Abstract

Arc behaviour is a significant factor in all arc welding processes. Understanding of arc types and their inherent properties can help enhance weld prediction and weld quality and reduce welding cost and production cycle time. Advanced welding processes utilize real-time control and prediction, increasing the need for detailed knowledge of arc characteristics and arc applications. This paper analyses the types of welding arcs used in the welding industry, explains corresponding features and characteristics, provides guidance for suitable applications, and presents arc type comparisons, benefits, and weaknesses. The study is based on a review of the literature, and it provides a comprehensive overview of arc phenomena. The results of this work show that in many applications, greater benefit accrues from spray and pulsed arcs than short and globular arc modes. Controlled short arc, heavy deposition rate arc, and controlled spray arc are enhanced arc processes offering significant improvements in efficiency and usability. This review can assist companies in making appropriate choices of arc and welding process for different materials and applications. Furthermore, it can be utilized as a basis for further research.

Similar content being viewed by others

Review

Introduction

Arc welding is a key process in industrial manufacturing (Naidu et al. 2003), and gas metal arc welding (GMAW) is commonly used in many manufacturing process industries due to its fundamental advantages, such as adjustable penetration profiles, smooth bead, low spatter, and high welding speed (Kah et al. 2009). In the past two decades, GMAW has become the main technology in the robotic welding industry (Chen and Wu 2009). Arc type is an important factor in many applications; however, the arc phenomenon is not fully explained and exhibits unknown properties and behaviours.

Use of an appropriate arc type in welding of different materials with different thicknesses creates cost savings, reduces production times, and improves quality. The joining of thin materials and materials sensitive to heat has lately become an important issue. Improved understanding of arc phenomena can help develop and refine integrated design for industrial welding systems (Iordachescu and Quintino 2008). With an increasing variety of materials being joined and many different arc processes, the need to understand the different types of arc welding processes is more urgent than ever. Furthermore, when controlling and modifying the welding process, knowledge of the arc phenomenon will make it easier to produce improved weld quality and reliable joints (Eagar 1990a, b).

This study gives a brief introduction to arc characteristics, discusses classification of welding arcs, presents a comparison of arcs, and discusses the benefits and weaknesses of different arcs. Finally, types of welding arcs and their role in industrial applications are examined.

Arc characteristics

The welding arc can be seen as a conductor of gas that transforms electrical energy into heat energy (Naidu et al. 2003). In the study by Lancaster (1984), the welding arc is viewed as a cylinder-shaped body of gas that is confined by the temperature gradient. One problem commonly faced by the welding industry is poor stability of the arc. Arc stability and arc length influence the behaviour of metal transfer (Pal et al. 2010). With a stable arc, metal transfer is uniform and the amount of spatter is minimal (Hermans and Ouden 1999). In a stable arc situation, a relationship can be found between the voltage and current, shown in Figure 1 (Ibrahim Khan 2007). The graph shows that the arc does not follow Ohm's law. Furthermore, the decreasing part of the arc characteristic is Ayrton's part and is characterized by unstable arc, while the Ohm's part, increasing area is the one applied in welding. Other factors such as the arc atmosphere, arc length, and metals involved also have an influence on the slope of the curve.

Typical arc characteristic compared with Ohm's law (Ibrahim Khan 2007 ).

Arc plasma

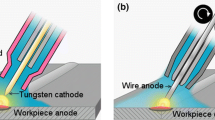

The arc plasma is the ionized state of the welding gas and is a mixture of almost equal amounts of electrons and ions. The plasma carries the arc current. Most of the current conduction is carried by the electrons. In the case of arc welding, the electrode is generally assumed to be the cathode and the workpiece is the anode. The electrons flow out from the electrode (i.e. the negative terminal) and are forwarded into the workpiece (i.e. the positive terminal) (Naidu et al. 2003). To determine the effects of arc plasma on the weld pool, four factors should be considered (i) heat flux, (ii) current density, (iii) shear stress, and (iv) arc pressure.

There is a direct relation between increasing heat flux and current density and the depth of the weld pool. Increasing the shear stress at the molten pool promotes the outward flow at the top of the weld pool, and increasing the arc pressure can lead to a more concave surface of the weld pool (Murphy et al. 2009). However, arc pressure has no influence on the flatness of the weld pool surface when the current is less than 200 A (Lin and Eagar 1985; Wang and Tsai 2001).

Arc temperature

Initially, the temperature of the welding arc was considered to consist of the heat of the arc plasma but Cobine and Burger (1955) showed that most of the heat transferred to the workpiece from the electrode originates from the flow of the current into the metal. Later, this insight was extended by Quigley et al. (1973) who noted that only 20% of the heat is carried by conduction from hot gases and 80% remains in the electric current. Depending on the precise nature of the plasma and the amount of current flowing through it, the welding arc temperature varies from 5,000 to 30,000 K (Naidu et al. 2003; Robert and Messler 2004). In some cases, the power is extremely high and the temperature can rise up to 50,000 K (Naidu et al. 2003).

Two significant factors influence the plasma temperature: the particular plasma and its density (Robert and Messler 2004). In arc welding with a one-component gas, which is found in some welding processes, the temperature is lower in GMAW because the molten droplet, vapour, and metal ions are more concentrated. Figure 2 shows an arc temperature distribution in GMA welding of aluminium at 250 A. As can be observed, the central core of the arc has the highest temperature, which changes depending on the shielding gas used (Robert and Messler 2004).

Arc temperature distribution in GMA welding of aluminium at 250 A (Smårs and Acinger 1968 ).

