Abstract

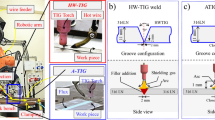

Ferritic stainless steels are widely used in transportation industry due to their exceptional performance regarding mechanical and corrosion properties. However, after a welding process, joints feature the sensitizing phenomenon because of the heat exchange from the torch affecting mechanical properties and corrosion resistance. This work describes the behavior firstly of mechanical properties of weld joints of ferritic stainless steel as base material without and with filler material (AISI 308L) by gas tungsten arc welding (GTAW). Operating parameters such as arc voltage, welding currrent, welding speed, feed speed, shielding gas flow were evaluated. Secondly, samples of weld joints were coated by flame spraying of composite particles in order to reduce the weight loss induced by corrosion in a salt spray (fog) apparatus. Changes induced from GTAW on the heat affected zone and Thermal Spraying on corrosion resistance, were monitored by optical and scanning electron microscopy, microhardness and longitudinal tensile testing. Results show that GTAW helps to control the size and the microstructure of heat affected zone improving simultaneously the mechanical properties. Meanwhile, welded joints covered by composite coatings feature a lower damage provided that the ceramic phase has been homogeneously dispersed.

Similar content being viewed by others

References

P. Sathiya, S. Aravindan and A.N. Haq, Int. J. Adv. Manuf. Tech. 31, 1076–1082 (2007).

K. Shanmugam, A.K. Lakshminarayanan and V. Balasubramanian, Int. J. Pres. Ves. Pip. 86, 519–524 (2009).

M. Mukherjee and T.K. Pal, Metall. Mater. Trans. A 43, 1791–1808 (2012).

R.W.K. Honeycombe and H.K.D.H. Bhadeshia, in Steels Microstructures and Properties, (Edward Arnold, London, 1995).

E. Bayraktar, J.P. Moiron and D. Kaplan, J. Mater. Process. Tech. 175, 20–26 (2006).

E. Bayraktar and D. Katundi, JAMME 44, 35–41 (2011).

C.J. Van Niekerk and M. Du Toit, J. S. Afr. I. Min. Metall. 111, 243–255 (2011).

D. Katundi, A. Tosun-Bayraktar, E. Bayraktar and D. Toueix, JAMME 38, 146–153 (2010).

O. Okada, K. Nakata and S. Kasahara, J. Nucl. Mater. 265, 232–239 (1999).

A.K. Lakshminarayanan and V. Balasubramanian, in Sensitization Resistance of Friction Stir Welded AISI 409 M, (Springer-Verlag, London, 2011), pp. 961–967.

S. Kou, Welding Metallurgy, 2nd ed. (University of Wisconsin, Departament of Materials Science and Engineering, 2003).

J. Velázquez M.Sc. Thesis, IPN, México, 2009.

R. Cuenca-Alvarez, C. Monterrubio-Badillo, F. Juarez-Lopez, H. Ageorges and P. Fauchais, in Advanced Plasma Spray Applications, edited by H. Jazi (INTECH Open Access Publisher, 2012), pp. 39–60.

J.R. Davis, Handbook of Thermal Spray Technology, (ASM International, 2004).

P. Fauchais and A. Vardelle, in Advanced Plasma Spray Applications, edited by H. Jazi (INTECH Open Access Publisher, 2012), pp. 3–38.

E92 - 82 ASTM Standard, ASTM International, 2004.

E8/E8M - 09 ASTM Standard, ASTM International, 2008.

B117 - 07a ASTM Standard, ASTM International, 2008.

A.K. Lakshminarayanan, K. Shanmugam and V. Balasubramanian, J. Iron Steel. Res. Int. 16, 66–72 (2009).

G1 - 03 ASTM Standard, ASTM International, 2011.

Acknowledgments

J. Delgado thanks CONACyT-México for the scholarship provided. CONACyT and SIP-IPN is also acknowledge by founds given to conduct this research.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Delgado-Venegas, J., Molina-Díaz, A., Ambriz-Rojas, R. et al. Microstructural, Mechanical Properties and Corrosion Resistance of Ferritic Stainless Steel Welded by GTAW and Coated by Flame Spraying. MRS Online Proceedings Library 1765, 3–9 (2015). https://doi.org/10.1557/opl.2015.799

Published:

Issue Date:

DOI: https://doi.org/10.1557/opl.2015.799