Abstract

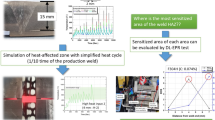

Microstructure sensitization after welding of 321H stainless steels may occur in the heat-affected zone (HAZ) of the joints welded by gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW) in case of high heat input. In this study, the effect of microstructural sensitization on the mechanical behavior of a 321H sensitized steel pipe is investigated. In this regard, mechanical tests including tensile, hardness, creep, and crack tip opening displacement (CTOD) have been conducted on samples in which sensitization of the HAZ area has been proven via intergranular corrosion test. The sensitized microstructure showed that despite some significant differences between properties of welded and non-welded samples, mechanical properties such as a hardness of ~ 200 HV, a tensile strength of ~ 600 MPa, and also high creep resistance at stresses below 200 MPa and temperatures up to 700 °C are in the acceptable range as per international standards and codes. However, the CTOD examinations showed that cracks in the HAZ area of the sensitized sample could propagate with definitely lower values of stress intensity (KIC) compared to those in a non-sensitized material.

Similar content being viewed by others

References

G. Golański and H. Purzyńska, Effect of Service on Microstructure and Mechanical Properties of Nb-Stabilised Austenitic Stainless Steel, Int. J. Press. Vessel. Pip., 2022, 195, p 104574. https://doi.org/10.1016/j.ijpvp.2021.104574

A. Belattar and L. Taleb, Experimental and Numerical Analyses of the Cyclic Behavior of Austenitic Stainless Steels After Prior Inelastic Histories, Int. J. Press. Vessel. Pip., 2021, 189, p 104256. https://doi.org/10.1016/j.ijpvp.2020.104256

B.S. Kong, J.H. Shin, C. Jeong, C. Jang, and S.-S. Kang, Effect of Microstructure Evolution at the Interphase Boundary on the Thermal Ageing Embrittlement of CF8M Cast Austenitic Stainless Steel, Int. J. Press. Vessel. Pip., 2022, 198, p 104679. https://doi.org/10.1016/j.ijpvp.2022.104679

F. Bigdeli, M. Javidi, M. Pakshir, A. Khezrloo, and M. Tayebi, Risk Assessment of the Corrosion Resistance Performances for Epoxy Coatings Under Drilling Environments Using AHP Method, Int. J. Press. Vessel. Pip., 2021, 193, p 104470. https://doi.org/10.1016/j.ijpvp.2021.104470

P. Dai, S. Li, L. Wu, Y. Wang, G. Feng, and D. Deng, A New Numerical Model to Predict Welding-Induced Sensitization in SUS304 Austenitic Stainless Steel Joint, J. Mater. Res. Technol., 2022, 17, p 234–243. https://doi.org/10.1016/j.jmrt.2022.01.015

M. Moshkbar Bakhshayesh, A. Farzadi, A. Doustahadi, and M. Nouripour, Measurement of Degree of Sensitization in Post-weld Heat Treated 13Cr-4Ni Martensitic Stainless Steel Clad Using Double Loop Electrochemical Potentiokinetic Technique, Eng. Fail. Anal., 2022, 134, p 106046. https://doi.org/10.1016/j.engfailanal.2022.106046

A.S. Lima, A.M. Nascimento, H.F.G. Abreu, and P. de Lima-Neto, Sensitization Evaluation of the Austenitic Stainless Steel AISI 304L, 316L, 321 and 347, J. Mater. Sci., 2005, 40, p 139–144. https://doi.org/10.1007/s10853-005-5699-9

N.S.-2018 Standard, Protection of Austenitic Stainless-steels from Polythionic Acid Stress Corrosion Cracking during a Shootdown of Refinery Equipment, NACE Int. USA (2018)

A.I. and S. Institute, A.I. and S.I.C. of S.S. Producers, High-temperature Characteristics of Stainless Steels, Committee of Stainless Steel Producers, American Iron and Steel Institute, 1979. https://books.google.com/books?id=v-j0mQEACAAJ.

R.K. Gupta, N. Parvathavarthini, A. Vinod Kumar, and R.K. Dayal, Influence of Inclusion and Specimen Orientations on Intergranular Corrosion Testing of AISI 316LN Stainless Steel, Trans. Indian Inst. Met., 2011, 64, p 365–375. https://doi.org/10.1007/s12666-011-0088-3

N. Upadhyay, M.G. Pujar, C. Mallika, and U. Kamachi Mudali, Correlation of Electrochemical Noise Parameters with Degree of Sensitization in AISI Type 316LN Stainless Steel, Trans. Indian Inst. Met., 2017, 70, p 2371–2379. https://doi.org/10.1007/s12666-017-1098-6

