Abstract

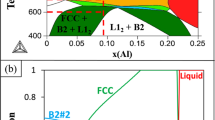

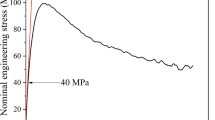

The strain rate sensitivity (m) of (Ni0.92Zr0.08)100−xAlx (0 ≤ x ≤ 4 at.%) eutectic with varying average lamellae thickness (λw) in the range of 39–275 nm has been investigated in the strain rate range of 8 × 10−5 and 8 × 10−3 s−1 at room temperature. The microstructure of the nano-/ultrafine eutectic composites (NECs) is comprised of alternate lamellae of fcc γ-Ni and Ni5Zr along with 20–31 vol% γ-Ni dendritic phase. The m value of all the investigated NECs lies between 0.0080 and 0.0102, whereas the activation volume (V*) has been estimated to be between 29.7b3 and 49.8b3. High-resolution transmission electron microscopy studies confirm the dislocation-mediated plastic flow including dislocation–lamellae interaction, and their pile-up at the interface, which result in the narrow variation of m for a wide range of λw due to its interlocked lamellar microstructure. A mathematical model has been developed to correlate the m with λw for the experimented NECs with wide microstructure length scale and solute content.

Similar content being viewed by others

References

Y. Wei, A.F. Bower, and H. Gao: Enhanced strain-rate sensitivity in fcc nanocrystals due to grain-boundary diffusion and sliding. Acta Mater. 56, 1741 (2008).

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma: Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater. Sci. Eng. A 381, 71 (2004).

R.W. Armstrong: Hall–Petch description of nanopolycrystalline Cu, Ni and Al strength levels and strain rate sensitivities. Philos. Mag. 96, 3097 (2016).

V. Maier, K. Durst, J. Mueller, B. Backes, H.W. Höppel, and M. Göken: Nanoindentation strain-rate jump tests for determining the local strain-rate sensitivity in nanocrystalline Ni and ultrafine-grained Al. J. Mater. Res. 26, 1421 (2011).

F.D. Torre, H.V. Swygenhoven, and M. Victoria: Nanocrystalline electrodeposited Ni: Microstructure and tensile properties. Acta Mater. 50, 3957 (2002).

E. Izadi and J. Rajagopalan: Texture dependent strain rate sensitivity of ultrafine-grained aluminum films. Scr. Mater. 114, 65 (2016).

I. Sabirov, M.R. Barnett, Y. Estrin, and P.D. Hodgson: The effect of strain rate on the deformation mechanisms and the strain rate sensitivity of an ultra-fine-grained Al alloy. Scr. Mater. 61, 181 (2009).

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, and S. Suresh: Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 51, 5159 (2003).

R.W. Hayes, D. Witkin, F. Zhou, and E.J. Lavernia: Deformation and activation volumes of cryomilled ultrafine-grained aluminium. Acta Mater. 52, 4259 (2004).

R. Fritz, D. Wimler, A. Leitner, V. Maier-Kiener, and D. Kiener: Dominating deformation mechanisms in ultrafine-grained chromium across length scales and temperatures. Acta Mater. 140, 176 (2017).

A.D. Kammers, J. Wongsa-Ngam, T.G. Langdon, and S. Daly: The microstructure length scale of strain rate sensitivity in ultrafine-grained aluminium. J. Mater. Res. 30, 981 (2015).

V. Maier, C. Schunk, M. Göken, and K. Durst: Microstructure-dependent deformation behaviour of bcc-metals–Indentation size effect and strain rate sensitivity. Philos. Mag. 95, 1766 (2015).

A.M. Glezer, E.V. Kozlov, N.A. Koneva, N.A. Popova, and I.A. Kurzina: Plastic Deformation of Nanostructured Materials (CRC Press, Boca Raton, London, 2017); pp. 133–135.

G.M. Cheng, W.W. Jian, W.Z. Xu, H. Yuan, P.C. Millett, and Y.T. Zhu: Grain size effect on deformation mechanisms of nanocrystalline bcc metals. Mater. Res. Lett. 1, 26 (2013).

D. Jang and M. Atzmon: Grain-size dependence of plastic deformation in nanocrystalline Fe. J. Appl. Phys. 93, 9282 (2003).

Q. Zhou, J. Zhao, J.Y. Xie, F. Wang, P. Huang, T.J. Lu, and K.W. Xu: Grain size dependent strain rate sensitivity in nanocrystalline body-centered cubic metal thin films. Mater. Sci. Eng. A 608, 184 (2014).

