Abstract

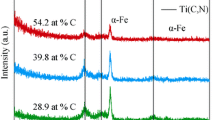

In this work, WTiN thin films were produced on silicon substrates using the DC magnetron sputtering technique varying the working pressure and keeping the power constant at 90 W and conducting the process at room temperature. The structure and morphology of the coatings were analyzed using the x-ray diffraction technique, which allowed the identification of a rock salt type FCC structure, with a relatively low micro-strain, and a grain size in the order of nm exhibiting a nanostructure formation. Elemental composition and the binding energies of samples were obtained using x-ray photoelectron spectroscopy and showed W-Ti-N chemical bonds and hence the formation of the ternary nitride. Moreover, a great influence of the pressure on the stoichiometry was identified, as a result of the differences in the deceleration and diffusion behavior of W and Ti atoms. The surface grain size and roughness (on average approximately 34 and 8.7 nm, respectively) of the coatings were determined using atomic force microscopy. Changes in the morphology can be attributed to re-sputtering and the adatoms mobility processes, as a part of the growth mechanism. Finally, for determining the tribological behavior, scratch and pin on disk tests were conducted. According to the results, the roughness and the pressure had a great influence on the coefficient of friction and the wear rate; however, the working pressure had no significant influence on the adherence of the films.

Similar content being viewed by others

References

T. Wang, Y. Jin, L. Bai, and G. Zhang, Structure and Properties of NbN/MoN Nano-multilayer Coatings Deposited by Magnetron Sputtering, J. Alloys Compd., 2016, 729, p 942-948

R.S. Ningthoujam and N.S. Gajbhiye, Synthesis, Electron Transport Properties of Transition Metal Nitrides and Applications, Prog. Mater. Sci., 2015, 70, p 50-154

X. Chen, Y. Xi, J. Meng, X. Pang, and H. Yang, Effects of Substrate Bias Voltage on Mechanical Properties and Tribological Behaviors of RF Sputtered Multilayer TiN/CrAlN Films, J. Alloys Compd., 2016, 665, p 210-217

V. Zin, E. Miorin, S.M. Deambrosis, F. Montagner, and M. Fabrizio, Mechanical Properties and Tribological Behaviour of Mo-N Coatings Deposited via High Power Impulse Magnetron Sputtering on Temperature Sensitive Substrates, Tribol. Int., 2018, 119, p 372-380

H.K. Sidana, R.A. Mir, and O. Pandey, Synthesis of Molybdenum Nitride (Mo2N) Nanoflakes via In-situ Reduction-Nitridation, J. Alloys Compd., 2017, 736, p 255

A. Vereschaka et al., Effect of Adhesion and Tribological Properties of Modified Composite Nano-structured Multi-layer Nitride Coatings on WC-Co Tools Life, Tribiol. Int., 2018, 128, p 313-327

W. Hsiao, C. Su, T. Huang, and W. Liao, The Microstructural Characteristics and Mechanical Properties of Ni-Al/h-BN Coatings Deposited Using Plasma Spraying, J. Alloys Compd., 2011, 509, p 8239-8245

D. Javdošňák et al., Tribological Properties and Oxidation Resistance of Tungsten and Tungsten Nitride Films at Temperatures up to 500 °C. Tribiol. Int., 2019, 132, p 211-220

F. Khatkhatay et al., Diffusion Barrier Properties of Nitride-Based Coatings on Fuel Cladding, J. Alloys Compd., 2013, 580, p 442-448

V.A. Alves, C.M.A. Brett, and A. Cavaleiro, Electrochemical Corrosion of Magnetron Sputtered WTiN-Coated Mild Steels in a Chloride Medium. Surf. Coatings Technol., 2002, 161, p 257-266

M. Fugger et al., Comparison of WTi and WTi(N) as Diffusion Barriers for Al and Cu Metallization on Si with Respect to Thermal Stability and Diffusion Behavior of Ti, Microelectron. Reliab. 2014, 54, p 2487-2493

S. Dong, X. Chen, X. Zhang, and G. Cui, Nanostructured Transition Metal Nitrides for Energy Storage and Fuel Cells. Coord. Chem. Rev., 2013, 257, p 1946-1956

L. Shaginyan et al., Composition, Structure, Microhardness and Residual Stress of W-Ti-N Films Deposited by Reactive Magnetron Sputtering, Thin Solid Films, 2002, 408, p 136-147

G. Abadias, P. Djemia, and L. Belliard, Alloying Effects on the Structure and Elastic Properties of Hard Coatings Based on Ternary Transition Metal (M = Ti, Zr or Ta) Nitrides, Surf. Coat. Technol., 2014, 257, p 129-137

H. Ramarotafika and G. Lemperiere, Influence of a d.c. Substrate Bias on the Resistivity, Composition, Crystallite Size and Microstrain of WTi and WTi-N films, Thin Solid Films, 1995, 266, p 267-273

M.R. Chavda, D.P. Dave, K.V. Chauhan, and S.K. Rawal, Tribological Characterization of TiN Coatings Prepared by Sputtering, Procedia Technol., 2016, 23, p 36-41

