Abstract

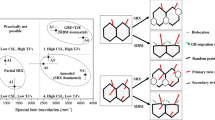

The effect of two varying strain levels (3 and 5%) produced by cold rolling and two solution-annealing heat treatment temperatures (1173 and 1273 K) on the evolution of low-energy configured coincident site lattice (CSL) boundaries in a 22-mm-thick 316LN stainless steel plate was investigated. A simple single-step strain-annealing approach was adopted to maximize the CSL boundaries and to obtain grain boundary-engineered (GBE) microstructure. The low-Σ CSL boundaries up to Σ ≤ 29b were quantified according to Brandon criteria for all the GBE-processed conditions and compared with the as-received condition. It was observed that the fraction of Σ3 and Σ9 boundaries saturated beyond deviation of 2° from their ideal misorientation based on Brandon criteria for most of the GBE-processed conditions. The prevalence of prolific twinning which usually occurs at triple boundary junctions was studied by mapping the nature of triple boundary junction (TBJ) segments and by estimating the relative distribution of Σ3, Σ9 and Σ27 boundaries. The extent of strain-induced boundary migration (SIBM) mechanism which is a prerequisite phenomenon for prolific twinning was assessed using electron backscatter diffraction (EBSD)-based kernel average misorientation (KAM) and grain average misorientation (GAM) mapping. The interdependence between KAM and GAM parameters with respect to the evolution of CSL boundaries was evaluated. The corrosion properties have been evaluated by estimating the degree of sensitization (% DOS) in all the GBE microstructures.

Similar content being viewed by others

Data and Code Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

J. Ganesh Kumar, M. Chowdary, V. Ganesan, R.K. Paretkar, K. Bhanu Sankara Rao, and M.D. Mathew, High Temperature Design Curves for High Nitrogen Grades of 316LN Stainless Steel, Nucl. Eng. Des., 2010, 240, p 1363–1370.

A.A. Tavassoli and F. Touboul, Austenitic Stainless Steels, Status of the Properties Database and Design Rule Development, J. Nucl. Mater., 1996, 233, p 51–61.

S.L. Mannan, S.C. Chetal, B. Raj, and S.B. Bhoje, Selection of Materials for Prototype Fast Breeder Reactor, Trans. Ind. Inst. Metals, 2003, 56(2), p 155–178.

M.D. Mathew, V. Ganesan, J. Ganesh Kumar, and K. Laha, Creep Properties and Design Curves for Nitrogen Enhanced Grade of 316LN Stainless Steel, Mater. High Temp., 2014, 32(4), p 363–368.

V. Ganesan, M.D. Mathew, and K.B. Sankara Rao, Influence of Nitrogen on Tensile Properties of 316LN SS, Mater. Sci. Technol., 2009, 25(5), p 614–618.

V. Ganesan, M.D. Mathew, P. Parameswaran, and K. Bhanu Sankara Rao, Creep Strengthening of Low Carbon Grade Type 316LN Stainless Steel by Nitrogen, Trans. Ind. Inst. Met., 2010, 63, p 417–421.

L. Tan, T.R. Allen, and J.T. Busby, Grain Boundary Engineering for Structure Materials of Nuclear Reactors, J. Nucl. Mater., 2013, 441, p 661–666.

V. Randle, Grain Boundary Engineering: An Overview After 25 Years, Mater. Sci. Technol., 2010, 26(3), p 253–261.

T. Watanabe and T. Sadahiro, The Control of Brittleness and Development of Desirable Mechanical Properties in Polycrystalline Systems by Grain Boundary Engineering, Acta Mater., 1999, 47(15), p 4171–4185.

S. Mandal, P.V. Sivaprasad, B. Raj, and V. Subramanya Sarma, Grain Boundary Microstructural Control through Thermomechanical Processing in a Titanium-Modified Austenitic Stainless Steel, Metall. Mater. Trans. A, 2008, 39, p 3298–3307.

S. Mandal, A.K. Bhaduri, and V. Subramanya Sarma, One-Step and Iterative Thermo-Mechanical Treatments to Enhance ∑3n Boundaries in a Ti-Modified Austenitic Stainless Steel, J. Mater. Sci., 2011, 46, p 275–284.

V. Randle, Twinning-Related Grain Boundary Engineering, Acta Mater., 2004, 52, p 4067–4081.

J. Gao, F. Chen, X. Tang, G. Ge, J. Lin, and S. Shen, Effects of Grain Boundary Structures on Primary Radiation Damage and Radiation-Induced Segregation in Austenitic Stainless Steel, J. Appl. Phys., 2020, 128, p 105304.

L. Tan, J.T. Busby, H.J.M. Chichester, K. Sridharan, and T.R. Allen, Thermomechanical Treatment for Improved Neutron Irradiation Resistance of Austenitic Alloy (Fe–21Cr–32Ni), J. Nucl. Mater., 2013, 437(1–3), p 70–74.

