Abstract

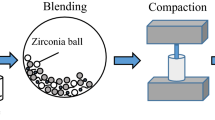

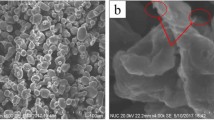

In the present work, aluminum matrix composites reinforced with graphene nanoplatelets (GNPs: 0.15-0.45wt.%) and silicon dioxide (SiO2: 1, 3, 6, 9wt.%) were produced by the powder metallurgy method. Hardness, compressive strength, density, friction coefficient, and wear rate of the prepared specimens were examined. According to the experimental results, the best compressive strength (~ 390 MPa), density (~ 2.66 g/cm3), hardness (~ 62 HV), the lowest porosity (~ 1.3%), friction coefficient (~ 0.19 for a load of 10 N), and wear rate (~ 0.003 mm3/Nm for a load of 5 N) were detected et al.-6SiO2-0.15graphene composite. Compared to pure Al, the compressive strength, hardness, and wear resistance of Al-6SiO2-0.15graphene composite were improved by ~ 110%, ~ 106%, and ~ 107, respectively. Hence, it may be concluded that SiO2 has excellent wear resistance and graphene has remarkable strength, good solid lubricating properties for Al-based composites.

Similar content being viewed by others

References

A. Saboori, C. Novara, M. Pavese, C. Badini, F. Giorgis, and P. Fino, An Investigation on the Sinterability and the Compaction Behavior of Aluminum/Graphene Nanoplatelets (GNPs) Prepared by Powder Metallurgy, J. Mater. Eng. Perform., 2017, 26, p 993–999.

A. Alizadeh, E. Taheri-Nassaj, and H.R. Baharvandi, Preparation and Investigation of Al-4 wt % B4C Nanocomposite Powders Using Mechanical Milling, B. Mater. Sci., 2011, 34, p 1039–1048.

B. Ramesh and T. Senthilvelan, Formability Characteristics of Aluminium Based Composites-a Review, Int. J. Eng. Technol., 2010, 2, p 1–6.

A. Parveen, N.R. Chauhan, and M. Suhaib, Study of Si3N4 Reinforcement on the Morphological and Tribo-mechanical Behaviour of Aluminium Matrix Composites, Mater. Res. Express., 2019, 6, p 1–6.

T.S. Srivatsan, I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia, Processing Techniques for Particulate-reinforced Metal Aluminium Matrix Composites, J. Mater. Sci., 1991, 26, p 5965–5978.

M. Shukla, S.K. Dhakad, P. Agarwal, and M.K. Pradhan, Characteristic Behaviour of Aluminium Metal Matrix Composites: A Review, Mater. Today-Proc., 2018, 5, p 5830–5836.

H.K. Issa, A. Taherizadeh, A. Maleki, and A. Ghaei, Development of an Aluminum/Amorphous Nano-SiO2 Composite using Powder Metallurgy and Hot Extrusion Processes, Ceram. Int., 2017, 43, p 14582–14592.

B. Singh, S. Chandel, and P. Singhal, Investigation of Mechanical Properties of Synthesized AA2024-T351/SiO2 Metal Matrix Nano-composite, Mater. Today-Proc., 2020, 26, p 1082–1086.

A.K. Geim and K.S. Novoselov, The Rise of Graphene, Nat. Mater., 2007, 6, p 183–191.

E.P. Randviir, D.A.C. Brownson, and C.E. Banks, A Decade of Graphene Research: Production, Applications and Outlook, Mater. Today-Proc., 2014, 17, p 426–432.

N. Savage, Materials Science: Super Carbon, Nature, 2012, 483, p 30–31.

V. Singh, D. Joung, L. Zhai, S. Das, S.I. Khondaker, and S. Seal, Graphene Based Materials: Past, Present and Future, Prog. Mater. Sci., 2012, 56, p 1178–1271.

D. Berman, A. Erdemir, and A.V. Sumant, Graphene: A new Emerging Lubricant, Mater. Today-Proc., 2014, 17, p 31–42.

S. Mohan, G. Gautam, N. Kumar, R.K. Gautam, A. Mohan, and A.K. Jaiswal, Dry Sliding wear Behavior of Al-SiO2 Composites, Compos. Interface., 2016, 23, p 493–502.