R. Priya, C. Mallika, and U.K. Mudali, Corrosion Behavior of Sensitized 304 SS in Nitric Acid Medium Containing Oxidizing Ions, Trans. Indian Inst. Met., 2014, 67, p 459–467. https://doi.org/10.1007/s12666-013-0366-3

B. Sadeghi, H. Sharifi, M. Rafiei, and M. Tayebi, Effects of Post Weld Heat Treatment on Residual Stress and Mechanical Properties of GTAW: The Case of Joining A537CL1 Pressure Vessel Steel and A321 Austenitic Stainless Steel, Eng. Fail. Anal., 2018 https://doi.org/10.1016/j.engfailanal.2018.08.007

Y. Li, J. Wang, and X. Wang, Improvement of Stress-Relief Cracking Resistance in Coarse-Grained Heat-Affected Zone of T23 Steel by Refining Sub-Structure Through Second Thermal Cycle, J. Mater. Res. Technol., 2020, 9, p 8568–8579. https://doi.org/10.1016/j.jmrt.2020.05.125

M. Xu, B. Liu, Z. Dong, and Z. Wang, Influence of Microstructure Evolution on Reheat Cracking Behavior of T23 Steel Weld Joint, ISIJ Int., 2020, 60, p 1291–1300. https://doi.org/10.2355/isijinternational.ISIJINT-2019-652

I. Dayalan, P. Frank Crasta, and S. Pradhan, R. Gupta, A Review on stress relaxation cracking in austenitic stainless steel BT: Proceedings of international conference on intelligent manufacturing and automation, in: ed by H. Vasudevan, V.K.N. Kottur, A.A. Raina (Springer Singapore, Singapore, 2020), pp. 427–434

A. Bahrami and P. Taheri, A Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit, Metals, 2019 https://doi.org/10.3390/met9090969

M. Chabaud-Reytier, L. Allais, C. Caes, P. Dubuisson, and A. Pineau, Mechanisms of Stress Relief Cracking in Titanium Stabilised Austenitic Stainless Steel, J. Nucl. Mater., 2003, 323, p 123–137. https://doi.org/10.1016/j.jnucmat.2003.08.034

Q. Auzoux, L. Allais, C. Caës, I. Monnet, A.F. Gourgues, and A. Pineau, Effect of Pre-strain on Creep of Three AISI 316 Austenitic Stainless Steels in Relation to Reheat Cracking of Weld-Affected Zones, J. Nucl. Mater., 2010, 400, p 127–137. https://doi.org/10.1016/j.jnucmat.2010.02.021

M. Chabaud-Reytier, L. Allais, D. Poquillon, C. Cäes-Hogrel, M. Mottot, and A. Pineau, Modelling Creep Damage in Heat Affected Zone in 321 Stainless Steel. Part I: Quantitative Study of Intergranular Damage, Mater. High Temp., 2001, 18, p 71–80. https://doi.org/10.1179/mht.2001.008

D. Poquillon, M. Chabaud-Reytier, L. Allais, and A. Pineau, Modelling Creep Damage in Heat Affected Zone in 321 Stainless Steel. Part II: Application to Creep Crack Initiation Simulations, Mater. High Temp., 2001, 18, p 81–90. https://doi.org/10.1179/mht.2001.009

M. Ghalambaz, M. Abdollahi, A. Eslami, and A. Bahrami, A Case Study on Failure of AISI 347H Stabilized Stainless Steel Pipe in a Petrochemical Plant, Case Stud. Eng. Fail. Anal., 2017, 9, p 52–62. https://doi.org/10.1016/j.csefa.2017.07.001

K.S. Guan, X.D. Xu, Y.Y. Zhang, and Z.W. Wang, Cracks and Precipitate Phases in 321 Stainless Steel Weld of Flue Gas Pipe, Eng. Fail. Anal., 2005, 12, p 623–633. https://doi.org/10.1016/j.engfailanal.2004.05.008

H. Vemanaboina, S. Akella, and R.K. Buddu, Welding Process Simulation Model for Temperature and Residual Stress Analysis, Procedia, Mater. Sci., 2014, 6, p 1539–1546. https://doi.org/10.1016/j.mspro.2014.07.135

D. Das, D.K. Pratihar, and G.G. Roy, Establishing a Correlation Between Residual Stress and Natural Frequency of Vibration for Electron Beam Butt Weld of AISI 304 Stainless Steel, Arab. J. Sci. Eng., 2020, 45, p 5769–5781. https://doi.org/10.1007/s13369-020-04560-0

H.M. Soltani, M. Tayebi, and H. Mohammad Soltani, Comparative Study of AISI 304L to AISI 316L Stainless Steels Joints by TIG and Nd:YAG Laser Welding, J. Alloys Compd., 2018, 767, p 112–121. https://doi.org/10.1016/j.jallcom.2018.06.302

