Abstract

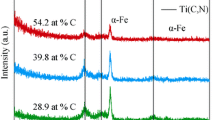

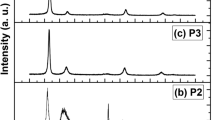

The surface treatment, which includes first a thermal diffusion process, such as nitriding and then a physical vapor deposition coating process as the working layer, is called duplex treatment in the literature. In this study, the effects of the duplex treatment on the hardness, adhesion, and wear performance of TiAlZrN coatings on the hardened AISI H13 steel produced using the closed field unbalanced magnetron sputtering method with variable Zr target current (2 A, 3 A, and 5 A) were investigated. Within the scope of these investigations, scanning electron microscope, x-ray diffracrometer, optical microscope, optical profilometer, energy-dispersive spectrometer, micro- and nano-hardness, scratch, and wear tests were used. In micro- and nano-hardness tests, it was determined that the hardness of the substrate increased significantly (approximately 400%) owing to the duplex treatment. In addition, with the increase in the Zr target current, it was observed that the hardness of the coatings was in an increasing trend. Adhesion strength increased with the enhancement of both the hardness of the substrate and the coatings. It was beheld that the adhesion strength of the coatings increased with the duplex treatment. Besides, the coating produced using the highest Zr target current reached maximum adhesion strength of 79 N in relation to superior hardness. Wear performance of the samples was determined using a ball-on-disk tribometer. As a result of wear tests, TiAlZrN coatings with duplex treatment were observed to notably improve the wear performance of the substrate material by 95 times. The effects of Zr target current on the wear performance of the coatings were similar to those of hardness and adhesion strength.

Similar content being viewed by others

References

R. Rodriguez-Baracaldo, J. Benito, E.S. Puchi-Cabrera, and M.H. Staia, High Temperature Wear Resistance of (TiAl)N PVD Coating on Untreated and Gas Nitrided AISI, H13 Steel With Different Heat Treatments, Wear, 2007, 262(3–4), p 380–389. https://doi.org/10.1016/j.wear.2006.06.010

H. Zhou, Q. Guo, and P. Lin, Influence of H13 Steel Unit on Wear Behavior of Vermicular Cast Iron, Appl. Surf. Sci., 2008, 255(5), p 3394–3399. https://doi.org/10.1016/j.apsusc.2008.09.065

G. Telasang, J. Dutta Majumdar, G. Padmanabham, and I. Manna, Wear and Corrosion Behavior of LAser Surface Engineered AISI, H13 Hot Working Tool Steel, Surf. Coat. Technol., 2015, 261, p 69–78. https://doi.org/10.1016/j.surfcoat.2014.11.058

P. Panjan, P. Cvathe, M. Cekada, B. Navinsek, and I. Urankar, PVD CrN Coating For Protection of Extrusion Dies, Vacuum, 2001, 61(2–4), p 241–244. https://doi.org/10.1016/S0042-207X(01)00113-0

K. Das, J. Alphonsa, M. Glosh, J. Ghanshyam, R. Rane, and S. Mukherjee, Influence of Pretreatment on Surface Behavior of Duplex Plasma Treated AISI, H13 Tool Steel, Surf. Interface, 2017, 8, p 206–213. https://doi.org/10.1016/j.surfin.2017.06.009

B. Gates, Road Ahead, Penguin Books, London, 1996

M. Nakai, M. Niinomi, T. Akahori, N. Ohtsu, H. Nishimura, H. Toda, H. Fukui, and M. Ogawa, Surface Hardening of Biomedical Ti-29Nb-13Ta-4.6Zr and Ti-6Al-4V ELI, by Gas Nıtriding, Mater. Sci. Eng. A, 2008, 486(1–2), p 193–201. https://doi.org/10.1016/j.msea.2007.08.065

S.R. Hosseini and A. Ahmadi, Evaluation of the Effects of Plasma Nitriding Temperature and Time on the Characterisation of Ti 6Al 4V Alloy, Vacuum, 2013, 87, p 30–39. https://doi.org/10.1016/j.vacuum.2012.06.008

J. Senatorski, J. Tacikowski, E. Rolinski, and S. Lampman, Tribology of Nitrided and Nitrocarburized Steels, ASM Handbook, Friction, Lubrication and Wear Technology, Vol 18, G. Totten, Ed., ASM International, Novelty, 2017, p 638–652