J. Hemanth and Abrasive, Slurry wear Behavior of Chilled Aluminum Alloy (A356) Reinforced with Fused Silica (SiO2p) Metal Matrix Composites, Compos. Part B-Eng., 2011, 42, p 1826–1833.

E.Q. Mokhnache, G. Wang, and L. Geng, Wearing Resistance of in-situ Al-based Composites with Different SiO2/C/Al Molar Ratios Fabricated by Reaction Hot Pressing, Trans. Nonferrous Met. Soc. China., 2016, 26, p 917–923.

H. Tan, Q. Sun, W. Chen, S. Zhu, J. Cheng, and J. Yang, Tribological Performance and wear Mechanisms of a High Temperature Wear-resistant Al-Si/SiAlON Composite, Tribol. Int., 2021, 164, p 1–9.

P. Thasleem, D. Kumar, M.L. Joy, and B. Kuriachen, Effect of Heat Treatment and Electric Dischage Alloying on the Lubricated Tribology of Al-Si Alloy Fabricated by Selective Laser Melting, Wear, 2022, 494–495, p 1–24.

J. Ma, C. Fan, W. Chen, H. Tan, S. Zhu, and Q. Li, Core-shell Structure in situ Reinforced Aluminum Matrix Composites: Microstructure, Mechanical and Tribological Properties, J. Alloys Compd., 2022, 901, p 1–14.

M. Gürbüz, M.C. Şenel, and E. Koç, The Effect of Sintering Temperature, Time and Graphene Addition on the Mechanical Properties and Microstructure of Aluminum Composites, J. Compos. Mater., 2018, 52, p 553–563.

M.C. Şenel, M. Gürbüz, and E. Koç, The Fabrication and Characterization of Aluminum Hybrid Composites Reinforced with Si3N4/GNPs Binary Particles, J. Compos. Mater., 2019, 53, p 4043–4054.

H.G.P. Kumar and M.A. Xavior, Fatigue and wear Behavior of Al6061-Graphene Composites Synthesized by Powder Metallurgy, T. Indian. I. Metals., 2016, 69, p 415–419.

S.E. Shin, Y.J. Ko, and D.H. Bae, Mechanical and Thermal Properties of Nanocarbon-reinforced Aluminum Matrix Composites at Elevated Temperatures, Compos. Part B-Eng., 2016, 106, p 66–73.

M.C. Şenel, M. Gürbüz, and E. Koç, Mechanical and Tribological Behaviours of Aluminium Matrix Composites Reinforced by Graphene Nanoplatelets, Mat. Sci. Tech. Ser., 2018, 34, p 1980–19890.

G. Iacob, V.G. Ghica, M. Buzatu, T. Buzatu, and M.I. Petrescu, Studies on wear Rate and Micro-hardness of the Al/Al2O3/Gr Hybrid Composites Produced Via Powder Metallurgy, Compos. Part B-Eng., 2015, 69, p 603–611.

J. Wang, Z. Li, G. Fan, H. Pan, Z. Chen, and S. Zhang, Reinforcement with Graphene Nanosheets in Aluminium Matrix Composites, Scripta. Mater., 2012, 66, p 594–597.

S.J. Yan, S.L. Dai, X.Y. Zhang, C. Yang, Q.H. Hong, J.Z. Chen, and Z.M. Lin, Investigating Aluminum Alloy Reinforced by Graphene Nanoflakes, Mater. Sci. Eng. A-Struct., 2014, 612, p 440–444.

W.S. AbuShanab, E.B. Moustafa, E. Ghandourah, and M.A. Taha, Effect of Graphene Nanoparticles on the Physical and Mechanical Properties of the Al2024-graphene Nanocomposites Fabricated by Powder Metallurgy, Results. Phys., 2020, 19, p 1–12.

L. Chen, Y. Qi, Y. Fei, Y. Liu, and Z. Du, GNP-reinforced Al2024 Composite Fabricated through Powder Semi-solid Processing, Mater. Trans., 2020, 61, p 1239–1246.