S. Kobayashi, W. Yang, Y. Tomobe, R. Okada, and S. Tsurekawa, Low-Angle Boundary Engineering for Improving High-Cycle Fatigue Property of 430 Ferritic Stainless Steel, J. Mater. Sci., 2020, 55(22), p 9273–9285.

S. Kobayashi, M. Hirata, S. Tsurekawa, and T. Watanabe, Grain Boundary Engineering for Control of Fatigue Crack Propagation in Austenitic Stainless Steel, Proced. Eng., 2011, 10, p 112–117.

Y. Gao, R.O. Ritchie, M. Kumar, and R.K. Nalla, High-Cycle Fatigue of Nickel-Based Superalloy ME3 at Ambient and Elevated Temperatures: Role of Grain-Boundary Engineering, Met. Mater. Trans. A, 2005, 36(12), p 3325–3333.

S. Spigarelli, M. Cabibbo, E. Evangelista, and G. Palumbo, Analysis of the Creep Strength of a Low-Carbon AISI 304 Steel with Low-Σ Grain Boundaries, Mater. Sci. Eng. A, 2003, 352, p 93–99.

V. Thaveeprungsriporn and G.S. Was, The Role of Coincidence-Site-Lattice Boundaries in Creep of Ni-16Cr-9Fe at 360 °C, Metall. Mat. Trans. A, 1997, 28(10), p 2101–2112.

A. Das, Grain Boundary Engineering: Fatigue Fracture, Phil. Mag., 2017, 97(11), p 867–916.

E.A. West and G.S. Was, IGSCC of Grain Boundary Engineered 316L and 690 in Supercritical Water, J. Nucl. Mater., 2009, 392(2), p 264–271.

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato, and I. Karibe, Optimization of Grain Boundary Character Distribution for Intergranular Corrosion Resistant 304 Stainless Steel by Twin-Induced Grain Boundary Engineering, Acta Mater., 2002, 50(9), p 2331–2341.

T.S. Prithiv, P. Bhuyan, S.K. Pradhan, V. Subramanya Sarma, and S. Mandal, A Critical Evaluation on Efficacy of Recrystallization vs. Strain Induced Boundary Migration in Achieving Grain Boundary Engineered Microstructure in a Ni-Base Superalloy, Acta Mater., 2018, 146, p 187–201.

C.S. Kim, Y. Hu, G.S. Rohrer, and V. Randle, Five-Parameter Grain Boundary Distribution in Grain Boundary Engineered Brass, Scr. Mater., 2005, 52, p 633–637.

J. Liu, H. Wu, S. Yang, M. Huang, and C. Ding, Effect of Strain and High Temperature Annealing on Grain Boundary Characteristic Distribution of Compositionally Complex Fe-Mn-Al-C-Cr Steel, Mater. Lett., 2021, 295, p 129841.

F. Bachmann, R. Hielscher, P.E. Jupp, W. Pantleon, H. Schaeben, and E. Wegert, Inferential Statistics of Electron Backscatter Diffraction Data from Within Individual Crystalline Grains, J. Appl. Crystallogr., 2010, 43(6), p 1338–1355.

ASTM G108-94 (2015) Standard Test Method for Electrochemical Reactivation (EPR) for Detecting Sensitization of AISI Type 304 and 304L Stainless Steels

M. Kumar, A.J. Schwartz, and W.E. King, Microstructural Evolution during Grain Boundary Engineering of Low to Medium Stacking Fault Energy FCC Materials, Acta Mater., 2002, 50, p 2599–2612.

V. Randle and G. Owen, Mechanisms of Grain Boundary Engineering, Acta Mater., 2006, 54, p 1777–1783.

Z. Zhuo, S. Xia, Q. Bai, and B. Zhou, The Effect of Grain Boundary Character Distribution on the Mechanical Properties at Different Strain Rates of a 316L Stainless Steel, J. Mater. Sci., 2018, 53, p 2844–2858.

D. Brandon, The Structure of High-Angle Grain Boundaries, Acta Metall., 1966, 14, p 1479–1484.

B. Shang, L. Lei, X. Wang, P. He, X. Yuan, W. Dai, J. Li, Y. Jiang, and Y. Sun, Effects of Grain Boundary Characteristics Changing with Cold Rolling Deformation on Intergranular Corrosion Resistance of 443 Ultra-Pure Ferritic Stainless Steel, Corros. Commun., 2022, 8, p 27–39.

S. Mandal, A.K. Bhaduri, and V. Subramanya Sarma, Grain Boundary Engineering in Alloy D9 through Thermo-Mechanical Processing: Influence of Process Variables and Aspects of Micro-Mechanisms, Int. J. Adv. Eng. Sci. Appl. Math., 2010, 2, p 149–160.

