Abstract

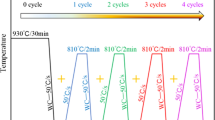

In this work, a novel heat treatment of quenching and partition (Q-P) combined cryogenic treatment (CT) was designed, to improve the mechanical properties of a 18CrNiMo7-6 steel. Based on the microstructure characterization and mechanical property testing, the effects of Q-P combined with CT on 18CrNiMo7-6 steel could be included as follows: (1) the grain size of 18CrNiMo7-6 steel after Q-P and CT could be refined from 0.31 to 0.20 μm; (2) the volume fraction of retained austenite in 18CrNiMo7-6 steel increased up to 10% and then decreased up to 6% for the transformation of unstable austenite to martensite during CT; (3) Q-P combined with CT could increase ultimate tensile strength of 18CrNiMo7-6 steel from 1560 to 1602 MPa, increase yield strength of 18CrNiMo7-6 steel from 1015 to 1280 MPa and increase total elongation of 18CrNiMo7-6 steel from 11.6 to 21.1%. Consequently, the Q–P combined with CT treatment is an effective method to refine the microstructure and improve the mechanical properties of 18CrNiMo7-6 steel.

Similar content being viewed by others

References

J.Z. Wu, H.J. Liu, P.T. Wei, Q.J. Lin and S.S. Zhou, Effect of Shot Peening Coverage on Residual Stress and Surface Roughness of 18CrNiMo7-6 Steel, Int. J. Mech. Sci., 2020, 183, p 105785.

G.T. Xu, M.F. Hao, Y.K. Qiao, Y.F. Zhang, G. Wang and M.H. Zhao, Characterization of Elastic-Plastic Properties of Surface-Modified Layers Introduced by Carburizing, Mech. Mater., 2020, 144, p 103364.

P. Fu, K. Zhan and C.H. Jiang, Micro-structure and Surface Layer Properties of 18CrNiMo7-6 Steel After Multistep Shot Peening, Mater. Des., 2013, 51, p 309–314.

J. Speer, D.K. Matlock, B.C. De Cooman and J.G. Schroth, Carbon Partitioning into Austenite After Martensite Transformation, Acta Mater., 2003, 51, p 2611–2622.

H.J. Pan, P. Jiang, Y. Zhang, W.P. Wu, Z.Z. Wang, Q. Wang and H.Y. Li, Microstructure and Mechanical Properties of a Novel Nb-Mo Bearing Medium-Mn alloy Affected by Intercritical Annealing and Tempering, Mater. Sci. Eng. A, 2021, 802, p 140680.

H.J. Pan, P. Jiang, Y. Zhang, W.P. Wu, Z.Z. Wang, Q. Wang and H.Y. Li, Microstructure Evolution and Enhanced Mechanical Properties of a Nb-Mo Microalloyed Medium Mn Alloy Fabricated by a Novel Cyclic Quenching Treatment, Mater. Sci. Eng. A, 2020, 797, p 140076.

H.J. Pan, M.H. Cai, H. Ding, S.H. Sun, H.S. Huang and Y.S. Zhang, Ultrahigh Strength-Ductile Medium-Mn Steel Auto-Parts Combining Warm Stamping and Quenching & Partitioning, Mater. Sci. Techno., 2019, 35, p 807–814.

H. Kong, Q. Chao, B. Rolfe and H. Beladi, One-Step Quenching and Partitioning Treatment of a Tailor Welded Blank of Boron and TRIP Steels for Automotive Applications, Mater. Des., 2019, 174, p 107799.

M. Wang and M.X. Huang, Abnormal TRIP Effect on the Work Hardening Behavior of a Quenching and Partitioning Steel at High Strain Rate, Acta Mater., 2020, 188, p 551–559.

D. Zou, S. Li and J. He, Temperature and Strain Rate Dependent Deformation Induced Martensitic Transformation and Flow Behavior of Quenching and Partitioning Steels, Mater. Sci. Eng. A, 2017, 680, p 54–63.

H.J. Pan, X.Y. Li, B. Qiao, Y. Zhang, N.M. Miao, L. Liu, H. Ding and M.H. Cai, New Insights to Understand the Influence of Nb/Mo on Hydrogen Embrittlement Resistance of Warm-Rolled Medium-Mn Steels, J. Mater. Eng. Perform., 2022, 31, p 3228–3233.

