V. Tonon, L.E. Kurozawa, G.C. Antonio, F.E.X. Murr, K.J. Park, Effect of osmotic dehydration on the drying kinetics and quality of cashew apple. Int. J. Food Sci. Technol. 44(5), 980–986 (2009). https://doi.org/10.1111/j.1365-2621.2008.01783

D.C. Santos, E.N.A. de Oliveira, J.N. Martins, A.P.T. Rocha, Secagem da polpa de caju em secador de leito de jorro. Rev. Bras. de Tecnol. Agroind. (2015). https://doi.org/10.3895/rbta.v9n2.2028

D.S. Bastos, P.M. do Gonçalves, C.T. de Andrade, L.K.G. de Araújo, R.M.H.M. da Leão, Microencapsulation of cashew apple (Anacardium occidentale, L) juice using a new chitosan–commercial bovine whey protein isolate system in spray drying. Food Bioprod. Process. 90(4), 683–692 (2012). https://doi.org/10.1016/j.fbp.2012.04.005

G. Musielak, D. Mierzwa, J. Kroehnke, Food drying enhancement by ultrasound–A review. Trends. Food Sci. Technol. 56, 126–141 (2016). https://doi.org/10.1016/j.tifs.2016.08.003

J.A. Moses, T. Norton, K. Alagusundaram, B.K. Tiwari, Novel drying techniques for the food industry. Food. Eng. Rev. 6, 43–55 (2014). https://doi.org/10.1007/s12393-014-9078-7

M.L. Rojas, I. Silveira, P.E.D. Augusto, Ultrasound and ethanol pre-treatments to improve convective drying: drying, rehydration and carotenoid content of pumpkin. Food Bioprod. Process. 119, 20–30 (2020). https://doi.org/10.1016/j.fbp.2019.10.008

N.C. Santos, R.L.J. Almeida, M.D.F.D. de Medeiros, R.T. Hoskin, M.R. da Silva Pedrini, Foaming characteristics and impact of ethanol pretreatment in drying behavior and physical characteristics for avocado pulp powder obtained by foam mat drying. J. Food Sci. 87(3), 1–12 (2022). https://doi.org/10.1111/1750-3841.16123

D. Huang, K. Men, D. Li, T. Wen, Z. Gong, B. Sunden, Z. Wu, Application of ultrasound technology in the drying of food products. Ultrason. Sonochem. 63(5), 104950 (2020). https://doi.org/10.1016/j.ultsonch.2019.104950

R. Osae, C. Zhou, B. Xu, W. Tchabo, H.E. Tahir, A.T. Mustapha, H. Ma, Effects of ultrasound, osmotic dehydration, and osmosonication pretreatments on bioactive compounds, chemical characterization, enzyme inactivation, color, and antioxidant activity of dried ginger slices. J. Food Biochem. 43(5), e12832 (2019). https://doi.org/10.1111/jfbc.12832

P.A. Ramos-Parra, C. García-Salinas, C.E. Rodríguez-López, N. García, G. García-Rivas, C. Hernández-Brenes, R.I.D. de la Garza, High hydrostatic pressure treatments trigger de novo carotenoid biosynthesis in papaya fruit (Carica papaya cv. Maradol). Food Chem. 277, 362–372 (2019). https://doi.org/10.1016/j.foodchem.2018.10.102

N.R.S. Hulle, P.S. Rao, Effect of high-pressure pretreatments on structural and dehydration characteristics of aloe vera (Aloe barbadensis Miller) cubes. Drying. Technol. 34(1), 105–118 (2015). https://doi.org/10.1080/07373937.2015.1037887

N. Palláres, H. Berrada, J. Tolosa, E. Ferrer, Effect of high hydrostatic pressure (HHP) and pulsed electric field (PEF) technologies on reduction of aflatoxins in fruit juices. LWT-Food Sci Technol 142, 111000 (2021). https://doi.org/10.1016/j.lwt.2021.111000

J. Xi, S. Luo, The mechanism for enhancing extraction of ferulic acid from Radix Angelica sinensis by high hydrostatic pressure. Sep. Purif. Technol. 165, 208–213 (2016). https://doi.org/10.1016/j.seppur.2016.04.011

