Abstract

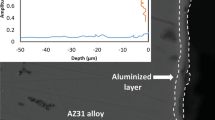

In this study, the effect of intermetallic compounds (ICMs) on the tribocorrosion behavior of the 7075 aluminum alloy was investigated. ICMs play important roles in the tribocorrosion resistance and mechanism of the sample. In the as-received sample, micron-sized Mg2Si, Al23Fe4Cu, and nanosized MgZn2 induced pitting corrosion and acted as abrasive materials. Accompanying the re-dissolution of Mg2Si and the growth of MgZn2, the pitting resistance worsened and adhesive wear took place. Subsequently, MgZn2 precipitated along the grain boundaries, which resulted in intergranular corrosion and aggravation of adhesive wear.

Similar content being viewed by others

References

P. Hidalgo, C.M. Cepeda-Jiménez, O.A. Ruano et al., Influence of the Processing Temperature on the Microstructure, Texture, and Hardness of the 7075 Aluminum Alloy Fabricated by Accumulative Roll Bonding [J], Metall. and Mater. Trans. A., 2010, 41(3), p 758–767.

K. Ma, T. Hu, H. Yang, T. Topping, A. Yousefiani, E.J. Lavernia, and J.M. Schoenung, Coupling of Dislocations and Precipitates: Impact on the mEchanical Behavior of Ultrafine Grained Al-Zn-Mg Alloys, Acta Mater., 2016, 103, p 153–164.

R.S. Rana, R. Purohit, and S. Das, Reviews on the Influences of Alloying Elements on the Microstructure and Mechanical Properties of Aluminum Alloys and Aluminum Alloy Composites, Int. J. Sci. Res. Publ., 2012, 2(6), p 1–7.

X. Yuan, K. Gao, G.S. Rohrer, and X. Fang, Grain Boundary Plane Distributions in a Hot Rolled 5a06 Aluminum Alloy, Adv. Eng. Mater., 2014, 16(9), p 1105–1110.

L. Yun and Y.H.Z. Le, Severe Corrosivity and its Eletrochemical Mechanism of Seawater in Xiamen Sea Area to Al-Mg Alloys, Electrochemistry, 2003, 9(3), p 300–307.

J. Chen, Q. Zhang, Q.-A. Li, S.-L. Fu, and J.-Z. Wang, Corrosion and Tribocorrosion Behaviors of Aisi 316 Stainless Steel and Ti6al4v Alloys in Artificial Seawater, Transact. Nonferr. Metals Soc. China, 2014, 24(4), p 1022–1031.

N. Li, C. Dong, C. Man, X. Li, D. Kong, Y. Ji, M. Ao, J. Cao, L. Yue, X. Liu, and M. Du, Insight into the Localized Strain Effect on Micro-Galvanic Corrosion Behavior in Aa7075-T6 Aluminum Alloy, Corr. Sci., 2021, 180, p 109174.

N. Birbilis, M.K. Cavanaugh, and R.G. Buchheit, Electrochemical Behavior and Localized Corrosion Associated with Al7cu2fe Particles in Aluminum Alloy 7075–T651, Corros. Sci., 2006, 48(12), p 4202–4215.

Z. Wang, H. Jiang, H. Li, and S. Li, Effect of Solution-Treating Temperature on the Intergranular Corrosion of a Peak-Aged Al-Zn-Mg-Cu Alloy, J. Market. Res., 2020, 9(3), p 6497–6511.

J. Basumatary and R.J.K. Wood, Synergistic Effects of Cavitation Erosion and Corrosion for Nickel Aluminium Bronze with Oxide Film in 3.5% Nacl Solution, Wear, 2017, 376, p 1286–1297.

J. Wang, B. Zhang, B. Wu, and X.L. Ma, Size-Dependent Role of S Phase in Pitting Initiation of 2024 Al Alloy, Corros. Sci., 2016, 105, p 183–189.

Y. Zhu and F. Gerald, Effect of Major Intermetallic Particles on Localized Corrosion of Aa2060-T8, Corrosion, 2018, 75(1), p 29–41.

