Abstract

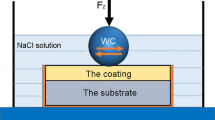

To prolong the longevity of rotary blades, Fe-based-Al2O3-B4C coatings were prepared on 65Mn substrate using high-velocity arc spraying technology. The coatings were subsequently heat-treated at 350, 450, 550, 650, and 750 °C for 2 hours. The effect of heat treatment temperatures on the microstructure, phase composition, microhardness, tensile bonding strength, and wear resistance of Fe-based-Al2O3-B4C coatings was studied by scanning electron microscope, x-ray diffractometer, Vickers microhardness tester, tensile tester, and friction wear tester, respectively. The results showed that with the increase in heat treatment temperature, the porosity of the coating gradually decreased while the compactness of the coating increased. At 650 °C, the tensile bonding strength of the coating was the highest at 35.6 ± 3.5 MPa, which was 1.2 times higher than that of the as-sprayed coating. When the coating crystallized at 550 °C, the average microhardness and Weibull modulus reached the peak values of 1508 ± 171 HV0.1 and 23.8, respectively. The wear resistance of the heat-treated coating was the best at 550 °C, the wear rate reached a minimum of (8.2 ± 0.7) ×10−6 mm3N−1m−1, which was 0.6 times lower than that of the as-sprayed coating. The main wear mechanism was adhesive wear and abrasive wear.

Similar content being viewed by others

References

J. Yu, H. Zhou, L. Zhang, L.W. Zhang, L. Lei, and D.P. Lu, Microstructure and Properties of Modified Layer on the 65Mn Steel Surface by Pulse Detonation-Plasma Technology, J. Mater. Eng. Perform., 2021, 31(2), p 1562–1572.

S. Kang, G.S. Cheema, and S. Singla, Wear Behavior of Hardfacings on Rotary Tiller Blades, Procedia Eng., 2014, 97, p 1442–1451.

J. Fiebig, E. Bakan, T. Kalfhaus, G. Mauer, O. Guillon, and Vassen, Thermal Spray Processes for the Repair of gas Turbine Components, Adv. Eng. Mater., 2020, 22(6), p 1901237.

K. Bobzin, W. Wietheger, G. Jacobs, D. Bosse, T. Schroder, and A. Rolink, Thermally Sprayed Coatings for Highly Stressed Sliding Bearings, Wear, 2020, 458, 203415.

J. Zhan, Z. Li, J. Lu, Y.J. Wu, L.Q. Zhao, and N. Yu, Technics and Performance Analysis of Monel Alloy Coating Prepared by High Velocity arc Spraying, Mater. Res. Innov., 2013, 17, p S112–S114.

N.J. Ndumia, M. Kang, B.V. Gbenontin, J.R. Lin, and S.M. Nyambura, A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coating, Nanomaterials, 2021, 11(10), p 2527.

C.M. Wang, H.F. Sun, Q. Song, and Z. Qu, Properties of Fe-based Cr3C2 Coatings Produced with a High-Velocity Arc-Spraying Process, J. Korean Phys. Soc., 2009, 54(3), p 1339–1343.

A. Datya, S. Koneti, G. Gomes, K.H. Wu, and H.T. Lin, Synthesis and Characterization of Aluminum Oxide Boron Carbide Coatings by Air Plasma Spraying, Ceram. Int., 2010, 36(5), p 1517–1522.

Y.X. Cao, C.B. Huang, W. Liu, W.G. Zhang, and L.Z. Du, Effects of Boron Carbide Content on the Microstructure and Properties of Atmospheric Plasma-Sprayed NiCoCrAlY/Al2O3-B4C Composite Coatings, J. Therm. Spray Technol., 2014, 23(4), p 716–724.

F. Huang, Research on Microstructure and Properties of FeMnCrNi Composite Coating by High Velocity arc Spraying, Thesis, Agricultural University, Nanjing, 2021. ((in Chinese))

P. Daram and C. Banjongprasert, The Influence of Post Treatments on the Microstructure and Corrosion Behavior of Thermally Sprayed NiCrMoAl Alloy Coating, Surf. Coat. Technol., 2020, 384, 125166.

H.Y. Li, G.L. Li, H.D. Wang, and B.S. Xu, Influence of Heat Treatment on Microstructure and Mechanical Properties of Iron-Based Coating, Mater. Des., 2011, 32(5), p 3004–3007.

Y.Y. Ge, J.B. Cheng, Y. Chen, B.S. Zhang, S.S. Zhu, L. Xue, S. Hong, Y.P. Wu, Z.B. Zhang, X.B. Liang, and X.C. Zhang, Thermally Induced Microstructure Evolution and Effects on the Corrosion Behaviors of AlFeSi Metallic Glass Coatings, Intermetallics, 2022, 143, 107473.