Y. Wang, Y. Liu, and J.T. Wang: Investigation on activation volume and strain-rate sensitivity in ultrafine-grained tantalum. Mater. Sci. Eng. A 635, 86 (2015).

D. Wu, X.L. Wang, and T.G. Nieh: Variation of strain rate sensitivity with grain size in Cr and other body-centred cubic metals. J. Phys. D Appl. Phys. 47, 175303 (2014).

D. Jia, K.T. Ramesh, and E. Ma: Effects of nanocrystalline and ultrafine grain sizes on constitutive behavior and shear bands in iron. Acta Mater. 51, 3495 (2003).

T.R. Malow and C.C. Koch: Mechanical properties, ductility, and grain size of nanocrystalline iron produced by mechanical attrition. Metall. Mater. Trans. A 29A, 2285 (1998).

S. Nemat-Nasser, W. Guo, and M. Liu: Experimentally-based micromechanical modelling of dynamic response of molybdenum. Scr. Mater. 40, 859 (1999).

G. He, J. Eckert, W. Löser, and L. Schultz: Novel Ti-base nanostructure-dendrite composite with enhanced plasticity. Nat. Mater. 2, 33 (2003).

T. Maity, A. Singh, A. Dutta, and J. Das: Microscopic mechanism on the evolution of plasticity in nanolamellar γ-Ni/Ni5Zr eutectic composites. Mater. Sci. Eng. A 666, 72 (2016).

T. Maity, B. Roy, and J. Das: Mechanism of lamellae deformation and phase rearrangement in ultrafine β-Ti/FeTi eutectic composites. Acta Mater. 97, 170 (2015).

A.H.W. Ngan, J.B. Pethica, and H.P. Ng: Strain-rate sensitivity of hardness of nanocrystalline Ni75at.%Al25at.% alloy film. J. Mater. Res. 18, 382 (2003).

J.T. Kim, S.H. Hong, Y.S. Kim, H.J. Park, T. Maity, N. Chawake, X.L. Bian, B. Sarac, J.M. Park, K.G. Prashanth, J.Y. Park, J. Eckert, and K.B. Kim: Cooperative deformation behavior between the shear band and boundary sliding of an Al-based nanostructure-dendrite composite. Mater. Sci. Eng. A 735, 81 (2018).

J.T. Kim, S.H. Hong, J.M. Park, J. Eckert, and K.B. Kim: Microstructure and mechanical properties of hierarchical multi-phase composites based on Al-Ni-type intermetallic compounds in the Al-Ni-Cu-Si alloy system. J. Alloys Compd. 749, 205 (2018).

J.T. Kim, S.H. Hong, H.J. Park, Y.S. Kim, J.Y. Suh, J.K. Lee, J.M. Park, T. Maity, J. Eckert, and K.B. Kim: Deformation mechanisms to ameliorate the mechanical properties of novel TRIP/TWIP Co-Cr-Mo-(Cu) ultrafine eutectic alloys. Sci. Rep. 7, 39959 (2017).

J.T. Kim, S.W. Lee, S.H. Hong, H.J. Park, J.-Y. Park, N. Lee, Y. Seo, W.-M. Wang, J.M. Park, and K.B. Kim: Understanding the relationship between microstructure and mechanical properties of Al–Cu–Si ultrafine eutectic composites. Mater. Des. 92, 1038 (2016).

A. Dutta and J. Das: Superior oxidation resistance of ultrafine Ni-Zr-(Al) eutectic composites in the temperature range of 500–900°C. J. Alloys Compd. (2020). doi: 10.1016/j.jallcom.2020.155998.

A. Neogi, L. He, and N. Abdolrahim: Atomistic simulations of shock compression of single crystal and core-shell Cu@Ni nanoporous metals. J. Appl. Phys. 126, 015901 (2019).

J. Alkorta and J.G. Sevillano: Measuring the strain rate sensitivity by instrumented indentation. Application to an ultrafine grain (equal channel angular-pressed) eutectic Sn-Bi alloy. J. Mater. Res. 19, 282 (2004).

H.E. Cline and D. Lee: Strengthening of lamellar vs. equiaxed Ag-Cu eutectic. Acta Metall. 18, 315 (1970).

I. Shohji, T. Yoshida, T. Takahashi, and S. Hioki: Tensile properties of Sn-Ag based lead-free solders and strain rate sensitivity. Mater. Sci. Eng. A 366, 50 (2004).

