Abstract

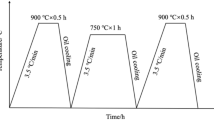

Austenitic stainless steel 304HCu is one of the candidate materials for superheater and re-heater tubing of advanced ultra-supercritical power plant. Though the material is expected to have Cu-rich nanosized precipitates in the matrix in the initial stages of aging, the other elements like Cr, Nb, C and N may lead to precipitations which significantly influence the deformation and fracture properties after long-term aging. This study carries out a detailed microstructural investigation for aging duration up to 20,000 h at 700 °C. The variation of hardness and room temperature tensile deformation parameters has been studied in the light of the microstructural variation during aging. It is understood that though the nanosized Cu-rich precipitates give rise to the initial hardening, the tensile and deformation properties are ultimately governed by the M23C6-type precipitates at the grain boundary and MX-type precipitates at the matrix. The as-received SS 304HCu shows a fracture toughness of 300 kJ m−2, which dropped to 100 kJ m−2 after 10,000 h of aging. This is attributed to grain boundary embrittlement arising from continuous network of M23C6-type precipitates.

Similar content being viewed by others

References

P.J. Maziasz, J.P. Shingledecker, N.D. Evans and M.P. Pollard, Developing new cast austenitic stainless steels with high-temperature creep resistance, J. Pressure Vessel Technol., 2009, 135(5), 051404. https://doi.org/10.1115/1.3141437

R. Viswanathan, R. Purget, P. Rawls, Coal-fired power materials, Adv. Mater. Processes (2008) 47.

R. Viswanathan, K. Coleman, Boiler materials for ultra-super critical (USC) coalpower plants, USC quarterly report (2004) 5.

T. Kan, Y. Sawaragi, Y. Yamadera, H. Okada, Proceeding of 6th Liege Conf on Materials for Advanced Power Engineering, part-1 (1998) 441.

A. Tohyama and Y. Minami, Development of the high temperature materials for ultra super critical boilers, NKK technical report, 2001, 84, p 30.

Salzgitter Mannesmann stainless tubes, 2008, Boiler grade DMV 304HCu, 2.

R. Viswanathan and J. Nutting Eds., Advanced heat resistant steels for power generation, IOM Communications Ltd., London, 1999

T. Sourmail, Precipitation in creep resistant austenitic stainless steels, Mater. Sci. Technol., 2001, 17(1), p 1–14. https://doi.org/10.1179/026708301101508972

K. Laha, J. Kyono and N. Shinya, An advanced creep cavitation resistance Cu-containing 18Cr–12Ni–Nb austenitic stainless steel, Scr. Mater., 2007, 56(10), p 915–918.

S. Caminada, G. Cumino, L. Cipolla, D. Venditti, A.D. Gianfrancesco, Y. Minami and T. Ono, Creep properties and microstructural evolution of austenitic TEMPALOY steels, Int. J. Press. Vessel. Pip., 2010, 87(6), p 336–344. https://doi.org/10.1016/j.ijpvp.2010.03.009

C.-y Chi, Yu. Hong-yao, J.-X. Dong, W.-Q. Liu, S.-C. Cheng, Z.-D. Liu and X.-S. Xie, The precipitation strengthening behavior of Cu-rich phase in Nb contained advanced Fe–Cr–Ni type austenitic heat resistant steel for USC power plant application, Prog. Nat. Sci.: Mater. Int., 2012, 22(3), p 175–185.

