Abstract

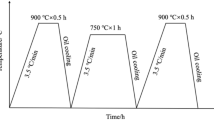

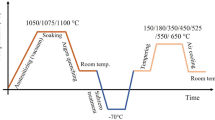

The present work investigates the effects of thermal cycling heat treatment (TCHT) on microstructure and mechanical properties of 13%Cr-4%Ni martensitic stainless steel (13-4MSS). As-received 13-4 MSS was subjected to three different thermal cycling schedules by using a thermo-mechanical simulator (Gleeble 3800). The evolved microstructures were studied at three cycles for each thermal cycling schedule with the help of optical, scanning electron microscopy, x-ray analysis, and transmission electron microscopy. Hardness and notched tensile tests were conducted to further characterize the as-received and processed specimens. This cyclic treatment raised the hardness to 413 HV (for TCHT at 950 °C) from 274 HV (for as-received). A 42% (for TCHT at 950 °C) and 39% (for TCHT at 1050 °C) hike in ultimate tensile strength (UTS) with a slight decline in ductility was observed as compared to the UTS and ductility of as-received steel. The evolved microstructure, dislocation density, and the refinement of martensitic blocks attributed to the enhanced hardness and UTS. The coarsening of laths (observed at 1050 °C) and bimodal lath structure (observed at 950 °C) were also found to control the mechanical properties of the present steel.

Similar content being viewed by others

References

G. Prakash and S.K. Nath, Studies on Enhancement of Silt Erosion Resistance of 13/4 Martensitic Stainless Steel by Low-Temperature Salt Bath Nitriding, J. Mater. Eng. Perform., 2018, 27(7), p 3206–3216

K. Nakazawa, Y. Kawabe, and S. Muneki, Grain Refinement of High-Strength Maraging Steels Through Cyclic Heat Treatment, Mater. Sci. Eng., 1978, 33(1), p 49–56

B.R. Kumar, S. Sharma, B.P. Kashyap, and N. Prabhu, Ultrafine Grained Microstructure Tailoring in Austenitic Stainless Steel for Enhanced Plasticity, Mater. Des., 2015, 68, p 63–71

J.N. Wang, J. Yang, Q. Xia, and Y. Wang, On the Grain Size Refinement of TiAl Alloys by Cyclic Heat Treatment, Mater. Sci. Eng., A, 2002, 329–331, p 118–123

P. Payson, W.L. Hodapp, and J. Leeder, The Spheroidizing of Steel by Isothermal Transformation, Trans. Am. Soc. Met., 1940, 28, p 306

A. Mishra, C. Mondal, and J. Maity, Microstructural Modifications in AISI, 1080 Eutectoid Steel Under Combined Cyclic Heat Treatment, Steel Res. Int., 2016, 87(4), p 424–435

A. Mishra and J. Maity, Structure-Property Correlation of AISI, 1080 Steel Subjected to Cyclic Quenching Treatment, Mater. Sci. Eng., A, 2015, 646, p 169–181

S. Mishra, A. Mishra, B.K. Show, and J. Maity, Simultaneous Enhancement of Ductility and Strength in AISI, 1080 Steel Through a Typical Cyclic Heat Treatment, Mater. Sci. Eng., A, 2017, 688, p 262–271

S. Maji, A.R. Subhani, B.K. Show, and J. Maity, Effect of Cooling Rate on Microstructure and Mechanical Properties of Eutectoid Steel Under Cyclic Heat Treatment, J. Mater. Eng. Perform., 2017, 26, p 3058–3070

Z.Q. Lv, B. Wang, Z.H. Wang, S.H. Sun, and W.T. Fu, Effect of Cyclic Heat Treatments on Spheroidizing Behavior of Cementite in High Carbon Steel, Mater. Sci. Eng., A, 2013, 574, p 143–148

A. Mishra, A. Saha, and J. Maity, Development of High Strength Ductile Eutectoid Steel Through Cyclic Heat Treatment Involving Incomplete Austenitization Followed by Forced Air Cooling, Mater. Charact., 2016, 114, p 277–288

A. Mishra, C. Mondal, and J. Maity, Effect of Combined Cyclic Heat Treatment on AISI, 1080 Steel: Part II-Mechanical Property Evaluation, Steel Res. Int., 2017, 88, p 1–10

Z.-Q. Lü, H.-F. Zhang, Q. Meng, Z.-H. Wang, and W.-T. Fu, Effect of Cyclic Annealing on Microstructure and Mechanical Properties of Medium Carbon Steel, J. Iron. Steel Res. Int., 2016, 23(2), p 145–150

A. Saha, D.K. Mondal, K. Biswas, and J. Maity, Microstructural Modifications and Changes in Mechanical Properties During Cyclic Heat Treatment of 0.16% Carbon Steel, Mater. Sci. Eng., A, 2012, 534, p 465–475

