Abstract

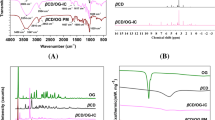

Antimicrobial and biodegradable film-forming biopolymers are of tremendous interest for their possible use in food packaging applications. In this study, solvent casting and evaporation techniques were used to fabricate biodegradable active films from chitosan that contained Mustard oil (MO) at 0, 0.5, 1, and 2 Wt.% (v/v) concentrations. Then, it was evaluated if the chitosan films combined with MO could be employed as naturally biodegradable films for food application by examining the physical properties, mechanical, thermal, antibacterial, and antioxidant activities of various films. Potential interactions between the MO and chitosan were confirmed by Fourier- transform infrared spectroscopy (FT-IR). The elongation at break (EB) and the thickness of the films increased significantly because of the higher MO content. In contrast, there was a significant drop in water solubility, tensile strength (TS) and young’s modulus (YM), and moisture content. With the inclusion of MO, creases and tiny droplets were seen on the otherwise fine surface morphology of the films, which explained why TS and YM was reduced. The addition of MO enhanced the film's water vapor barrier properties while having slight improvement in their thermal stability. Moreover, the antibacterial and antioxidant characteristics of the chitosan films were evaluated and investigated, revealing a specific capacity to scavenge DPPH radicals while demonstrating a significant inhibitory effect against Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli). The prepared composite films were 45–70% soil biodegradation after 21 days. In conclusion, the introduction of MO to chitosan-based films has shown significant promise for use in food packaging applications.

Similar content being viewed by others

References

Priyadarshi R, Sauraj KB et al (2018) Chitosan films incorporated with apricot (Prunus armeniaca) kernel essential oil as active food packaging material. Food Hydrocoll 85:158–166. https://doi.org/10.1016/j.foodhyd.2018.07.003

Robertson GL (2005) Food packaging: principles and practice. CRC Press, Boca Raton

Bastarrachea L, Dhawan S, Sablani SS (2011) Engineering properties of polymeric-based antimicrobial films for food packaging: a review. Food Eng Rev 3:79–93

Narayanan M, Loganathan S, Valapa RB et al (2017) UV protective poly (lactic acid)/rosin films for sustainable packaging. Int J Biol Macromol 99:37–45

de Braz EM, A, Silva SCCC e., da Silva DA, et al (2018) Modified chitosan-based bioactive material for antimicrobial application: synthesis and characterization. Int J Biol Macromol 117:640–647. https://doi.org/10.1016/j.ijbiomac.2018.05.205

Park S, Zhao Y (2004) Incorporation of a high concentration of mineral or vitamin into chitosan-based films. J Agric Food Chem 52:1933–1939

Maliki S, Sharma G, Kumar A et al (2022) Chitosan as a tool for sustainable development: a mini review. Polymers (Basel) 14:1475

Marroquin JB, Rhee KY, Park SJ (2013) Chitosan nanocomposite films: enhanced electrical conductivity, thermal stability, and mechanical properties. Carbohydr Polym 92:1783–1791. https://doi.org/10.1016/j.carbpol.2012.11.042

Kloster GA, Marcovich NE, Mosiewicki MA (2015) Composite films based on chitosan and nanomagnetite. Eur Polym J 66:386–396. https://doi.org/10.1016/j.eurpolymj.2015.02.042

Gupta I, Kumar A, Bhatt AN et al (2022) Green synthesis-mediated silver nanoparticles based biocomposite films for wound healing application. J Inorg Organomet Polym Mater. https://doi.org/10.1007/s10904-022-02333-w

Rahman PM, Mujeeb VMA, Muraleedharan K (2017) Flexible chitosan-nano ZnO antimicrobial pouches as a new material for extending the shelf life of raw meat. Int J Biol Macromol 97:382–391. https://doi.org/10.1016/j.ijbiomac.2017.01.052

Ni Y, Nie H, Wang J et al (2022) Enhanced functional properties of chitosan films incorporated with curcumin-loaded hollow graphitic carbon nitride nanoparticles for bananas preservation. Food Chem 366:130539

Shankar S, Khodaei D, Lacroix M (2021) Effect of chitosan/essential oils/silver nanoparticles composite films packaging and gamma irradiation on shelf life of strawberries. Food Hydrocoll 117:106750. https://doi.org/10.1016/j.foodhyd.2021.106750

Kaewklin P, Siripatrawan U, Suwanagul A, Lee YS (2018) Active packaging from chitosan-titanium dioxide nanocomposite film for prolonging storage life of tomato fruit. Int J Biol Macromol 112:523–529

Zhang W, Li X, Jiang W (2020) Development of antioxidant chitosan film with banana peels extract and its application as coating in maintaining the storage quality of apple. Int J Biol Macromol 154:1205–1214. https://doi.org/10.1016/j.ijbiomac.2019.10.275

