Abstract

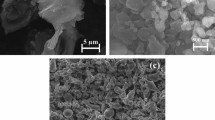

Recently, aluminum matrix composites have been fabricated by pure zirconia (ZrO2) or pure graphene in the aluminum matrix because of good solid lubricant property of graphene and high compressive strength of ZrO2. Nevertheless, there is no study on the effect of both ZrO2 and graphene reinforced aluminum composite. In this current work, the tribological behaviors of Al-ZrO2 and Al-ZrO2-graphene composites with various contents (ZrO2: 1–12wt.%; graphene: 0.15–0.45wt.%) were investigated under different loads (5 and 10 N) via the pin-on-disk wear test unit. The density, porosity, hardness, and compressive strength were investigated by the Archimedes’ principle kit, Vickers hardness test unit, and universal test machine, respectively. According to the test results, the micro-Vickers hardness, porosity, and compressive strength enhanced from 30 ± 1.2 HV, 7%, 186 ± 4 MPa (pure Al) to 75 ± 2 HV, 3.7%, 490 ± 4 MPa (Al-9%ZrO2-0.15%graphene), respectively. Similarly, the lowest friction coefficient (0.18 under a 10 N load), the mass loss (0.011 g under a 5 N load), and wear rate (0.0031 mm3/(Nm) under a 5 N load) were obtained at the Al-9%ZrO2-0.15%graphene composite. The mechanical strength and tribological behaviors of Al hybrid composites deteriorated in the case of over 9wt.%ZrO2 and 0.15wt.%graphene contents due to the agglomerations of graphene and ZrO2 nanoparticles. Therefore, it may be concluded that graphene is an excellent solid lubricator, and ZrO2 has a remarkable wear resistance for Al hybrid composites.

Similar content being viewed by others

References

Dieter, G.E.: Mechanical Metallurgy. McGraw-Hill, London (1961)

Song, W.; Veca, L.M.; Anderson, A.; Cao, M.; Cao, L.; Sun, Y.: Light-weight nanocomposite materials with enhanced thermal transport properties. Nanotechnol. Rev. 1(4), 363–376 (2012). https://doi.org/10.1515/ntrev-2012-0023

Khan, A.; Matli, P.R.; Nawaz, M.; Mattli, M.R.: Microstructure and mechanical behavior of hot extruded aluminum/tin-bismuth composites produced by powder metallurgy. Appl. Sci. 10(8), 1–14 (2020). https://doi.org/10.3390/app10082812

Reddy, M.; Khan, A.; Reddy, P.; Yusuf, M.; Ashraf, A.A.; Shakoor, R.A.: Gupta, M: Effect of Inconel625 particles on the microstructural, mechanical, and thermal properties of Al-Inconel625 composites. Mater. Today Commun. 25, 1–12 (2020). https://doi.org/10.1016/j.mtcomm.2020.101564

Sharma, P.; Sharma, S.; Kandhuja, D.: Production and some properties of Si3N4 reinforced aluminium alloy. J. Asian. Ceram. Soc. 3(3), 352–359 (2015). https://doi.org/10.1016/j.jascer.2015.07.002

Şenel, M.C.; Gürbüz, M.; Koç, E.: The fabrication and characterization of synergistic Al-SiC-GNPs hybrid composites. Compos. Part B Eng. 154, 1–9 (2018). https://doi.org/10.1016/j.compositesb.2018.07.035

Khademian, M.; Alizadeh, A.; Abdollahi, A.: Fabrication and characterization of hot rolled and hot extruded boron carbide (B4C) reinforced A356 aluminum alloy matrix composites produced by stir casting method. T. Indian I. Metals 70(6), 1635–1646 (2017). https://doi.org/10.1007/s12666-016-0962-0

Gostariani, R.; Ebrahimi, R.; Asadabad, M.A.; Paydar, M.H.: Mechanical properties of Al/BN nanocomposites fabricated by planetary ball milling and conventional hot extrusion. Acta Metall. Sin. 31, 245–253 (2018). https://doi.org/10.1007/s40195-017-0640-1

