Abstract

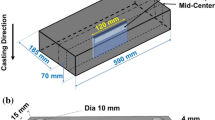

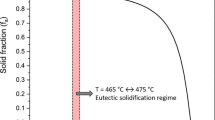

The elastic properties of the Al-Mg-Si direct-chill-cast AA6111 alloy were determined during the unloading stage of the cyclic tensile test over a wide range of temperatures (25-550 °C), and particular attention was paid to high temperatures near the solidus. Young’s modulus was calculated based on macroscopic and localized strains, which were measured using an extensometer and the digital image correlation (DIC) method. Poisson's ratio was determined based on the localized axial and lateral strains measured using DIC method. Over the entire temperature range, the DIC method demonstrated a higher stability in its accuracy with increasing temperature than that using the extensometer. A sharp change in the slope of Young's modulus as a function of the temperature, starting from the solidus temperature, was detected using the DIC method. Correlations between Young's modulus and temperature in both the solid and semi-solid states were established. Poisson’s ratio as a function of the temperature exhibited a dramatic change near the solidus temperature because of the presence of liquid pockets. The onset brittle temperature of AA6111 alloy in the semi-solid state was estimated to be 550 °C based on the critical values of Poisson’s ratio and the shear modulus to bulk modulus ratio.

Similar content being viewed by others

References

J. Sarkar, T.R.G. Kutty, D.S. Wilkinson, J.D. Embury, and D.J. Lloyd, Tensile Properties and Bendability of T4 Treated Aa6111 Aluminum Alloys, Mater. Sci. Eng. A., 2004, 369, p 258–266. https://doi.org/10.1016/j.msea.2003.11.022

J.Y. Lee, M.G. Lee, F. Barlat, K.H. Chung, and D.J. Kim, Effect of Nonlinear Multi-Axial Elasticity and Anisotropic Plasticity on Quasi-Static Dent Properties of Automotive Steel Sheets, Int. J. Solids Struct., 2016, 87, p 254–266. https://doi.org/10.1016/j.ijsolstr.2016.01.020

M. Jolly and L. Katgerman, Modelling of Defects in Aluminium Cast Products, Prog. Mater. Sci., 2022, 123, p 100824. https://doi.org/10.1016/j.pmatsci.2021.100824

D. Zakarian, A. Khachatrian, and S. Firstov, Universal Temperature Dependence of Young’s Modulus, Met. Powder Rep., 2019, 74, p 204–206. https://doi.org/10.1016/j.mprp.2018.12.079

H.Y. Yu, Variation of Elastic Modulus during Plastic Deformation and its Influence on Springback, Mater. Des., 2009, 30, p 846–850. https://doi.org/10.1016/j.matdes.2008.05.064

S. Vitzthum, M. Eder, C. Hartmann, and W. Volk, Investigation on Strain Dependent Elastic Behavior for Accurate Springback Analysis, J. Phys. Conf. Ser., 2018, 1063, p 1–6. https://doi.org/10.1088/1742-6596/1063/1/012118

P. van Liempt and J. Sietsma, A Physically Based Yield Criterion I. Determination of the Yield Stress Based on Analysis of Pre-Yield Dislocation Behaviour, Mater. Sci. Eng. A., 2016, 662, p 80–87. https://doi.org/10.1016/j.msea.2016.03.013

Z. Chen, U. Gandhi, J. Lee, and R.H. Wagoner, Variation and Consistency of Young’s Modulus in Steel, J. Mater. Process. Technol., 2016, 227, p 227–243. https://doi.org/10.1016/j.jmatprotec.2015.08.024

J. Mendiguren, F. Cortés, X. Gómez, and L. Galdos, Elastic Behaviour Characterisation of TRIP 700 Steel by Means of Loading-Unloading Tests, Mater. Sci. Eng. A, 2015, 634, p 147–152. https://doi.org/10.1016/j.msea.2015.03.050

G. Zhu, C. Yang, G. Shen, Y. Peng, and B. Shi, The Asymmetric Pre-Yielding Behaviour during Tension and Compression for a Rolled AZ31 Mg Alloy, Int. J. Mater. Form., 2022, 15, p 1–12. https://doi.org/10.1007/s12289-022-01683-7

S.J. Wu, P.C. Chin, and H. Liu, Measurement of Elastic Properties of Brittle Materials by Ultrasonic and Indentation Methods, Appl. Sci., 2019, 9, p 1–11. https://doi.org/10.3390/app9102067

ASTM E111 2010: Standard Test Method for Young’s Modulus Tangent Modulus, and Chord Modulus, https://doi.org/10.1520/E0111-04R10.