Wang Q, Tian F, Feng Z et al (2015) Antioxidant activity and physicochemical properties of chitosan films incorporated with Lycium barbarum fruit extract for active food packaging. Int J Food Sci Technol 50:458–464

Rambabu K, Bharath G, Banat F et al (2019) Mango leaf extract incorporated chitosan antioxidant film for active food packaging. Int J Biol Macromol 126:1234–1243. https://doi.org/10.1016/j.ijbiomac.2018.12.196

Yuan G, Lv H, Yang B et al (2015) Physical properties, antioxidant and antimicrobial activity of chitosan films containing carvacrol and pomegranate peel extract. Molecules 20:11034–11045

Siripatrawan U, Vitchayakitti W (2016) Improving functional properties of chitosan films as active food packaging by incorporating with propolis. Food Hydrocoll 61:695–702. https://doi.org/10.1016/j.foodhyd.2016.06.001

Zhang X, Lian H, Shi J et al (2020) Plant extracts such as pine nut shell, peanut shell and jujube leaf improved the antioxidant ability and gas permeability of chitosan films. Int J Biol Macromol 148:1242–1250. https://doi.org/10.1016/j.ijbiomac.2019.11.108

Nadira PP, Mujeeb VMA, Rahman PM, Muraleedharan K (2022) Effects of cashew leaf extract on physicochemical, antioxidant, and antimicrobial properties of N, O-Carboxymethyl chitosan films. Carbohydr Poly Technol Appl 3:100191. https://doi.org/10.1016/j.carpta.2022.100191

Peng Y, Wu Y, Li Y (2013) Development of tea extracts and chitosan composite films for active packaging materials. Int J Biol Macromol 59:282–289

Liu T, Wang J, Chi F et al (2020) Development and characterization of novel active chitosan films containing fennel and peppermint essential oils. Coatings 10:1–10. https://doi.org/10.3390/coatings10100936

Han Lyn F, Nur Hanani ZA (2020) Effect of lemongrass (Cymbopogon citratus) Essential Oil on the Properties of Chitosan Films for Active Packaging. J Packag Technol Res 4:33–44. https://doi.org/10.1007/s41783-019-00081-w

BiswalP H, Saha S AK (2020) Efficient and prolonged antibacterial activity from porous PLGA microparticles and their application in food preservation. Mater Sci Eng C 108:110496. https://doi.org/10.1016/j.msec.2019.110496

Burt S (2004) Essential oils: their antibacterial properties and potential applications in foods—a review. Int J Food Microbiol 94:223–253

Liu K, Huang RL, Zha XQ et al (2020) Encapsulation and sustained release of curcumin by a composite hydrogel of lotus root amylopectin and chitosan. Carbohydr Polym 232:115810. https://doi.org/10.1016/j.carbpol.2019.115810

Waterhouse AL (2002) Determination of total phenolics. Curr Protocol Food Anal Chem 6:I1-1

Vasile C, Sivertsvik M, Miteluţ AC et al (2017) Comparative analysis of the composition and active property evaluation of certain essential oils to assess their potential applications in active food packaging. Materials. https://doi.org/10.3390/ma10010045

Rahman PM, Mujeeb VMA, Muraleedharan K, Thomas SK (2018) Chitosan/nano ZnO composite films: enhanced mechanical, antimicrobial and dielectric properties. Arab J Chem 11:120–127

Lawrie G, Keen I, Drew B et al (2007) Interactions between alginate and chitosan biopolymers characterized using FTIR and XPS. Biomacromolecules 8:2533–2541. https://doi.org/10.1021/bm070014y

Altiok D, Altiok E, Tihminlioglu F (2010) Physical, antibacterial and antioxidant properties of chitosan films incorporated with thyme oil for potential wound healing applications. J Mater Sci Mater Med 21:2227–2236. https://doi.org/10.1007/s10856-010-4065-x

Kaya M, Khadem S, Cakmak YS et al (2018) Antioxidative and antimicrobial edible chitosan films blended with stem, leaf and seed extracts of Pistacia terebinthus for active food packaging. RSC Adv 8:3941–3950

Liu Z, Du M, Liu H et al (2021) Chitosan films incorporating litchi peel extract and titanium dioxide nanoparticles and their application as coatings on watercored apples. Prog Org Coat 151:106103. https://doi.org/10.1016/j.porgcoat.2020.106103

Shen Z, Kamdem DP (2015) Development and characterization of biodegradable chitosan films containing two essential oils. Int J Biol Macromol 74:289–296. https://doi.org/10.1016/j.ijbiomac.2014.11.046

