Abstract

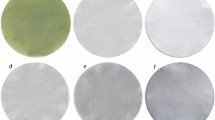

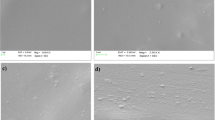

In the present study, we investigate PE/POE/PA6 blends containing nano silica and clay, which is one of the most important synthetic polymers utilized in food packaging industry. Nanocomposite films including C0S0, C1S0.75, and C2S0.75 (C and S denoting nanoclay and nanosilica, respectively) were prepared via melt mixing method. Then, structural, mechanical, thermal, and morphological traits of the prepared films were evaluated. Analysis of variance (ANOVA) results for parameters including strain and energy in the tensile test, elasticity modulus, and work in penetration test were significant at 0.05% probability. X-ray diffraction (XRD) patterns showed that polymer mixing resulted in the removal of 2.5–3 pick and the tendency of 3.5–4.5 and 6.5–7.5 picks appear at lower angles, suggesting the layers openness and partly sheet structure of the nanoparticles. According to SEM micrographs, soil nanoparticle distribution is almost suitable and there is no accumulation at various fracture surface areas. Thermo gravimetric analysis (TGA) presented a relatively good thermos ability. The results of the Differential scanning calorimetry test in the nanocomposite packaging films showed that enthalpy (ΔHm and ΔHc) and crystallinity percentage in all nanocomposites with PA6 and LDPE polymeric components from C0S0, C1S0.75, and C2S0.75 nanocomposite films had a decreasing trend. Therefore, physical, mechanical, thermal and morphological properties of PE/POE/PA6 blends containing Nano silica and clay were improved and increasing storage life, which are important in economic, marketability, and exporting terms.

Graphic abstract

Similar content being viewed by others

References

J.Y. Huang, X. Li, W. Zhou, Trends Food Sci. Technol. 45(2), 187–199 (2015). https://doi.org/10.1016/j.tifs.2015.07.002

H. Wei, Y. Yan Jun, L. Ning Tao, W. Li Bing, Application and safety assessment for nano-composite materials in food packaging. Chin. Sci. Bull. 56(12), 1216–1225 (2011). https://doi.org/10.1007/s11434-010-4326-6

G. Gorrasi, V. Bugatti, L. Tammaro, L. Vertuccio, G. Vigliotta, V. Vittoria, Food Control 64, 10–16 (2016). https://doi.org/10.1016/j.foodcont.2015.12.002

V. Siracusa, Chapter 7—Packaging material in the food industry, in Antimicrobial Food Packaging, ed. by J. Barros-Velázquez, (Academic Press, San Diego, 2016), pp. 95–106. https://doi.org/10.1016/B978-0-12-800723-5.00007-3

D. Mousavian, A.M. Nafchi, L. Nouri, A. Abedinia, J. Food Meas. Charact. 2020, 1–9 (2020). https://doi.org/10.1007/s11694-020-00690-z

A. Gopanna, K.P. Rajan, S.P. Thomas, M. Chavali, Materials for Biomedical Engineering (Elsevier, Amsterdam, 2019), pp. 175–216. https://doi.org/10.1016/B978-0-12-816874-5.00006-2

S. Lange, T. Arroval, R. Saar, I. Kink, J. Aarik, A. Krumme, Polym.-Plast. Technol. Eng. 54, 301–304 (2015). https://doi.org/10.1080/03602559.2014.977426

N. Bumbudsanpharoke, W. Lee, S. Ko, Polym. Compos. (2017). https://doi.org/10.1002/pc.24325

F. Chivarc, E. Pollet, L. Averous, Mater. Sci. Eng. R Rep. 67, 1–17 (2009). https://doi.org/10.1016/j.mser.2009.09.002

K. Soon, E.H. Jones, R.S. Rajeev, G. Menary, P.J. Martin, C.G. Armstrong, Polym. Eng. Sci. 52, 532–548 (2012). https://doi.org/10.1002/pen.22114

E. Jamróz, G. Khachatryan, P. Kopel, L. Juszczak, A. Kawecka, P. Krzyściak, M. Kucharek, Carbohydr. Polym. 240, 116244 (2020). https://doi.org/10.1016/j.carbpol.2020.116244

T.V. Duncan, J. Colloid Interface Sci. 363(1), 1–24 (2011). https://doi.org/10.1016/j.jcis.2011.07.017

A. Sorrentino, G. Gorrasi, V. Vittoria, Trends Food Sci. Technol. 18(2), 84–95 (2007). https://doi.org/10.1016/j.tifs.2006.09.004

