Abstract

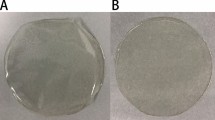

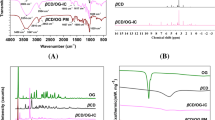

In this study, the chitosan (1% w/v) was hydrated in an aqueous solution of glacial acetic acid (1% w/v) by using a magnetic stirrer and mixed with glycerol (0.75% v/v), as a plasticizer. The four types of chitosan films were fabricated by adding 1.5% cinnamaldehyde and 0.05% ε-poly-l-lysine, and the mechanical, physical and antibacterial properties of the treatments were determined. Mechanical results indicated that the addition of cinnamaldehyde significantly increased the tensile strength and decreased the elongation at break. Moreover, the addition of cinnamaldehyde increased the thickness and decreased water solubility, moisture and water vapor permeability. FT-IR showed the formation of Schiff base and hydrogen bonds between the functional groups of the components, which improved the mechanical and physical properties of the treatments. Changes in the surface of the films were evaluated by SEM images. Further, the antimicrobial activity of the films containing cinnamaldehyde and ε-poly-l-lysine was confirmed against gram-negative bacteria Escherichia coli and Salmonella typhimurium and gram-positive Staphylococcus aureus and Bacillus subtilis. Based on the results, the films containing cinnamaldehyde and ε-poly-l-lysine can be used as the functional packaging for food products.

Similar content being viewed by others

References

M.C. Heller, S.E.M. Selke, G.A. Keoleian, Mapping the influence of food waste in food packaging environmental performance assessments. J. Ind. Ecol. 23(2), 480–495 (2018). https://doi.org/10.1111/jiec.12743

D. Alves, C. Brandão, V. Manuella, F. Vidal, R. Leitão, F. Karine, J. Moreira, M. Moreira, L. Coelho, B. Souza, Chitosan-based edible films produced from Crab-Uçá (Ucides cordatus) waste : physicochemical, mechanical and antimicrobial properties. J. Polym. Environ. 28(9), 694–706 (2020). https://doi.org/10.1007/s10924-020-01913-6

M.B. Vásconez, S.K. Flores, C.A. Campos, J. Alvarado, L.N. Gerschenson, Antimicrobial activity and physical properties of chitosan-tapioca starch based edible films and coatings. Food Res. Int. 42(7), 762–769 (2009). https://doi.org/10.1016/j.foodres.2009.02.026

S. Paidari, N. Zamindar, R. Tahergorabi, M. Kargar, S. Ezzati, S.H. Musavi, Edible coating and films as promising packaging: a mini review. J. Food Meas. Charact. 15, 4205–4214 (2021). https://doi.org/10.1007/s11694-021-00979-7

S. Valizadeh, M. Naseri, S. Babaei, S.M.H. Hosseini, Shelf life extension of fish patty using biopolymer-coated active paper sheets. Food Packag. Shelf Life. 26, 100603 (2020). https://doi.org/10.1016/j.fpsl.2020.100603

N. Oladzadabbasabadi, A.M. Nafchi, F. Ariffin, M.J.O. Wijekoon, A.A. Al-Hassan, M.A. Dheyab, M. Ghasemlou, Recent advances in extraction, modification, and application of chitosan in packaging industry. Carbohydr. Polym. 277, 118876 (2022). https://doi.org/10.1016/j.carbpol.2021.118876

N. Mahdavi Asl, H. Ahari, A.A.M. Moghanjoghi, S. Paidari, Assessment of nanochitosan packaging containing silver NPs on improving the shelf life of caviar (Acipenser persicus) and evaluation of nanoparticles migration. J. Food Meas. Charact. 15(6), 5078–5086 (2021). https://doi.org/10.1007/s11694-021-01082-7

A. Mehdizadeh, S. Shahidi, N. Shariatifar, M. Shiran, A. Ghorbani-HasanSaraei, Evaluation of chitosan-zein coating containing free and nano-encapsulated Pulicaria gnaphalodes (Vent.) Boiss. extract on quality attributes of rainbow trout. J. Aquat. Food Prod. Technol. 30, 62–75 (2021). https://doi.org/10.1080/10498850.2020.1855688

M.M. Marvizadeh, A. Tajik, V. Moosavian, N. Oladzadabbasabadi, A. Mohammadi Nafchi, Fabrication of cassava starch/mentha piperita essential oil biodegradable film with enhanced antibacterial properties. J. Chem. Health Risks 11(1), 23–29 (2021). https://doi.org/10.22034/jchr.2020.1900584.1135

S.M. Ojagh, M. Rezaei, S.H. Razavi, S.M.H. Hosseini, Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem. 122(1), 161–166 (2010). https://doi.org/10.1016/j.foodchem.2010.02.033