Arc current

The welding process is affected by several factors, such as arc current, arc voltage, travel speed of the torch, filler wire, and spin frequency (Lu et al. 2009; Moon et al. 2006). When selecting these parameters, the amount of heat input and the desired fusion should be considered (Min et al. 2011). The mode of the arc, and therefore the weld quality, is greatly influenced by the current (Hu and Tsai 2006). The penetration depth is also significantly affected by the arc current. In gas metal arc welding, increase in the arc current increases joint penetration. However, increased joint penetration also increases the possibility of burn-through and solidification cracking. Experiments done by Hu and Tsai (2006) showed that a higher current leads to a higher electromagnetic force, which causes the droplet to detach from electrode to the weld pool. Furthermore, with a higher current, the size of the molten droplet is smaller and there is a higher droplet frequency.

Arc voltage

The arc voltage is proportional to the arc length. Therefore, the arc voltage can be controlled by changing the arc length (Naidu et al. 2003). Figure 3 shows the arc voltage curves of a typical power source within a welding current and voltage diagram. It can be seen that a small change in voltage results in a very large change in the welding current. As a consequence of the relationship between welding current and arc voltage, weld properties and geometry can be predicted (Shoeb et al. 2013): welding with a high voltage produces a very wide bead with possible undercuts and a concave shape, and welding with too low a voltage produces a low-quality weld bead.

Self-regulation of arc voltage (Naidu et al. 2003 ).

As can be seen from Figure 3, the voltage changes significantly with small change in arc length while low variation occurs for the current. Consequently, the arc length has more effect on the voltage than on the welding current. The arc length in this diagram is divided into three parts: long, medium, and small, which are so-called voltage source curves. The junction of the CC and CV curves with the voltage source curve is called the operating point of power supply and can be changed during the welding process (Naidu et al. 2003).

Arc penetration

To determine arc penetration, it is necessary to know the arc position, which is computed from parameters such as the welding voltage, welding current, and wire feed speed. The arc position is defined as the sum of the wire extension and the arc length. In Figure 4, these parameters are shown for GMAW by L and La, respectively. The distance between the welding torch and workpiece is H, and the parameter P depicts the depth of penetration (Iwata et al. 2009a, b).

Figure 5 illustrates the correlation between the arc position and penetration during the welding of flat plates by SAW. The fitting line on the graph shows that the values of arc penetration and arc position are very close. The relationship is therefore as anticipated (Iwata et al. 2009a, b).

Arc efficiency

Arc efficiency is an important factor in arc welding processes and is generally explained as the heat input into the metal divided by the total heat energy of the arc (Eagar 1990a). In other words, arc efficiency is measured as the amount of arc energy delivered to the substrate (Dupont and Marder 1995). Arc efficiency has an effect on the welding rate and can vary from 60% to 99% for different welding processes (Eagar 1990b). It is essential to know arc efficiency in order to measure the melting efficiency, both by experiment and by utilizing heat-flow models (Dupont and Marder 1995). Welding parameters (e.g. current and voltage) have few effects on arc efficiency for a given process, and the arc efficiency of non-consumable electrode processes is considered to be a bit lower than that of consumable processes (Kou 1987; Lancaster 1984). Heat input can be calculated using arc efficiency by the formula shown in Equation 1 (Gunaraj and Murugan 2002):

Arc stability

Arc stability is another important characteristic of arc welding. Arc stability is influenced by parameters such as arc power, metal transfer mode, and the regularity of the metal transfer mode (Ghosh et al. 2006). The emission of spatter during welding is the main negative result of poor arc stability; spatter creates material losses, extends cleaning time, and decreases weld bead quality (Suban and Tusek 2003).

The properties of an ideal and stable welding arc are as follows (Suban and Tusek 2003): (i) the shape of all transferred material is constant, (ii) the length of the arc is constant, and (iii) there is a low level of spatter or no spatter at all.

During welding with a consumable electrode, e.g. GMAW, arc stability is affected by the behaviour of the arc root (Costa et al. 2010). Another factor in arc stability is the shielding gas mixture. The stability of the arc is lower in a gas mixture with higher carbon dioxide (CO2) content. Figure 6 shows that longer arc length and thinner isothermal distribution are two characteristics of a mixture with a low carbon dioxide content (Pires et al. 2007).

Temperature distribution for mixtures: high (left) and low (right) content of carbon dioxide. For the same current and voltage, I1 is higher than I2 (Pires et al. 2007)

Arc blow

Arc blow is a phenomenon in which the arc tends to become separated from the point of welding, as though a strong wind were blowing (Naidu et al. 2003). The reason for the occurrence of arc blow is imbalance in the magnetic field surrounding the workpiece (Gerbec 2009). Generally, this phenomenon occurs in three situations: (i) the direction of the current changes, (ii) there are magnetic materials around the welding arc, and (iii) there are magnetic materials near the edge of the plate (Naidu et al. 2003). Arc blow is generally found only with high DC welding currents. It can be prevented by reducing the current level, by using an AC welding current, and by demagnetizing the fixture (Gerbec 2009). Arc voltage affects arc deflection such that an arc with a lower voltage is shorter and stiffer and has better resistance to deflection than an arc with a higher arc voltage.

As mentioned earlier, the arc's heat energy is created by electrical reactions between the anode and cathode area inside the plasma. Parts of the energy generated melt the electrode. The melting rate (MR) is influenced by the cathode heating (current) and can be calculated by the formula shown in Equation 2.

In the given formula, both α and β are constants, l s is electrode resistivity, α ω is the cross-sectional area of the wire, and I is the welding current (Naidu et al. 2003).