A.M. Hezma, A. Rajeh, M.A. Mannaa, Colloids Surf. A Physicochem. Eng. Aspects 581, 123821 (2020). https://doi.org/10.1016/j.colsurfa.2019.123821

H. Sepet, N. Tarakcioglu, R.D.K. Misra, J. Compos. Mater. 50, 3105–3116 (2016). https://doi.org/10.1177/0021998315615653

G. Venkatesh, A. Deb, A. Karmarkar, S.S. Chauhan, Mater. Des. 37, 285–291 (2012). https://doi.org/10.1016/j.matdes.2011.12.034

R.M. Meri, J. Zicans, R. Maksimovs, T. Ivanova, M. Kalnins, R. Berzina, G. Japins, Compos. Struct. 111, 453–458 (2014). https://doi.org/10.1016/j.compstruct.2014.01.017

B. Akbari, R. Bagheri, Polym.-Plast. Technol. Eng. 53, 156–161 (2014). https://doi.org/10.1080/03602559.2013.843702

N. Follain, B. Alexandre, C. Chappey, L. Colasse, P. Mederic, S. Marais, Compos. Sci. Technol. 136, 18–28 (2016). https://doi.org/10.1016/j.compscitech.2016.09.023

H.M. Wilhelm, M.R. Sierakowski, G.P. Souza, F. Wypych, Carbohydr. Polym. 52(2), 101–110 (2003). https://doi.org/10.1016/S0144-8617(02)00239-4

N.F. Magalhaes, C.T. Andrade, Carbohydr. Polym. 75, 712–718 (2009). https://doi.org/10.1016/j.carbpol.2008.09.020

M.S. Islam, M.B. Ahmad, M. Hasan, S.A. Aziz, M. Jawaid, M.M. Haafiz, S.A. Zakaria, BioResources 10(1), 1394–1407 (2015) https://bioresources.cnr.ncsu.edu/issues/vol10-issue1/page/12/

D. Adame, G. Beall, Appl. Clay Sci. 42(3–4), 545–552 (2009). https://doi.org/10.1016/j.clay.2008.03.005

F.M. Yang, H.M. Li, F. Li, Z.H. Xin, L.Y. Zhao, Y.H. Zheng, Q.H. Hu, J. Food Sci. 75(3), C236–C240 (2010). https://doi.org/10.1111/j.1750-3841.2010.01520.x

M. Parvinzadeh, S. Moradian, A. Rashidi, M.E. Yazdanshena, Appl. Surf. Sci. 256, 2792–2802 (2010). https://doi.org/10.1016/j.apsusc.2009.11.030

L.F. Wang, J.W. Rhim, Int. J. Biol. Macromol. 80, 460–468 (2015). https://doi.org/10.1016/j.ijbiomac.2015.07.007

S.S. Ray, M. Okamoto, Prog. Polym. Sci. 28(11), 1539–1641 (2003). https://doi.org/10.1016/j.progpolymsci.2003.08.002

A. Hu, H. WandFu, Packag. Eng. 24, 22–24 (2003)

X. Li, W. Li, Y. Jiang, Y. Ding, J. Yun, T. Yao, P. Zhang, Int. J. Food Sci. Technol. 46, 1947–1955 (2011). https://doi.org/10.1111/j.1365-2621.2011.02706.x

A. Emamifar, M. Kadivar, M. Shahedi, S. Soleimanianzad, Innov. Food Sci. Emerg. Technol. 11, 742–748 (2010). https://doi.org/10.1016/j.ifset.2010.06.003

H. Barikloo, E. Ahmadi, Sci. Horticult. 240, 496–508 (2018). https://doi.org/10.1016/j.scienta.2018.06.012

S. Hotta, D.R. Paul, Polymer 45, 7639–7654 (2004). https://doi.org/10.1016/j.compscitech.2007.03.007

ASTM D638-14, Standard Test Method for Tensile Properties of Plastics (ASTM International, West Conshohocken, PA, 2014, www.astm.org). https://doi.org/10.1520/D0638-14

ASTM F1306-16, Standard Test Method for Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates (ASTM International, West Conshohocken, PA, 2016), www.astm.org). https://doi.org/10.1520/F1306-16

S. Ahmadi, A.-J. Morshedi, S.A. Ashemi, J. Vinyl Addit. Technol. 16(2), 152–160 (2010). https://doi.org/10.1002/vnl.20223