Şenel, M.C.; Gürbüz, M.: Investigation on mechanical properties and microstructures of aluminum hybrid composites reinforced with Al2O3/GNPs binary particles. Arch. Metall. Mater. 66(1), 97–106 (2021). https://doi.org/10.24425/amm.2021.134764

Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M.: Fabrication and mechanical properties of titanium carbide reinforced aluminium composites. Mater. Today. Proc. 18(7), 2649–2655 (2019). https://doi.org/10.1016/j.matpr.2019.07.125

Suresh, S.; Shenbag, N.; Moorhi, V.: Aluminium-titanium diboride (Al-TiB2) metal matrix composites: challenges and opportunities. Procedia Eng. 38, 89–97 (2012). https://doi.org/10.1016/j.proeng.2012.06.013

Khan, A.; Abdelrazeq, M.W.; Mattli, M.R.; Yusuf, M.M.; Alashraf, A.; Matli, P.R.; Shakoor, R.A.: Structural and mechanical properties of Al-SiC-ZrO2 nanocomposites fabricated by microwave sintering technique. Curr. Comput. Aid. Drug Des. 10(10), 1–12 (2020). https://doi.org/10.3390/cryst10100904

Ravichandran, M.; Naveen Sait, A.; Anandakrishnan, V.: Al–TiO2–Gr powder metallurgy hybrid composites with cold upset forging. Rare Met. 33(6), 686–696 (2014). https://doi.org/10.1007/s12598-014-0239-x

Elango, G.; Raghunath, B.K.: Tribological behavior of hybrid (LM25Al + SiC+ TiO2) metal matrix composites. Procedia Eng. 64, 671–680 (2013). https://doi.org/10.1016/j.proeng.2013.09.142

El Mahallawi, I.; Shash, Y.; Rashad, R.M.; Abdelaziz, M.H.; Mayer, J.; Schwedt, A.: Hardness and wear behaviour of semi-solid cast A390 alloy reinforced with Al2O3 and TiO2 nanoparticles. Arab. J. Sci. Eng. 39, 5171–5184 (2014). https://doi.org/10.1007/s13369-014-1179-3

Mohapatra, S.; Mishra, D.K.; Mishra, G.; Roy, G.S.; Behera, D.; Mantry, S.; Singh, S.K.: A study on sintered TiO2 and TiO2/SiC composites synthesized through chemical reaction based solution method. J. Compos. Mater. 47(24), 3081–3089 (2013). https://doi.org/10.1177/0021998312462430

Muley, A.V.; Aravindan, S.; Singh, I.P.: Nano and hybrid aluminum based metal matrix composites: an overview. Manuf. Rev. 2(15), 1–13 (2015). https://doi.org/10.1051/mfreview/2015018

Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H.: Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 4(4), 434–445 (2015). https://doi.org/10.1016/j.jmrt.2015.05.003

Madhukar, P.; Selvaraj, N.; Rao, C.S.P.: Manufacturing of aluminium nano hybrid composites: a state of review. IOP Conf. Ser. Mater. Sci. Eng. 149(012114), 1–12 (2016). https://doi.org/10.1088/1757-899X/149/1/012114

Iacob, G.; Ghica, V.G.; Buzatu, M.; Buzatu, T.; Petrescu, M.I.: Studies on wear rate and micro-hardness of the Al/Al2O3/Gr hybrid composites produced via powder metallurgy. Compos. Part B Eng. 69, 603–611 (2015). https://doi.org/10.1016/j.compositesb.2014.07.008

Alizadeh, A.; Abdollahi, A.; Biukani, H.: Creep behavior and wear resistance of Al 5083 based hybrid composites reinforced with carbon nanotubes (CNTs) and boron carbide (B4C). J. Alloys. Compd. 650, 783–793 (2015). https://doi.org/10.1016/j.jallcom.2015.07.214

Zhang, X.N.; Geng, L.; Wang, G.S.: Fabrication of Al-based hybrid composites reinforced with SiC whiskers and SiC nanoparticles by squeeze casting. J. Mater. Process. Technol. 176(1–3), 146–151 (2006). https://doi.org/10.1016/j.jmatprotec.2006.03.125

