Abstract

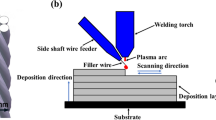

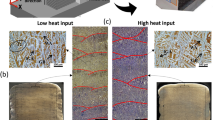

Wire and arc additive manufacturing (WAAM) is a viable technique to fabricate low to medium geometric complexity and medium to large structural components. High-strength low-alloy (HSLA) steels have been widely used in pressure vessels, structural applications and marine and shipbuilding industries. In this study, an 800-MPa-class HSLA steel block part was manufactured by a WAAM system based on a gas metal arc welding system. The microstructure and mechanical properties were investigated. The results show that the microstructure was predominantly martensite/bainite (M/B). The deposit exhibits excellent strength–ductility balance. The average yield strength and fracture elongation exceed 840 MPa and 16%, respectively, for samples extracted from different directions of the deposit. Meanwhile, the deposit exhibits excellent low-temperature toughness, i.e., the absorbed energy exceeds 100 J at − 50°C. The microhardness varied from 265 to 365 HV, which indicates that there are softened zones as well as hardened zones, which resulted from different thermal histories. This would influence the tensile and impact behaviors of samples taken from different directions of the deposit. This study elucidates an 800-MPa HSLA steel block part with excellent strength–toughness balance fabricated by WAAM, which verifies the fabrication feasibility of a large-scale, high-strength and toughness block part fabricated by WAAM.

Similar content being viewed by others

References

R.L. Truby and J.A. Lewis, Printing Soft Matter in Three Dimensions, Nature, 2016, 540, p 371–378. https://doi.org/10.1038/nature21003

K.V. Wong and A. Hernandez, A Review of Additive Manufacturing, ISRN Mech. Eng., 2012, 2012, p 1–10. https://doi.org/10.5402/2012/208760

D. Ding, Z. Pan, D. Cuiuri and H. Li, Wire-feed Additive Manufacturing of Metal Components: Technologies, Developments and Future Interests, Int. J. Adv. Manuf. Tech., 2015, 81, p 465–481. https://doi.org/10.1007/s00170-015-7077-3

K. Paul, H. Latifi, R. Suoranta, J. Martikainen and M. Pirinen, Usability of Arc Types in Industrial Welding, Int. J. Mech. Mater. Eng., 2014, 9, p 1–12. https://doi.org/10.1186/s40712-014-0015-6

F. Martina, J. Mehnen, S.W. Williams, P. Colegrove and F. Wang, Investigation of the Benefits of Plasma Deposition for the Additive Layer Manufacture of Ti-6Al-4 V, J. Mater. Process. Tech., 2012, 212, p 1377–1386. https://doi.org/10.1016/j.jmatprotec.2012.02.002

J.P. Oliveira, B. Crispim, Z. Zeng, T. Omori, F.M. Braz Fernandes and R.M. Miranda, Microstructure and Mechanical Properties of Gas Tungsten Arc Welded Cu-Al-Mn Shape Memory Alloy Rods, J. Mater. Process. Tech., 2019, 271, p 93–100. https://doi.org/10.1016/j.jmatprotec.2019.03.020

S.W. Williams, F. Martina, A.C. Addison, J. Ding, G. Pardal and P. Colegrove, Wire + Arc Additive Manufacturing, Mater. Sci. Tech., 2016, 32, p 641–647. https://doi.org/10.1179/1743284715Y.0000000073

A.V. Nemani, M. Ghaffari and A. Nasiri, Comparison of Microstructural Characteristics and Mechanical Properties of Shipbuilding Steel Plates Fabricated by Conventional Rolling Versus Wire Arc Additive Manufacturing, Addit. Manuf., 2020, 32, p 101086. https://doi.org/10.1016/j.addma.2020.101086

Y. Zhao, X. Tong, X.H. Wei, S.S. Xu, S. Lan, X.L. Wang and Z.W. Zhang, Effects of Microstructure on Crack Resistance and Low-Temperature Toughness of Ultra-Low Carbon High Strength Steel, Int. J. Plast., 2019, 116, p 203–215. https://doi.org/10.1016/j.ijplas.2019.01.004

X.D. Li, X.P. Ma, S.V. Subramanian, C.J. Shang and R.D.K. Misra, Influence of Prior Austenite Grain Size on Martensite-Austenite Constituent and Toughness in the Heat Affected Zone of 700 MPa High Strength Linepipe Steel, Mater. Sci. Eng. A., 2014, 616, p 141–147. https://doi.org/10.1016/j.msea.2014.07.100

L.B. Sun, F.C. Jiang, R.S. Huang, D. Yuan and C.H. Guo, Anisotropic Mechanical Properties and Deformation Behavior of Low-Carbon High-Strength Steel Component Fabricated by Wire and Arc Additive Manufacturing, Mater. Sci. Eng. A., 2020, 787, p 139514. https://doi.org/10.1016/j.msea.2020.139514