Pinch effect

The arc in all conductors carrying current is surrounded by a magnetic field (Luksa 2006). In arc welding, the cross-sectional area of the consumable electrode varies, and the direction of the electromagnetic force depends on the flow direction of the welding current. The magnetic field has a force that is directed to the center of the arc, the so-called Lorenz force. With increasing amperage, the amount of current and the arc radial constriction increase, due to the greater magnetic force. This process is called the pinch effect (Dzelnitzki 2000; Robert and Messler 2004). The amount of pinch force has a direct relation to the welding current and the diameter of the wire and has an influence on drop detachment to the weld join (Kasikci 2003). The pinch effect is shown in Figure 7 (Nadzam 2006).

Pinch effect during short-circuiting transfer (Nadzam 2006 ).

When the cross-sectional area of the electrode increases, the Lorentz force is exerted in the same direction as the current flow. Decreasing the cross-sectional area of the electrode causes the Lorentz force to act in the reverse direction to the current flow. The Lorentz force can act in two ways to detach droplets from the electrode tip to the weld pool. First, if the electrode is positive and the size of the droplet is larger than the diameter of the wire electrode, the magnetic force separates the drop. Second, there is a constriction or necking down. In this case, the magnetic force acts in both directions away from the point of the constriction (Robert and Messler 2004).

Arc types

Following the first classification of arc types in 1976 (Lancaster 1984), several further classifications have been proposed. Short arc, globular arc, and spray arc are the three major classifications of arc types by the American Welding Society (AWS) (Iordachescu and Quintino 2008). The International Institute of Welding (IIW), in 1984, divided spray arc types into the three categories: (i) drop spray or projected spray, (ii) rotating spray, and (iii) streaming spray (Iordachescu and Quintino 2008; Lancaster 1986). Norrish (2003) and then Ponomarev et al. (2003) modified this categorization. Utilization of digital control of power sources has led to many improvements in arc control, especially in welding with short and pulsed arcs. Digital control increases the reaction speed of the power source inverter and the use of sophisticated software makes it possible to directly influence the arc (Weman 2003; Iordachescu and Quintino 2008).

Table 1 summarizes the attempt to classify metal transfer. Utilization of digital control of power sources has led to many improvements in arc control, especially in welding with short and pulsed arcs. Digital control increases the reaction speed of the power source inverter and the use of sophisticated software makes it possible to directly influence the arc (Weman 2003; Iordachescu and Quintino 2008). The current IIW arc classification is shown in Table 2. The table also includes an example welding process and the dominant force for each type of transfer mode (Iordachescu and Quintino 2008; Robert and Messler 2004).

Different factors have motivated efforts to classify arc and metal transfer, among them, a need for better understanding of the process to be able to examine and control it better. Better classification has allowed distinction of the arc based on droplet transfer. Thus, depending on the arc stability, desirable (e.g. bridging, spray) or undesirable (e.g. repelled, explosive) metal transfer can occur.

In bridging transfer, the molten metal grows until it touches the weld pool. A short circuit occurs and current rises; thus, the constriction and the breaking detach the droplet. In flight transfer, no contact exists between the electrode wire and the weld pool (Li and Zhang 2007). If the size of drops detached from the electrode to the molten weld pool is smaller than the diameter of the electrode wire, the arc mode is projected spray. If the molten metal from the electrode rotates, it is called rotating spray arc. Projected spray is mostly called spray arc to simplify the terminology (Robert and Messler 2004). Characteristics that are generally typical of a projected spray arc are steady detachment, low spatter, constant size of the droplet, and direct droplet transfer. Therefore, this mode of arc is preferred in conventional GMAW (Li and Zhang 2007).

Arc modes are related to arc voltage and the level of current. By changing these two parameters, the modes of the arc can be changed. With small current, the droplet does not form until it touches the weld pool; this mode of arc is a so-called short arc. The arc mode changes to a globular arc when the current is increased so that a small electromagnetic force is generated (Wang et al. 2004). In a globular arc, the diameter of the droplet is bigger than the electrode and the droplet is formed by the gravitational force. By further increasing the current, the type of arc changes to a projected spray arc, then a streaming arc, and finally a rotating arc (Li and Zhang 2007). The different types of arcs can be shown in diagrams of arc voltage and current.

As an illustration of the influence of current, voltage, and shielding gas composition, Iordachescu and Quintino in an IIW meeting in 2003 classified arc types on the basis of ‘natural transfer modes’. Today, however, due to the use of more developed controllers, natural transfer modes are no longer used as often (Iordachescu and Quintino 2008). Figure 8 from Ponomarev's study shows arc type as a function of current, voltage, and shielding gas (Ponomarev et al. 2003).

IIW classification of metal transfer depicted in an arc voltage and welding current diagram (Ponomarev et al. 2003 ).

The transition current has been an important topic in the type of arc in GMA welding. It sets the limit between globular and spray arc and determines the working conditions of the welding process, as suggested by Ponomarev et al. (2003) in Figure 8. According to Iordachescu and Quintino (2008), there could be a second transition current between short arc and globular arc, as illustrated in Figure 9. The aim of the suggestion is to cover both normal spray and projected spray.

Fundamental transfer modes. U (I) diagram based on the classification by Iordachescu and Quintino (2008).

In addition to a second transition current line, the study by Iordachescu and Quintino (2008) suggested a new transfer mode classification of the arc in GMAW as a function of the current, voltage, and shielding gas: short circuiting, globular drop, globular repelled, drop spray, streaming, and rotating transfer modes. Figure 9 illustrates this classification of arcs in GMAW (Iordachescu and Quintino 2008). The figure shows the controlled, fundamental, and transfer modes in the same diagram, and each part is separated by transition current zones. The first transition current separates the controlled and fundamental modes, and the second transition current separates the spray and globular fundamental group areas. In addition, the mode of arc changes with increasing welding current and arc voltage. The figure shows that the electric current in short arc transfer is lower than in other types of arcs and that rotating transfer needs a high current.