J.H. Koo, Polymer Nanocomposites: Processing, Characterization, and Applications, vol 272 (The McGraw-Hill Companies, Inc, New York, 2006)

D. Makwana, J. Castaño, R.S. Somani, H.C. Bajaj, Arab. J. Chem. 13(1), 3092–3099 (2020). https://doi.org/10.1016/j.arabjc.2018.08.017

G. Mohammed, A.M. El Sayed, S. El-Gamal, J. Inorg. Organomet. Polym. 30, 1306–1319 (2020). https://doi.org/10.1007/s10904-019-01307-9

M. Khutia, G.M. Joshi, J. Mater, Sci. Mater. Electron. 26(7), 5475–5488 (2015). https://doi.org/10.1007/s10854-015-3104-2

J. Luecha, N. Sozer, J.L. Kokini, J. Mater. Sci. 45, 3529–3537 (2010). https://doi.org/10.1007/s10853-010-4395-6

M. Farhoodi, S.M. Mousavi, R. Sotudeh-Gharebagh, Z. Emam-Djomeh, A. Oromiehie, Packag. Technol. Sci. 27(2), 161–168 (2014). https://doi.org/10.1002/pts.2017

B.N. Jung, D. Kang, S. Cheon, J.K. Shim, S.W. Hwang, J. Appl. Polym. Sci. 136, 47476 (2019). https://doi.org/10.1002/app.47476

H.M. Moghaddam, M.H. Khoshtaghaza, A. Salimi, M. Barzegar, Polym.-Plast. Technol. Eng. 53(17), 1759–1767 (2014). https://doi.org/10.1080/03602559.2014.919647

M.M. Reddy, R.K. Gupta, S.N. Bhattacharya, R. Parthasarathy, Korea-Aust. Rheol. J. 19(3), 133–139 (2007) www.researchgate.net/publication/283352900

A. Casariego, B.W.S. Souza, M.A. Cerqueira, J.A. Teixeira, L. Cruz, R. Diaz, A.A. Vicente, Food Hydrocolloids 23, 1895–1902 (2009). https://doi.org/10.1016/j.foodhyd.2009.02.007

N. Bumbudsanpharoke, W. Lee, J.C. Choi, S.J. Park, M. Kim, S. Ko, Clay Clay Miner. 65(6), 387–397 (2017). https://doi.org/10.1346/CCMN.2017.064071

H. Li, F. Li, L. Wang, J. Sheng, Z. Xin, L. Zhao, H. Xiao, Y. Zheng, Q. Hu, Food Chem. 114, 547–562 (2009). https://doi.org/10.1016/j.foodchem.2008.09.085

N. Du, H.B. Park, M.M. Dal-Cin, M.D. Guiver, Energy Environ. Sci. 5, 7306–7322 (2012). https://doi.org/10.1039/C1EE02668B

R. Gholami, E. Ahmadi, S. Farris, Food Packag. Shelf Life 14, 88–95 (2017). https://doi.org/10.1016/j.fpsl.2017.09.001

A.L. Rubio, E. Almenar, P.H. Munoz, J.M. Lagaron, R. Catala, R. Gavara, Food Rev. Int. 20, 357–387 (2004). https://doi.org/10.1081/FRI-200033462

P. Kanmani, J.W. Rhim, Carbohydr. Polym. 106, 190–199 (2014). https://doi.org/10.1016/j.carbpol.2014.02.007

T. Malwela, S. Sinha, Polymer 52(5), 1297–1301 (2011) hdl.handle.net/10204/5468

V. Viswanathan, T. Laha, K. Balani, A. Agarwal, S. Seal, Mater. Sci. Eng. R Rep. 54, 121–285 (2006). https://doi.org/10.1016/j.mser.2006.11.002

B. Kord, A. Hemmasi, I. Ghasemi, Wood Sci. Technol. 45, 111–119 (2011). https://doi.org/10.1007/s00226-010-0309-7

S. Dadashi, M. Mousavi, Z. Emam-Djomeh, Iran. J. Sci. Technol. 25(2), 127–136 (2012). https://doi.org/10.22063/jipst.2012.555

A.S. Alex, R. Rajeev, K. Krishnaraj, N. Sreenivas, S. Manu, C. Gouri, V. Sekkar, Polym. Degrad. Stab. 144, 281–291 (2017). https://doi.org/10.1016/j.polymdegradstab.2017.08.026