K.D. Ralston, N. Birbilis, M.K. Ca Vanaugh, M. Weyland, B.C. Muddle, and R. Marceau, Role of Nanostructure in Pitting of Al-Cu-Mg Alloys, Electrochim. Acta, 2010, 55(27), p 7834–7842.

Z. Wu, Y.F. Cheng, L. Liu, W. Lv, and W. Hu, Effect of Heat Treatment on Microstructure Evolution and Erosion-Corrosion Behavior of a Nickel-Aluminum Bronze Alloy in Chloride Solution, Corros. Sci., 2015, 98, p 260–270.

C.N. Panagopoulos, E.P. Georgiou, and A.G. Gavras, Corrosion and Wear of 6082 Aluminum Alloy, Tribol. Int., 2009, 42(6), p 886–889.

W. Li, R. Di, R. Yuan, H. Song, and J. Lei, Microstructure, Wear Resistance and Electrochemical Properties of Spherical/Non-Spherical Wc Reinforced Inconel 625 Superalloy by Laser Melting Deposition, J. Manuf. Process., 2022, 74, p 413–422.

K. Wang, Y. Wang, X. Yue, and W. Cai, Multiphysics Modeling and Uncertainty Quantification of Tribocorrosion in Aluminum Alloys, Corr. Sci., 2021, 178, p 109095.

W.B. Bouaeshi and D.Y. Li, Effects of Y2o3 Addition on Microstructure, Mechanical Properties, Electrochemical Behavior, and Resistance to Corrosive Wear of Aluminum, Tribol. Int., 2007, 40(2), p 188–199.

Y. Liu, J.M.C. Mol and, G.C.A.M. Janssen, Combined Corrosion and Wear of Aluminium Alloy 7075–T6, J. Bio-and Tribo-Corr., 2016, 2(2), p 1–7.

H. Mindivan, M. Baydogan, E.S. Kayali, and H. Cimenoglu, Wear Behaviour of 7039 Aluminum Alloy, Mater Charact, 2005, 54(3), p 263–269.

X. Yan, S. Yin, C. Chen, C. Huang, R. Bolot, R. Lupoi, M. Kuang, W. Ma, C. Coddet, H. Liao, and M. Liu, Effect of Heat Treatment on the Phase Transformation and Mechanical Properties of Ti6al4v Fabricated by Selective Laser Melting, J. Alloy. Compd., 2018, 764, p 1056–1071.

F.R. Kaschel, R.K. Vijayaraghavan, A. Shmeliov, E.K. McCarthy, M. Canavan, P.J. McNally, D.P. Dowling, V. Nicolosi, and M. Celikin, Mechanism of Stress Relaxation and Phase Transformation in Additively Manufactured Ti-6al-4v Via in Situ High Temperature Xrd and Tem Analyses, Acta Mater., 2020, 188, p 720–732.

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, and M. Qian, Additive Manufacturing of Strong and Ductile Ti-6al-4v by Selective Laser Melting Via in Situ Martensite Decomposition, Acta Mater., 2015, 85, p 74–84.

S.Q. Wu, Y.J. Lu, Y.L. Gan, T.T. Huang, C.Q. Zhao, J.J. Lin, S. Guo, and J.X. Lin, Microstructural Evolution and Microhardness of a Selective-Laser-Melted Ti-6al-4v Alloy after Post Heat Treatments, J. Alloy. Compd., 2016, 672, p 643–652.

A. Robin and J.P. Meirelis, Influence of Fluoride Concentration and Ph on Corrosion Behavior of Titanium in Artificial Saliva, J. Appl. Electrochem., 2007, 37(4), p 511–517.

M. Stancheva and M. Bojinov, Influence of Fluoride Content on the Barrier Layer Formation and Titanium Dissolution in Ethylene Glycol-Water Electrolytes, Electrochim. Acta, 2012, 78, p 65–74.

Z.B. Wang, H.X. Hu, C.B. Liu, and Y.G. Zheng, The Effect of Fluoride Ions on the Corrosion Behavior of Pure Titanium in 0.05m Sulfuric Acid, Electrochim. Acta, 2014, 135, p 526–535.