A. Cabo, Tribological Behaviour of Nitrided and Nitrocarburized Carbon Steel used to Produce Engine Parts, Ind. Lubr. Tribol., 2016, 68, p 125–133. https://doi.org/10.1108/ILT-07-2015-0101

H. Li, Z. Cui, Z. Li, S. Zhu, and X. Yang, Effect of Gas Nitriding Treatment on Cavitation Erosion Behavior of Commercially Pure Ti and Ti-6Al-4V alloy, Surf. Coat. Technol., 2013, 221, p 29–36. https://doi.org/10.1016/j.surfcoat.2013.01.023

S.-J. Hsueh, J.-Y. Huang, C.-G. Chao, J.-Y. Juang, and T.-F. Liu, Mechanical Behavior and Electrochemical Stability of Gas-Nitrided FeMnAlC Alloy in Simulated Body Fluid, Mater. Lett., 2018, 216, p 150–153. https://doi.org/10.1016/j.matlet.2018.01.019

Y. Wang, J. Li, C. Dang, Y. Wang, and Y. Zhu, Influence of Carbon Contents on the Structure and Tribocorrosion Properties of TiSiCN Coatings on Ti6Al4V, Tribol. Int., 2017, 109, p 285–296. https://doi.org/10.1016/j.triboint.2017.01.002

J. Li, Y. Wang, Y. Yao, Y. Wang, and L. Wang, Structure and Tribological Properties of TiSiCN Coating on Ti6Al4V by Arc Ion Plating, Thin Solid Films, 2017, 644, p 115–119. https://doi.org/10.1016/j.tsf.2017.09.053

A.F. Yetim, A. Celik, and A. Alsaran, Improving Tribological Properties of Ti6Al4V Alloy with Duplex Surface Treatment, Surf. Coat. Technol., 2010, 205(2), p 320–324. https://doi.org/10.1016/j.surfcoat.2010.06.048

D. Monaghan and R.D. Arnell, Novel PVD Films by Unbalanced Magnetron Sputtering, Vacuum, 1992, 43(1–2), p 77–81. https://doi.org/10.1016/0042-207X(92)90189-4

R. Ramadoss, N. Kumar, R. Pandian, S. Dash, T.R. Ravindran, D. Arivuoli, and A.K. Tyagi, Tribological Properties and Deformation Mechanism of TiAlN Coating Sliding with Various Counterbodies, Tribol. Int., 2013, 66, p 143–149. https://doi.org/10.1016/j.triboint.2013.05.001

S. Wilson and A.T. Alpas, TiN Coating Wear Mechanisms in Dry Sliding Contact Against High Speed Steel, Surf. Coat. Technol., 1998, 108–109, p 369–376. https://doi.org/10.1016/S0257-8972(98)00593-3

Z.-Y. Zeng, H.-Q. Xıao, X.-H. Jıe, and Y.-M. Zhang, Friction and Wear Behaviors of TiCN Coating Based ob Electrical Discharge Coating, Trans. Nonferrous Met. Soc. China, 2015, 25(11), p 3716–3722. https://doi.org/10.1016/S1003-6326(15)64013-4

J.H. Ouyang, T. Murakami, and S. Sasaki, High-Temperature Tribological Properties of A Cathodic Arc Ion-Plated (V, Ti)N Coating, Wear, 2007, 263(7–12), p 1347–1353. https://doi.org/10.1016/j.wear.2006.12.031

D. Yin, Y. Yang, X. Peng, Y. Qin, and Z. Wang, Tensile and Fracture Process of the TiN/VN Interface From First Principles, Ceram. Int., 2014, 40(9), p 14453–14462. https://doi.org/10.1016/j.ceramint.2014.07.016

D.B. Lewis, S. Creasey, Z. Zhou, J.J. Forsyth, A.P. Ehiasarian, P.E. Hovsepian, Q. Luo, W.M. Rainforth, and W.D. Münz, The Effect of (Ti + Al): V Ratio on the Structure and Oxidation Behavior of TiAlN/VN Nano-Scale Multilayer Coatings, Surf. Coat. Technol., 2004, 177–178, p 252–259. https://doi.org/10.1016/j.surfcoat.2003.09.041