Table 3 shows an arc type transfer mode from the DIN standards classification in GMA welding (Iordachescu and Quintino 2008). Droplet size and metal transfer mode are also named for each type of arc. Knowing the type of arc and the related transfer mode is mitigated if their related application is ignored. The importance of their corresponding applications rises with the development of new heat-sensitive metal (Matusiak and Pfeifer 2011).

Comparison of different arc types: benefits and weaknesses

A comparison of the types of welding arc is given in this section. The welding arc list consists of natural and controlled types. Table 4 presents a comparative table of key properties of the arc types. Depending on the arc type and arc properties, the table indicates the performance in the industrial application. It can be observed that traditional control arc exhibit weaker arc stability and consequently low performance in term of weld quality. In addition, the operation is not possible in all position except for short arc. The controlled arc exhibits higher deposition rate and better stability. As a consequence of the stability increases, the productivity is greater. The cost saving is the highest, but the equipment are a little more expensive. The level of spatter generated is higher with uncontrolled globular arc; however, the control short arc can achieve virtually free spatter welding. The heat input is minimized with controlled short arc, but higher deposition rate arc requires sufficient heat input. The control focuses on limiting unexpected short circuiting arc, the operation is stable, and the saving cost is significantly improves. Weakness of globular arc can be successfully reduced by buried arc control, the penetration is greater, and spatter is suppressed. Pulse control is the most stable arc with the higher range of current; therefore, a thicker section can be welded and wider range of metal.

Applications of different arc types

A proper selection of an arc type can reduce the risk of weld flaws and improve productivity. In this section, arc type applications are discussed. The discussion starts with natural arc, then followed by controlled arc. The discussion is based on the comparative feature from Table 4 regarding their application, and Table 5 presents the arc type and their applications.

Short arc

A short arc is suited to applications that require low heat input, and it allows the joining of thin materials and sheet metals in any position. It is a good choice when distortion of the construction needs to be minimized. It is suitable for grooved welds as the root pass or for filling the gaps of joints, as well as for the root pass of open groove joints and plate groove welds. The short arc mode is widely used in the pipe industry and very applicable to root pass welds in pipes. It can be utilized with carbon steel with 100% carbon dioxide shielding gas or a blend of a maximum of 25% CO2 and a balance of argon. The short arc mode is also applicable to low carbon steel, low alloy steel, and stainless steel with thicknesses between 0.5 and 2.6 mm. However, it is unable to perform welding of aluminium (Deruntz 2003). Although, conventional short arc is used in many applications, its use is limited by high potential excessive spatter generation, fume generation, lack of fusion, lower gap bridgability, and arc instability (Hermans and Ouden 1999; Jenkins et al. 2005). The poor performance of conventional short arc results from the limited ability of the power source to control every sequence of the short circuiting metal transfer mode (Lyttle and Praxair 1990; Althouse et al. 2004; Laren 2004; Goecke 2005a, b; Jeffus and Bower 2010). As a consequence of this limitation, conventional short arc is being progressively replaced by controlled short arc in root-pass sheet metal welding.

Globular arc

The globular arc mode has few applications due to its many deficiencies. Because of the size of the drop (bigger than the electrode diameter), it may unexpectedly touch the weld pool and cause a short circuit. The arc root is highly mobile, so the arc forces tend to move the droplet in an irregular manner, which causes a high level of spatter and weld instability. In addition, the molten metal is not accelerated towards the weld pool, leading to a shallow and broad weld bead. The large droplets are detached at low frequencies (<10 Hz) resulting in low productivity. Consequently, global arc mode is limited to low-quality welded joints welded in a flat welding position or vertical down position (Kou 2003; Xu and Wu 2007). The most suitable application for a globular arc is welding of thin materials at a very low current range. Although it can also be used with a higher current, this is not efficient. It is suitable for GMAW on steel (Althouse et al. 2004; Jeffus and Bower 2010).

Spray arc

Spray arc is required for thicker section than short arc. It is very suitable when a high deposition rate is needed and when deep penetration is required for welding of massive base materials that can tolerate high heat input. The large weld pool makes vertical or overhead position welding difficult, especially in the case of plain carbon steel and stainless steels. For joining steels, the transition current can be varied more than when welding aluminium alloys. A spray arc can be used with almost all common alloys containing aluminium and also nickel alloys, copper alloys, stainless steels, magnesium, and carbon steels (Lyttle and Praxair 1990; Althouse et al. 2004; Robert and Messler 2004; Goecke 2005a, b; Jeffus and Bower 2010). Despite the advantages of conventional spray arc, odd arc instabilities and disordered metal transfer have restricted its adoption. In spray arc mode, the current and voltage are almost steady, which leads to random droplet size and frequency (Hutt and Lucas 1982). Therefore, high fume, spatter, and heat input are generated. As a result of insufficient control, the weld quality can be adversely affected. It should also be noted that the argon-based shielding gas used to achieve spray arc is more expensive than CO2. In view of these drawbacks, spray arc is unsuitable for aluminium, structural steel, coated steel, and high-strength steels.