T.A. Rodrigues, V. Duarte, J.A. Avila, T.G. Santo and R.M. Miranda, Wire and Arc Additive Manufacturing of HSLA steel: Effect of Thermal Cycles on Microstructure and Mechanical Properties, Addit. Manuf., 2019, 27, p 440–450. https://doi.org/10.1016/j.addma.2019.03.029

B.Q. Cong, Z.W. Qi, B.J. Qi, H.Y. Sun, G. Zhao and J.L. Ding, A Comparative Study of Additively Manufactured Thin Wall and Block Structure With Al-6.3%Cu Alloy Using Cold Metal Transfer Process, Appl. Sci., 2017, 7, p 1–11. https://doi.org/10.3390/app7030275

G.J. Mao, R. Cao, J. Yang and J.H. Chen, Effect of Ni Alloying on Microstructure and Property in Low-Carbon Bainitic Weld Metal, J. Mater. Eng. Perform., 2017, 26, p 2057–2071. https://doi.org/10.1007/s11665-017-2638-2

A. Lambert-Perlade, A.F. Gourgues and A. Pineau, Austenite to Bainite Phase Transformation in the Heat-Affected Zone of a High Strength Low Alloy Steel, Acta Mater., 2004, 52, p 2337–2348. https://doi.org/10.1016/j.actamat.2004.01.025

Y.S. Sato, M. Urata, H. Kokawa and K. Ikeda, Hall - Petch Relationship in Friction Stir Welds of Equal Channel Angular-Pressed Aluminum Alloys, Mater. Sci. Eng. A., 2003, 3(54), p 298–305. https://doi.org/10.1016/S0921-5093(03)00008-X

P. Zhang, S.X. Li, Z.F. Zhang, General Relationships between Strength and Hardness, Mater. Sci. Eng. A., 2011, 529, p 62–73. https://doi.org/10.1016/j.msea.2011.08.061

J. Alcisto, A. Enriquez, H. Garcia, S. Hinkson, T. Steelman, E. Silverman, P. Valdovino, H. Gigerenzer, J. Foyos, J. Ogren, J. Dorey, K. Karg, T. McDonald and O.S. Es-Said, Tensile Properties and Microstructures of Laser-Formed Ti-6Al-4 V, J. Mater. Eng. Perform., 2011, 20, p 203–212. https://doi.org/10.1007/s11665-010-9670-9

N. Tsuchida, H. Nakano, T. Okamoto and T. Inoue, Effect of Strain Rate on True Stress-True Strain Relationships of Ultrafine-Grained Ferrite-Cementite Steels Up to Plastic Deformation Limit, Mater. Sci. Eng. A., 2015, 626, p 441–448. https://doi.org/10.1016/j.msea.2014.12.080

C.G. Zhang, P.M. Lu and X.Z. Hu, Residual Stress and Softening in Welded High-Strength Low-Alloy Steel with a Buffering Layer, J. Mater. Process. Tech., 2014, 214, p 229–237. https://doi.org/10.1016/j.jmatprotec.2013.09.002

J.R. Griffiths and D.R.J. Owen, An Elastic - Plastic Stress Analysis for a Notched Bar in Plane Strain Bending, J. Mech. Phys. Solids, 1971, 19, p 419–431. https://doi.org/10.1016/0022-5096(71)90009-3

X.D. Li, X.P. Ma, S.V. Subramanian, R.D.K. Misra and C.J. Shang, Structure-Property- Fracture Mechanism Correlation in Heat-Affected Zone of X100 Ferrite-Bainite Pipeline Steel, Metall. Mater. Trans. E., 2015, 2, p 1–11. https://doi.org/10.1007/s40553-014-0036-3

Acknowledgments

This work was supported by the National Key R&D Program of China (Grant Numbers 2017YFB1103700 and 2017YFB1103703) and the Joint Doctoral Training Foundation of Hebei University of Technology (Grant Number 2018GN0003). The authors would like to thank Dr Dayue Zhang and Hongjian Zhao for proofreading the article.

Author information

Authors and Affiliations

Contributions

QF involved in conceptualization, investigation, data curation, writing—original draft. LZ took part in funding acquisition, writing—review & editing. BL involved in writing—review & editing. CC involved in writing—review & editing. YP took part in project administration. ZT involved in supervision. FY took part in supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors report no declarations of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fang, Q., Zhao, L., Liu, B. et al. Microstructure and Mechanical Properties of 800-MPa-Class High-Strength Low-Alloy Steel Part Fabricated by Wire Arc Additive Manufacturing. J. of Materi Eng and Perform 31, 7461–7471 (2022). https://doi.org/10.1007/s11665-022-06784-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06784-7