Hafsa J, Smach M, ali, ben Khedher MR, et al (2016) Physical, antioxidant and antimicrobial properties of chitosan films containing Eucalyptus globulus essential oil. LWT Food Sci Technol 68:356–364. https://doi.org/10.1016/j.lwt.2015.12.050

Dou B, Dupont V, Williams PT et al (2009) Thermogravimetric kinetics of crude glycerol. Bioresour Technol 100:2613–2620

Coats AW, Redfern JP (1963) Thermogravimetric analysis. A review. Analyst 88:906–924

Hemalatha T, UmaMaheswari T, Senthil R et al (2017) Efficacy of chitosan films with basil essential oil: perspectives in food packaging. J Food Measurement Characterization 11:2160–2170. https://doi.org/10.1007/s11694-017-9601-7

Fundo JF, Quintas MAC, Silva CLM Influence of film forming solutions on properties of chitosan/glycerol films, 11th International Congress on Engineering and Food - Athens, Greece, 2011

Souza VGL, Fernando AL, Pires JRA et al (2017) Physical properties of chitosan films incorporated with natural antioxidants. Ind Crops Prod 107:565–572

Enos-Berlage JL, Guvener ZT, Keenan CE, McCarter LL (2005) Genetic determinants of biofilm development of opaque and translucent Vibrio parahaemolyticus. Mol Microbiol 55:1160–1182

Zhao J, Wang Y, Liu C (2022) Film transparency and opacity measurements. Food Anal Methods. https://doi.org/10.1007/s12161-022-02343-x

Galus S, Kadzińska J (2016) Whey protein edible films modified with almond and walnut oils. Food Hydrocoll 52:78–86

López-Mata MA, Ruiz-Cruz S, Silva-Beltrán NP et al (2015) Physicochemical and antioxidant properties of chitosan films incorporated with cinnamon oil. Int J Polym Sci. https://doi.org/10.1155/2015/974506

Pires C, Ramos C, Teixeira G et al (2011) Characterization of biodegradable films prepared with hake proteins and thyme oil. J Food Eng 105:422–428. https://doi.org/10.1016/j.jfoodeng.2011.02.036

Gioielli LA (2006) Food processing: principles and applications. Revista Brasileira de Ciências Farmacêuticas 42:307–307. https://doi.org/10.1590/s1516-93322006000200017

Li Y, Tang C, He Q (2021) Effect of orange (Citrus sinensis L.) peel essential oil on characteristics of blend films based on chitosan and fish skin gelatin. Food Biosci 41:100927. https://doi.org/10.1016/j.fbio.2021.100927

Martins JT, Cerqueira MA, Vicente AA (2012) Influence of α-tocopherol on physicochemical properties of chitosan-based films. Food Hydrocoll 27:220–227. https://doi.org/10.1016/j.foodhyd.2011.06.011

Akyuz L, Kaya M, Ilk S et al (2018) Effect of different animal fat and plant oil additives on physicochemical, mechanical, antimicrobial and antioxidant properties of chitosan films. Int J Biol Macromol 111:475–484. https://doi.org/10.1016/j.ijbiomac.2018.01.045

Ojagh SM, Rezaei M, Razavi SH, Hosseini SMH (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122:161–166. https://doi.org/10.1016/j.foodchem.2010.02.033

Sánchez-González L, Cháfer M, Chiralt A, González-Martínez C (2010) Physical properties of edible chitosan films containing bergamot essential oil and their inhibitory action on Penicillium italicum. Carbohydr Polym 82:277–283. https://doi.org/10.1016/j.carbpol.2010.04.047

Jahed E, Khaledabad MA, Almasi H, Hasanzadeh R (2017) Physicochemical properties of Carum copticum essential oil loaded chitosan films containing organic nanoreinforcements. Carbohydr Polym 164:325–338

Atarés L, Chiralt A (2016) Essential oils as additives in biodegradable films and coatings for active food packaging. Trends Food Sci Technol 48:51–62. https://doi.org/10.1016/j.tifs.2015.12.001

Perdones Á, Chiralt A, Vargas M (2016) Properties of film-forming dispersions and films based on chitosan containing basil or thyme essential oil. Food Hydrocoll 57:271–279. https://doi.org/10.1016/j.foodhyd.2016.02.006

Wang L, Liu F, Jiang Y et al (2011) Synergistic antimicrobial activities of natural essential oils with chitosan films. J Agric Food Chem 59:12411–12419. https://doi.org/10.1021/jf203165k

Cota-Arriola O, Onofre Cortez-Rocha M, Burgos-Hernández A et al (2013) Controlled release matrices and micro/nanoparticles of chitosan with antimicrobial potential: development of new strategies for microbial control in agriculture. J Sci Food Agric 93:1525–1536. https://doi.org/10.1002/jsfa.6060