A.F. Rousseau, J.G. Partridge, E.L.H. Mayes, J.T. Toton, M. Kracica, D.G. McCulloch, and E.D. Doyle, Microstructural and Tribological Characterisation of a Nitriding/TiAlN PVD Coating Duplex Treatment Applied to M2 High Speed Steel Tools, Surf. Coat. Technol., 2015, 272, p 403–408. https://doi.org/10.1016/j.surfcoat.2015.03.034

J.D. Bressan, R. Hesse, and E.M. Silva, Jr., Abrasive Wear Behavior of High Speed Steel and Hard Metal Coated with TiAlN and TiCN, Wear, 2001, 250(1–12), p 561–568. https://doi.org/10.1016/S0043-1648(01)00638-X

G.S. Fox-Rabinovich, K. Yamomoto, S.C. Veldhuis, A.I. Kovalev, and G.K. Dosbaeva, Tribological Adaptability of TiAlCrN PVD Coatings Under High Performance Dry Machining Conditions, Surf. Coat. Technol., 2005, 200, p 1804–1813. https://doi.org/10.1016/j.surfcoat.2005.08.057

O. Knotek, T. Leyendecker, and F. Jungblut, On The Properties of Physically Vapour-Deposited Ti-Al-V-N Coatings, Thin Solid Films, 1987, 153, p 83–90. https://doi.org/10.1016/0040-6090(87)90172-6

J. Pi, Y. Kong, L. Chen, and Y. Du, Ab Initio Molecular Dynamics Studies on Effect of Zr on Oxidation Resistance of TiAlN Coatings, Appl. Surf. Sci., 2016, 378, p 293–300. https://doi.org/10.1016/j.apsusc.2016.04.002

Z. Lei, Y. Liu, F. Ma, Z. Song, and Y. Li, Oxidation Resistance of TiAlN/ZrN Multilayer Coatings, Vacuum, 2016, 127, p 22–29. https://doi.org/10.1016/j.vacuum.2016.02.004

V. Braic, C.N. Zoita, M. Balaceanu, A. Kiss, A. Vladescu, A. Popescu, and M. Braic, TiAlN/TiAlZrN Multilayered Hard Coatings For Enhanced Performance of HSS Drilling Tools, Surf. Coat. Technol., 2010, 204, p 1925–1928. https://doi.org/10.1016/j.surfcoat.2009.08.011

A. Eser, C. Broeckmann, and C. Simsir, Multiscale Modeling of Tempering of AISI, H13 Hot-Work Tool Steel- Part 1: Prediction of Microstructure Evolution and Coupling with Mechanical Properties, Comput. Mater. Sci., 2016, 113, p 280–291. https://doi.org/10.1016/j.commatsci.2015.11.020

M.X. Wei, S.Q. Wang, L. Wang, X.H. Cui, and K.M. Chen, Effect of Tempering Conditions on Wear Resistance in Various Wear Mechanisms of H13 Steel, Tribol. Int., 2011, 44(7–8), p 898–905. https://doi.org/10.1016/j.triboint.2011.03.005

J.C. Diaz-Guillen, M. Naeem, H.M. Hdz-Garcia, J.L. Acevedo-Davila, M.R. Diaz-Guillen, M.A. Khan, J. Iqbal, and A.I. Mtz-Enriquez, Duplex Plasma Treatment of AISI, D2 Tool Steel by Combining Plasma Nitriding (With and Without White Layer) and Post-Oxidation, Surf. Coat. Technol., 2020, 385, p 125420. https://doi.org/10.1016/j.surfcoat.2020.125420

Q. Kong, L. Ji, H. Li, X. Liu, Y. Wang, J. Chen, and H. Zhou, Influence of Substrate Bias Voltage on the Microstructure and Residual Stress of CrN Films Deposited by Medium Frequency Magnetron Sputtering, Mater. Sci. Eng. B, 2011, 176(11), p 850–854. https://doi.org/10.1016/j.mseb.2011.04.015

J.-W. Lee, S.-K. Tien, and Y.-C. Kuo, The Effects of Pulse Frequency and Substrate Bias to the Mechanical Properties of CrN Coatings Deposited by Pulsed DC Magnetron Sputtering, Thin Solid Films, 2006, 494, p 161–167. https://doi.org/10.1016/j.tsf.2005.07.190

