Abstract

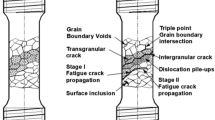

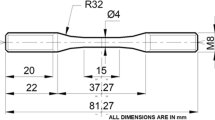

Corrosion fatigue crack growth (CFCG) behavior of type 316LN stainless steel (SS) and its weldments are studied in acidified 5M NaCl + 0.15M Na2SO4 + 2.5 ml/l HCl medium under open circuit condition at a stress ratio (R) of 0.5 (R = ΔKmin/ΔKmax) and at a frequency (η) of 0.1 Hz for different stress intensity factor range (ΔK). At a value of ΔK corresponding to stress intensity factor for stress corrosion cracking (KISCC = 27.5 MPa.m0.5), the Paris region deviates from linearity as the crack growth/cycle increases dramatically for the base and weld metal indicating Type B behavior of an environmentally assisted cracking process. CFCG rate is compared with fatigue crack growth (FCG) rate at room temperature (RT) and at 450°C (HT). Type 316N weld metal (WM) showed lower threshold (ΔKth) values and higher crack growth rates (CGRs) than type 316LN SS. Cracking initiated in the transgranular (TG) mode for both the metallurgical conditions. Besides TG cracking of the austenite, dissolution of delta-ferrite (δ-Fe) was observed in the weld metal.

Similar content being viewed by others

References

K.S. Kang, Heavy Components Replacement in Nuclear Power Plants: Guidelines and Experiences, Press. Vessels Pip. Conf., 2010, 49262, p 229–235.

J.W. Simmons, Overview: High-Nitrogen Alloying of Stainless Steels, Mater. Sci. Eng., 1996, 207, p 159–169.

D. Du, J. Wang, K. Chen, L. Zhang and P.L. Andresen, Environmentally Assisted Cracking of Forged 316LN Stainless Steel and Its Weld in High Temperature Water, Corros. Sci., 2019, 147, p 69–80.

Z. Zhang, J. Tan, X. Wu, E.H. Han, W. Ke and J. Rao, Effects of Temperature on Corrosion Fatigue Behavior of 316LN Stainless Steel in High-Temperature Pressurized Water, Corros. Sci., 2019, 146, p 80–89.

M.O. Speidel and R.M. Pedrazzoli, High nitrogen stainless steels in chloride solutions, Mater. Perfm., 1992, 31(9), p 59–61.

R.F.A. Jargelius-Pettersson, Electrochemical Investigation of the Influence of Nitrogen Alloying on Pitting Corrosion of Austenitic Stainless Steels, Corros. Sci., 1999, 41, p 1639–1664.

A. Poonguzhali, M.G. Pujar and U.K. Mudali, Effect of Nitrogen and Sensitization on the Microstructure and Pitting Corrosion Behavior of AISI type 316LN Stainless Steels, J Mater. Eng. Perform., 2013, 22, p 1170–1178.

A.S. Vanini, J.P. Audouard and P. Marcus, The Role of Nitrogen in the Passivity of Austenitic Stainless Steels, Corros. Sci., 1994, 36, p 1825–1834.

R.D. Willenbruch, C.R. Clayton, M. Oversluizen, D. Kim and Y. Lu, An XPS and Electrochemical Study of the Influence of Molybdenum and Nitrogen on the Passivity of Austenitic Stainless Steel, Corros. Sci., 1990, 31, p 179–190.

H. Ha and H. Kwon, Effects of Cr2N on the Pitting Corrosion of High Nitrogen Stainless Steels, Electrochim. Acta., 2007, 52, p 2175–2180.

D. Féron, Nuclear Corrosion Science and Engineering, Woodhead Publishing, Philadelphia, 2012.

T.R. Allen and J.T. Busby, Radiation Damage Concerns for Extended Light Water Reactor Service, Jom., 2009, 61, p 29–34.

A.F. Liu, Mechanics and Mechanisms of Fracture: An Introduction, ASM International, USA, 2005.