M.E. Orazem and B. Tribollet, An Integrated Approach to Electrochemical Impedance Spectroscopy, Electrochim. Acta, 2008, 53(25), p 7360–7366.

D.-S. Kong and Y.-Y. Feng, Electrochemical Anodic Dissolution Kinetics of Titanium in Fluoride-Containing Perchloric Acid Solutions at Open-Circuit Potentials, J. Electrochem. Soc., 2009, 156(9), p C283.

D. Kong, C. Dong, X. Ni, L. Zhang, H. Luo, R. Li, L. Wang, C. Man, and X.J.C.S. Li, Superior Resistance to Hydrogen Damage for Selective Laser Melted 316l Stainless Steel in a Proton Exchange Membrane Fuel Cell Environment, Corr. Sci., 2020, 166, p 108425.

J.F. Li, Z. Zheng, J. Na, and C. Tan, Localized Corrosion Mechanism of 2xxx Series Al Alloy Containing S(Al2cumg) and Θ’(Al2cu) Precipitates in 4.0% Nacl Solution at Ph 6.1, Mater. Chem. Phys., 2005, 91(2–3), p 325–329.

H. Ahlatci, Production and Corrosion Behaviours of the Al-12si-Xmg Alloys Containing in Situ Mg2si Particles, J. Alloy. Compd., 2010, 503(1), p 122–126.

F.-L. Zeng, Z.-L. Wei, J.-F. Li, C.-X. Li, X. Tan, Z. Zhang, and Z.-Q. Zheng, Corrosion Mechanism Associated with Mg2si and Si Particles in Al-Mg-Si Alloys, Transact. Nonferrous Metals Soc. China, 2011, 21(12), p 2559–2567.

N. Li, C. Dong, X. Wei, C. Man, J. Yao, J. Cao, and X. Li, Scanning Kelvin Probe Force Microscopy and Density Functional Theory Studies on the Surface Potential of the Intermetallics in Aa7075-T6 Alloys, J. Mater. Eng. Perform., 2019, 28(7), p 4289–4301.

M. Li, A. Seyeux, F. Wiame, P. Marcus, and J. Światowska, Insights on the Al-Cu-Fe-Mn Intermetallic Particles Induced Pitting Corrosion of Al-Cu-Li Alloy, Corros. Sci., 2020, 176, 109040.

Y. Sun, Q. Pan, Y. Sun, W. Wang, Z. Huang, X. Wang, and Q. Hu, Localized Corrosion Behavior Associated with Al7cu2fe Intermetallic in Al-Zn-Mg-Cu-Zr Alloy, J. Alloy. Compd., 2019, 783, p 329–340.

G.S. Chen, M. Gao, and R.P. Wei, Microconstituent-Induced Pitting Corrosion in Aluminum Alloy 2024–T3, Corrosion, 1996, 52(1), p 8–15.

Z. Fan, P. Jinshan, and N. Jan-Olov, In Situ and Operando Afm and Eis Studies of Anodization of Al 6060: Influence of Intermetallic Particles, J. Electrochem. Soc., 2016, 163, p C609–C618.

P. Leblanc and G.S. Frankel, A Study of Corrosion and Pitting Initiation of Aa2024-T3 Using Atomic Force Microscopy, J. Electrochem. Soc., 2002, 149(6), p B239–B247.

L.L. Li, B. Zhang, B. Tian, Y. Zhou, J.Q. Wang, E.H. Han, and W. Ke, Svet Study of Galvanic Corrosion of Al/Mg2si Couple in Aqueous Solutions at Different Ph, J. Electrochem. Soc., 2017, 164(6), p C240–C249.

J. Chen, J.Z. Wang, F.Y. Yan, Q. Zang, and Q.-A. Li, Effect of Applied Potential on the Tribocorrosion Behaviors of Monel K500 Alloy in Artificial Seawater, Tribol. Int., 2015, 81, p 1–8.

J. Ureña, S. Tsipas, A.M. Pinto et al., Corrosion and Tribocorrosion Behaviour of β-type ti-nb and ti-mo Surfaces Designed by Diffusion Treatments for Biomedical Applications, Corros. Sci., 2018, 140, p 51–60.