K.O.P. Inada, S. Nunes, J.A. Martinez-Blazquez, F.A. Tomás-Barberán, D. Perrone, M. Monteiro, Effect of high hydrostatic pressure and drying methods on phenolic compounds profile of jabuticaba (Myrciaria jaboticaba) peel and seed. Food Chem. 309, 125794 (2020). https://doi.org/10.1016/j.foodchem.2019.125794

U. Yucel, H. Alpas, A. Bayindirli, Evaluation of high pressure pretreatment for enhancing the drying rates of carrot, apple, and green bean. J. Food Eng. 98(2), 266–272 (2010). https://doi.org/10.1016/j.jfoodeng.2010.01.006

L. Zhang, L. Liao, Y. Qiao, C. Wang, D. Shi, K. An, J. Hu, Effects of ultrahigh pressure and ultrasound pretreatments on properties of strawberry chips prepared by vacuum-freeze drying. Food Chem. (2019). https://doi.org/10.1016/j.foodchem.2019.125386

L. Zhang, Y. Qiao, C. Wang, L. Liao, D. Shi, K. An, L. Shi, Influence of high hydrostatic pressure pretreatment on properties of vacuum-freeze dried strawberry slices. Food Chem. 331, 127203 (2020). https://doi.org/10.1016/j.foodchem.2020.127203

A.O.A.C., Official methods of analysis of AOAC International, 20th edn. (AOAC international, Rockville, 2016)

A. Kaleta, K. Górnicki, Evaluation of drying models of apple (var. McIntosh) dried in a convective dryer. Int. J. Food Sci. Technol. 45(5), 891–898 (2010). https://doi.org/10.1111/j.1365-2621.2010.02230.x

L.M. Diamante, R. Ihns, G.P. Savage, L. Vanhanen, A new mathematical model for thin layer drying of fruits. Int. J. Food Sci. Technol. 45(9), 1956–1962 (2010). https://doi.org/10.1111/j.1365-2621.2010.02345.x

W.P. Silva, C.M.D.P.S. Silva, J.A.R. Sousa, V.S.O. Farias, Empirical and diffusion models to describe water transport into chickpea (Cicer arietinum L.). Int. J. Food Sci. Technol. 48(2), 267–273 (2013). https://doi.org/10.1111/j.1365-2621.2012.03183.x

Silva, W.P., & Silva, C.M.D.P.S. (2008). LAB Fit Curve Fitting Software (Nonlinear Regression and Treatment of Data Program) V 7.2.50 (2008), online, available from world wide web: <www.labfit.net>, date of Accessed: 2020-April-10.

N.C. Santos, R.L.J. Almeida, G.M. da Silva, V.M.D.A. Silva, V.H.D.A. Ribeiro, A.C.D.O. Brito, L.M.S. Rodrigues, R.M.S. Santos, M.M.T. Saraiva, Impact of pre-treatments with ethanol and freezing on drying slice papaya: drying performance and kinetic of ultrasound-assisted extraction of phenolics compounds. J. Sci. Food Agric. 102(11), 1–10 (2022). https://doi.org/10.1002/jsfa.12119

A.V. Luikov, Analytical heat diffusion theory (Academic Press, Inc. Ltd, London, 1968)

W.P. Silva, J.W. Precker, C.M.D.P.S. Silva, J.P. Gomes, Determination of effective diffusivity and convective mass transfer coefficient for cylindrical solids via analytical solution and inverse method: application to the drying of rough rice. J. Food Eng. 98(3), 302–308 (2010). https://doi.org/10.1016/j.jfoodeng.2009.12.029

N. Milićević, P. Kojić, M. Sakač, A. Mišan, J. Kojić, C. Perussello, B. Tiwari, Kinetic modelling of ultrasound-assisted extraction of phenolics from cereal brans. Ultrason. Sonochem. 79, 105761 (2021). https://doi.org/10.1016/j.ultsonch.2021.105761

R. Re, N. Pellegrini, A. Proteggente, A. Pannala, M. Yang, C. RiceEvans, Antioxidant activity applying an improved ABTS•+ radical cation decolorization assay. Free Radical Biol. Med. 26, 1231–1237 (1999)