A. Saha, D.K. Mondal, K. Biswas, and J. Maity, Development of High Strength Ductile Hypereutectoid Steel by Cyclic Heat Treatment Process, Mater. Sci. Eng., A, 2012, 541, p 204–215

A. Saha, D.K. Mondal, and J. Maity, Effect of Cyclic Heat Treatment on Microstructure and Mechanical Properties of 0.6 wt% Carbon Steel, Mater. Sci. Eng., A, 2010, 527(16–17), p 4001–4007

B. Smoljan, An Analysis of Combined Cyclic Heat Treatment Performance, J. Mater. Process. Technol., 2004, 155–156(1–3), p 1704–1707

J.Y. Koo and G. Thomas, Thermal Cycling Treatments and Microstructures for Improved Properties of Fe-0.12% C-0.5% Mn Steels, Mater. Sci. Eng., 1976, 24(2), p 187–198

H.-Y. Li, M.-S. Han, D.-W. Li, J. Li, and D.-C. Xu, Effect of Cyclic Heat Treatment on Microstructure and Mechanical Properties of 50CrV4 Steel, J. Cent. South Univ., 2015, 22(2), p 409–415

Z. Lv, X.-P. Ren, Z.-H. Li, Z.-M. Lu, and M.-M. Gao, Effects of Two Different Cyclic Heat Treatments on Microstructure and Mechanical Properties of Ti-V Microalloyed Steel, Mater. Res., 2015, 18(2), p 304–312

B.R. Kumar, B. Mahato, S. Sharma, and J.K. Sahu, Effect of Cyclic Thermal Process on Ultrafine Grain Formation in AISI, 304L Austenitic Stainless Steel, Metall. Mater. Trans. A, 2009, 40A, p 3226–3234

B.R. Kumar and D. Raabe, Tensile Deformation Characteristics of Bulk Ultrafine-Grained Austenitic Stainless Steel Produced by Thermal Cycling, Scr. Mater., 2012, 66(9), p 634–637

S. Tu, X. Ren, B. Nyhus, O.M. Akselsen, J. He, and Z. Zhang, A Special Notched Tensile Specimen to Determine the Flow Stress-Strain Curve of Hardening Materials Without Applying the Bridgman Correction, Eng. Fract. Mech., 2018, 179, p 225–239

S. Kumar, G.P. Chaudhari, S.K. Nath, and B. Basu, Effect of Preheat Temperature on Weldability of Martensitic Stainless Steel, Mater. Manuf. Process., 2012, 27(12), p 1382–1386

Z.L. Zhang, M. Hauge, C. Thaulow, and J. Ødegård, A Notched Cross Weld Tensile Testing Method for Determining True Stress-Strain Curves for Weldments, Eng. Fract. Mech., 2002, 69(3), p 353–366

V. Olden and Z.L. Zhang, Material Characterisation for Ductile Fracture by Testing of Notched Tensile Specimens, (Cracow), ECF14, 2002, https://www.gruppofrattura.it/ocs/index.php/esis/ECF14/schedConf/presentations. Accessed 17 April 2019

B. Kishor, G.P. Chaudhari, and S.K. Nath, Slurry Erosion of Thermo-Mechanically Processed 13Cr4Ni Stainless Steel, Tribol. Int., 2016, 93, p 50–57

Y. Wang, M. Chen, F. Zhou, and E. Ma, High Tensile Ductility in a Nanostructured Metal, Nature, 2002, 419, p 912–915

F. Ren, F. Chen, and J. Chen, Investigation on Dynamic Recrystallization Behavior of Martensitic Stainless Steel, Adv. Mater. Sci. Eng., 2014, 2014, p 1–16

L.F. Alvarez, C. Garcia, and V. Lopez, Continuous Cooling Transformations in Martensitic Stainless Steels, ISIJ Int., 1994, 34(6), p 516–521

E.I. Galindo-Nava and P.E.J. Rivera-Díaz-Del-Castillo, Understanding the Factors Controlling the Hardness in Martensitic Steels, Scr. Mater., 2016, 110, p 96–100

T. Ohmura, T. Hara, and K. Tsuzaki, Relationship Between Nanohardness and Microstructures in High-Purity Fe-C As-Quenched and Quench-Tempered Martensite, J. Mater. Res., 2003, 18(6), p 1465–1470

A. Akhiate, E. Braud, D. Thibault, and M. Brochu, Carbon Content and Heat Treatment Effects on Microstructures and Mechanical Properties of 13% Cr–4% Ni Martensitic Stainless Steel, Metall. Mater. Trans. B, 2014, p 5000–3000.