M. Shabanlo, R.A. Najafabadi, and A. Meysami, Evaluation and Comparison the Effect of Heat Treatment on Mechanical Properties of NiCrBSi Thermally Sprayed Coatings, Anti-Corros. Methods Mater., 2018, 65(1), p 34–37.

B.Y. Fu, D.Y. He, and L.D. Zhao, Effect of Heat Treatment on the Microstructure and Mechanical Properties of Fe-based Amorphous Coatings, J. Alloy. Compd., 2009, 480(2), p 422–427.

W.C. Sun, F. Zhang, P. Zhang, K. Zhao, P. Li, and H.J. Wei, Influence of Heat Treatment on the Microstructure and Wear Resistance of HVOF WC-17Co Coatings, J. Chn. Coal. Soc., 2015, 40(2), p 476–480. ((in Chinese))

Y.L. Si, X.F. Wang, F.S. Han, J.J. Zhu, Z.Z. Li, and G.B. Feng, Effects of Heat Treatment on Microstructure and Properties of NiCr-Cr3C2 Coatings by Supersonic Flame Spraying, Hot Working Technol., 2020, 49(8), p 8. ((in Chinese))

O. Sarikaya, Effect of the Substrate Temperature on Properties of Plasma Sprayed Al2O3 Coatings, Mater. Des., 2005, 26(1), p 53–57.

Y.P. Cao, Q.S. Wang, Y.B. Liu, and X.J. Ning, High-Temperature Thermal Properties of ba(Ni1/3Ta2/3)O-3 Ceramic and Characteristics of Plasma-Sprayed Coatings, J. Therm. Spray Technol., 2018, 27(8), p 1594–1601.

ASTM C633-13, Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings, ASTM International: West Conshohocken, PA (2013)

A. Dey, A.K. Mukhopadhyay, S. Gangadharan, M.K. Sinha, and D. Basu, Weibull Modulus of Nano-Hardness and Elastic Modulus of Hydroxyapatite Coating, J. Mater. Sci., 2009, 44(18), p 4911–4918.

ASTM G133-05, Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear, ASTM International, West Conshohocken, PA, (2008)

X.J. Cui, C.M. Ning, L.L. Shang, G.A. Zhang, and X.Q. Liu, Structure and Anticorrosion, Friction, and Wear Characteristics of Pure Diamond-Like Carbon (DLC), Cr-DLC, and Cr-H-DLC Films on AZ91D Mg Alloy, J. Mater. Eng. Perform., 2019, 28(2), p 1213–1225.

H.J. Zhang, Y.F. Gong, B.T. Zhang, X.Y. Cheng, L.J. Fang, P.P. Jin, and H. Li, Corrosion and Algal Behaviors of HVOF Sprayed Fe-based Amorphous Coatings for Marine Applications, J. Therm. Spray Technol., 2019, 27(1–2), p 283–290.

Z.Q. Zhang, K.K. Song, R. Li, Q.S. Xue, S. Wu, D.L. Yan, X.L. Li, B. Song, B. Sarac, J.T. Kim, P. Ramasamy, L. Wang, and J. Eckert, Polymorphic Transformation and Magnetic Properties of Rapidly Solidified Fe26. 7Co26. 7Ni26. 7Si8 9B11. 0 High-Entropy Alloys, Materials, 2019, 12(4), p 590.

R.W. Li, Q.C. Chen, L. Ouyang, Y.J. Zhang, B.J. Nie, and Y.L. Ding, Insight into the Strengthening Mechanism of Alpha-Al2O3/Gamma-Fe Ceramic-Metal Interface Doped with Cr, Ni, Mg, and Ti, Ceram. Int., 2021, 47(16), p 22810–22820.

W.S. Yang, S.C. Chen, Y.B. Pei, R.Z. Chen, and H.J. Guo, A Study into Enhanced Oxidation Resistance and its Mechanism in Cr1-xAlxN/CrN/Cr Multilayer Films Deposited on 9–12 % Cr Heat-Resistant Steel, Ceram. Int., 2021, 47(13), p 19134–19141.

B.X. Ma and J.Y. Li, ZrB2-SiC-ZrC Coating on ZrC Ceramics Deposited by Plasma Spraying, Results Phys., 2019, 15, 102550.

Q. Liu, Y. Wang, Y. Bai, Z.D. Li, G.L. Tan, M.Y. Bao, X.J. Li, H. Zhan, Y.W. Sun, N.J. Chong, R.J. Wang, and Y.S. Ma, Formation Mechanism of Gas Phase in Supersonic Atmospheric Plasma Sprayed NiCr-Cr3C2 Cermet Coatings, Surf. Coat. Technol., 2020, 397, 126052.

T. Kobayashi, T. Maruyama, and M. Kano, Characterization of Pure Aluminum and Zinc Sprayed Coatings Produced by Flame Spraying, Mater. Trans., 2003, 44(12), p 2711–2717.