P. Paris and F. Erdogan, A Critical Analysis of Crack Propagation Laws, J. Basic. Eng., 1963, 85, p 528–534.

P.C. Paris, A Rational Analytic Theory of Fatigue, The trend in Eng., 1961, 13, p 9–14.

A. Poonguzhali, S. Ningshen and G. Amarendra, Corrosion Fatigue Crack Initiation of Type 316N Weldment Under the Influence of Cyclic Stress Amplitude, Met. Mater. Int., 2020, 26, p 1545–1554.

H. Shaikh, A. Poonguzhali, N. Sivaibharasi, R.K. Dayal and H.S. Khatak, Corrosion Fatigue of AISI Type 316LN Stainless Steel and its Weld Metal, Corros., 2009, 65, p 37–48.

Test Method for Evaluating Stress corrosion cracking resistance of metals and alloys in a boiling magnesium chloride solution. G 36-94(2006), Annual Book of ASTM Standards, 2018, p 1-29.

Test Method for Linear-Elastic Plane-Strain Fracture Toughness KIc of Metallic Materials. E 399, Annual Book of ASTM Standards, ASTM, 1997, p 413-443.

Test Method for Measurement of Fatigue Crack Growth Rates. E 647, Annual Book of ASTM Standards, 2015, p 1-49.

S.J. Hudak Jr., Small Crack Behavior and the Prediction of Fatigue Life, J Eng. Mater. Technol. Trans., 1981, 103, p 26–35.

R.O. Ritchie and S. Suresh, Some Considerations on Fatigue Crack Closure at Near-Threshold Stress Intensities due to Fracture Surface Morphology, Metall. Trans. A, 1982, 13, p 937–940.

S. Suresh, Fatigue of Materials, Cambridge University Press, Cambridge, 1998.

J. Petit, C and Sarrazin-Baudoux, Some Critical Aspects of Low Rate Fatigue Crack Propagation in Metallic Materials, Int. J. Fatigue., 2010, 32, p 962–970.

M.N. Babu and G. Sasikala, Effect of Temperature on the Fatigue Crack Growth Behaviour of SS316L (N), Int. J. Fatig., 2020, 140, p 105815. https://doi.org/10.1016/j.ijfatigue.2020.105815

K.G. Samuel, G. Sasikala and S.K. Ray, On R Ratio Dependence of Threshold Stress Intensity Factor Range for Fatigue Crack Growth in Type 316 (N) Stainless Steel Weld, Mater. Sci. Technol., 2011, 27, p 371–376.

H. Shaikh, T. Anita, R.K. Dayal and H.S. Khatak, Effect of Metallurgical Variables on the Stress Corrosion Crack Growth Behaviour of AISI Type 316LN Stainless Steel, Corros. Sci., 2010, 52, p 1146–1154.

H.R. Baker, M.C. Bloom, R.N. Bolster and C.R. Singleterry, Film and pH Effects in the Stress Corrosion Cracking of Type 304 Stainless Steel, Corros., 1970, 26, p 420–426.

F. Menan and G. Henaff, Synergistic Action of Fatigue and Corrosion During Crack Growth in the 2024 Aluminium Alloy, Proc. Eng., 2010, 2, p 1441–1450.

K.S. Chan, Roles of Microstructure in Fatigue Crack Initiation, Int. J. Fatigue., 2010, 32, p 1428–1447.

L. Tang, C. Qian, A. Ince, J. Zheng, H. Li and Z. Han, Fatigue Crack Growth Behavior of the MIG Welded Joint of 06Cr19Ni10 Stainless Steel, Materials, 2018, 11, p 1336. https://doi.org/10.3390/ma11081336

J. Petit, G. Henaff and C. Sarrazin-Baudoux, Environmentally Assisted Fatigue in the Gaseous Atmosphere, Compr. Struct. Integr., 2003, 6, p 211–280.

V.D. Vijayanand, K. Laha, P. Parameswaran, V. Ganesan and M.D. Mathew, Microstructural evolution during creep of 316LN stainless steel multi-pass weld joints, Mater. Sci. Eng. A, 2014, 607, p 138–144.