R.R. Gadkari, S. Suwalka, M.R. Yogi, W. Ali, A. Das, R. Alagirusamy, Green Synthesis of chitosan-cinnamaldehyde cross-linked nanoparticles: characterization and antibacterial activity. Carbohydr. Polym. 226, 115298 (2019). https://doi.org/10.1016/j.carbpol.2019.115298

S.N. Ashakirin, M. Tripathy, U.K. Patil, A.B.A. Majeed, Chemistry and bioactivity of cinnamaldehyde: a natural molecule of medicinal importance. Int. J. Pharm. Sci. Res. 8(6), 2333–2340 (2017). https://doi.org/10.13040/IJPSR.0975-8232.8(6).2333-40

A.O. Gill, R.A. Holley, Mechanisms of bactericidal action of Cinnamaldehyde against Listeria monocytogenes and of Eugenol against L. monocytogenes and Lactobacillus sakei. Appl. Environ. Microbiol. 70(10), 5750–5755 (2004). https://doi.org/10.1128/AEM.70.10.5750

L.S.M. Ooi, Y. Li, S. Kam, H. Wang, E.Y.L. Wong, V.E.C. Ooi, antimicrobial activities of cinnamon oil and Cinnamaldehyde from the Chinese medicinal herb Cinnamomum cassia Blume. Am. J. Chin. Med. 34(3), 511–522 (2006). https://doi.org/10.1142/S0192415X06004041

F. Liu, Y. Liu, Z. Sun, D. Wang, H. Wu, L. Du, D. Wang, Preparation and antibacterial properties of ε-polylysine-containing gelatin/chitosan nanofiber films. Int. J. Biol. Macromol. 164, 3376–3387 (2020). https://doi.org/10.1016/j.ijbiomac.2020.08.152

R. Ye, H. Xu, C. Wan, S. Peng, L. Wang, H. Xu, Z.P. Aguilar, Y. Xiong, Z. Zeng, H. Wei, Biochemical and biophysical research communications antibacterial activity and mechanism of action of ε-poly-l-lysine. Biochem. Biophys. Res. Commun. 439, 148–153 (2013). https://doi.org/10.1016/j.bbrc.2013.08.001

I.L. Shih, M.H. Shen, Y.T. Van, Microbial synthesis of poly(ε-lysine) and its various applications. Bioresour. Technol. 97(9), 1148–1159 (2006). https://doi.org/10.1016/j.biortech.2004.08.012

R. Razavi, H. Tajik, M. Moradi, R. Molaei, P. Ezati, Antimicrobial, microscopic and spectroscopic properties of cellulose paper coated with chitosan sol-gel solution formulated by epsilon-poly-l-lysine and its application in active food packaging. Carbohydr Res. 489, 107912 (2020). https://doi.org/10.1016/j.carres.2020.107912

X. Shen, M. Zhang, K. Fan, Z. Guo, Effects of ε-polylysine/chitosan composite coating and pressurized argon in combination with MAP on quality and microorganisms of fresh-cut potatoes. Food Bioprocess Technol. 13(1), 145–158 (2020). https://doi.org/10.1007/s11947-019-02388-7

F. Nowzari, B. Shábanpour, S.M. Ojagh, Comparison of chitosan-gelatin composite and bilayer coating and film effect on the quality of refrigerated rainbow trout. Food Chem. 141(3), 1667–1672 (2013). https://doi.org/10.1016/j.foodchem.2013.03.022

S. Valizadeh, M. Naseri, S. Babaei, S.M.H. Hosseini, A. Imani, Development of bioactive composite films from chitosan and carboxymethyl cellulose using glutaraldehyde, cinnamon essential oil and oleic acid. Int. J. Biol. Macromol. 134, 604–612 (2019). https://doi.org/10.1016/j.ijbiomac.2019.05.071

L.F. Ballesteros, M.A. Cerqueira, J.A. Teixeira, S.I. Mussatto, Production and physicochemical properties of carboxymethyl cellulose films enriched with spent coffee grounds polysaccharides. Int. J. Biol. Macromol. 106, 647–655 (2018). https://doi.org/10.1016/j.ijbiomac.2017.08.060

Z. Mousavi, M. Naseri, S. Babaei, S.M.H. Hosseini, S.S. Shekarforoush, The effect of cross-linker type on structural, antimicrobial and controlled release properties of fish gelatin-chitosan composite films incorporated with ε-poly-l-lysine. Int. J. Biol. Macromol. 183, 1743–1752 (2021). https://doi.org/10.1016/j.ijbiomac.2021.05.159

N.A. Azlim, A. Mohammadi Nafchi, N. Oladzadabbasabadi, F. Ariffin, P. Ghalambor, S. Jafarzadeh, A.A. Al-Hassan, Fabrication and characterization of a pH-sensitive intelligent film incorporating dragon fruit skin extract. Food Sci. Nutr. (2021). https://doi.org/10.1002/fsn3.2680

