Abstract

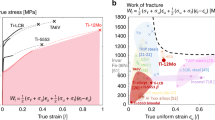

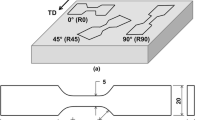

The mechanical response of the Ti-4.5Al-2.9V-3Fe alloy demonstrates a significant strain rate strengthening effect and strong ductility at high strain rates (3.0 × 103/s), contrary to the typical behavior of titanium and its alloys which exhibit a trade-off between these properties. Our recent studies have revealed that this unusual improvement can be attributed to a transformation in the plastic deformation mechanism, specifically from slip-dominating to twinning–slipping combination, under dynamic loading conditions compared to quasi-static loading conditions. Microstructure characterization before and after loading confirms this change in deformation mechanism. Furthermore, simulation predicts a dramatic adiabatic temperature rise in the necking region, which may contribute to strain softening effects observed experimentally. These findings provide valuable insights for manufacturing strategies and enhance our understanding of the mechanical behavior exhibited by titanium alloys.

Similar content being viewed by others

References

Q. Zhao, Q. Sun, S. Xin, Y. Chen, C. Wu, H. Wang, J. Xu, M. Wan, W. Zeng, and Y. Zhao, High-Strength Titanium Alloys for Aerospace Engineering Applications: A Review on Melting-Forging Process, Mater. Sci. Eng.: A, 2022, 845, p 143260.

A. Arab, P. Chen, and Y. Guo, Effects of Microstructure on the Dynamic Properties of TA15 Titanium Alloy, Mech. Mater., 2019, 137, p 103121.

C. Ran, Z. Sheng, P. Chen, W. Zhang, and Q. Chen, Effect of Microstructure on the Mechanical Properties of Ti–5Al–5Mo–5V–1Cr–1Fe Alloy, Mater. Sci. Eng., A, 2020, 773, p 138728.

W. Shi, S. Lu, J. Shen, B. Chen, J. Umeda, Q. Wei, K. Kondoh, and Y. Li, ASB Induced Phase Transformation in High Oxygen Doped Commercial Purity Ti, Mater. Sci. Eng., A, 2022, 830, p 142321.

P.E. Markovsky, J. Janiszewski, V.I. Bondarchuk, O.O. Stasyuk, D.G. Savvakin, M.A. Skoryk, K. Cieplak, P. Dziewit, and S.V. Prikhodko, Effect of Strain Rate on Microstructure Evolution and Mechanical Behavior of Titanium-Based Materials, Metals, 2020, 10(11), p 1404.

W. Liu, P. Cao, C. Zhao, Y. Song, and C. Tang, Effect of Temperature and Strain Rate on Deformation Mode and Crack Behavior of 7B52 Laminated Aluminum Alloy Under Impact Loading, Met. Mater. Int., 2020, 27(11), p 4397–4407.

S.-G. Hong, S.H. Park, and C.S. Lee, Role of 10–12 Twinning Characteristics in the Deformation Behavior of a Polycrystalline Magnesium Alloy, Acta Mater., 2010, 58(18), p 5873–5885.

X. Xu, T. Ali, L. Wang, H. Cheng, Z. Zhou, Z. Ning, X. Liu, A. Liu, B. Zhang, and X. Cheng, Research on Dynamic Compression Properties and Deformation Mechanism of Ti6321 Titanium Alloy, J. Market. Res., 2020, 9(5), p 11509–11516.

X. Chen, X. Zhang, C. Chen, and K. Zhou, Mechanical Response and Deformation Mechanisms of TB17 Titanium Alloy at High Strain Rates, Processes, 2021, 9(3), p 484.

W.Y. Huang Wen, L. Zi-ran, and X. Yuan-ming, Influences of Temperature and Strain Rate on Deformation Twinning of Polycrystalline Titanium, Chin. J. Nonferr. Metals, 2008, 18, p 1440–1445.

D.R. Chichili, K.T. Ramesh, and K.J. Hemker, The High-Strain-Rate Response of Alpha-Titanium: Experiments, Deformation Mechanisms and Modeling, Acta Mater., 1998, 46(3), p 1025–1043.

M. Ahmed, D. Wexler, G. Casillas, D.G. Savvakin, and E.V. Pereloma, Strain Rate Dependence of Deformation-Induced Transformation and Twinning in a Metastable Titanium Alloy, Acta Mater., 2016, 104, p 190–200.

J.L. Sun, P.W. Trimby, F.K. Yan, X.Z. Liao, N.R. Tao, and J.T. Wang, Grain Size Effect on Deformation Twinning Propensity in Ultrafine-Grained Hexagonal Close-Packed Titanium, Scr. Mater., 2013, 69(5), p 428–431.

C. Zhang, A. Mu, Y. Wang, and H. Zhang, Study on Dynamic Mechanical Properties and Constitutive Model Construction of TC18 Titanium Alloy, Metals, 2019, 10(1), p 44.