S.E. Hussain, W. Wang, X. Gu, Y. Cui, A. Du, S. Chen, and Y. Lin, Effects of α-γ-α Phase Transformation on the Σ3 Boundaries in High-Purity Iron, J. Mater. Eng. Perfom., 2021, 30(8), p 6167–6174.

R. Jones, V. Randle, D. Engelberg, and T.J. Marrow, Five-Parameter Grain Boundary Analysis of a Grainboundary–Engineered Austenitic Stainless Steel, J. Microscopy, 2009, 233(3), p 417–422.

C.B. Thomson and V. Randle, “Fine Tuning” at Σ3n Boundaries in Nickel, Acta Mater., 1997, 45(12), p 4909–4916.

S.I. Wright, M.M. Nowell, and D.P. Field, A Review of Strain Analysis using Electron Backscatter Diffraction, Microsc. Microanal., 2011, 17, p 316–329.

V.D. Vijayanand, V. Ganesan, J. Ganesh Kumar, P. Parameswaran, Naveena, and K. Laha, Assessment of Creep Strain Distribution Across Base Metal of 316LN Austenitic Stainless Steel Weld Joint by an EBSD-Based Parameter. Metall. Mater. Trans. A 46(11), p 5456-5466 (2015)

Y.A. Betanda, A.L. Helbert, F. Brisset, M.-H. Mathon, T. Waeckerlé, and T. Baudin, Measurement of Stored Energy in Fe–48%Ni Alloys Strongly Cold-Rolled Using Three Approaches: Neutron Diffraction Dillamore and KAM Approaches, Mater. Sci. Eng. A, 2014, 614, p 193–198.

C. Moussa, M. Bernacki, R. Besnard, and N. Bozzolo, About Quantitative EBSD Analysis of Deformation and Recovery Substructures in PURE TANTALUM, IOP Conf. Ser. Mater. Sci. Eng., 2015, 89, p 12038.

M. Kamaya, Assessment of Local Deformation using EBSD: Quantification of Accuracy of Measurement and Definition of Local Gradient, Ultramicroscopy, 2011, 111, p 1189–1199.

F.J. Humphreys, Grain Characterization by Electron Backscatter Diffraction, J. Mater. Sci., 2001, 36, p 3833–3854.

N.K. Sharma and S. Shekhar, New Perspectives on Twinning Events during Straininduced Grain Boundary Migration (SIBM) in Iteratively Processed 316L Stainless Steel, J. Mater. Sci., 2021, 56, p 792–814.

X. Yang, P. Wang, and M. Huang, Grain Boundary Evolution during Low-Strain Grain Boundary Engineering Achieved by Strain-Induced Boundary Migration in Pure Copper, Mater. Sci. Eng. A, 2022, 833, p 142532.

A. Ravi Shankar, V. Shankar, R.P. George, and J. Philip, Enhancing the Intergranular Corrosion Resistance of High Nitrogen Containing 316L Stainless Steels by Grain Boundary Engineering via Thermo-mechanical Treatment, Corrosion, 2020, 76(9), p 835–842.

S. Aamani, C.R. Das, S.K. Martha, and B.B. Panigrahi, Effect of Nitrogen on Grain Boundary Character Distribution in 316 Stainless Steel, Mater. Lett., 2021, 288, p 129387.

Acknowledgments

The authors thank Dr. B. Venkatraman, Director, Indira Gandhi Centre for Atomic Research (IGCAR); Dr. R. Divakar, Director, Metallurgy & Materials Group (MMG) and Materials Science Group (MSG); and Dr. M. Vasudevan, Associate Director, Materials Development & Technology Group (MDTG) for their unconditional support and encouragement. The authors would like to thank Dr. Poonguzhali for the help rendered during carrying out corrosion studies. Special thanks to Dr. Diptimayee Samantaray, Head, High-temperature Materials Technology Section (HMTS), for providing the cold rolling facility and Shri. A. Arasu, High-temperature Materials Technology Section (HMTS) for his valuable help during the rolling operation. Also, we thank our collaborator Dr. Ramakrishna Pagoti, SRI, AERB, Kalpakkam, for his help rendered during analysis of EBSD data in MATLAB®.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

DPRP involved in conceptual, experimental, investigation, formal analysis and writing the original draft manuscript. VDV involved in conceptual, supervision, validation, review and editing the draft manuscript. KM involved in formal characterization and review. VG involved in analysis and review. GVPR involved in project resources, review and editing. AN involved in project administration, review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Palaparti, D.P.R., Vijayanand, V.D., Mariappan, K. et al. Interdependency between Electron Backscatter Diffraction-Based Misorientation Parameters and Coincidence Site Lattice Boundaries in 316LN Stainless steel. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08862-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08862-w