M.R. Rahman, J. Lai Chang Hui, S.B. Hamdan, Polyvinyl alcohol/silica/clay nanocomposites: effect of clay on surface morphology, electrical, in Silica and Clay Dispersed Polymer Nanocomposites, (Woodhead Publishing, Cambridge, 2018). https://doi.org/10.1016/B978-0-08-102129-3.00004-X

S. El-Gamal, M. Elsayed, Polym. Test. 2020, 106681 (2020). https://doi.org/10.1016/j.polymertesting.2020.106681

A.M. Hezma, I.S. Elashmawi, E.M. Abdelrazek, A. Rajeh, M. Kamal, Prog. Nat. Sci.-Mater. 27(3), 338–343 (2017). https://doi.org/10.1016/j.pnsc.2017.06.001

S. Ayaz, M. Ishaq, K. Saeed, I. Ahmed, N.K. Khalil, J. Vinyl Addit. Technol. 23(2), 80–85 (2017). https://doi.org/10.1002/vnl.21488

J. Golebiewski, A. Galeski, Compos. Sci. Technol. 67, 3442–3447 (2007). https://doi.org/10.1016/j.compscitech.2007.03.007

D. Liu, H. Li, L. Jiang, Y. Chuan, M. Yuan, H. Chen, Molecules 21, 695 (2016). https://doi.org/10.3390/molecules21060695

A. Buzarovska, A. Grozdanov, J. Appl. Polym. Sci. 123, 2187–2193 (2011). https://doi.org/10.1002/app.34729

H. Tian, H. Tagaya, J. Mater. Sci. 42, 3244–3250 (2007). https://doi.org/10.1007/s10853-006-0230-5

H. Tian, H. Tagaya, J. Mater. Sci. 43, 766–770 (2008)

R. Sahraeian, S.A. Hashemi, M. Esfandeh, I. Ghasemi, Polym. Polym. Compos. 20, 639 (2012). https://doi.org/10.1177/096739111202000708

R. Sahraeian, M. Esfandeh, S.A. Hashemi, Polym. Compos. 21, 243 (2013). https://doi.org/10.1177/096739111302100406

R. Sahraeian, M. Esfandeh, Polym. Bull. 74, 1327–1341 (2017). https://doi.org/10.1007/s00289-016-1779-z

M.S. Radoičić, Z. Aponjic, M.T. Marinović-Cincović, S. Ahrenkiel, N. Bibić, J.M. Nedeljkovic, J. Serb. Chem. Soc. 77(5), 699–714 (2012). https://doi.org/10.2298/JSC110331161R

M. Murariu, A. Doumbia, L. Bonnaud, Y. Dechief, M. Ferreira, C. Campagne, E. Devaux, P. Dubois, Biomacromolecules 12, 1762–1771 (2011). https://doi.org/10.1021/bm2001445

E. Lizundia, L. Pérez-Álvarez, M. Sáenz-Pérez, D. Patrocinio, J.L. Vilas, L.M. León, J. Appl. Polym. Sci. 133, 43619 (2016). https://doi.org/10.1002/app.43619

Y. Zare, H. Garmabi, J. Appl. Polym. Sci. 124, 1225–1233 (2012). https://doi.org/10.1002/app.3513

S.M. Davachi, A.S. Shekarabi, J. Biol. Macromol. 113, 66–72 (2018). https://doi.org/10.1016/j.ijbiomac.2018.02.106

N. Shimpi, S. Shirole, S. Mishra, Polym. Compos. 38, 1273–1279 (2017). https://doi.org/10.1002/pc.23692

N. Delpouve, G. Stoclet, A. Saiter, E. Dargent, S. Marais, J. Phys. Chem. B 116, 4615–4625 (2012). https://doi.org/10.1021/jp211670g

R. Shanks, in Handbook of Plastic Films, ed. by E. M. Abdel-Bary, (Rapra Technology Ltd, Shropshire, 2003), pp. 5–38 http://researchbank.rmit.edu.au/view/rmit:3684

Author information

Authors and Affiliations

Contributions

HB—Ph.D Student, Collected test data and drafted the manuscript, designed the study and interpreted the results. EA—Supervisor, definition, design and supervision of the project, review and interpret the results. SA—Advisor, method of testing, setting and calibrating devices, result discussion.

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barikloo, H., Ahmadi, E. & Ahmadi, S. Evaluation of PE/POE/PA6 blends containing silica and clay toward nano composite packaging film. Food Measure 15, 2297–2308 (2021). https://doi.org/10.1007/s11694-020-00781-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00781-x