H.J. Amarendra, P. Kalhan, G.P. Chaudhari, S.K. Nath, and S. Kumar, Slurry Erosion Response of Heat Treated 13Cr-4Ni Martensitic Stainless Steel, Mater. Sci. Forum, 2012, 710, p 500–505

V. Olden, Z.L. Zhang, E. Østby, B. Nyhus, and C. Thaulow, Notch tensile testing of high strength steel weldments, in 2nd International Symposium on High Strength Steel (Verdal, Norway, 2002), p. 1–8.

M.A. Maleque, Y.M. Poon, and H.H. Masjuki, The Effect of Intercritical Heat Treatment on the Mechanical Properties of AISI, 3115 Steel, J. Mater. Process. Technol., 2004, 154, p 482–487

L. Morsdorf, O. Jeannin, D. Barbier, M. Mitsuhara, D. Raabe, and C.C. Tasan, Multiple Mechanisms of Lath Martensite Plasticity, Acta Mater., 2016, 121, p 202–214

S. Zhang, P. Wang, D. Li, and Y. Li, Investigation of the Evolution of Retained Austenite in Fe-13%Cr-4%Ni Martensitic Stainless Steel during Intercritical Tempering, Mater. Des., 2015, 84, p 385–394

M. Moeser, in Fractography with the SEM (Failure Analysis), ed. by J. Bethge and H. Heydnreich (Elsevier Science Ltd, Amsterdam, 1987). http://www.martin-moeser.de. Accessed 13 May 2019

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino, Crystallographic Features of Lath Martensite in Low-Carbon Steel, Acta Mater., 2006, 54, p 1279–1288

S. Morito, H. Yoshida, T. Maki, and X. Huang, Effect of Block Size on the Strength of Lath Martensite in Low Carbon Steels, Mater. Sci. Eng., A, 2006, 440, p 237–240

C. Zhang, Q. Wang, J. Ren, R. Li, M. Wang, F. Zhang, and K. Sun, Effect of Martensitic Morphology on Mechanical Properties of an As-Quenched and Tempered 25CrMo48V Steel, Mater. Sci. Eng., A, 2012, 534, p 339–346

J.S.J. Hargreaves, Some Considerations Related to the Use of the Scherrer Equation in Powder X-Ray Diffraction as Applied to Heterogeneous Catalysts, Catal. Struct. React., 2016, 2(1-4), p 33–37

G.K. Williamson and R.E. Smallman, III, Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the X-Ray Debye-Scherrer Spectrum, Philos. Mag., 1956, 1(1), p 34–46

G. Krauss, Steels: Processing, Structure, and Performance, ASM International, Cleveland, 2005

S. Morito, J. Nishikawa, and T. Maki, Dislocation Density Within Lath Martensite in Fe–C and Fe–Ni Alloys, ISIJ Int., 2003, 43(9), p 1475–1477

E.I. Galindo-Nava and P.E.J. Rivera-Díaz-del-Castillo, A Model for the Microstructure Behaviour and Strength Evolution in Lath Martensite, Acta Mater., 2015, 98, p 81–93

H. Nakagawa and T. Miyazaki, Effect of Retained Austenite on the Microstructure and Mechanical Properties of Martensitic Precipitation Hardening Stainless Steel, J. Mater. Sci., 1999, 34(16), p 3901–3908

S. Morito, K. Oh-ishi, K. Hono, and T. Ohba, Carbon Enrichment in Retained Austenite Films in Low Carbon Lath Martensite Steel, ISIJ Int., 2011, 51(7), p 1200–1202

X.D. Wang, N. Zhong, Y.H. Rong, T.Y. Hsu, Z.Y. Xu, and L. Wang, Novel Ultrahigh-Strength Nanolath Martensitic Steel by Quenching–Partitioning–Tempering Process, J. Mater. Res., 2009, 24(1), p 260–267

R. Bhadeshia and H. Honeycombe, Steels: Microstructure and Properties, 3rd ed., Butterworth-Heinemann, Oxford, 2006

C. Du, J.P.M. Hoefnagels, R. Vaes, and M.G.D. Geers, Block and Sub-block Boundary Strengthening in Lath Martensite, Scr. Mater., 2016, 116, p 117–121

B. Hutchinson and J. Hagstro, Microstructures and Hardness of As-Quenched Martensites (0.1–0.5%C), Acta Mater., 2011, 59, p 5845–5858

Z. Jiang, Z. Guan, and J. Lian, Effects of Microstructural Variables on the Deformation Behaviour of Dual-Phase Steel, Mater. Sci. Eng., A, 1995, 190, p 55–64

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, J., Nath, S.K. Effects of Cyclic Heat Treatment on Microstructure and Mechanical Properties of 13%Cr-4%Ni Martensitic Stainless Steel. J. of Materi Eng and Perform 29, 2478–2490 (2020). https://doi.org/10.1007/s11665-020-04787-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04787-w