Controlled short circuiting arc

These types of arc belong to the category of waveform-controlled modes. The droplet detachment during short circuiting is controlled so as to reduce spatter and fume generation and improve productivity (Stava 1993; Goecke 2005a, b; Huisman 2000). These arcs are commercially marketed under different trade market names: Cold Metal transfer (CMT): (FRONIUS International GmbH), ColdArc: (EWM Hightec Welding GmbH), Surface Tension Transfer (STT): (Lincoln Electric), Cold Process (CP): (CLOOS), FastRoot (KEMPPI), Regulated Metal Deposition (RMD): (Miller Electric Mfg), etc. Pépe et al. (2011) investigated the efficiency of controlled GMAW. The results revealed for STT, fast root and CMT an efficiency of around 85%. Controlled short arc can be used in almost all welding positions, with almost all kinds of metallic materials, and with different thicknesses. Controlled short arc is applicable to joining thin sheets, joining zinc-coated and non-coated stainless steel metal sheets, and joining aluminium alloys. Welding of very thin metal sheets made of carbon steel, high alloy steel, low alloy steels, and aluminium is also possible (Deruntz 2003). Nowadays, the thicknesses of materials used in the car industry are becoming lower than 0.3 mm and the GMAW process with short arc is no longer suitable. Further applications of controlled short arc are GMAW robot welding and brazing for ultra-light gauge sheets in both manual and automatic modes in any position. Dissimilar materials can be welded, such as aluminium and steel, steel and magnesium, and also magnesium alloys (Rosado et al. 2008; Srinivasan and Balasubramanian 2011; Matusiak and Pfeifer 2011). Although the control of short arc gives more flexibility of applications, it requires advanced power source and sometimes special designed torches.

Controlled globular arc

In this mode, the arc is used at the range of the globular arc current but with short arc length. This enables the arc to work under the weld pool surface (a so-called ‘buried arc’) and take advantage of the arc pressure of the shielded CO2 to trap spatter. According to Nishiguchi et al. (1975), the buried arc welding technique is capable of achieving higher welding speeds and filler metal deposition rates than a globular arc. Weld speed can reach 2,540 mm/min and clean-up is minimal (Lienert et al. 2011). Stol et al. (2006) studied the use of buried arc GMAW for seam welds. The buried arc approach has great potential for use in the automotive, railroad, and marine industries for welding subassemblies. An example application is welding of edges and sides of aluminium parts as an alternative to GMAW. Controlled globular arc mode can be used for fillet or seam welds in lap or T-joints and square groove butt joints. It is suitable for the mechanized welding of thin section material at high speeds and can be used in fully mechanized or automatic gas metal arc welding. It is also used in the welding of pipe cylinders. A buried arc can be used in car applications in butt welding for the body and semi-automatic welding for the frame and body (Kielhorn et al. 2001; Aoki et al. 2003; Kah et al. 2013).

Controlled spray arc

In order to control heat input and reduce spatter generation and fumes, power sources have been developed with the ability to release one drop for a sequence of arc and pulsed time. The arc uses direct current (e.g. pulsed GMAW) or alternative current (e.g. AC-GMAW) with different current waveforms. A pulsed arc can be used in all welding positions and with all base material thicknesses in both manual and automatic welding systems. Out of position welding is also possible due to the lower than average current level. Because of the low heat input, this mode is suitable for filling gaps. It is widely used in the GMAW of aluminium (Kah et al. 2012). The method is suitable for welding all standard and high performance grades of stainless steel when nickel base or stainless steel filler metals are used. High alloy steels can also be welded by pulsed arc. Super austenitic stainless steel exhibits better mechanical and metallurgical properties with optimized parameters in GMA welding compare to conventional spray (Sathiya et al. 2012). Pulsed arc welding has applications in the shipbuilding industry, for example, out of position welding of high strength low alloy base materials in ship hull fabrication. The advantages of pulsed arc in shipbuilding are that its electrode efficiency is higher compared to flux-core arc welding (FCAW), and it can deliver lower hydrogen weld deposits (Lyttle and Praxair 1990; Knopp and Lorenz 2002; Althouse et al. 2004; Laren 2004; Ueyama et al. 2005; Lebedev 2010; Torbati et al. 2011; Kah et al. 2013).

Higher-power arc

Stream and rotating metal transfer occur at higher power ranges. The rotation of the molten metal is the result of longer electrode stick out (25 to 35 mm) and higher current and voltage, which cause stream metal to deflect out of its symmetry axis and start to rotate under magnetic forces. Although butt welding is the most typical application of rotating arc mode welding, a rotating arc can also be used in narrow gap welding. Heavy thick plates can be welded using this method. Due to the flexibility, efficiency, and productivity of this mode, it can be used in the manufacturing of large and heavy structural parts (Church and Imaizumi 1990). Although the process is reported by Church and Imaizumi (1990) as requiring quaternary shielding (He-Ni-CO2 and O2), which allows very limited tolerance, Suban and Tusek (2003) indicated that a binary shielding gas (argon and CO2) could produce satisfactory results with optimized welding parameters. Full exploitation of its potential is in completely mechanized procedures (Masseti 2010). Large-scale bridge parts, heavy machinery, shipbuilding, and heavy cylindrical structures are some examples of its applications. A new development of the rotating arc, rotation that is not due to the magnetic effect but to special small rotating torches, makes it possible to apply a rotating arc mode to fillet welding in shipbuilding, bridges, etc. The mode is also suitable for low carbon steel plates (Iwata et al. 2009a, b; Yang et al. 2009; Christensen et al. 2005).

Conclusions

The study reviewed and collated information related to the welding arc. Heat flux, current density, shear stress, and arc pressure are four major factors that should be considered when ascertaining the influence of arc plasma on the weld pool. From the study, the following insights are of importance:

Only 20% of the heat is carried by conduction from hot gases, and 80% remains with the electric current in the weld pool. The range of the arc temperature varies between 5,000 and 30,000 K, depending on the precise nature of the plasma and the amount of current flowing through it. Arc current and arc voltage are the two most important factors determining the arc characteristics affecting the weld quality.