I. Sen, E. Amankwah, N. Kumar and E. Fleury, Microstructure and mechanical properties of annealed SUS 304H austenitic stainless steel with copper, Mater. Sci. Eng. A., 2011, 528(13), p 4491–4499. https://doi.org/10.1016/j.msea.2011.02.019

K.K. Alaneme, S.M. Hong, I. Sen, E. Fleury and U. Ramamurty, Effect of copper addition on the fracture and fatigue crack growth behavior of solution heat treated SUS 304H austenitic steel, Mater. Sci. Eng. A, 2010, 527, p 4600–4604. https://doi.org/10.1016/j.msea.2010.04.018

T. Dudziak, E. Rząd, G. Golanski, M. Solecka, Ł Boron and P. Wieczorek, Effect of aging process on steam oxidation behavior of austenitic steels Super 304H and HR3C, Int. J. Press. Vessel. Pip., 2021, 191, p 10–11. https://doi.org/10.1016/j.ijpvp.2021.104344

A. Zielinski, G. Golanski and M. Sroka, Evolution of the microstructure and mechanical properties of HR3C austenitic stainless steel after aging for up to 30,000 h at 650–750°C, Mater. Sci. Eng. A, 2020, 796, 139944. https://doi.org/10.1016/j.msea.2020.139944

ASTM E92: Standard test methods for vickers hardness and Knoop hardness of Metallic Materials Metric, ASTM International.

ASTM E8/E8M-21: Standard test methods for tension testing of metallic materials metric, ASTM International.

ASTM E1820–20: Standard test methods for measurement of fracture toughness, ASTM International.

H. Tripathy et al., Calorimetric investigation of thermal stability of 304H Cu (Fe-17.7Cr-9.3Ni-2.95Cu-0.91Mn-0.58Nb-0.24Si-0.1C-0.12N-WtPct) Austenitic Stainless Steel, Metall. Mater. Trans E 3(4) , 234–249 (2016) https://doi.org/10.1007/s40553-016-0079-8

H. Yu and C. Chi, Precipitation behavior of Cu-rich phase in 18Cr9Ni3CuNbN austenitic heat resistant steel at early aging stage, Chin. J. Mater. Res., 2015, 29(3), p 195–200. https://doi.org/10.11901/1005.3093.2014.610

C.Y. Chi, J.X. Dong, W.Q. Liu and X.S. Xie, 3DAP Investigation of precipitation behavior of Cu- rich phase in super 304H heat resistant steel, Acta. Metall. Sin., 2010, 46, p 1141–1146.

O. Ping, H. Xing, X. Wang, J. Sun, Z. Cui, C. Yang, Coarsening and Hardening Behaviors of Cu-Rich Precipitates in Super304H austenitic Steel, Metall and Mater Trans A 46, (2015) 3909–3916.

J.W. Bai, P.P. Liu, Y.M. Zhu, X.M. Li, C.Y. Chi, H.Y. Yu, X.S. Xie and Q. Zhan, Coherent precipitation of copper in Super 304 H Austenitic steel, Mater. Sci. Eng. A, 2013, 584, p 57–62.

R.W. Hertzberg, Deformation and fracture mechanics of engineering materials, 4th ed. John Wiley & Sons Inc, Hoboken, 1996.

J.H. Hollomon, Trans. AIME, 1945, 162, p 268–290.

P. Ludwik, Elemente der Technologischen Mechanik, Springer, Leipzig, 1909, p 32

D.C. Ludwigson, Metall. Trans. A, 1971, 2, p 2825–2828.

E. Voce, J. Inst. Metal, 1948, 74, p 537–562.

B.K. Choudhary, E.I. Samuel, K. Bhanu Sankara Rao, S.L. Mannan, Tensile stress–strain and work hardening behaviour of 316LN austenitic stainless steel, Mater. Sci. Technol. 223–231 (2001).

A.S. Tetelman and A.J. McEvily, Fracture of structural materials, Wiley, New York, 1967.

Acknowledgments

The authors sincerely acknowledge AUSC PEC for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shanthi, G., Nanibabu, M., Krishnan, S.A. et al. Effect of Thermal Aging on Deformation and Fracture Properties of SS 304HCu. J. of Materi Eng and Perform 32, 4575–4584 (2023). https://doi.org/10.1007/s11665-022-07408-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07408-w