P.K. Aw, A.W. Batchelor, and N.L. Loh, Structure and Tribological Properties of Plasma Nitreded Surface Films on Inconel 718, Surf. Coat. Technol., 1997, 89(1–2), p 70–76. https://doi.org/10.1016/S0257-8972(96)02937-4

İ. Çelik and M. Karakan, Investigation of Structural and Tribological Properties of Duplex Treated Pure Titanium, Kovave Mater., 2016, 54, p 37–43. https://doi.org/10.4149/km_2016_1_37

S.A. Glatz, R. Hollerweger, P. Polcik, R. Rachbauer, J. Paulitsch, and P.H. Mayrhofer, Thermal Stability and Mechanical Properties of Arc Evaporated Ti-Al-Zr-N Hard Coatings, Surf. Coat. Technol., 2015, 266, p 1–9. https://doi.org/10.1016/j.surfcoat.2015.01.042

X.T. Zeng, TiN/NbN Superlattice Hard Coatings Deposited by Unbalanced Magnetron Sputtering, Surf. Coat. Technol., 1999, 113(1–2), p 75–79. https://doi.org/10.1016/S0257-8972(98)00825-1

P.H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens, Microstructural Design of Hard Coatings, Prog. Mater. Sci., 2006, 51(8), p 1032–1114. https://doi.org/10.1016/j.pmatsci.2006.02.002

L. Chen, D. Holec, Y. Du, and P.H. Mayrhofer, Influence of Zr on Structure, Mechanical and Thermal Properties of Ti-Al-N, Thin Solid Films, 2011, 59(16), p 5503–5510. https://doi.org/10.1016/j.tsf.2011.03.139

Y. Yang, C. Zang, Z. Ding, C. Su, T. Yan, Y. Song, and Y. Cheng, A Correlation Between Micro- and Nano-Indentation on Materials Irradiated by Highenergy Heavy Ions, J. Nucl. Mater., 2018, 498, p 129–136. https://doi.org/10.1016/j.jnucmat.2017.10.025

A.K. Bhattacharya, Analysis of Elastic and Plastic Deformation Associated With Indentation Testing of Thin Films on Substrates, Int. J. Solids Struct., 1988, 24, p 1287–1298. https://doi.org/10.1016/0020-7683(88)90091-1

Y. Li, Y. He, J. Wei, W. Wang, Y. Zhu, and B. Hu, Wear and Corrosion Properties of AISI, 420 Martensitic Stainless Steel Treated by Active Screen Plasma Nitriding, Surf. Coat. Technol., 2017, 329, p 184–192. https://doi.org/10.1016/j.surfcoat.2017.09.021

N. Hansen, Hall-Petch Relation and Boundary Strengthening, Scr. Mater., 2004, 51(8), p 801–806. https://doi.org/10.1016/j.scriptamat.2004.06.002

J.C.A. Batista, M.C. Joseph, C. Godoy, and A. Matthews, Micro-Abrasion Wear Testing of PVD TiN Coatings on Untreated and Plasma Nitrided AISI, H13 Steel, Wear, 2011, 249(10–11), p 971–979. https://doi.org/10.1016/S0043-1648(01)00833-X

K. Levent, A. Hojjat, and K. Özcan, The Effect of TiN, TiAlN, CrAlN, and TiAlN/TiSiN Coatings on the Wear Properties of AISI, H13 Steel at Room Temperature, Surf. Rev. Lett., 2019, 26(9), p 1950063. https://doi.org/10.1142/S0218625X1950063X

K. Halim, A. Hojjat, A. Çiğdem, A. Akgün, and Ç. Ayhan, Effect of Plasma Nitriding Parameters on the Wear Resistance of Alloy Inconel 718, Met. Sci. Heat Treat., 2016, 58, p 23–28. https://doi.org/10.1007/s11041-016-0037-1

Acknowledgment

This research is partially supported by TUBITAK (Scientific and Technical Research Council of Turkey) Grant No:116M734.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sert, Y., Küçükömeroğlu, T., Ghahramanzadeh Asl, H. et al. Hardness, Adhesion, and Wear Performance of Duplex Treatment Coatings of Nitride/TiAlZrN with Different Zr Target Currents. J. of Materi Eng and Perform 30, 638–651 (2021). https://doi.org/10.1007/s11665-020-05354-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05354-z