N. Yan, H.S. Di, R.D.K. Misra, H.Q. Huang and Y.L. Li, Enhancing Austenite Stability in a New Medium-Mn Steel by Combining Deep Cryogenic Treatment and Intercritical Annealing: An Experimental and Theoretical Study, Mater. Sci. Eng. A, 2019, 753, p 11–21.

S. Li, J. Li, X. Wu, C. Li and L. Tang, Experimental Verification of Segregation of Carbon and Precipitation of Carbides Due to Deep Cryogenic Treatment for Tool Steel by Internal Friction Method, Mater. Sci. Eng. A, 2013, 575, p 51–60.

H.J. Pan, X.Y. Li, B. Qiao, N.M. Miao, F. Qi and Y. Zhang, A Medium-Mn Steel Stamped Parts Overcoming Lüders Deformation by Increasing Dislocation Density, J. Mater. Eng. Perform., 2022, 31, p 1259–1265.

Q. Gao, X.S. Jiang, H.L. Sun, Y.J. Fang, D.F. Mo, X. Li and R. Shu, Effect Mechanism of Cryogenic Treatment on Ferroalloy and Nonferrous Alloy and their Weldments: A Review, Mater. Today. Commun., 2022, 33, p 104830.

B. Che, L.W. Lu, J.L. Zhang, J.H. Zhang, M. Ma, L.F. Wang and F.G. Qi, Effects of Cryogenic Treatment on Microstructure and Mechanical Properties of AZ31 Magnesium Alloy Rolled at Different Paths, Mater. Sci. Eng. A, 2022, 832, p 142475.

D.B. Park, M.Y. Huh, J.H. Shim, J.Y. Suh, K.H. Lee and W.S. Jung, Strengthening Mechanism of Hot Rolled Ti and Nb Microalloyed HSLA Steels Containing Mo and W with Various Coiling Temperature, Mater. Sci. Eng. A, 2013, 560, p 528–534.

H.J. Pan, H. Ding and M.H. Cai, Microstructural Evolution and Precipitation Behavior of the Warm-Rolled Medium Mn Steels Containing Nb or Nb-Mo During Intercritical Annealing, Mater. Sci. Eng. A, 2018, 736, p 375–382.

J. Hu, J.M. Zhang, G.S. Sun, L.X. Du, Y. Liu, Y. Dong and R.D.K. Misra, High Strength and Ductility Combination in Nano-/Ultrafine-Grained Medium-Mn Steel by Tuning the Stability of Reverted Austenite Involving Intercritical Annealing, J. Mater. Sci., 2019, 54, p 6565–6578.

Z.C. Li, H. Ding, R.D.K. Misra, Z.H. Cai and H.X. Li, Microstructural Evolution and Deformation Behavior in the Fe-(6,8.5) Mn-3Al-0.2C TRIP Steels, Mater. Sci. Eng. A, 2016, 672, p 161–169.

Z.C. Li, H. Ding and Z.H. Cai, Mechanical Properties and Austenite Stability in Hot-Rolled 0.2C–1.6/3.2Al-6Mn-Fe TRIP Steel, Mater. Sci. Eng. A, 2015, 639, p 559–566.

J. Hu, L.X. Du, W. Xu, J.H. Zhai, Y. Dong, Y.J. Liu and R.D.K. Misra, Ensuring Combination of Strength, Ductility and Toughness in Medium Manganese Steel Through Optimization of Nano-Scale Metastable Austenite, Mater. Charact., 2018, 136, p 20–26.

Acknowledgments

The present work was financially supported by the National Natural Science Foundation of China (Nos. 52204382 and 52274381), Natural Science Foundation of Jiangsu Province (Nos. BK20200985 and BK20220629), and the General Postdoctoral Program in China (Nos. 2021M701717 and 2022M711436), and the Fourth Batch Leading Innovative Talents Introduction and Cultivation Project of Changzhou (No. CQ20210102), the Hunan Provincial Natural Science Foundation in China (No. 2022JJ50128), and the Scientific Research Foundation of Jiangsu Provincial Education Department, China (No. 21KJB460029).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pan, H., Zhao, S., Qiao, B. et al. Enhanced Mechanical Properties and Ultrafine Microstructure of 18CrNiMo7-6 Steel Prepared by Quenching and Partitioning Combined Cryogenic Treatment. J. of Materi Eng and Perform 32, 10236–10242 (2023). https://doi.org/10.1007/s11665-023-07863-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07863-z