M. Quanjin, M.R.M. Rejab, Q. Halim, M.N.M. Merzuki, and M.A.H. Darus, Experimental Investigation of the Tensile Test using Digital Image Correlation (DIC) Method, Mater. Today Proc., 2020, 27, p 757–763. https://doi.org/10.1016/j.matpr.2019.12.072

L. Yu and B. Pan, Overview of High-Temperature Deformation Measurement using Digital Image Correlation, Exp. Mech., 2021, 61, p 1121–1142. https://doi.org/10.1007/s11340-021-00723-8

B. Pan, Recent Progress in Digital Image Correlation, Exp. Mech., 2011, 51, p 1223–1235. https://doi.org/10.1007/s11340-010-9418-3

J. Rakhmonov, M. Qassem, D. Larouche, K. Liu, M. Javidani, X.-G. Chen, and J. Colbert, A New Approach to Determine Tensile Stress-Strain Evolution in Semi-Solid State at Near-Solidus Temperature of Aluminum Alloys, Metals (Basel), 2021, 11, p 396. https://doi.org/10.3390/met11030396

S.F. Pugh, Relations Between the Elastic Moduli and the Plastic Properties of Polycrystalline Pure Metals, Philos. Mag., 1954, 7, p 823–843.

A.B. Phillion, S. Thompson, S.L. Cockcroft, and M.A. Wells, Tensile Properties of as-Cast Aluminum Alloys AA3104, AA6111 and CA31218 at above Solidus Temperatures, Mater. Sci. Eng. A, 2008, 497, p 388–394. https://doi.org/10.1016/j.msea.2008.07.027

EN ISO 9513 : Metallic materials - Calibration of Extensometers Used in Uniaxial Testing, (2002).

M. Qassem, M. Javidani, D. Larouche, J. Colbert, and X.-G. Chen, Effect of Chemical Composition on the Semisolid Tensile Properties and Hot Tearing Susceptibility of AA6111 DC Cast Alloys, J Mater Sci., 2022, 57, p 1–18. https://doi.org/10.1007/s10853-022-07960-9

B. Koohbor, S. Ravindran, and A. Kidane, Experimental Determination of Representative Volume Element (RVE) Size in Woven Composites, Opt. Lasers Eng., 2017, 90, p 59–71. https://doi.org/10.1016/j.optlaseng.2016.10.001

H. Qiu, R. Ueji, Y. Kimura, and T. Inoue, Heterogeneous Distribution of Microstrain Evolved during Tensile Deformation of Polycrystalline Plain Low Carbon Steel, Metals (Basel)., 2020, 10, p 1–11. https://doi.org/10.3390/met10060774

L. Sweet, S.M. Zhu, S.X. Gao, J.A. Taylor, and M.A. Easton, The Effect of Iron Content on the Iron-Containing Intermetallic Phases in a Cast 6060 Aluminum Alloy, Metall, Mater. Trans. A Phys. Metall. Mater. Sci., 2011, 42, p 1737–1749. https://doi.org/10.1007/s11661-010-0595-6

S. Kumar, P.S. Grant, and K.A.Q. O’Reilly, Fe Bearing Intermetallic Phase Formation in a Wrought Al-Mg-Si Alloy, Trans. Indian Inst. Met., 2012, 65, p 553–557. https://doi.org/10.1007/s12666-012-0221-y

H. Cline and D. Lee, Strengthening of Lamellar vs Equiaxed Ag-Cu Eutectic, Acta Metall., 1970, 18, p 315–323.

W. Xu and L.P. Dávila, Size Dependence of Elastic Mechanical Properties of Nanocrystalline Aluminum, Mater. Sci. Eng. A., 2017, 692, p 90–94. https://doi.org/10.1016/j.msea.2017.03.065

T. Sumitomo, C.H. Cáceres, and M. Veidt, The Elastic Modulus of Cast Mg-Al-Zn alloys, J. Light Met., 2002, 2, p 49–56. https://doi.org/10.1016/S1471-5317(02)00013-5

D. Larouche, Computation of Solidification Paths in Multiphase Alloys with Back-Diffusion, Calphad Comput. Coupling Phase Diagrams Thermochem., 2007, 31, p 490–504. https://doi.org/10.1016/j.calphad.2007.04.002

M. Radovic, M.W. Barsoum, T. El-Raghy, S.M. Wiederhorn, and W.E. Luecke, Effect of Temperature, Strain Rate and Grain Size on the Mechanical Response of Ti3SiC2 in Tension, Acta Mater., 2002, 50, p 1297–1306. https://doi.org/10.1016/S1359-6454(01)00424-4

L.F. Mondolfo, Aluminum Alloys: Structure and Properties, Butterworths, London, Boston, 1979.

