Abstract

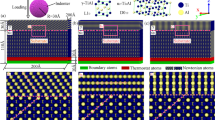

The indentation size effect (ISE) has been investigated in a series of (Ti0.705Fe0.295)100-xSnx (0 ≤ x ≤ 4) ultrafine eutectic composites (UECs) by both the micro- and nanoindentation and has been correlated for a wide range of depth between 300 nm and 10 µm. The lamellar composites are comprised of ultrafine FeTi and β-Ti lamellae phases with lamellae thickness between 0.32 and 0.81 μm. The contribution of the individual lamellae phases and the prior deformation on the ISE have been investigated to study the evolution of geometrically necessary dislocations (GNDs) and statistically stored dislocations (SSDs). X-ray diffraction, transmission electron microscopic studies, and the model calculations have revealed that a significant portion of the lamellae interface in the as-solidified composites aid in the development of high GND density ≈ 1015/m2 and exhibit hardness ≈ 16 GPa, which further enhanced up to ≈ 1016/m2 and ≈ 22 GPa upon severe forging. A model has been established to correlate the micro- and nanoindentation hardness by considering the size effect and the microstructure length scale.

Similar content being viewed by others

References

M. Atkinson, Further Analysis of the Size Effect in Indentation Hardness Tests of Some Metals, J. Mater. Res., 1995, 10, p 2908–2915.

M.R. Begley and J.W. Hutchinson, The Mechanics of Size-Dependent Indentation, J. Mech. Phys. Solids, 1998, 46, p 2049–2068.

A. Gunti and J. Das, Size Effect and Anisotropy in Cold Rolled Zr-Base Bulk Metallic Glasses during Nanoindentation, J. Non-Cryst. Solids, 2022, 593, p 121767.

Q. Ma and D.R. Clarke, Size Dependent Hardness in Silver Single Crystals, J. Mater. Res., 1995, 10, p 853–863.

K.W. McElhaney, J.J. Vlassak, and W.D. Nix, Determination of Indenter Tip Geometry and Indentation Contact Area for Depth Sensing Indentation Experiments, J. Mater. Res., 1998, 13, p 1300–1306.

W.D. Nix and H. Gao, Indentation Size Effects in Crystalline Materials: A Law for Strain Gradient Plasticity, J. Mech. Phys. Solids, 1998, 46, p 411–425.

N.A. Stelmashenko, M.G. Walls, L.M. Brown, and Y.V. Milman, Microindentation on W and Mo Oriented Single Crystals: An ASTM Study, Acta Metall. Mater., 1993, 41, p 2855–2865.

J.G. Swadener, E.P. George, and G.M. Pharr, The Correlation of the Indentation Size Effect Measured with Indenters of Various Shapes, J. Mech. Phys. Solids, 2002, 50, p 681–694.

Y.Y. Lim and M.M. Chaudhri, The Effect of the Indenter Load on the Nanohardness of Ductile Metals: An Experimental Study on Polycrystalline Work-Hardened and Annealed Oxygen Free Copper, Philos. Mag. A, 1999, 79, p 2979–3000.

K. Durst, B. Backes, and M. Goeken, Indentation Size Effect in Metallic Materials: Correcting for the Size of the Plastic Zone, Scr. Mater., 2005, 52, p 1093–1097.

G. Feng and W.D. Nix, Indentation Size Effect in MgO, Scr. Mater., 2004, 51, p 599–603.

Y. Liu and A.H.W. Ngan, Depth Dependence of Hardness in Copper Single Crystals Measured by Nanoindentation, Scr. Mater., 2002, 44, p 237–241.

A.A. Elmustafa and D.S. Stone, Nanoindentation and the Indentation Size Effect: Kinetics of Deformation and Strain Gradient Plasticity, J. Mech. Phys. solids, 2003, 51, p 357–381.

J.G. Swadener, A. Misra, R.G. Hoagland, and M. Nastasi, A Mechanistic Description of Combined Hardening and Size Effects, Scr. Mater., 2002, 47, p 343–348.

J.Y. Kim, B.W. Lee, D.T. Read, and D. Kwon, Influence of Tip Bluntness on the Size-Dependent Nanoindentation Hardness, Scr. Mater., 2005, 52, p 353–358.