T. Hanawa, K. Asami, and K. Asaoka, Repassivation of Titanium and Surface Oxide Film Regenerated in Simulated Bioliquid, J. Biomed. Mater. Res., 2015, 40(4), p 530–538.

Y. Zhang, X. Yin, and F. Yan, Effect of Halide Concentration on Tribocorrosion Behaviour of 304ss in Artificial Seawater, Corros. Sci., 2015, 99, p 272–280.

C.N. Panagopoulos, P.E. Agathocleous, V.D. Papachristos, and A. Michaelides, Sliding Wear Behaviour of Zinc–Iron Alloy Electrodeposits, Surf. Coat. Technol., 2000, 123(1), p 62–71.

Y. Sun and E. Haruman, Effect of Electrochemical Potential on Tribocorrosion Behavior of Low Temperature Plasma Carburized 316l Stainless Steel in 1m H2so4 Solution, Surf. Coat. Technol., 2011, 205(17–18), p 4280–4290.

J.K. Park, Influence of Retrogression and Reaging Treatments on the Strength and Stress Corrosion Resistance of Aluminium Alloy 7075-T 6, Mater. Sci. Eng. A, 1988, 103, p 223–231.

M. Tash, Microstructure, Hardness, Wear and Corrosion Resistance of Heat-Treated 7075 Aluminum Alloy Casting Mahmoud Tash, Mater. Design Appl. III, 2021, 149, p 199–219.

P.C. Bai, F. Liu, X.H. Hou, C.W. Zhao, and Y.M. Xing, Experimental Examination of Strain Field within Gp Zone in an Al-Zn-Mg-Cu Alloy, Physica B, 2012, 407(22), p 4466–4469.

S. Muraishi, S. Kumai and, A. Sato, Competitive Nucleation and Growth of 111 with 001 Gp Zones and in a Stress-Aged Al-Cu-Mg-Ag Alloy, Mater. Transact, 2004, 45(10), p 2974–2980.

R. Ghosh, A. Venugopal, P. Sankaravelayudham, R. Panda, S.C. Sharma, K.M. George, and V.S. Raja, Effect of Thermomechanical Treatment on the Environmentally Induced Cracking Behavior of Aa7075 Alloy, J. Mater. Eng. Perform., 2014, 24(2), p 545–555.

A.H.M.E.T. Karaaslan, I. Kaya, and H. Atapek, Effect of Aging Temperature and of Retrogression Treatment Time on the Microstructure and Mechanical Properties of Alloy AA 7075, Metal Sci. Heat Treatm., 2007, 49(9–10), p 443–447.

S.V. Emani, J. Benedyk, P. Nash, and D. Chen, Double Aging and Thermomechanical Heat Treatment of Aa7075 Aluminum Alloy Extrusions, J. Mater. Sci., 2009, 44(23), p 6384–6391.

M. Baydogan, H. Cimenoglu, E. Sabri Kayali, and J. Rasty, Improved Resistance to Stress-Corrosion-Cracking Failures via Optimized Retrogression and Reaging of 7075–T6 Aluminum Sheets, Metall. Mater. Transact A, 2008, 39, p 2470–2476.

D.J. Kelly and M.J. Robinson, Influence of Heat Treatment and Grain Shape on Exfoliation Corrosion of Al-Li Alloy 8090, Corr. -Houston Tx-, 1993, 49(10), p 787–795.

M.J. Robinson and N.C. Jackson, The Influence of Grain Structure and Intergranularcorrosion Rate on Exfoliation and Stress Corrosion Crackingof High Strength Al-Cu-Mg Alloys, Corros. Sci., 1999, 41(5), p 1013–1028.

P.A. Rometsch, Y. Zhang, and S. Knight, Heat Treatment of 7xxx Series Aluminium Alloys—Some Recent Developments, Transact. Nonferrous Metals Soc. China, 2014, 24(7), p 2003–2017.

T. Sunar and D. Özyürek, A Research on the Effect of Retrogression and Re-Aging Heat Treatment on Hot Tensile Properties of Aa7075 Aluminum Alloys, J. Manufact. Sci. Eng., 2022, 144(1), p 011005–011098.