M.S.M. Rufino, R.E. Alves, E.S. Brito, S.M. Morais, C.G. Sampaio, J.P. Jimenez, F.D.S. Calixto, Determinação da atividade antioxidante total em frutas pela captura do radical livre DPPH•. Comunicado Técnico Embrapa. 127, 1–4 (2007)

M.M.R. do Socorro, R.E. Alves, E.S. de Brito, J. Pérez-Jiménez, F. Saura-Calixto, J. Mancini-Filho, Bioactive compounds and antioxidant capacities of non –traditional tropical fruits from Brazil. Food Chem. 121(4), 996–1002 (2010). https://doi.org/10.1016/j.foodchem.2010.01.037

I.F. Benzie, J. Strain, The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal. Biochem. 239, 70–76 (1996). https://doi.org/10.1006/abio.1996.0292

S. Arslan-Tontul, Moisture sorption isotherm, isosteric heat and adsorption surface area of whole chia seeds. LWT-Food Sci. Technol. 119, 108859 (2020). https://doi.org/10.1016/j.lwt.2019.108859

J.V. García-Pérez, J.A. Cárcel, G. Clemente, A. Mulet, Water sorption isotherms for lemon peel at different temperatures and isosteric heats. LWT-Food Sci. Technol. 41(1), 18–25 (2008). https://doi.org/10.1016/j.lwt.2007.02.010

C.R. Oswin, The kinetics of package life. III. the isotherm. J Soc. Chem. Ind. 65(12), 419–421 (1946). https://doi.org/10.1002/jctb.5000651216

K.W. Lang, M.P. Steinberg, Predicting water activity from 0.30 to 0.95 of a multicomponent food formulation. J. Food Sci. 46(3), 670–672 (1981). https://doi.org/10.1111/j.1365-2621.1981.tb15320.x

N.C. Santos, R.L.J. Almeida, G.M. da Silva, S.S. Monteiro, V.H. de Alcântara Ribeiro, A.P. de França Silva, M.M. de Almeida Mota, Influence of high hydrostatic pressure (HHP) pretreatment on plum (Prunus salicina) drying: drying approach, physical, and morpho-structural properties of the powder and total phenolic compounds. J. Food Process. Preserv. (2022). https://doi.org/10.1111/jfpp.16968

W. Luo, S. Tappi, C. Wang, Y. Yu, S. Zhu, P. Rocculi, Study and optimization of high hydrostatic pressure (HHP) to improve mass transfer and quality characteristics of candied green plums (Prunus mume). J. Food Process. Preserv. 42(11), e13769 (2018). https://doi.org/10.1111/jfpp.13769

E.V. Silva Júnior, L.L. Melo, R.A.B. Medeiros, Z.M.P. Barros, P.M. Azoubel, Influence of ultrasound and vacuum assisted drying on papaya quality parameters. LWT Food Sci. Technol. 97, 317–322 (2018). https://doi.org/10.1016/j.lwt.2018.07.017

E.S. Silva, S.C.R. Brandão, A.L. da Silva, J.H.F. da Silva, A.C.D. Coêlho, P.M. Azoubel, Ultrasound-assisted vacuum drying of nectarine. J. Food Eng. 246, 119–124 (2019). https://doi.org/10.1016/j.jfoodeng.2018.11.013

N.C. Santos, R.L.J. Almeida, G.M. Silva, S.S. Monteiro, A.M.M.C.N. André, Effect of ultrasound pre-treatment on the kinetics and thermodynamic properties of guava slices drying process. Innov. Food Sci. Emerg. Technol. 66(12), 102507 (2020). https://doi.org/10.1016/j.ifset.2020.102507

N.C. Santos, R.L.J. Almeida, S.S. Monteiro, E.T. de Vilela Silva, V.M. de Alcântara Silva, A.M.M. André, V.H.A. Ribeiro, A.C.O. de Brito, Influence of ethanol and ultrasound on drying, bioactive compounds, and antioxidant activity of strawberries (Fragaria× ananassa). J. Indian Chem. Soc. 99(7), 100542 (2022). https://doi.org/10.1016/j.jics.2022.100542