W. Köster and H. Franz, Poisson’s Ratio for Metals and Alloys, Metall. Rev., 1961, 6, p 1–56. https://doi.org/10.1179/mtlr.1961.6.1.1

A. Graziani, M. Bocci, and F. Canestrari, Complex Poisson’s Ratio of Bituminous Mixtures: Measurement and Modeling, Mater. Struct., 2014, 47, p 1131–1148. https://doi.org/10.1617/s11527-013-0117-2

A.P. Tarkov and V.V. Vavakin, Poisson’s Ratio Behaviour in Various Crystalline Rocks: Application to the Study of the Earth’s Interior, Phys. Earth Planet. Inter., 1982, 29, p 24–29. https://doi.org/10.1016/0031-9201(82)90134-0

O.N. Senkov, M. Dubois, and J.J. Jonas, Elastic Moduli of Titanium-Hydrogen Alloys in the Temperature Range 20°C to 1100°C, Metall, Mater. Trans. A Phys. Metall. Mater. Sci., 1996, 27, p 3963–3970. https://doi.org/10.1007/BF02595645

I. McEnteggart, Extensometer, in: W. Sharpe (Ed.), Exp. Solid Mech., 2008: pp. 335–346.

H. Wang, P. Ge, S. Wu, B. Wang, Y. Wang, X. Kong, and Y. Pang, Improvement Method of High-Temperature Digital Image Correlation Measurement Accuracy Based on Image Processing, Meas. J. Int. Meas. Confed., 2022, 190, p 110723. https://doi.org/10.1016/j.measurement.2022.110723

K. Tanaka and M. Koiwa, Elastic Properties of High-Temperature Intermetallics, High Temp. Mater. Process., 1999, 18, p 323–336.

S. Saimoto, H. Sang, and L.R. Morris, Microplastic Bases for Constitutive Relations Found in Tensile Testing, Acta Metall., 1981, 29, p 215–228. https://doi.org/10.1016/0001-6160(81)90101-2

S.A. El-Naaman, K.L. Nielsen, and C.F. Niordson, An Investigation of Back Stress Formulations under Cyclic Loading, Mech. Mater., 2019, 130, p 76–87. https://doi.org/10.1016/j.mechmat.2019.01.005

M. Yang, Y. Pan, F. Yuan, Y. Zhu, and X. Wu, Back Stress Strengthening and Strain Hardening in Gradient Structure, Mater. Res. Lett., 2016, 4, p 145–151. https://doi.org/10.1080/21663831.2016.1153004

C. Zener and J.H. Hollomon, Problems in Non-Elastic Deformation of Metals, J. Appl. Phys., 1946, 17, p 69–82. https://doi.org/10.1063/1.1707696

J.D. Eshelby, The Determination of the Elastic Field of an Ellipsoidal Inclusion, and Related Problems, Proc. R. Soc. London. Ser. A. Math. Phys. Sci., 1957, 241, p 376–396. https://doi.org/10.1098/rspa.1957.0133

R.W. Style, R. Boltyanskiy, B. Allen, K.E. Jensen, H.P. Foote, J.S. Wettlaufer, and E.R. Dufresne, Stiffening Solids with Liquid Inclusions, Nat. Phys., 2015, 11, p 82–87. https://doi.org/10.1038/nphys3181

G.N. Greaves, A.L. Greer, R.S. Lakes, and T. Rouxel, Poisson’s Ratio and Modern Materials, Nat. Mater., 2011, 10, p 823–837. https://doi.org/10.1038/nmat3134

R.M. Christensen, The Ductile/Brittle Transition, is it Well Posed and Determinable, Int. J. Eng. Sci., 2021, 158, p 103424. https://doi.org/10.1016/j.ijengsci.2020.103424

A.E.H. Love, A Treatise on the Mathematical Theory of Elasticity, Dover Publications, New York, 1944.

R.P. Thompson and W.J. Clegg, Predicting Whether a Material is Ductile or Brittle, Curr. Opin. Solid State Mater. Sci., 2018, 22, p 100–108. https://doi.org/10.1016/j.cossms.2018.04.001

O.N. Senkov and D.B. Miracle, Generalization of Intrinsic Ductile-to-Brittle Criteria by Pugh and Pettifor for Materials with a Cubic Crystal Structure, Sci. Rep., 2021, 11, p 10–13. https://doi.org/10.1038/s41598-021-83953-z

W.H. Suyitno and L.K. Kool, Hot Tearing Criteria Evaluation for Direct-Chill Casting of an Al-4.5 pct Cu alloy, Metall, Mater. Trans. A Phys. Metall. Mater. Sci., 2005, 36, p 1537–1546. https://doi.org/10.1007/s11661-005-0245-6

Q.L. Bai, J.C. Liu, H.X. Li, Q. Du, L. Katgerman, J.S. Zhang, and L.Z. Zhuang, A Modified Hot Tearing Criterion for Direct Chill Casting of Aluminium Alloys, Mater. Sci. Technol. (United Kingdom), 2016, 32, p 846–854. https://doi.org/10.1080/02670836.2015.1104081

Acknowledgments

The authors would like to acknowledge the financial support given by the Fonds de recherche du Québec—Nature et technologies (FRQNT) under Grant No. 2018-LU-252831 and the Mitacs Acceleration under Grant No. IT14722.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qassem, M., Javidani, M., Larouche, D. et al. Temperature Dependence of Elastic Properties of Al-Mg-Si Direct-Chill-Cast AA6111 Alloy at Near-Solidus Temperatures. J. of Materi Eng and Perform 33, 987–998 (2024). https://doi.org/10.1007/s11665-023-08006-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08006-0