V. Pershin, M. Lufitha, S. Chandra, and J. Mostaghimi, Effect of Substrate Temperature on Adhesion Strength of Plasma-Sprayed Nickel Coatings, J. Therm. Spray Technol., 2003, 12(3), p 370–376.

A. Abdelgawad and K. Al-Athel, Effect of TGO Thickness, Pores, and Creep on the Developed Residual Stresses in Thermal Barrier Coatings Under Cyclic Loading using SEM Image-Based Finite Element Model, Ceram. Int., 2021, 47(14), p 20064–20076.

Z. Zhang, Z.F. Hu, L.F. Zhang, K. Chen, and P.M. Singh, Effect of Temperature and Dissolved Oxygen on Stress Corrosion Cracking Behavior of P92 Ferritic-Martensitic Steel in Supercritical Water Environment, J. Nucl. Mater., 2018, 498, p 89–102.

W. Brandl, D. Toma, and G. Matthaus, The Oxidation Behaviour of HVOF Thermal-Sprayed MCrA1Y Coatings, Surf. Coat. Technol., 2014, 94–5(1–3), p 21–26.

M. Schlogl, J. Paulitsch, J. Kecskes, and P.H. Mayrhofer, Influence of AlN Layers on Mechanical Properties and Thermal Stability of Cr-Based Nitride Coatings, Thin Solid Films, 2013, 531, p 113–118.

C.C. Chen and S.J. Ding, Effect of Heat Treatment on Characteristics of Plasma Sprayed Hydroxyapatite Coatings, Mater. Trans., 2006, 47(3), p 935–940.

A. Singh, G. Singh, and V. Chawla, Characterization of Vacuum Plasma Sprayed Reinforced Hydroxyapatite Coatings on Ti-6Al-4V Alloy, Trans. Indian Inst. Met., 2017, 70(10), p 2609–2628.

W.X. Ma, Y. Ge, L.X. Zhang, F. Chen, Y.J. Zheng, and Z.H. Qi, Study on the Friction Performance of Cerium Oxide on Supersonic Flame-Sprayed WC-10Co-4Cr Coating, Coatings, 2021, 11(1), p 24.

J.R. Lin, Z.H. Wang, P.H. Lin, J.B. Cheng, J.J. Zhang, and X. Zhang, Microstructure and Corrosion Resistance of Fe-Based Coatings Prepared by Twin Wires Arc Spraying Process, J. Therm. Spray Technol., 2014, 23(3), p 333–339.

Y.J. Hu, J. Wan, L. Yuan, T. Zhang, J.N. Cao, F. Li, X.L. Cheng, X.H. Jie, and H.Y. Zhang, Influence of the Phase Composition and Microstructure of Plasma Cladding Fe-Cr-Ni-C Alloy Coating on Residual Stress and Crack Formation, Int. J. Adv. Manuf. Technol., 2018, 96(5–8), p 1607–1613.

N.J. Ndumia, M. Kang, J.R. Lin, J.T. Liu, and H. Li, Influence of Heat Treatment on the Microstructure and Wear Properties of Arc-Sprayed FeCrAl/Al Coating, Coatings, 2022, 12(3), p 374.

H.L. Tian, S.C. Wei, Y.X. Chen, H. Tong, Y. Liu, and B.S. Xu, Microstructure and Wear Resistance Property of the FeAlCr Coating Prepared by High Velocity Arc Spraying, Rare Metal Mat. Eng., 2014, 43(1), p 135–139.

C. Trevisiol, A. Jourani, and S. Bouvier, Effect of Hardness, Microstructure, Normal Load and Abrasive Size on Friction and on Wear Behavior of 35NCD16 Steel, Wear, 2017, 388, p 101–111.

K.Y. Ding, T.T. Cheng, and P.C. Lu, Effect of Isothermal Heat Treatment on Abrasive Wear Resistance of HVOF WC-10Co-4Cr Coating, J. Mater. Process. Technol., 2012, 538–541, p 200–206.

S. Harsha, D.K. Dwivedi, and A. Agarwal, Performance of Flame Sprayed Ni-WC Coating Under Abrasive Wear Conditions, J. Mater. Eng. Perform., 2008, 17(1), p 104–110.

Acknowledgments

This present work was supported by the National Natural Science Foundation of China (No. 52109091), Jiangsu Provincial Key Research and Development Plan (No. BE2020311) and the Natural Science Foundation of Jiangsu Province of China (No. BK20210409).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, H., Kang, M., Ndumia, J.N. et al. Influence of Heat Treatment on Microstructure and Properties of High-Velocity Arc-Sprayed Fe-Based-Al2O3-B4C Coating. J. of Materi Eng and Perform 31, 9878–9887 (2022). https://doi.org/10.1007/s11665-022-07039-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07039-1