L. Deng, X. Li, K. Miao, X. Mao, M. Han, D. Li, C. Mu, L. Ge, Development of disulfide bond crosslinked gelatin/ε-polylysine active edible film with antibacterial and antioxidant activities. Food Bioprocess Technol. 13(2), 577–588 (2020). https://doi.org/10.1007/s11947-020-02420-1

F. Xue, Y. Chungu, C. Li, B. Adhikari, Encapsulation of essential oil in emulsion based edible films prepared by soy protein isolate-gum acacia conjugates. Food Hydrocoll. 96, 178–189 (2019). https://doi.org/10.1016/j.foodhyd.2019.05.014

S.F. Hosseini, J. Ghaderi, M.C. Gómez-Guillén, trans-Cinnamaldehyde-doped quadripartite biopolymeric films : rheological behavior of film-forming solutions and biofunctional performance of films. Food Hydrocoll. 112, 106339 (2021). https://doi.org/10.1016/j.foodhyd.2020.106339

N. Matan, H. Rimkeeree, A.J. Mawson, P. Chompreeda, V. Haruthaithanasan, M. Parker, Antimicrobial activity of cinnamon and clove oils under modified atmosphere conditions. Int. J. Food Microbiol. 107, 180–185 (2006). https://doi.org/10.1016/j.ijfoodmicro.2005.07.007

S. Park, Y. Zhao, Incorporation of a high concentration of mineral or vitamin into chitosan-based films. J. Agric. Food Chem. 52, 1933–1939 (2004). https://doi.org/10.1021/jf034612p

S.S. Narasagoudr, V.G. Hegde, V.N. Vanjeri, R.B. Chougale, S.P. Masti, Ethyl vanillin incorporated chitosan/poly(vinyl alcohol) active films for food packaging applications. Carbohydr. Polym. 236, 116049 (2020). https://doi.org/10.1016/j.carbpol.2020.116049

H. Chen, X. Hu, E. Chen, S. Wu, D.J. McClements, S. Liu, B. Li, Y. Li, Preparation, characterization, and properties of chitosan films with cinnamaldehyde nanoemulsions. Food Hydrocoll. 61, 662–671 (2016). https://doi.org/10.1016/j.foodhyd.2016.06.034

Y. Wang, F. Liu, C. Liang, F. Yuan, Y. Gao, Effect of Maillard reaction products on the physical and antimicrobial properties of edible films based on ε-polylysine and chitosan. J. Sci. Food Agric. 94(14), 2986–2991 (2014). https://doi.org/10.1002/jsfa.6644

J. Wang, Z. Lian, H. Wang, X. Jin, Y. Liu, Synthesis and antimicrobial activity of schiff base of chitosan and acylated chitosan. J. Appl. Polym. Sci. 123, 3242–3247 (2012). https://doi.org/10.1002/app

E. Kenawy, A.M. Omer, T.M. Tamer, M.A. Elmeligy, M.S.M. Eldin, Fabrication of biodegradable gelatin/chitosan/cinnamaldehyde crosslinked membranes for antibacterial wound dressing applications. Int. J. Biol. Macromol. 139, 440–448 (2019). https://doi.org/10.1016/j.ijbiomac.2019.07.191

C. Zhang, Z. Wang, Y. Li, Y. Yang, X. Ju, R. He, The preparation and physiochemical characterization of rapeseed protein hydrolysate-chitosan composite films. Food Chem. 272, 694–701 (2019). https://doi.org/10.1016/j.foodchem.2018.08.097

M. Pereda, A.G. Ponce, N.E. Marcovich, R.A. Ruseckaite, J.F. Martucci, Chitosan-gelatin composites and bi-layer films with potential antimicrobial activity. Food Hydrocoll. 25(5), 1372–1381 (2011). https://doi.org/10.1016/j.foodhyd.2011.01.001

C. Wu, J. Sun, Y. Lu, T. Wu, J. Pang, Y. Hu, In situ self-assembly chitosan/ε-polylysine bionanocomposite film with enhanced antimicrobial properties for food packaging. Int. J. Biol. Macromol. 132, 385–392 (2019). https://doi.org/10.1016/j.ijbiomac.2019.03.133

J. Xu, R. Wei, Z. Jia, R. Song, Characteristics and bioactive functions of chitosan/gelatin-based film incorporated with ε-polylysine and astaxanthin extracts derived from by-products of shrimp (Litopenaeus vannamei). Food Hydrocoll. 100, 105436–105446 (2020). https://doi.org/10.1016/j.foodhyd.2019.105436

Acknowledgements

This Project funded by Shiraz University. Also, the authors thank the staff of the Fisheries Laboratory and the Food Science and Technology Laboratory of Shiraz University (Grant No. 98GCU1M340880).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mousavi, Z., Babaei, S., Naseri, M. et al. Utilization in situ of biodegradable films produced with chitosan, and functionalized with ε-poly-l-lysine: an effective approach for super antibacterial application. Food Measure 16, 1416–1425 (2022). https://doi.org/10.1007/s11694-022-01297-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01297-2