D. Verma, N. Kaushik, P.S. Rao, Application of high hydrostatic pressure as a pretreatment for osmotic dehydration of banana slices (Musa cavendishii) finish-dried by dehumidified air drying. Food Bioprocess. Technol. 7(5), 1281–1297 (2014). https://doi.org/10.1007/s11947-013-1124-6

J.P. Ferreira, W.P. Silva, A.J. Queiroz, R.M. Figueirêdo, J.P. Gomes, B.A. Melo, A.G. Lima, Description of cumbeba (Tacinga inamoena) waste drying at different temperatures using diffusion models. Foods 9(12), 1818 (2020). https://doi.org/10.3390/foods9121818

J.P.D.L. Ferreira, A.J.D.M. Queiroz, R.M.F.D. Figueirêdo, W.P. Silva, J.P. Gomes, D.D.C. Santos, R.O.D. Andrade, Utilization of cumbeba (Tacinga inamoena) residue: drying kinetics and effect of process conditions on antioxidant bioactive compounds. Foods 10(4), 788 (2021). https://doi.org/10.3390/foods10040788

W.P. Silva, V.S.F. Oliveira, G.N. Araújo, A.G.B. Lima, Modeling of water transport in roof tiles by removal of moisture at isothermal conditions. Heat Mass Transf. 48(5), 809–821 (2012). https://doi.org/10.1007/s00231-011-0931-4

R.L.J. Almeida, N.C. Santos, C.E. Padilha, S.S. Monteiro, E.S. Santos, Impact of hydrothermal pretreatments on physicochemical characteristics and drying kinetics of starch from red rice (Oryza sativa L.). J. Food Proc. Preserv. 45, e.15448 (2021). https://doi.org/10.1111/jfpp.15448

M.J. Torres-Ossandón, L. Castillo, K.S. Ah-Hen, A. Vega-Gálvez, Effect of high hydrostatic pressure processing on phytochemicals, antioxidant activity, and behavior of Botrytis cinerea in white grape juice concentrate. J. Food Process. Preserv. 44(11), e14864 (2020). https://doi.org/10.1111/jfpp.14864

Y. Ma, J. Yi, J. Bi, Y. Zhao, X. Li, X. Wu, Q. Du, Effect of ultrasound on mass transfer kinetics and phenolic compounds of apple cubes during osmotic dehydration. LWT-Food Sci. Technol. 151, 112186 (2021). https://doi.org/10.1016/j.lwt.2021.112186

R.D. Khandare, P.D. Tomke, V.K. Rathod, Kinetic modeling and process intensification of ultrasound-assisted extraction of d-limonene using citrus industry waste. Chem. Eng. Proc.-Proc. Int. 159, 108181 (2021). https://doi.org/10.1016/j.cep.2020.108181

N. Kutlu, A. Isci, O. Sakiyan, A.E. Yilmaz, Effect of ohmic heating on ultrasound extraction of phenolic compounds from cornelian cherry (Cornus mas). J. Food Process. Preserv. 45(10), e15818 (2021). https://doi.org/10.1111/jfpp.15818

M. Babotă, O. Frumuzachi, A. Gâvan, C. Iacoviță, J. Pinela, L. Barros, A. Mocan, Optimized ultrasound-assisted extraction of phenolic compounds from Thymus comosus Heuff. ex Griseb. et Schenk (wild thyme) and their bioactive potential. Ultrason. Sonochem. 84, 105954 (2022). https://doi.org/10.1016/j.ultsonch.2022.105954

A.A. Casazza, B. Aliakbarian, E. Sannita, P. Perego, High-pressure high-temperature extraction of phenolic compounds from grape skins. Int. J. Food Sci. Technol. 47(2), 399–405 (2011). https://doi.org/10.1111/j.1365-2621.2011.02853.x

L. Eroman Unni, O.P. Chauhan, P.S. Raju, High pressure processing of garlic paste: effect on the quality attributes. Int. J. Food Sci. Technol. 49(6), 1579–1585 (2013). https://doi.org/10.1111/ijfs.12456

I. Park, J.U. Kim, H.M. Shahbaz, D. Jung, M. Jo, K.S. Lee, J. Park, High hydrostatic pressure treatment for manufacturing of garlic powder with improved microbial safety and antioxidant activity. Int. J. Food Sci. Technol. 54(2), 325–334 (2018). https://doi.org/10.1111/ijfs.13937