H.G.P. Kumar and M.A. Xavior, Assessment of Mechanical and Tribological Properties of Al2024-SiC-graphene Hybrid Composites, Procedia. Eng., 2017, 174, p 992–999.

M.C. Şenel and M. Gürbüz, Investigation on Mechanical Properties and Microstructure of B4C/Graphene Binary Particles Reinforced Aluminum Hybrid Composites, Met. Mater. Int., 2021, 27, p 2438–2449.

W. Zhai, X. Shi, J. Yao, A.M.M. Ibrahim, Z. Xu, Q. Zhu, Y. Xiao, L. Chen, and Q. Zhang, Investigation of Mechanical and Tribological Behaviors of Multilayer Graphene Reinforced Ni3Al Matrix Composites, Compos. Part B-Eng., 2015, 70, p 149–155.

M.C. Şenel and M. Gürbüz, Investigation on Mechanical Properties and Microstructures of Aluminum Hybrid Composites Reinforced with Al2O3/GNPs Binary Particles, Arch. Metall. Mater., 2021, 66, p 97–106.

B. Hariyanto, D.A.P. Wardani, N. Kurniawati, and N.P. Har, X-Ray peak Profile Analysis of Silica by Williamson-hall and Size-strain Plot Methods, J. Phys. Conf. Ser., 2019, 1, p 1–5.

J.W. Kaczmar, K. Pietrzak, and W. Wlosinski, The Production and Application of Metal Matrix Composite Materials, J. Mater. Process. Tech., 2000, 106, p 58–67.

Z. Hu, G. Tong, Q. Nian, R. Xu, M. Saei, F. Chen, C. Chen, M. Zhang, H. Guo, and J. Xu, Laser Sintered Single Layer Graphene Oxide Reinforced Titanium Matrix Nanocomposites, Compos. Part B-Eng., 2016, 93, p 352–359.

Z. Cao, X. Wang, J. Li, Y. Wu, H. Zhang, J. Guo, and S. Wang, Reinforcement with Graphene Nanoflakes in Titanium Matrix Composites, J. Alloy. Compd., 2017, 696, p 498–502.

J.M. Torralba, C.E. Costa, and F. Velasco, P/M Aluminum Matrix Composites: An Overview, J. Mater. Process. Tech., 2003, 133, p 203–206.

R. Liu and D.Y. Li, Modification of Archard’s Equation by Taking Account of Elastic/ Pseudoelastic Properties of Materials, Wear, 2001, 251, p 956–964.

V.R. Rajeev, D.K. Dwivedi, and S.C. Jain, Dry Reciprocating wear of Al-Si-SiCp Composites: A Statistical Analysis, Tribol. Int., 2010, 43, p 1532–1541.

Y. Liu, Z. Han, and H. Cong, Effects of Sliding Velocity and Normal Load on the Tribological Behavior of a Nnanocrystalline Al Based Composite, Wear, 2010, 268, p 976–983.

N.M. Kumar, S.S. Kumaran, and L.A. Kumaraswamidhas, Wear Behaviour of Al 2618 Aalloy Reinforced with Si3N4, AlN and ZrB2 in situ Composites at Elevated Temperatures, Alex. Eng. J., 2016, 55, p 19–36.

Acknowledgements

The authors of this study thank Black Sea Advanced Technology Research and Application Center (KITAM) in Ondokuz Mayıs University (OMU) for SEM and XRD analysis. They also thank Assoc. Prof. Dr. Mevlüt Gürbüz for useful suggestions related to induction heat treatment and microstructure analyses. This work was supported by the [Scientific Researched Project Department of Ondokuz Mayıs University] under [grant number PYO.MUH.1901.20.001].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

ŞENEL, M.C., ÜSTÜN, M. Effect of Silicon Dioxide-Graphene Content on the Microstructure, Sliding Wear Behavior, and Compressive Strength of Aluminum Hybrid Composites. J. of Materi Eng and Perform 32, 1248–1260 (2023). https://doi.org/10.1007/s11665-022-07194-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07194-5