S. Qu, T. Siegmund, Y. Huang, P.D. Wu, F. Zhang, and K.C. Hwang, A study of Particle Size Effect and Interface Fracture in Aluminum Alloy Composite via an Extended Conventional Theory of Mechanism-Based Strain-Gradient Plasticity, Compos. Sci. Technol., 2005, 65, p 1244–1253.

Y. Huang, F. Zhang, K.C. Hwang, W.D. Nix, G.M. Pharr, and G. Feng, A Model Size Effect in Nano-indentation, J. Mech. Phys. Solids, 2006, 54, p 1668–1686.

A.A. Elmustafa, A.A. Ananda, and W.M. Elmahboub, Dislocation Mechanics Simulations of the Bilinear Behavior in Micro- and Nanoindentation, J. Mater. Res., 2004, 19, p 768–779.

X. Qiu, Y. Huang, W.D. Nix, K.C. Hwang, and H. Gao, Effect of Intrinsic Lattice Resistance in Strain Gradient Plasticity, Acta Mater., 2001, 49, p 3949–3958.

G.M. Pharr, J. Strader, and W.C. Oliver, Critical Issues in Making Small-Depth Mechanical Property Measurements by Nanoindentation with Continuous Stiffness Measurement, J. Mater. Res., 2009, 24, p 653–666.

K. Durst, O. Franke, A. Böhner, and M. Göken, Indentation Size Effect in Ni-Fe Solid-Solutions, Acta Mater., 2007, 55, p 6825–6833.

K.S. Kumar, S.H. Van, and S. Suresh, Mechanical Behavior of Nanocrystalline Metals and Alloys, Acta Mater., 2003, 51, p 5743–5774.

E. Ma, Eight Routes to Improve the Tensile Ductility of Bulk Nanostructured Metals and Alloys, JOM, 2006, 58, p 49–53.

J.M. Park, D.H. Kim, K.B. Kim, and W.T. Kim, Deformation-Induced Rotational Eutectic Colonies Containing Length-Scale Heterogeneity in an Ultrafine Eutectic Fe83Ti7Zr6B4 Alloy, Appl. Phys. Lett., 2007, 91, 131907.

J. Das, K.B. Kim, F. Baier, and W. Loser, High Strength Ti-Base Ultrafine Eutectic with Enhanced Ductility, Appl. Phys. Lett., 2005, 87, 161907.

K.B. Kim, J. Das, F. Baier, and J. Eckert, Propagation of Shear Bands in Ti66.1Cu8Ni4.8Sn7.2Nb13.9 Nanostructure-Dendrite Composite during Deformation, Appl. Phys. Lett., 2005, 86, p 171909.

J. Das, K.B. Kim, W. Loser, and J. Eckert, Formation of Ductile Ultrafine Eutectic Structure in Ti-Fe-(Sn) Alloy, Mater. Sci. Eng. A, 2008, 449–451, p 737–740.

D.V. Louzguine, H. Kato, and A. Inoue, High Strength and Ductile Ti-Fe Composite, J. Alloys Compd., 2004, 384, p L1–L3.

S.W. Lee, J.T. Kim, S.H. Hong, H.J. Park, J.Y. Park, N.S. Lee, Y. Seo, J.Y. Suh, J. Eckert, D.M. Kim, J.M. Park, and K.B. Kim, Micro-to-Nano-Scale Deformation Mechanism of a Bimodal Ultrafine Eutectic Composite, Sci. Rep., 2014, 4, p 06500.

J.M. Park, S.W. Sohn, T.E. Kim, K.B. Kim, W.T. Kim, and D.H. Kim, Nanostructure-Dendrite Composites in the Fe-Zr Binary Alloy System Exhibiting High Strength and Plasticity, Scr. Mater., 2007, 57, p 1153–1156.

T. Maity and J. Das, High Strength Ni-Zr-(Al) Nanoeutectic Composites with Large Plasticity, Intermetallics, 2015, 63, p 51–58.

J.M. Park, K.B. Kim, W.T. Kim, M.H. Lee, J. Eckert, and D.H. Kim, High Strength Ultrafine Eutectic Fe-Nb-Al Composites with Enhanced Plasticity, Intermetallics, 2008, 16, p 642–650.