AWS has classified welding arcs into three main categories: short, globular, and spray arcs. Other variations of arcs mentioned in this study are pulsed, cold, rotating, buried, and rapid arcs. A stable arc has three main features: a constant shape of droplets, constant length of arc, and low amount of spatter.

When welding with a short arc, there can be a lack of fusion and the deposition rate is low. Consequently, the main applications of this mode are limited to carbon steel, low carbon steel, low alloy steel, and stainless steel with a thickness of 0.5 to 2.6 mm.

Spray arc is limited to flat and horizontal welding positions, but almost all materials can be welded using this mode. Globular arc is rarely used in industry because it produces a high level of spatter.

Control of the arc has significantly improved the control of heat input, spatter, and fume generation. Pulsed arc, has demonstrated 75% undercutting, a 10% to 30% reduction of the cycle time due to higher welding speed, and an ability to weld metals such as aluminium and high-strength steel. New variants of pulsed arc, such as double pulsed and variable polarity pulsed arc, enable melting efficiency control and bridge ability.

Controlled short arc is applicable for thinner cross sections and is less harmful to zinc coated metal. It has been found to provide 85% arc efficiency. The arc is more stable, is virtually spatter free, and generates fewer fumes than conventional short arc.

In future research aimed at improving understanding of arc phenomena, the distributions of velocity, pressure, temperature, current density, and the magnetic field of plasma arcs could be calculated using computational fluid dynamics (CFD). Improved two- or three-dimensional modelling of different types of welding arc would enhance understanding of welding results. Furthermore, predictability of the effects of different arcs on different materials and applications would be improved.

References

Althouse, AD, Turnquist, CH, Bowditch, WA, Bowditch, KE, & Bowditch, MA. (2004). Modern welding. Tinley Park: Goodheart-Willcox Co.

Aoki, S, Kaiden, T, Kavagwa, Y, Nagashima, T, Fujimoto, T, & Hosaka, S. (2003). New leading car Mc5 for Yamanashi Maglec test line – Aiming to reduce the impact on environment. Mitsubishi Heavy Ind Ltd, 40(3), 1–9.

Bolmsjo, G, Olsson, M, & Cederberg, P. (2001). Robotic arc welding - Trends and developments for higher autonomy. Lund: Lund University.

Chen, S, & Wu, J. (2009). Intelligentized methodology for arc welding dynamical process. Berlin: Springer.

Christensen, KH, Sorensen, T, & Kristensen, JK. (2005). Gas metal arc welding of butt joint with varying gap width based on neural networks. Science and Technology of Welding and Joining, 10(1), 33–43.

Church, G, & Imaizumi, H. (1990). Welding characteristics of a new welding process (T.I.M.E process. Doc. IIW com. XII-1199-90). Villepinte, France: International Institute of Welding.

Cobine, LD, & Burger, EE. (1955). Analysis of electrode phenomena in the high-current arc. Journal of Applied Physics, 26, 895.

Costa, MCMDS, Starling, CMD, & Modenesi, PJ. (2010). Characterization of GMAW arc instability phenomena related to low oxidation potential shielding gases. Welding International, 24(3), 181–189.

DeRuntz, BD. (2003). Assessing the benefits of surface tension transfer welding to industry. Journal of Industrial Technology, National Association of Industrial Technology, 19(1), 1–8.

Dupont, JN, & Marder, AR. (1995). Thermal efficiency of arc welding processes. Welding Journal, 74(12), 406s–416s.

Dzelnitzki, D. (2000). Increasing the deposition volume or the welding speed? - Advantages of heavy-duty MAG welding. Muendersbach: EWM Hightec Welding.

Eagar, TW. (1990a). An iconoclast's view of the physics of welding-rethinking old ideas. In SA David & JM Vitek (Eds.), Recent trends in welding science and technology (pp. 341–346). Materials Park: ASM International.

Eagar, TW. (1990b). The physics of arc welding processes. In TH North (Ed.), Advanced joining technologies. London: Chapman and Hall.

Gerbec, D. (2009). Minimizing defects in submerged arc welding. Welding Journal, 88(9), 78–79.

Ghosh, PK, Dhiman, HK, & Kumar, M. (2006). Thermal and metal transfer behaviors in pulsed current gas metal arc welding deposition of Al-Mg alloy. Science and Technology of Welding and Joining, 11, 232–242.

Goecke, SF. (2005a). Energiereduziertes Lichtbogen-Fuegeverfahren fuer Waermeempfindliche Werkstoffe (Reduced energy laser process for heat-sensitive materials). DVS-Berichte, 237, 44–48.

Goecke, SF. (2005b). Low energy arc joining process for materials sensitive to heat. Mundersbach: EWM Hightec Welding.

Gunaraj, V, & Murugan, N. (2002). Prediction of heat-affected zone characteristics in submerged arc welding of structural steel pipes. Welding Journal, 81(7), 94s–98s.

Hermans, MJM, & Ouden, GD. (1999). Process behavior and stability in short circuit gas metal arc welding. Welding Research Supplement, 78, 1372–141s.

Hu, J, & Tsai, HL. (2006). Effects of current on droplet generation and arc plasma in gas metal arc welding. Journal of Applied Physics, American Institute of Physics, 100(053304), 1–12.

Huisman, G. (2000). Direct control of material transfer: The controlled short circuiting (CSC) MIG process, Proc. Gas Metal Arc Welding for the 21th century. Orlando: American Welding Society.

