Abstract

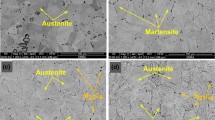

The performance and properties of austenitic stainless steels are strongly linked to their microstructures, mainly the amount, distribution and orientation of delta (δ) ferrite and the presence of sigma (σ) phase. AISI 202 steel in annealed (as received-AR) as well as heat treated and forced air cooled (FAC)/furnace cooled (FC) conditions contains austenitic phase and ~ 4 vol.% δ-ferrite phases. In FC condition σ-phase is also observed which is formed during the slow cooling of steel in the temperature range of 850-450 °C. Impact properties are found to be better at room temperature than 77 K. Higher impact strength is found for FAC than FC condition both at 300 and 77 K. The test temperature dependent reduction in impact strength is found to be higher for FC specimens compared to AR and FAC specimens. U-notch showed higher impact values compared to V-notch specimens at 77 K test temperature. With 4 vol.% δ-ferrite having aspect ratio of ~ 4-40, the notch direction has not shown significant effect on the impact properties.

Similar content being viewed by others

References

P. Barnard, Materials for Ultra-supercritical and Advanced Ultra-supercritical Power Plants, Elsevier, 2017, p 99–119

V.S. Raja and T. Shoji, Stress Corrosion Cracking Theory and Practice, 1st ed. Woodhead Publishing, 2011, p 199–244

R.L. Plaut, C. Herrera, D.M. Escriba, P.R. Rios, and A.F. Padilha, A Short Review on Wrought Austenitic Stainless Steels at High Temperatures: Processing, Microstructure, Properties and Performance, Mater. Res., 2007, 10(4), p 453–460.

M.A. Martorano, C.F. Tavares, and A.F. Padilha, Predicting Delta Ferrite Content in Stainless Steel Castings, ISIJ Int., 2012, 52(6), p 1054–1065.

C. Wu, S. Li, C. Zhang, and X. Wang, Microstructural Evolution in 316LN Austenitic Stainless Steel during Solidification Process under Different Cooling Rates, J. Mater. Sci., 2016, 51, p 2529–2539.

M.A. Valiente Bermejo, Materials Behaviour and Weldability Influence of the [creq+Nieq] Alloy Level on the Transition between Solidification Modes in Austenitic Stainless Steel, Weld Metal. Weld World, 2012, 56, p 2–14.

C.-C. Hsieh, W. Wu, Overview of Intermetallic Sigma (σ) Phase Precipitation in Stainless Steels. ISRN Metallurgy, 2012, 1–16.

P. Duhaj, J. Ivan, and E. Makovicky, Sigma Phase Precipitation in Austenitic Steels, J. Iron Steel Inst., 1968, 206, p 1245–1252.

M.S. Dean and W.J. Plumbridge, Prediction of Sigma Phase Formation in Stainless Steels, Nuclear Energy, 1982, 21(2), p 119–135.

J. Barcik, The Process of σ-Phase Solution in 25 pct Cr-20 pct Ni Austenitic Steels, Metall. Trans. A, 1987, 18A(7), p 1171–1177.

J. Barcik, Mechanism of σ Phase Precipitation in Cr-Ni Austenitic Steels, Mater. Sci. Technol., 1988, 4(1), p 5–15.

A.V. Kington and F.W. Noble, Formation of σ Phase in Wrought 310 Stainless Steel, Mater. Sci. Technol., 1995, 11(3), p 268–283.

D.M. Escriba Villanueva, F.C. Pimenta Jr., R.L. Plaut, and A.F. Padilha, Comparative Study on Sigma Phase Precipitation of Three Types of Stainless Steels: Austenitic, Superferritic and Duplex, Mater. Sci. Technol., 2006, 22(9), p 1098–1104.

K. Shinohara, T. Seo, and K. Kumada, Recrystailization and Sigma Phase Formation as Concurrent and Interacting Phenomena in 25%Cr-20%Ni Steel, Mater. Trans., 1979, 20(12), p 713–723.

A.F. Padilha, R.L. Plaut, P.R. Rios, and G.E. Totten (ed.), Stainless steels heat treatment (chapter 12), in Steel Heat Treatment Handbook, 2nd edn. (CRC Press, Boca Raton, 2007), p. 695–739.

F.B. Waanders, S.W. Vorster, and H. Pollak, The Influence of Temperature on σ-Phase Formation and the Resulting Hardening of Fe-Cr-Mo-Alloys, Hyperfine Interact., 1999, 120–121(1–8), p 751–755.

J.T. Gow and O.E. Harder, Balancing the Composition of Cast 25 Per Cent Chromium-12 Per Cent Nickel Type Alloys, Trans. Am. Soc. Met., 1942, 30, p 855–935.

L.R. Woodyatt, Austenitic Stainless Steels: Microstructure and Mechanical Properties, 1st ed. Springer, London, 1984.