Rodríguez-Núñez JR, López-Cervantes J, Sánchez-Machado DI et al (2012) Antimicrobial activity of chitosan-based films against Salmonella typhimurium and Staphylococcus aureus. Int J Food Sci Technol 47:2127–2133. https://doi.org/10.1111/j.1365-2621.2012.03079.x

Genskowsky E, Puente LA, Pérez-Álvarez JA et al (2015) Assessment of antibacterial and antioxidant properties of chitosan edible films incorporated with maqui berry (Aristotelia chilensis). LWT Food Sci Technol 64:1057–1062. https://doi.org/10.1016/j.lwt.2015.07.026

Kim KW, Min BJ, Kim YT et al (2011) Antimicrobial activity against foodborne pathogens of chitosan biopolymer films of different molecular weights. LWT Food Sci Technol 44:565–569. https://doi.org/10.1016/j.lwt.2010.08.001

Fenwick GR, Heaney RK, Mullin WJ (1982) Glucosinolates and their breakdown products in food and food plants. C R C Crit Rev Food Sci Nutr 18:123–201. https://doi.org/10.1080/10408398209527361

Lin CM, Preston JF, Wei CI (2000) Antibacterial mechanism of allyl isothiocyanate. J Food Prot 63:727–734. https://doi.org/10.4315/0362-028X-63.6.727

Turgis M, Han J, Caillet S, Lacroix M (2009) Antimicrobial activity of mustard essential oil against Escherichia coli O157:H7 and Salmonella typhi. Food Control 20:1073–1079. https://doi.org/10.1016/j.foodcont.2009.02.001

Isshiki K, Tokuoka K, Mori R, Chiba S (1992) Preliminary examination of allyl isothiocyanate vapor for food preservation. Biosci Biotechnol Biochem 56:1476–1477. https://doi.org/10.1271/bbb.56.1476

Ouattara B, Simard RE, Holley RA et al (1997) Antibacterial activity of selected fatty acids and essential oils against six meat spoilage organisms. Int J Food Microbiol 37:155–162. https://doi.org/10.1016/S0168-1605(97)00070-6

Alboofetileh M, Rezaei M, Hosseini H, Abdollahi M (2014) Antimicrobial activity of alginate/clay nanocomposite films enriched with essential oils against three common foodborne pathogens. Food Control 36:1–7. https://doi.org/10.1016/j.foodcont.2013.07.037

Janu C, Kumar DRS, Reshma M, v, et al (2014) Comparative study on the total phenolic content and radical scavenging activity of common edible vegetable oils. J Food Biochem 38:38–49. https://doi.org/10.1111/jfbc.12023

Ruiz-Navajas Y, Viuda-Martos M, Sendra E et al (2013) In vitro antibacterial and antioxidant properties of chitosan edible films incorporated with thymus moroderi or thymus piperella essential oils. Food Control 30:386–392. https://doi.org/10.1016/j.foodcont.2012.07.052

Basavegowda N, Baek KH (2021) Synergistic antioxidant and antibacterial advantages of essential oils for food packaging applications. Biomolecules. https://doi.org/10.3390/biom11091267

Santos-Sánchez NF, Salas-Coronado R, Villanueva-Cañongo C, Hernández-Carlos B (2019) Antioxidant compounds and their antioxidant mechanism. Antioxidants 10:1–29

Darwish MSA, Mostafa MH, Hussein LI et al (2021) Preparation, characterization, mechanical and biodegradation behavior of polypropylene-chitosan/ZnO nanocomposite. Polymer-Plastics Technol Mater 60:1630–1640

Mittal M, Chaudhary R (2019) Biodegradability and mechanical properties of pineapple leaf/coir fiber reinforced hybrid epoxy composites. Mater Res Express 6:45301

Huang C, Liao Y, Zou Z et al (2022) Novel strategy to interpret the degradation behaviors and mechanisms of bio- and non-degradable plastics. J Clean Prod 355:131757. https://doi.org/10.1016/j.jclepro.2022.131757

Acknowledgements

The authors thank Dr. Seenuvasan Vedachalam (National Institute of Technology, karaikal) for assistance with the NMR analysis and biodegradation mechanism part.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All authors contributed to study concepts, experiment design, material preparation, data collection and analysis. The first draft of the manuscript was written by SM. All authors read and approved the final manuscript submitted for review.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohan, S., Unnikrishnan, T.G., Dubey, U. et al. Development and Characterization of Mustard Oil Incorporated Biodegradable Chitosan Films for Active Food Packaging Applications. J Polym Environ 31, 2190–2203 (2023). https://doi.org/10.1007/s10924-022-02719-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02719-4