Geim, A.K.; Novoselov, K.S.: The rise of graphene. Nat. Mater. 6, 183–191 (2007). https://doi.org/10.1038/nmat1849

Savage, N.: Materials science: super carbon. Nature 483, 30–31 (2012). https://doi.org/10.1038/483S30a

Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S.: Graphene based materials: past, present and future. Prog. Mater. Sci. 56(8), 1178–1271 (2012). https://doi.org/10.1016/j.pmatsci.2011.03.003

Berman, D.; Erdemir, A.; Sumant, A.V.: Graphene: a new emerging lubricant. Mater. Today 17(1), 31–42 (2014). https://doi.org/10.1016/j.mattod.2013.12.003

Udayashankar, S.; Ramamurthy, V.S.: Development and characterization of Al6061-zirconium dioxide reinforced particulate composites. Int. J. Eng. Technol. 7(3.12), 128–132 (2018). https://doi.org/10.14419/ijet.v7i3.12.15901

Kumar, H.G.P.; Xavior, M.A.: Effect of graphene addition on flexural properties of Al6061 nano composites. Mater. Today. Proc. 4(8), 8127–8133 (2017). https://doi.org/10.1016/j.matpr.2017.07.153

Boppana, S.B.; Dayanand, S.; Kumar, A.; Kumar, V.; Aravinda, T.: Synthesis and characterization of nano graphene and ZrO2 reinforced Al 6061 metal matrix composites. J. Mater. Res. Tech. 9(4), 7354–7362 (2020). https://doi.org/10.1016/j.jmrt.2020.05.013

Chen, L.; Qi, Y.; Fei, Y.; Du, Z.: Enhanced mechanical properties and thermal conductivity for GNPs/Al2024 composites with in situ SiC nanorods. Met. Mater. Int. (2021). https://doi.org/10.1007/s12540-020-00803-9

AbuShanab, W.S.; Moustafa, E.B.; Ghandourah, E.; Taha, M.A.: Effect of graphene nanoparticles on the physical and mechanical properties of the Al2024-graphene nanocomposites fabricated by powder metallurgy. Results Phys. 19, 1–12 (2020). https://doi.org/10.1016/j.rinp.2020.103343

Shin, S.E.; Ko, Y.J.; Bae, D.H.: Mechanical and thermal properties of nanocarbon-reinforced aluminum matrix composites at elevated temperatures. Compos. Part B Eng. 106, 66–73 (2016). https://doi.org/10.1016/j.compositesb.2016.09.017

Zheng, Z.; Yang, X.; Li, J.C.; Zhang, X.X.; Muhammad, I.; Geng, L.: Preparation and properties of graphene nanoplatelets reinforced aluminum composites. Trans. Nonferrous Met. Soc. China 31(4), 878–886 (2021). https://doi.org/10.1016/S1003-6326(21)65546-2

Chak, V.; Chattopadhyay, H.: Fabrication and heat treatment of graphene nanoplatelets reinforced aluminium nanocomposites. Mat. Sci. Eng. A Struct. 791, 1–10 (2021). https://doi.org/10.1016/j.msea.2020.139657

Yu, H.; Zhang, S.Q.; Xia, J.H.; Su, Q.; Ma, B.C.; Wu, J.H.; Zhou, J.X.; Wang, X.T.; Hu, L.X.: Microstructural evolution, mechanical and physical properties of graphene reinforced aluminum composites fabricated via powder metallurgy. Mat. Sci. Eng. A Struct. 802, 1–10 (2021). https://doi.org/10.1016/j.msea.2020.140669

Kumar, H.G.P.; Xavior, M.A.: Assessment of mechanical and tribological properties of Al 2024-SiC-Graphene hybrid composites. Procedia Eng. 174, 992–999 (2017). https://doi.org/10.1016/j.proeng.2017.01.251

Şenel, M.C.; Gürbüz, M.; Koç, E.: Mechanical and tribological behaviours of aluminium matrix composites reinforced by graphene nanoplatelets. Mater. Sci. Tech. Lond. 34(16), 1980–1989 (2018). https://doi.org/10.1080/02670836.2018.1501839