K.S. Min, K.J. Kim, and S.W. Nam, Investigation of the Effect of the Types and Densities of Grain Boundary Carbides on Grain Boundary Cavitation Resistance of AISI 321 Stainless Steel Under Creep–Fatigue Interaction, J. Alloys Compd., 2004, 370, p 223–229. https://doi.org/10.1016/j.jallcom.2003.09.129

R.C. de Sousa, J.C.C. Filho, A.A. Tanaka, A.C.S. de Oliveira, and W.E.I. Ferreira, Effects of Solution Heat Treatment on Grain Growth and Degree of Sensitization of AISI 321 Austenitic Stainless Steel, J. Mater. Sci., 2006, 41, p 2381–2386. https://doi.org/10.1007/s10853-006-2468-3

S. Mohan Kumar and N. Siva Shanmugam, Studies on the Weldability, Mechanical Properties and Microstructural Characterization of Activated Flux TIG Welding of AISI 321 Austenitic Stainless Steel, Mater. Res. Express., 2018, 5, p 106524. https://doi.org/10.1088/2053-1591/aad99f

S. Zhang, Z. Jiang, H. Li, H. Feng, and B. Zhang, Detection of Susceptibility to Intergranular Corrosion of Aged Super Austenitic Stainless Steel S32654 by a Modified Electrochemical Potentiokinetic Reactivation Method, J. Alloys Compd., 2017, 695, p 3083–3093. https://doi.org/10.1016/j.jallcom.2016.11.342

P.K. Gajjar, B.C. Khatri, A.M. Siddhpura, and M.A. Siddhpura, Sensitization and Desensitization (Healing) in Austenitic Stainless Steel: A Critical Review, Trans. Indian Inst. Met., 2022, 75, p 1411–1427. https://doi.org/10.1007/s12666-021-02439-8

Data sheet of 347H and 16.8.2 For high temperature 3xxh stainless steels, metrode products Ltd, 2009.

V. der Westhuizen and E. Christian, Stress Relaxation Cracking Of Welded Joints In Thick Sections of A Tp347 Stabilized Grade Of Stainless Steel., Corrosion. (2008)

ASTM A262-15, Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless-steels, ASTM Int. (n.d.)

API 942 B-2017, Material, Fabrication, and Repair Considerations for Austenitic Alloys Subject to Embrittlement and Cracking in High Temperature 565 °C to 760 °C, 2017 (n.d.).

H. Sharifi, S. Raisi, and M. Tayebi, The Effect of Stress Relieving Treatment on Mechanical Properties and Microstructure of Different Welding Areas of A517 Steel, Mater. Res. Express., 2017 https://doi.org/10.1088/2053-1591/aa97c2

M. Tayebi, A. Rajaee, H.M. Soltani, Laser welding, in: K. Cooke (Ed.), Weld. Princ. Appl., (IntechOpen, 2022)

H. van Wortel, Control of Relaxation Cracking in Austenitic High Temperature Components, Corrosion. (2007).

H. Mohammad Soltani, and M. Tayebi, Microstructural and Mechanical Investigation of Brazing 304L Stainless Steel with Corner Joint Using a Ni-Based Shim and Wire, Mater. Res. Express, 2021, 8, p 46532. https://doi.org/10.1088/2053-1591/abf76c

J. Brnic, G. Turkalj, M. Canadija, D. Lanc, S. Krscanski, M. Brcic, Q. Li, and J. Niu, Mechanical Properties, Short Time Creep, and Fatigue of an Austenitic Steel, Materials (Basel, Switzerland), 2016 https://doi.org/10.3390/ma9040298

K. Devendranath Ramkumar, B. Pavan, and V. Chandrasekar, Development of Improved Microstructural Traits and Mechanical Integrity of Stabilized Stainless Steel Joints of AISI 321, J. Manuf. Process., 2018, 32, p 582–594. https://doi.org/10.1016/j.jmapro.2018.03.029

H. Deng, Y. Chen, Y. Jia, Y. Pang, T. Zhang, S. Wang, and L. Yin, Microstructure and Mechanical Properties of Dissimilar NiTi/Ti6Al4V Joints Via Back-Heating Assisted Friction Stir Welding, J. Manuf. Process., 2021, 64, p 379–391. https://doi.org/10.1016/j.jmapro.2021.01.024

A. Shekhter, S. Kim, D.G. Carr, A.B.L. Croker, and S.P. Ringer, Assessment of Temper Embrittlement in an Ex-Service 1Cr-1Mo-0.25V Power Generating Rotor by Charpy V-Notch Testing, KIc Fracture Toughness and Small Punch Test, Int. J. Press. Vessel. Pip., 2002, 79, p 611–615. https://doi.org/10.1016/S0308-0161(02)00087-X

O.R. Arzate and L. Martinez, Creep Cavitation in Type 321 Stainless Steel, Mater. Sci. Eng. A, 1988, 101, p 1–6. https://doi.org/10.1016/0921-5093(88)90043-3

M. Kvapilová, M. Ohanková, P. Král, J. Dvořák, K. Kuchařová, J. Čmakal, and V. Sklenička, Characterization of Creep Properties and the Microstructure of a Service-Exposed Low Alloy CrMoV Steel Steam Pipe, Mater. Sci. Eng. A, 2022, 853, p 143684.