C.K. Lin and I.L. Lan, Fatigue Behavior of AISI 347 Stainless Steel in Various Environments, J. Mater. Sci., 2004, 39, p 6901–6908.

R.P. Wei and G. Shim, Fracture mechanics and corrosion fatigue, Corrosion Fatigue: Mechanics, Metallurgy, Electrochemistry, and Engineering. T.W. Crooker, B.N. Leis Ed., . ASTM STP 801. Philadelphia, 1983, p 5–25

K. Makhlouf and J.W. Jones, Effects of Temperature and Frequency on Fatigue Crack Growth in 18% Cr Ferritic Stainless Steel, Int. J. Fatigue., 1993, 15, p 163–171.

H. Shaikh, G. George, H.S. Khatak, F. Schneider and K. Mummert, Stress Corrosion Crack Growth Studies on Nitrogen Added AISI type 316 Stainless Steel and its Weld Metal in Boiling Acidified Sodium Chloride Solution Using the Fracture Mechanics Approach, Mater. Corros., 2000, 51, p 719–727.

G. Sasikala, M. Nani Babu, B. Shashank Dutt and S. Venugopal, Characterisation of Fatigue Crack Growth and Fracture Behaviour of SS 316L (N) Base and Weld Materials, Adv. Mater. Res., 2013, 794, p 449–459.

T.P.S. Gill, U.K. Mudali, V. Seetharaman and J.B. Gnanamoorthy, Effect of Heat Input and Microstructure on Pitting Corrosion in AISI 316L Submerged Arc Welds, Corros., 1988, 44, p 511–516.

M.G. Pujar, R.K. Dayal, T.P.S. Gill and S.N. Malhotra, Evaluation of Microstructure and Electrochemical Corrosion Behavior of Austenitic 316 Stainless Steel Weld Metals with Varying Chemical Compositions, J. Mater. Eng. Perform., 2005, 14, p 327–342.

L. Dong, Q. Peng, Z. Zhang, T. Shoji, E.H. Han, W. Ke and L. Wang, Effect of Dissolved Hydrogen on Corrosion of 316NG Stainless Steel in High Temperature Water, Nucl. Eng. Des., 2015, 295, p 403–414.

K. Mukahiwa, F. Scenini, M.G. Burke, N. Platts, D.R. Tice and J.W. Stairmand, Corrosion Fatigue and Microstructural Characterisation of Type 316 Austenitic Stainless Steels Tested in PWR Primary Water, Corros. Sci., 2018, 131, p 57–70.

R. Soulas, M. Cheynet, E. Rauch, T. Neisius, L. Legras, C. Domain and Y. Brechet, TEM Investigations of the Oxide Layers Formed on a 316L Alloy in Simulated PWR Environment, J. Mater. Sci., 2013, 48, p 2861–2871.

W.A. Baeslack, W.F. Savage and D.J. Duquette, Effect of Strain Rate on Stress Corrosion Cracking in Duplex type 304 Stainless Steel Weld Metal, Metall. Trans. A., 1979, 10, p 1429–1435.

A. Poonguzhali, M.G. Pujar, C. Mallika and U. Kamachi Mudali, Characterisation of Microstructural Damage Due to Corrosion Fatigue in AISI type 316 LN Stainless Steels with Different Nitrogen Contents, Corros. Eng. Sci. Tech., 2016, 51, p 408–415.

J. Man, M. Valtr, M. Petrenec, J. Dluhoš, I. Kuběna, K. Obrtlik and J. Polak, AFM and SEM-FEG Study on Fundamental Mechanisms Leading to Fatigue Crack Initiation, Int. J. Fatig., 2015, 76, p 11–18.

Funding

This study received no any funding or NIL funded.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict in financial interests or personal relationships that could influence the work reported in this paper. The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Poonguzhali, A., Babu, M.N., Ravi, S. et al. Effect of Environment on Fatigue Crack Growth Behavior of Type 316 LN Stainless Steel and its Weldments. J. of Materi Eng and Perform 31, 3918–3929 (2022). https://doi.org/10.1007/s11665-021-06496-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06496-4