A.E. Geckinli and C.R. Barrett: Superplastic deformation of the Pb-Sn eutectic. J. Mater. Sci. 11, 510 (1976).

K. Edalati, T. Masuda, M. Arita, M. Furui, X. Sauvage, Z. Horita, and R.Z. Valiev: Room-temperature superplasticity in an ultrafine-grained magnesium alloy. Sci. Rep. 7, 2662 (2017).

H. Baker: Alloy Phase Diagram, ASM Handbook, Vol. 3 (ASM International, OH, 1992).

T. Maity and J. Das: High strength Ni-Zr-(Al) nanoeutectic composites with large plasticity. Intermetallics 63, 51 (2015).

A. Dutta, P.P. Jana, and J. Das: Effect of cooling rate and composition on the microstructure and mechanical properties of (Ni0.92Zr0.08)100-xAlx (0≤x≤4 at.%) ultrafine eutectic composites. J. Mater. Res. 34, 1704 (2019).

J.E. Bailey and P.B. Hirsch: The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 5, 485 (1960).

S. Graça, R. Colaço, P.A. Carvalho, and R. Vilar: Determination of dislocation density from hardness measurements in metals. Mater. Lett. 62, 3812 (2008).

W.D. Callister, Jr., and D.G. Rethwisch: Materials Science and Engineering: An Introduction, 2nd ed. (Wiley India Pvt. Ltd., New Delhi, India, 2014).

K. Jonnalagadda, N. Karanjgaokar, I. Chasiotis, J. Chee, and D. Peroulis: Strain rate sensitivity of nanocrystalline Au films at room temperature. Acta Mater. 58, 4674 (2010).

R.Z. Valiev, E.V. Kozlov, Y.F. Ivanov, J. Lian, A.A. Nazarov, and B. Baudelet: Deformation behaviour of ultra-fine-grained copper. Acta Metall. 42, 2467 (1994).

J. Lian and B. Baudelet: A modified Hall-Petch relationship for nanocrystalline materials. Nanostruct. Mater. 2, 415 (1993).

C.D. Gu, J.S. Lian, Q. Jiang, and W.T. Zheng: Experimental and modelling investigations on strain rate sensitivity of an electrodeposited 20 nm grain sized Ni. J. Phys. D Appl. Phys. 40, 7440 (2007).

Y. Gu, Y. Xiang, D.J. Srolovitz, and J.A. El-Awady: Self-healing of low angle grain boundaries by vacancy diffusion and dislocation climb. Scr. Mater. 155, 155 (2018).

J. Du, B. Wen, R. Melnik, and Y. Kawazoe: First-principles studies on structural, mechanical, thermodynamic and electronic properties of Ni5Zr intermetallic compounds. Intermetallics 54, 110 (2014).

T. Maity, K.G. Prashanth, Ö Balçi, Z. Wang, Y.D. Jia, and J. Eckert: Plastic deformation mechanisms in severely strained eutectic high entropy composites explained via strain rate sensitivity and activation volume. Compos. B Eng. 150, 7 (2018).

W. Wang, Y. Ma, M. Yang, P. Jiang, F. Yuan, and X. Wu: Strain rate effect on tensile behavior for a high specific strength steel: From quasi-static to intermediate strain rates. Metals 8, 11 (2018).

A.V.D. Beukel and U.F. Kocks: The strain dependence of static and dynamic strain-aging. Acta Metall. 30, 1027 (1982).

A.V.D. Beukel: Theory of the effect of dynamic strain aging on mechanical properties. Phys. Status Solidi 30, 197 (1975).

C.X. Huang, W.P. Hu, and Q.Y. Wang: Strain-rate sensitivity, activation volume and mobile dislocations exhaustion rate in nanocrystalline Cu-11.1 at% Al alloy with low stacking fault energy. Mater. Sci. Eng. A 611, 274 (2014).

Acknowledgments

The authors acknowledge the technical support of M. Das, S. Maity, and R. Kundu at Central Research Facility, IIT Kharagpur. The authors further acknowledge the Naval Research Board, GOI (NRB/4003/PG/357), and IIT Kharagpur SRIC (SGIRG) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dutta, A., Das, J. Strain rate sensitivity and deformation mechanism of nano-lamellar γ-Ni/Ni5Zr eutectic at room temperature. Journal of Materials Research 35, 2777–2788 (2020). https://doi.org/10.1557/jmr.2020.188

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.188