S. Konosu, H. Mashiba, M. Takeshima, and T. Ohtsuka, Effects of Pretest Aging on Creep Crack Growth Properties of Type 308 Austenitic Stainless Steel Weld Metals, Eng. Fail. Anal., 2001, 8(1), p 75–85.

M.C. Mataya and M.J. Carr, Characterization of inhomogeneities in complex austenitic stainless steel forgings, in Deformation, Processing, and Structure, ASM Materials Science Seminar (St. Louis, 1982).

G.S. Reis, A.M. Jorge, and O. Balancin, Influence of the Microstructure of Duplex Stainless Steels on Their Failure Characteristics during Hot Deformation, Mater. Res., 2000, 3, p 31–35.

N. Lopez, M. Cid, and M. Puiggali, Influence of σ-Phase on Mechanical Properties and Corrosion Resistance of Duplex Stainless Steels, Corros. Sci., 1999, 41(8), p 1615–1631.

V. Anil Kumar, R.K. Gupta, M.K. Karthikeyan, F. Gino Prakash, and P. Ramkumar, Development of High Nitrogen Stainless Steel for Cryogenic Applications, Mater. Sci. Forum, 2015, 830–831, p 23–26.

J.W. Simmons, Overview: High-Nitrogen Alloying of Stainless Steels, Mater. Sci. Eng. A, 1996, 207, p 159–169.

M.O. Speidel, Properties and applications of high nitrogen steels, in HNS 88, Lille, France, May 1988, ed. by J. Foct, A. Hendry (The Institute of Metals, London, 1989), p. 92.

J. Srinath, K. Manwatkar Sushant, S.V.S. Narayana Murty, P. Ramesh Narayanan, S.C. Sharma and M. George Koshy, Metallurgical Analysis of a Failed 17–4 PH Stainless Steel Pyro Bolt Used in Launch Vehicle Separation Systems, Mater. Perform. Charact., 2015, 4(1), p 29–44.

ASTM E23-12C: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials (ASTM International, West Conshohocken, 2007). www.astm.org.

T.V. Rajan, C.P. Sharma, and A. Sharma, Heat Treatment-Principles and Techniques, Prentice-Hall of India, 1994.

R.J. Gray, V.K. Sikka, and R.T. King, Detecting Transformation of Delta-Ferrite to Sigma Phase in Stainless Steels by Advanced Metallographic Techniques, J. Met., 1978, 30(11), p 18–26.

C.C. Hsieh, The Study of δ/σ/γ Phase Transformation in 309LSÍ Stainless Steels After Aging under Nitrogen Atmospheres. M.S. thesis, I-Shou University, Taiwan, 2004.

X. Tang, Sigma Phase Characterization in AISI 316 Stainless Steel, Microsc. Microanal., 2005, 11(2), p 78–79.

D.M.E. Villanueva, F.C.P. Junior, R.L. Plaut, and A.F. Padilha, Comparative Study on Sigma Phase Precipitation of Three Types of Stainless Steels: Austenitic, Superferritic and Duplex, Mater. Sci. Technol., 2006, 22(9), p 1098–1104.

P.V. Muterlle, M. Zendron, and M. Perina, A. Molinari, Influence of delta ferrite on mechanical properties of Stainless steel produced by MIM, in Proceedings of COBEM 2009, 20th International Congress of Mechanical Engineering November 15–20, 2009.

R. Ghasemi, B. Beidokhti, and M. Fazel-Najafabadi, Effect of Delta Ferrite on the Mechanical Properties of Dissimilar Ferritic-Austeniticstainless Steel Welds, Arch. Metall. Mater., 2018, 63(1), p 437–443.

S.A. Bashu, K. Singh, and M.S. Rawat, Effect of Heat Treatment on Mechanical Properties and Fracture Behaviour of a 12CrMoV Steel, Mater. Sci. Eng. A, 1990, 127, p 7–15.

D. Carrouge, H.K.D.H. Bhadeshia, and P. Woollin, Effect of δ-Ferrite on Impact Properties of Supermartensitic Stainless Steel Heat Affected Zones, Sci. Technol. Weld. Join., 2004, 9, p 377–389.

P. Wang, S.P. Lu, N.M. Xiao, D.Z. Li, and Y.Y. Li, Effect of Delta Ferrite on Impact Properties of Low Carbon 13Cr-4Ni Martensitic Stainless Steel, Mater. Sci. Eng. A, 2010, 527, p 3210–3216.

Acknowledgments

The authors thank the Group Director (VSSC), MMG, Deputy Director (VSSC), MME and Director of Vikram Sarabhai Space Centre (VSSC) for granting permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ranjith, R., Rao, G.S., Manwatkar, S.K. et al. Effect of Heat Treatment on Mechanical Properties of AISI 202 Steel at Room Temperature and 77 K. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08332-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08332-3