P. Liu, J.-Y. Hu, H.-X. Li, S.-Y. Sun, and Y.-B. Zhang, Effect of Heat Treatment on Microstructure, Hardness and Corrosion Resistance of 7075 Al Alloys Fabricated by Slm, J. Manuf. Process., 2020, 60, p 578–585.

N. Birbilis and R.G. Buchheit, Electrochemical Characteristics of Intermetallic Phases in Aluminum Alloys an Experimental Survey and Discussion, J. Electrochem. Soc., 2005, 152(4), p 467–472.

R.G. Buchheit, A Compilation of Corrosion Potentials Reported for Intermetallic Phases in Aluminum Alloys, J. Electrochem. Soc., 1995, 142(11), p 3994–3996.

J. Wit, Local Potential Measurements with the Skpfm on Aluminium Alloys, Electrochim. Acta, 2004, 49(17–18), p 2841–2850.

P.S. Pao, C.R. Feng, and S.J. Gill, Corrosion Fatigue Crack Initiation in Aluminum Alloys 7075 and 7050, Corros. Sci., 2000, 56(10), p 1022–1031.

N. Li, C. Dong, C. Man, and J. Yao, In Situ Electrochemical Atomic Force Microscopy and Auger Electro Spectroscopy Study on the Passive Film Structure of 2024–T3 Aluminum Alloy Combined with a Density Functional Theory Calculation, Adv. Eng. Mater., 2019, 21(12), p 1900386.

K.A. Yasakau, M.L. Zheludkevich, and S.V. Lamaka et al., Role of intermetallic phases in localized corrosion of aa5083, Electrochim. Acta, 2007, 52(27), p 7651–7659.

N.Li. (2021) Study on first-principles calculation of micro-galvanic effect of compounds and prediction of corrosion behavior in aluminum alloy,Ph.D. Thesis, University of Science and Technology Beijing, .

S.-S. Wang, J.-T. Jiang, G.-H. Fan, L. Yang, S.-L. Dai, G.S. Frankel, and L. Zhen, Microstructure Evolution in Abrasion-Induced Surface Layer on an Al-Zn-Mg-Cu Alloy, Mater Charact, 2014, 98, p 18–25.

N. Birbilis and R. Buchheit, Corrosion Damage Accumulation on High Strength Al-Alloys: Some Advances in Understanding the Role of Intermetallics, Corr. Mater, 2004, 29(6), p S4–S8.

A.C. Crossland, H. Habazaki, K. Shimizu, P. Skeldon, G.E. Thompson, G.C. Wood, X. Zhou, and C. Smith, Residual Flaws Due to Formation of Oxygen Bubbles in Anodic Alumina, Corros. Sci., 1999, 41(10), p 1945–1954.

L. Chauke, H. Moeller, U.A. Curie, and G. Govender, Anodising of Al-Mg-Si-(Cu) Alloys Produced by R-Hpdc, Mater. Sci. Forum, 2013, 765, p 658–662.

S. Mischler, Triboelectrochemical Techniques and Interpretation Methods in Tribocorrosion: A Comparative Evaluation, Tribol. Int., 2008, 41(7), p 573–583.

J.A. Richardson and G.C. Wood, A Study of the Pitting Corrosion of Al Byscanning Electron Microscopy, Corros. Sci., 1970, 10(5), p 313–323.

ASTM G119-09, Standard Guide for Determining Synergism Between Wear and Corrosion [S].

ASTM G102-89(2004)e1, Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements [S].

Acknowledgments

This work is supported by the National Key Research and Development Program of China (No. 2021YFE0114000), National Natural Science Foundation of China (No. 51901216, U2106216), the National Science and Technology Resource Investigation Program of China (No. 2019FY101400), Key Research and Development Program of Shandong Province (No. 2020CXGC010305), Fundamental Research Funds for the Central Universities (No. 202241012, 202262011) , and Shanghai Key Laboratory of Materials Protection and Advanced Materials in Electric Power.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, Q., Zhang, H., Man, C. et al. The Effect of Intermetallic Compounds on Corrosion and Tribocorrosion Behavior of 7075 Aluminum Alloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08771-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08771-y