F.J. Barba, N.S. Terefe, R. Buckow, D. Knorr, V. Orlien, New opportunities and perspectives of high pressure treatment to improve health and safety attributes of foods a review. Food Res. Int. 77, 725–742 (2015). https://doi.org/10.1016/j.foodres.2015.05.015

G. Zhao, R. Zhang, M. Zhang, Effects of high hydrostatic pressure processing and subsequent storage on phenolic contents and antioxidant activity in fruit and vegetable products. Int. J. Food Sci. Technol. 52(1), 3–12 (2016). https://doi.org/10.1111/ijfs.13203

S. Dede, H. Alpas, A. Bayındırlı, High hydrostatic pressure treatment and storage of carrot and tomato juices: antioxidant activity and microbial safety. J. Sci. Food Agric. 87(5), 773–782 (2007). https://doi.org/10.1002/jsfa.2758

S. Zhang, Y. Zhao, X. Yao, Z. Zheng, C. Zheng, Z. Jiang, Effect of high hydrostatic pressure pretreatment on flavour and physicochemical properties of freeze-dried carambola slices. Int. J. Food Sci. Technol. 57(7), 1–10 (2022). https://doi.org/10.1111/ijfs.15748

G.A. Collazos-Escobar, N. Gutiérrez-Guzmán, H.A. Váquiro-Herrera, J. Bon, J.V. Garcia-Perez, Thermodynamic analysis and modeling of water vapor adsorption isotherms of roasted specialty coffee (Coffee arabica L. cv. Colombia). LWT-Food Sci. Technol. 160, 113335 (2022). https://doi.org/10.1016/j.lwt.2022.113335

P.P. Lewicki, The applicability of the GAB model to food water sorption isotherms. Int. J. Food Sci. Technol. 32(6), 553–557 (2008). https://doi.org/10.1111/j.1365-2621.1997.tb02131.x

R.F. Zabalaga, S.C. Carballo, Convective drying and water adsorption behavior of unripe banana: mathematical modeling. J. Food Process. Preserv. 39(6), 1334–1341 (2015). https://doi.org/10.1111/jfpp.12352

H. Al-Muhtaseb, M.A. Hararah, E.K. Megahey, W.A.M. McMinn, T.R.A. Magee, Moisture adsorption isotherms of microwave-baked Madeira cake. LWT-Food Sci. Technol. 43(7), 1042–1049 (2010). https://doi.org/10.1016/j.lwt.2010.01.003

S. Brunauer, L.S. Deming, W.E. Deming, E. Teller, On a theory of the van der Waals adsorption of gases. J. Am. Chem. Soc. 62(7), 1723–1732 (1940). https://doi.org/10.1021/ja01864a025

J.S. Zeymer, P.C. Corrêa, G.H. de Oliveira, F.M. Baptestini, R.C. Freitas, Desorption isotherms of Lactuca sativa seeds. Rev. Bras. de Eng Agríc e Ambient. 21, 568–572 (2017). https://doi.org/10.1590/1807-1929/agriambi.v21n8p568-572

K. Gościnna, J. Pobereżny, E. Wszelaczyńska, W. Szulc, B. Rutkowska, Effects of drying and extraction methods on bioactive properties of plums. Food Control 122, 107771 (2021). https://doi.org/10.1016/j.foodcont.2020.107771

Acknowledgements

NCS and RLJA were supported by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES). The authors are grateful to the Federal University of Rio Grande do Norte (UFRN), Federal University of Ceará (UFC), Federal University of Campina Grande (UFCG) and Federal Institute of Sertão Pernambucano (IFSertãoPE) for technical support.

Funding

Coordenação de Aperfeiçoamento de Pessoal de Nível Superior

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Ethical approval

Ethics approval was not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Santos, N.C., Almeida, R.L.J., da Silva, G.M. et al. Impact of high hydrostatic pressure (HHP) pre-treatment drying cashew (Anacardium occidentale L.): drying behavior and kinetic of ultrasound-assisted extraction of total phenolics compounds. Food Measure 17, 1033–1045 (2023). https://doi.org/10.1007/s11694-022-01688-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01688-5