Hutt, GA, & Lucas, W. (1982). Arc disturbances in consumable electrode welding - a review of literature (Welding Institute Research Report, 173/1982). Cambridge, UK: The Welding Institute. www.twi-glbal.com

Ibrahim Khan, M. (2007). Welding science and technology. New Delhi: New Age International Publishers.

Iordachescu, D, & Quintino, L. (2008). Steps toward a new classification of metal transfer in gas metal arc welding. Journal of Materials Processing Technology, 202, 391–397.

Iwata, S, Murayama, M, & Kojima, Y. (2009a). Application of narrow gap welding process with high speed rotating arc to box column joints of heavy thick plates. Jef Technical Report, 14(14), 16–21.

Iwata, S, Nishi, Y, & Ozamoto, D. (2009b). Practical system to monitor and control the penetration depth of welding by submerged arc welding (SAW) with multiple electrodes (JFE Technical Report No.14, pp. 22–25).

Izutani, S, Shimizu, H, Suzuki, K, & Koshiishi, F. (2006). Observation and classification of droplet transfer in gas metal arc welding (IIW Doc. 212-1090-06). Villepinte, France: International Institute of Welding.

Jeffus, L, & Bower, L. (2010). Welding skills, processes and practices for entry-level welders. Connecticut, USA: Cengage Learning.

Jenkins, NT, Pierce, WMG, & Eagar, TW. (2005). Particle size distribution of gas metal and flux cored arc welding fumes. Welding Journal, 84, 156s–63s.

Kah, P, Jibril, A, Martikainen, J, & Suoranta, R. (2012). Process possibility of welding thin aluminium alloys. International Journal of Mechanical and Materials Engineering, 7(3), 232–242.

Kah, P, Martikainen, J, Jernstrom, P, & Uusitalo, J. (2009). Influence of joint geometry and fit-up gaps on quality of corner joints in new modified short arc GMAW. International Scientific-Technical and Production Journal, The Paton Welding Journal, 5, 27–33.

Kah, P, Mvola, B, Suoranta, R, & Martikainen, J. (2013). Modified GMAW processes: Control of heat input. Advanced Science Letters, 19(3), 710–718.

Kang, MJ, Kim, Y, Ahn, S, & Rhee, S. (2003). Spatter rate estimation in the short-circuit transfer region of GMAW. Welding Journal, 82, 188s–196s.

Kasikci, I. (2003). Effect of gap distance on the mechanical properties and cross-sectional characteristics of the MIG-MAG butt welds. Ankara: The Middle East Technical University.

Kielhorn, WH, Adonyi, Y, Holdren, RL, Horrocks, RC, & Nissley, NE. (2001). Survey of joining, cutting, and allied processes (9th ed.). New York: AWS.

Knopp, N, & Lorenz, H. (2002). MIG welding of aluminum materials made easy. Solingen: EWM Hightec Welding GmbH.

Kou, S. (1987). Welding metallurgy. New York: Wiley.

Kou, S. (2003). Welding metallurgy (2nd ed.). New Jersey: Wiley.

Lancaster, J. (1984). The physics of welding. New York: International Institute of Welding.

Lancaster, JF. (1986). The physics of welding (2nd ed.). Oxford: International Institute of Welding.

Laren, M. (2004). The Avesta welding manual: Practice and products for stainless steel welding. Sweden: Avesta Welding AB.

Lebedev, VA. (2010). Tendencies in development of mechanized welding with controlled transfer of electrode metal (review). International Science and Technology and Production Journal, 10, 37–44.

Li, K, & Zhang, Y. (2007). Metal transfer in double-electrode gas metal arc welding. Manufacturing Science and Engineering, 129(6), 991–999.

Lienert, T, Siewert, T, Babu, S, & Acoff, V. (2011). ASM handbook vol. 6A: welding fundamentals and processes. Ohio: ASM International.

Lin, ML, & Eagar, TW. (1985). Influence of arc pressure on weld pool geometry. Welding Journal, 64(6), 163s–169s.

Lu, Q, Yu, Z, Xu, G, & He, J. (2009). Research on narrow gap welding parameters optimization. In International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, Hunan, April.

Lucas, W, Iordachescu, D, & Ponomarev, V. (2005). Classification of metal transfer modes in GMAW, IIW Doc. XII-1859-05. Villepinte, France: International Institute of Welding.

Luksa, K. (2006). Influence of weld on short circuit GMA welding arc stability. Journal of Materials Processing Technology, 175, 285–290.

Lyttle, KA, & Praxair, I. (1990). ASM handbook, vol. 6. Ohio: ASM International.

Masseti, F. (2010). New welding techniques for suspension bridges. Welding International, 18(10), 785–797.

Matusiak, J, & Pfeifer, T. (2011). Low-energy arc welding with gas shielding – the effect of material and technological conditions on joint quality and the emission of impurities in the workplace. Welding International, 25(1), 24–31.

Min, D, Xin-hua, T, Feng-gui, L, & Shun, Y. (2011). Welding of quenched and tempered steels with high-spin arc narrow gap MAG system. Int J Adv Manuf Technol, Springer Science, 55(5-8), 527–533.

Moon, H-S, Kim, YB, & Beattie, RJ. (2006). Multi sensor data fusion for improving performance and reliability of fully automatic welding system. International Journal of Advanced Manufacturing Technology, 28, 286–293.

Murphy, AB, Tanaka, M, Yamamoto, K, Tashiro, S, & Lowke, JJ. (2009). CFD modelling of arc welding: The importance of the arc plasma. In Seventh International Conference on CFD in the Minerals and Process Industries, Melbourne, December.

Nadzam, J. (2006). GMAW welding guide. Ohio, USA: Lincoln Electric.

