Abstract

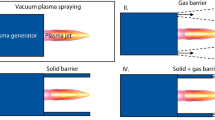

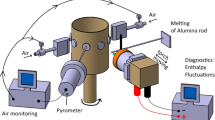

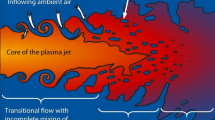

This paper investigates the impact of shrouded shield structure on plasma spray processes and the selection of optimal shield structure. Response of plasma flame characteristics to solid shield structures is studied first, and experimental investigations are then performed for both atmospheric (APS) and shrouded (SPS) plasma spray processes. It is found that the usage of conical shield (divergence angle 5.5°) with 90 mm in length is effective to form a low-oxygen (<2%) and high-temperature (>3000 K) region in the plasma flame and this region can cover the majority area for particles passing by. The average particle temperature is higher in SPS than in APS with the given conditions, and such behavior is intensified as solid shield length increases. Using the SPS process, more disk-shaped splats are obtained, and the oxygen concentration in coating is significantly reduced. The degree of the oxidation in the coatings is further reduced as the length of the solid shield increases from 50 to 90 mm. Applying solid shield will lead to high flame temperature and low oxidation; however, the substrate overheating and velocity reduction may occur. For the cases studied, the optimal shield length is around 90 mm.

Similar content being viewed by others

Abbreviations

- Cp :

-

Specific heat, J/(kg K)

- h :

-

Convective heat transfer coefficient, W/(m2 K)

- k :

-

Thermal conductivity, W/(m K)

- r, R i :

-

Radial coordinate, m

- t :

-

Time, s

- T :

-

Temperature, K

- \(\vec{v}\) :

-

Velocity vector, m/s

- x :

-

Axial coordinate, m

- H :

-

Specific enthalpy, J

- \(\upmu\) :

-

Viscosity, kg/(s m)

- \(\uprho\) :

-

Density, kg/m3

References

S. Deshpande, S. Sampath, and H. Zhang, Mechanisms of Oxidation and Its Role in Microstructural Evolution of Metallic Thermal Spray Coatings—Case Study for Ni-Al, Surf. Coat. Technol., 2006, 200(18), p 5395-5406

J.A. Gan and C.C. Berndt, Review on the Oxidation of Metallic Thermal Sprayed Coatings: A Case Study with Reference to Rare-Earth Permanent Magnetic Coatings, J. Therm. Spray. Technol., 2013, 22(7), p 1069-1091

C.-J. Li and W.-Y. Li, Effect of Sprayed Powder Particle Size on the Oxidation Behavior of MCrAlY Materials During High Velocity Oxygen-Fuel Deposition, Surf. Coat. Technol., 2003, 162(1), p 31-41

S. Hartfield-Wünsch and S. Tung, The Effect of Microstructure on the Wear Behavior of Thermal Spray Coatings, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, Materials Park, OH (United States), 1994,

M. Planche, H. Liao, and C. Coddet, Oxidation Control in Atmospheric Plasma Spraying Coating, Surf. Coat. Technol., 2007, 202(1), p 69-76

S. Matthews, Shrouded Plasma Spray of Ni-20Cr Coatings Utilizing Internal Shroud Film Cooling, Surf. Coat. Technol., 2014, 249, p 56-74

D. Gawne, T. Zhang, and B. Liu, Computational Analysis of the Influence of a Substrate, Solid Shield and Gas Shroud on the Flow Field of a Plasma Jet, Surf. Coat. Technol., 2002, 153(2), p 138-147

M. Morks and C. Berndt, Corrosion and Oxidation Properties of NiCr Coatings Sprayed in Presence of Gas Shroud System, Appl. Surf. Sci., 2010, 256(13), p 4322-4327

H.-X. Wang, X. Chen, and W. Pan, Effects of the Length of a Cylindrical Solid Shield on the Entrainment of Ambient Air into Turbulent and Laminar Impinging Argon Plasma Jets, Plasma Chem. Plasma Process., 2008, 28(1), p 85-105

N. Sakakibara, Y. Manabe, Y. Hiromoto, and Y. Kobayashi, Development of High Quality Thermal Spraying Process by Shielding Control, Sci. Technol. Weld. Join., 2008, 13(4), p 344-348

M. Jankovic and J. Mostaghimi, A new Nozzle Design for dc Plasma Spray Guns, Plasma Chem. Plasma Process., 1995, 15(4), p 607-628

I. Thomson, V. Pershin, J. Mostaghimi, and S. Chandra, Experimental Testing of a Curvilinear Gas Shroud Nozzle for Improved Plasma Spraying, Plasma Chem. Plasma Process., 2001, 21(1), p 65-82

T. Liu, L. Zheng, G. Zhang, and H. Zhang, Effects of Solid Shield and Shroud on Plasma Jet Flame in APS Process, ASME 2014 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, 2014

F. Litvin and M. De Donno, Computer Methods in Applied Mechanics and Engineering, Gear Research Laboratory, Department of Mechanical Engineering, University of Illinois at Chicago, Chicago, IL, 2006

H.-B. Xiong, L.-L. Zheng, S. Sampath, R.L. Williamson, and J.R. Fincke, Three-Dimensional Simulation of Plasma Spray: Effects of Carrier Gas Flow and Particle Injection on Plasma Jet and Entrained Particle Behavior, Int. J. Heat Mass Transf., 2004, 47(24), p 5189-5200

C. Chang and J. Ramshaw, Numerical Simulations of Argon Plasma Jets Flowing into Cold Air, Plasma Chem. Plasma Process., 1993, 13(2), p 189-209

J. Fincke, C. Chang, W. Swank, and D. Haggard, Entrainment and Demixing in Subsonic Thermal Plasma Jets: Comparison of Measurements and Predictions, Int. J. Heat Mass Transf., 1994, 37(11), p 1673-1682

C. Moreau, P. Gougeon, M. Lamontagne, V. Lacasse, G. Vaudreuil, and P. Cielo, On-line Control of the Plasma Spraying Process by Monitoring the Temperature, Velocity, and Trajectory of in-Flight Particles, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, Materials Park, OH (United States), 1994,

J.-M. Le Breton, J. Teillet, P.J. McGuiness, D.S. Edgley, and R. Harris, The Oxidation of a Nd-Fe-B Permanent Magnet at 400 °C: A SEM, Microhardness and Mossbauer Study, IEEE Trans. Magn., 1992, 28(5), p 2157-2159

Acknowledgments

The authors are grateful to Professor Guanzhong Zhang for his assistance in preparing plasma spray coatings. This work is partially supported by the Civil Aviation Science and Technology Project of China (Grant No. 20150215), by the National Natural Science Foundation of China (Grant No. 91224008) and by the National Basic Research Program of China (973 Program No. 2012CB719705).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 7th Asian Thermal Spray Conference (ATSC 2015) and has been expanded from the original presentation. ATSC 2015 was held in Xi’an, China, September 23–25, 2015, and was organized by the Asian Thermal Spray Society in association with Xi’an Jiaotong University, State Key Laboratory for Mechanical Behavior of Materials.

Rights and permissions

About this article

Cite this article

Liu, T., Zheng, L. & Zhang, H. Effect of Solid Shield on Coating Properties in Atmospheric Plasma Spray Process. J Therm Spray Tech 25, 1502–1515 (2016). https://doi.org/10.1007/s11666-016-0442-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0442-4