Gürbüz, M.; Şenel, M.C.: Koç, E: The effect of sintering temperature, time and graphene addition on the mechanical properties and microstructure of aluminum composites. J. Compos. Mater. 52(4), 553–563 (2018). https://doi.org/10.1177/0021998317740200

Şenel, M.C.; Gürbüz, M.; Koç, E.: The fabrication and characterization of aluminum hybrid composites reinforced with silicon nitride/graphene nanoplatelet binary particles. J. Compos. Mater. 53, 4043–4054 (2019). https://doi.org/10.1177/0021998319853329

Pandiyarajan, R.; Maran, P.; Marimuthu, S.; Ganesh, K.C.: Mechanical and tribological behavior of the metal matrix composite AA6061/ZrO2/C. J. Mech. Sci. Technol. 31(10), 4711–4717 (2017). https://doi.org/10.1007/s12206-017-0917-3

Kumar, G.B.V.; Pramod, R.; Sekhar, C.G.; Kumar, G.P.; Bhanumurthy, T.: Investigation of physical, mechanical and tribological properties of Al6061-ZrO2 nano-composites. Heliyon 5(11), 1–8 (2019). https://doi.org/10.1016/j.heliyon.2019.e02858

Abdizadeh, H.; Baghchesara, M.A.: Investigation on mechanical properties and fracture behavior of A356 aluminum alloy based ZrO2 particle reinforced metal-matrix composites. Ceram. Int. 39(2), 2045–2050 (2013). https://doi.org/10.1016/j.ceramint.2012.08.057

Salimi, A.; Borhani, E.; Emadoddin, E.: Evaluation of mechanical properties and structure of 1100-Al reinforced with ZrO2 nano-particles via accumulatively roll-bonded. Proc. Mat. Sci. 11, 67–73 (2015). https://doi.org/10.1016/j.mspro.2015.11.094

Hemanth, J.: Development and property evaluation of aluminum alloy reinforced with nano-ZrO2 metal matrix composites (NMMCs). Mater. Sci. Eng. A Struct. 507(1–2), 110–113 (2009). https://doi.org/10.1016/j.msea.2008.11.039

Madhusudhan, M.; Naveen, G.J.; Mahesha, K.: Mechanical characterization of AA7068-ZrO2 reinforced metal matrix composites. Mater. Today Proc. 4(2), 3122–3130 (2017). https://doi.org/10.1016/j.matpr.2017.02.196

Ramachandra, M.; Abhishek, A.; Siddeshwar, P.; Bharathi, V.: Hardness and wear resistance of ZrO2 nano particle reinforced Al nanocomposites produced by powder metallurgy. Proc. Mater. Sci. 10, 212–219 (2015). https://doi.org/10.1016/j.mspro.2015.06.043

Zhai, W.; Shi, X.; Yao, J.; Ibrahim, A.M.M.; Xiu, Z.; Zhu, Q.; Xiao, Y.; Chen, L.; Zhang, Q.: Investigation of mechanical and tribological behaviors of multilayer graphene reinforced Ni3Al matrix composites. Compos. Part B Eng. 70, 149–155 (2015). https://doi.org/10.1016/j.compositesb.2014.10.052

Liu, R.; Li, D.Y.: Modification of Archard’s equation by taking account of elastic/ pseudoelastic properties of materials. Wear 251(1–12), 956–964 (2001). https://doi.org/10.1016/S0043-1648(01)00711-6

Kaczmar, J.W.; Pietrzak, K.; Wlosinski, W.: The production and application of metal matrix composite materials. J. Mater. Process. Tech. 106(1–3), 58–67 (2000). https://doi.org/10.1016/S0924-0136(00)00639-7

Li, G.; Xiong, B.: Effects of graphene content on microstructures and tensile property of graphene-nanosheets/aluminum composites. J. Alloy. Compd. 697, 31–36 (2017). https://doi.org/10.1016/j.jallcom.2016.12.147