Naidu, DS, Ozcelik, S, & Moore, K. (2003). Modeling, sensing and control of gas metal arc welding (1st ed.). UK: Elsevier.

Nishiguchi, K, Matsuyama, K, Terai, K, & Ikeda, K. (1975). Bead formation in high speed gas shielded metal arc welding (Proc. 2nd Int. Symp. of the Japan Welding Soc. on Advanced Welding Technology). Osaka: Japan Welding Society. Paper 2-2-(10).

Norrish, J. (2003). A review of metal transfer classification in arc welding (IIW DOC. XII-1769-03. Bucharest). Villepinte, France: International Institute of Welding.

Pal, K, Bhattacharya, S, & Pal, SK. (2010). Investigation on arc sound and metal transfer modes for on-line monitoring in pulsed gas metal arc welding. Journal of Materials Processing Technology, 210, 1397–1410.

Pépe, N, Egerland, S, Colegrove, AP, Yapp, D, Leonhartsberger, A, & Scotti, A. (2011). Measuring the process efficiency of controlled gas metal arc welding processes. Science and Technology of Welding & Joining, 16(5), 412–417.

Pires, I, Quintino, L, & Miranda, RM. (2007). Analysis of the influence of shielding gas mixture on the gas metal arc metal transfer modes and fume formation rate. Material and Design, 28, 1623–1631.

Ponomarev, V, Scotti, A, Silvinskiy, A, & Al-Erhayem, O. (2003). Atlas of MIG/MAG welding metal transfer modes (IIW Doc. XII-1771 to 1775–03. Bucharest). Villepinte, France: International Institute of Welding.

Quigley, MBC, Richards, PH, Swift- Hook, DT, & Gick, AEF. (1973). Heat flow to the workpiece from a TIG welding arc. Journal of Physics D: Applied Physics, 6, 2250.

Robert, W, & Messler, J. (2004). Principle of welding. Singapore: Wiley-VCH Verlag GmbH & Co.

Rosado, T, Almeida, P, Pires, I, Miranda, R, & Quintino, L. (2008). Innovation in arc welding. 5° Congresso Luso-Moçambicano de Engenharia, Maputo, September. Portugal: INEGI, Leça do Balio.

Sathiya, P, Sudhakaran, A, & Soundararajan, R. (2012). Mechanical and metallurgical investigation on gas metal arc welding of super austenitic stainless steel. International Journal of Mechanical and Materials Engineering, 7(1), 107–112.

Saunders, HL. (1997). Welding aluminum: Theory and practice. USA: American Society for Metals.

Scotti, A, Ponomarev, V, & Lucas, W. (2012). A scientific application oriented classification for metal transfer modes in GMA welding. Journal of Materials Processing Technology, 212(6), 1406–1413.

Shoeb, M, Parvez, M, & Kumari, P. (2013). Effect of MIG welding input process parameters on weld bead geometry on HSLA steel. International Journal of Engeneering Science and Technology., 5(1), 200–212.

Smårs, E, & Acinger, K. (1968). Material transport and temperature distribution in arc melting. IIW-Document 212-168-68, International Institute of Welding Study Group SG212, Physics of Welding. Villepinte, France: International Institute of Welding.

Srinivasan, K, & Balasubramanian, V. (2011). Effect of surface tension metal transfer on fume formation rate during flux-cored arc welding of HSLA steel. The International Journal of Advanced Manufacturing Technology, 56(1–4), 125–134.

Stava, EK. (1993). The surface-tension-transfer power source: a new low-spatter arc welding machine. Welding Journal, 72(1), 25–29.

Stol, I, Williams, KL, & Gaydos, DW. (2006). Using a buried gas metal arc for seam welds. American Welding Society, 85, 28–33.

Suban, M, & Tusek, J. (2003). Methods for the determination of arc stability. Journal of Materials Processing Technology, 143–144, 430–437.

Suzuki, R. (2012). State of art of process control of molten droplet and pool in gas metal arc welding. Welding International, 79(6), 569–575.

Torbati, AM, Miranda, RM, Quintino, L, Williams, S, & Yapp, D. (2011). Optimization procedures for GMAW of bimetal pipes. Journal of Materials Processing Technology, 211(6), 1112–1116.

Ueyama, T, Tong, H, Harada, S, Passmore, R, & Ushio, M. (2005). AC pulsed GMAW improves sheet metal joining. Welding Journal, 84(2), 40–46.

Wang, G, Huang, PG, & Zhang, YM. (2004). Numerical analysis of metal transfer in gas metal arc welding under modified pulsed current conditions. Metallurgical and Materials Transactions B, 35B, 857–866.

Wang, Y, & Tsai, HL. (2001). Impingement of filler droplets and weld pool dynamics during gas metal arc welding process. International Journal of Heat and Mass Transfer, 44, 2067–2080.

Weman, K. (2003). Welding Process Handbook. Cambridge: Woodhead Publishing Ltd.

Xu, G, & Wu, C. (2007). Numerical analysis of weld pool geometry in globular-transfer gas metal arc welding. Frontiers of Materials Science in China, 1(1), 24–29.

Yang, CL, Guo, N, Lin, SB, Fan, CL, & Zhang, YQ. (2009). Application of rotating arc system to horizontal narrow gap welding. Science and Technology of Welding and Joining, Institute of Materials, Minerals and Mining, 14(2), 172–177.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

The main authors PK and HL have prepared the paper and the other authors RS, JM, MP have checked and provided significant suggestions to improve the paper. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kah, P., Latifi, H., Suoranta, R. et al. Usability of arc types in industrial welding. Int J Mech Mater Eng 9, 15 (2014). https://doi.org/10.1186/s40712-014-0015-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40712-014-0015-6