P. Zhou, B. Liu, and F. Sun, Mechanical Properties and Fracture Mechanism of Laser Solid Formed TC4 Titanium Alloy under Dynamic Compression, J. Phys: Conf. Ser., 2020, 1635, p 012088.

C. Ran, Q. Zhou, P. Chen, Q. Chen, and W. Zhang, Comparative Experimental Study of the Dynamic Properties and Adiabatic Shear Susceptibility of Titanium Alloys, Eur. J. Mech. A. Solids, 2021, 85, p 104137.

B. Wang, J. Li, J. Sun, X. Luo, Z. Liu, and H. Liu, Adiabatic Shear Bands in Ti-6Al-4V Alloy with Lamellar Microstructure, J. Mater. Eng. Perform., 2014, 23(5), p 1896–1903.

Y. Guo, R. Liu, A. Arab, Q. Zhou, B. Guo, Y. Ren, W. Chen, C. Ran, and P. Chen, Dynamic Behavior and Adiabatic Shearing Formation of the Commercially Pure Titanium with Explosion-Induced Gradient Microstructure, Mater. Sci. Eng., A, 2022, 833, p 142340.

Y. Guo, Q. Ruan, S. Zhu, Q. Wei, J. Lu, B. Hu, X. Wu, and Y. Li, Dynamic Failure of Titanium: Temperature Rise and Adiabatic Shear Band Formation, J. Mech. Phys. Solids, 2020, 135, p 103811.

G. Prakash, N.K. Singh, and N.K. Gupta, Flow Behaviour of Ti-6Al-4V Alloy in a Wide Range of Strain Rates and Temperatures under Tensile, Compressive and Flexural Loads, Int. J. Impact Eng., 2023, 176, p 104549.

G. Prakash, N.K. Singh, P. Sharma, and N.K. Gupta, Tensile, Compressive, and Flexural Behaviors of Al5052-H32 in a Wide Range of Strain Rates and Temperatures, J. Mater. Civ. Eng., 2020, 32(5), p 04020090.

G. Prakash, N.K. Singh, and N.K. Gupta, Mechanical Behavior of Magnesium Alloy AZ61 at Different Strain Rates and Temperatures under Tensile, Compressive, and Flexural Loads, J. Mater. Civ. Eng., 2020, 32(11), p 04020336.

N.K. Singh, E. Cadoni, M.K. Singha, and N.K. Gupta, Dynamic Tensile and Compressive Behaviors of Mild Steel at Wide Range of Strain Rates, J. Eng. Mech., 2013, 139(9), p 1197–1206.

B. Zhang, J. Wang, Y. Wang, Y. Wang, and Z. Li, Strain-Rate-Dependent Tensile Response of Ti(-)5Al(-)2.5Sn Alloy, Materials, 2019, 12(4), p 659.

P.E. Markovsky and V.I. Bondarchuk, Influence of Strain Rate, Microstructure and Chemical and Phase Composition on Mechanical Behavior of Different Titanium Alloys, J. Mater. Eng. Perform., 2017, 26(7), p 3431–3449.

Z. Yan, L. Wang, X. Xu, Z. Zhou, A. Liu, and Z. Ning, Response of Ti6321 Titanium Alloy at Different Strain Rates under Tensile Loading, Mater. Sci. Technol., 2022, 38(14), p 1037–1045.

A. Momeni, S.M. Abbasi, M. Morakabati, and A. Akhondzadeh, Yield Point Phenomena in TIMETAL 125 Beta Ti Alloy, Mater. Sci. Eng., A, 2015, 643, p 142–148.

H. Shi, X. Guo, J. Li, J. Mao, and W. Lu, The Gradual Disappearance of Yield Plateau in Zr–Sn–Nb–Fe–Mo Alloy by the Trace Addition of Cr and V, Mater. Sci. Eng., A, 2019, 760, p 407–414.

Q. Luan, T.B. Britton, and T.-S. Jun, Strain Rate Sensitivity in Commercial Pure Titanium: The Competition Between Slip and Deformation Twinning, Mater. Sci. Eng., A, 2018, 734, p 385–397.

R. Guo, B. Liu, R. Xu, Y. Cao, J. Qiu, F. Chen, Z. Yan, and Y. Liu, Microstructure and Mechanical Properties of Powder Metallurgy High Temperature Titanium Alloy with High Si Content, Mater. Sci. Eng., A, 2020, 777, p 138993.

Acknowledgments

The authors would like to express their sincere thanks for the financial support of ‘National Natural Science Foundation of China (NSFC)’ under Grant no. 12172304

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hui, Y., Shen, J., Shi, X. et al. Superior Strain Rate Strengthening Effect and Ductility of a Ti-4.5Al-2.9V-3Fe Alloy under High Strain Rate Loading. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09071-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09071-1