Q. Zhu, J. Chen, G. Gou, H. Chen, and P. Li, Ameliorated Longitudinal Critically Refracted: Attenuation Velocity Method for Welding Residual Stress Measurement, J. Mater. Process. Technol., 2017, 246, p 267–275. https://doi.org/10.1016/j.jmatprotec.2017.03.022

J.-C. He, S.-P. Zhu, C. Luo, X. Niu, and Q. Wang, Size Effect in Fatigue Modelling of Defective Materials: Application of the Calibrated Weakest-Link Theory, Int. J. Fatigue, 2022, 165, p 107213. https://doi.org/10.1016/j.ijfatigue.2022.107213

L. Liang, M. Xu, Y. Chen, T. Zhang, W. Tong, H. Liu, H. Wang, and H. Li, Effect of Welding Thermal Treatment on the Microstructure and Mechanical Properties of Nickel-Based Superalloy Fabricated by Selective Laser Melting, Mater. Sci. Eng. A, 2021, 819, p 141507. https://doi.org/10.1016/j.msea.2021.141507

D. Liao, S.-P. Zhu, B. Keshtegar, G. Qian, and Q. Wang, Probabilistic Framework for Fatigue Life Assessment of Notched Components Under Size Effects, Int. J. Mech. Sci., 2020, 181, p 105685. https://doi.org/10.1016/j.ijmecsci.2020.105685

M. Blinn and W. RA, Design for Fracture Toughness, Mater. Sel. Des., 1977, 20, p 533–544.

K.S. Prakash et al., Microstructure, Mechanical Properties and Fracture Toughness of SS 321 Stainless Steel Manufactured Using Wire Arc Additive Manufacturing, Trans. Indian Inst. Metals, 2023, 76(2), p 537–544.

X.-K. Zhu and J.A. Joyce, Review of Fracture Toughness (G, K, J, CTOD, CTOA) Testing and Standardization, Eng. Fract. Mech., 2012, 85, p 1–46. https://doi.org/10.1016/j.engfracmech.2012.02.001

B.S. Institution, BS-8571: Method of Test for Determination of Fracture Toughness in Metallic Materials Using Single Edge Notched Tension (SENT) Specimens (2014)

H.K.D.H. Bhadeshia and L.-E. Svensson, Modelling the Evolution of Microstructure in Steel Weld Metal (1993)

K.E. Easterling, Solidification Microstructure of Fusion Welds, Mater. Sci. Eng., 1984, 65, p 191–198. https://doi.org/10.1016/0025-5416(84)90212-X

R. Ramesh, I. Dinaharan, R. Ravikumar, and E.T. Akinlabi, Microstructural Characterization and Tensile Behavior of Nd:YAG Laser Beam Welded Thin High Strength Low Alloy Steel Sheets, Mater. Sci. Eng. A, 2020, 780, p 139178. https://doi.org/10.1016/j.msea.2020.139178

Z. Han, H. Luo, Y. Zhang, and J. Cao, Effects of Micro-Structure on Fatigue Crack Propagation and Acoustic Emission Behaviors in a Micro-Alloyed Steel, Mater. Sci. Eng. A, 2013, 559, p 534–542. https://doi.org/10.1016/j.msea.2012.08.138

S. Ravi, V. Balasubramanian, and S. Nemat Nasser, Effect of Mis-Match Ratio (MMR) on Fatigue Crack Growth Behaviour of HSLA Steel Welds, Eng. Fail. Anal., 2004, 11, p 413–428. https://doi.org/10.1016/j.engfailanal.2003.05.013

L.W. Tsay, C.S. Chung, and C. Chen, Fatigue Crack Propagation of D6AC Laser Welds, Int. J. Fatigue, 1997, 19, p 25–31. https://doi.org/10.1016/S0142-1123(96)00049-7

Acknowledgments

The authors would like to thank ITT Holding, Milan, Italy, for financial and technical support of this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Beigi, M., Khosravifard, A., Rabiezadeh, A. et al. Effect of Microstructural Sensitization on Mechanical Properties of a Welded Chemically Stabilized Stainless Steel Pipe. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09353-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09353-2