Habibi, M.K.; Joshi, S.P.; Gupta, M.: Hierarchical magnesium nano-composites for enhanced mechanical response. Acta Mater. 58(18), 6104–6114 (2010). https://doi.org/10.1016/j.actamat.2010.07.028

Hu, Z.; Tong, G.; Nian, Q.; Xu, R.; Saei, M.; Chen, F.; Chen, C.; Zhang, M.; Guo, H.; Xu, J.: Laser sintered single layer graphene oxide reinforced titanium matrix nanocomposites. Compos. Part B Eng. 93, 352–359 (2016). https://doi.org/10.1016/j.compositesb.2016.03.043

Cao, Z.; Wang, X.; Li, J.; Wu, Y.; Zhang, H.; Guo, J.; Wang, S.: Reinforcement with graphene nanoflakes in titanium matrix composites. J. Alloy. Compd. 696, 498–502 (2017). https://doi.org/10.1016/j.jallcom.2016.11.302

Torralba, J.M.; Costa, C.E.; Velasco, F.: P/M aluminum matrix composites: an overview. J. Mater. Process. Tech. 133(1–2), 203–206 (2003). https://doi.org/10.1016/S0924-0136(02)00234-0

Chen, L.Y.; Konishi, H.; Fehrenbacher, A.; Ma, C.; Xu, J.Q.; Choi, H.; Xu, H.F.; Pfefferkorn, F.E.; Li, X.C.: Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scripta Mater. 67(1), 29–32 (2012). https://doi.org/10.1016/j.scriptamat.2012.03.013

Wang, J.; Li, Z.; Fan, G.; Pan, H.; Chen, Z.; Zhang, D.: Reinforcement with graphene nanosheets in aluminum matrix composites. Scripta Mater. 66, 594–597 (2012). https://doi.org/10.1016/j.scriptamat.2012.01.012

Wang, Z.; Georgarakis, K.; Zhang, W.W.; Prashanth, K.G.; Eckert, J.; Scudino, S.: Reciprocating sliding wear behavior of high-strength nanocrystalline Al84Ni7Gd6Co3 alloys. Wear 382–383, 78–84 (2017). https://doi.org/10.1016/j.wear.2017.04.013

Rajeev, V.R.; Dwivedi, D.K.; Jain, S.C.: Dry reciprocating wear of Al–Si–SiCp composites: a statistical analysis. Tribol. Int. 43(8), 1532–1541 (2010). https://doi.org/10.1016/j.triboint.2010.02.014

Liu, Y.; Han, Z.; Cong, H.: Effects of sliding velocity and normal load on the tribological behavior of a nanocrystalline Al based composite. Wear 268(7–8), 976–983 (2010). https://doi.org/10.1016/j.wear.2009.12.027

Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A.: Wear behaviour of Al 2618 alloy reinforced with Si3N4, AlN and ZrB2 in situ composites at elevated temperatures. Alex. Eng. J. 55(1), 19–36 (2016). https://doi.org/10.1016/j.aej.2016.01.017

Kumar, H.G.P.; Xavior, M.A.: Fatigue and wear behavior of Al6061–graphene composites synthesized by powder metallurgy. T. Indian I. Metals 69(2), 415–419 (2016). https://doi.org/10.1007/s12666-015-0780-9

Acknowledgements

The authors of this study thank Black Sea Advanced Technology Research and Application Center (KITAM) in Ondokuz Mayıs University (OMU) for SEM and XRD analysis. They also thank Assoc. Prof. Dr. Mevlüt Gürbüz for useful suggestions related to induction heat treatment and microstructure analyses. This work was supported by the [Scientific Researched Project Department of Ondokuz Mayıs University] under [Grant number PYO.MUH.1901.20.001].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Rights and permissions

About this article

Cite this article

Şenel, M.C., Üstün, M. Dry Sliding Wear and Friction Behavior of Graphene/ZrO2 Binary Nanoparticles Reinforced Aluminum Hybrid Composites. Arab J Sci Eng 47, 9253–9269 (2022). https://doi.org/10.1007/s13369-022-06661-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06661-4