C.H. Lee, S.H. Hong, J.T. Kim, H.J. Park, G.A. Song, J.M. Park, J.Y. Suh, Y. Seo, M. Qian, and K.B. Kim, Chemical Heterogeneity-Induced Plasticity in Ti-Fe-Bi Ultrafine Eutectic Alloys, Mater. Des., 2014, 60, p 363–367.

G.A. Song, W. Lee, N.S. Lee, K.B. Kim, J.M. Park, D.H. Kim, J. Lee, and J.S. Park, Microstructure Evolution and Mechanical Properties of Mg-Cu-Zn Ultrafine Eutectic Composites, J. Mater. Res., 2009, 24, p 2892–2898.

T. Maity and J. Das, Microstructure and Size Effect in Ultrafine (Ti0.705Fe0.295)100-xSnx (0 ≤ x ≤ 4 at.%) Composites, J. Alloys Compd., 2014, 585, p 54–62.

T. Maity and J. Das, Origin of Plasticity in Ultrafine Lamellar Ti-Fe-(Sn) Composites, AIP Adv., 2012, 2, p 032175.

T. Maity, B. Roy, and J. Das, Mechanism of Lamellae Deformation and Phase Rearrangement in Ultrafine β-Ti/FeTi Eutectic Composites, Acta Mater., 2015, 97, p 170–179.

T. Maity, K.G. Prashanth, Ö. Balcı, J.T. Kim, T. Schöberl, Z. Wang, and J. Eckert, Influence of Severe Straining and Strain Rate on the Evolution of Dislocation Structures during Micro/Nanoindentation in High Entropy Lamellar Eutectics, Int. J. Plast., 2018, 109, p 121–136.

T. Maity, K.G. Prashanth, Ö. Balçi, Z. Wang, Y.D. Jia, and J. Eckert, Plastic Deformation Mechanisms in Severely Strained Eutectic High Entropy Composites Explained via Strain Rate Sensitivity and Activation Volume, Compos. B Eng., 2018, 150, p 7–13.

A. Gunti and J. Das, Effect of Testing Conditions on the Nanomechanical Behaviour of Surface and Inner Core of as-cast Zr-Base Bulk Metallic Glassy Plates, Mater. Sci. Eng. A, 2022, 845, p 143206.

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564–1583.

G.H. Xiao, N.R. Tao, and K. Lu, Effects of Strain, Strain-Rate and Temperature on Deformation Twinning in a Cu-Zn Alloy, Scr. Mater., 2008, 59, p 975–978.

S.M. Allen, Foil Thickness Measurements from Convergent-Beam Diffraction Pattern, Philos. Mag. A, 1981, 43, p 325–335.

D. Chicot, Hardness Length-Scale Factor to Model Nano- and Micro-Indentation Size Effects, Mater. Sci. Eng. A, 2009, 499, p 454–461.

G.M. Pharr, Measurement of Mechanical Properties by Ultra-Low Load Indentation, Mater. Sci. Eng. A, 1998, 253, p 151–159.

K. Durst, B. Backes, O. Franke, and M. Goeken, Indentation Size Effect in Materials: Modeling Strength from Pop-in to Macroscopic Hardness Using Geometrically Necessary Dislocation, Acta Mater., 2006, 54, p 2547–2555.

D. Kuhlmann-Wilsdorf and N. Hansen, Geometrically Necessary, Incidental and Subgrain Boundaries, Scr. Metall. Mater., 1991, 25, p 1557–1562.

N. Hansen, X. Huang, and D.A. Hughes, Microstructural Evolution and Hardening Parameters, Mater. Sci. Eng. A, 2001, 317, p 3–11.

L.S. Toth, C.F. Gu, B. Beausir, J.J. Fundenberger, and M. Hoffman, Geometrically Necessary Dislocations Favor the Taylor Uniform Deformation Mode in Ultra-Fine-Grained Polycrystals, Acta Mater., 2016, 117, p 35–42.

Acknowledgments

We thank S. Maity and P. Das for their technical assistance. Financial support through SRIC IIT Kharagpur through the SGIRG project “Studies on the deformation mechanism and evolution of plasticity in nano-/ultrafine lamellar composites” is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gunti, A., Maity, T. & Das, J. Size Effect in Ultrafine Ti-Fe-(Sn) Lamellar Composites during Micro- and Nanoindentation. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09364-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09364-z