J. Yang et al., Thermally Induced Surface Integrity Changes of Ground WC-Co Hardmetals, Procedia CIRP, 2016, 45, p 91-94

J.M. Castanho and M.T. Vieira, The Influence of the Interstitial Element on Tribological Behaviour of Tungsten Coatings, Surf. Coat. Technol., 1998, 102, p 50-62

R.F. Londoño-Menjura et al., Influence of Deposition Temperature on WTiN Coatings Tribological Performance, Appl. Surf. Sci., 2018, 427, p 1096-1104

E.G. Sheikin, The Pressure Dependence of the Deposition Rate in a Magnetron Sputtering System, Thin Solid Films 2015, 574, p 52-59

S. Wu, H. Chen, X. Du, and Z. Liu, Effect of Deposition Power and Pressure on Rate Deposition and Resistivity of Titanium Thin Films Grown by DC Magnetron Sputtering, Spectrosc. Lett. 49, p 514-519 (2016)

H. Ju et al., Crystal Structure and the Improvement of the Mechanical and Tribological Properties of Tungsten Nitride Films by Addition of Titanium, Surf. Coat. Technol., 2018, 345, p 132-139

A. Cavaleiro, B. Trindade, and M.T. Vieira, Influence of Ti Addition on the Properties of W-Ti-C/N Sputtered Films, .Surf. Coat. Technol., 2003, 174-175, p 68-75

A.V. Kuchuk et al., Relationship Between Condition of Deposition and Properties of W-Ti-N Thin Films Prepared by Reactive Magnetron Sputtering, Adv. Eng. Mater., 2006, 8, p 209-212

W. Wong, H. McMurdie, B. Paretzkin, C. Hubbard, and A. Dragoo, PDF card 00-038-1420. (1987).

P.N. Silva, J.P. Dias, and A. Cavaleiro, Performance of W-TI-(N) Coated Pins in Lubricated Pin-on-Disk Tests, Surf. Coat. Technol., 2008, 202, p 2338-2343

M. Wen et al., Growth, Stress and Hardness of Reactively Sputtered Tungsten Nitride Thin Films, Surf. Coat. Technol.. 2010, 205, 1953-1961

B.D. Ozsdolay et al., Cubic β-WN x Layers: Growth and Properties vs N-to-W Ratio, Surf. Coat. Technol., 2016, 304, 98-107

C.C. Baker and S.I. Shah, Reactive Sputter Deposition of Tungsten Nitride Thin Films, J. Vac. Sci. Technol. Vac. Surfaces Film. 2002, 20, p 1699-1703

T. Shimizu et al., Pressure Dependence of (Ti, Al)N Film Growth on Inner Walls of Small Holes in High-Power Impulse Magnetron Sputtering, Thin Solid Films, 2017, 624, p 189-196

Y.G. Shen, and Y. Mai, Microstructure and Structure Characteristics of Cubic WNx Compounds, Mater. Sci. Eng. A , 2000, 288, p 47-53

K. Balasubramanian, S. Khare, and D. Gall, Vacancy-Induced Mechanical Stabilization of Cubic Tungsten Nitride, Phys. Rev. B, 2016, 94, p 174111

M.J. Mehl, D. Finkenstadt, C. Dane, G.L.W. Hart, and S. Curtarolo, Finding the Stable Structures of W x N 1-x With an Ab-initio High-Throughput Approach, Phys. Rev., 2015, 91, 184110

S. Zhou, W. Liu, H. Liu, and C. Cai, Structural and Electrical Properties of Ti-W-N Thin Films Deposited by Reactive RF Sputtering, Phys. Procedia, 2011, 18, p 66-72

D. Escobar, R. Ospina, A.G. Gómez, E. Restrepo-Parra, and P.J. Arango, X-ray Microstructural Analysis of Nanocrystalline TiZrN thin Films by Diffraction Pattern Modeling, Mater. Charact., 2014, 88, p 119-126

P. Scardi, M. Leoni, and R. Delhez, Line Broadening Analysis Using Integral Breadth Methods: A Critical Review, J. Appl. Crystallogr., 2004, 37, p 381-390

G. Williamson and W. Hall, X-ray Line Broadening from Filed Aluminium and Wolfram, Acta Metall., 1953,1, p 22-31

Y.M. Liu, R.Q. Han, F. Liu, Z.L. Pei, and C. Sun, Sputtering Gas Pressure and Target Power Dependence on the Microstructure and Properties of DC-magnetron Sputtered AlB2-type WB2 Films, J. Alloys Compd., 2017, 703, p 188-197

Zhongguo jin shu xue hui., V. C. R. J. R., Zhongguo cai liao yan jiu xue hui., V. C. R. J. R. & International Centre for Materials Physics. J. Materi.Sci. Technol., 2010, 26

M. Cheviot, M. Gouné, and A. Poulon-Quintin, Monitoring Tantalum Nitride Thin Film Structure by Reactive RF Magnetron Sputtering: Influence of Processing Parameters, Surf. Coatings Technol., 2015, 284, p 192-197

L.R. Shaginyan et al., Composition, Structure, Microhardness and Residual Stress of W-Ti-N Films Deposited by Reactive Magnetron Sputtering, Thin Solid Films, 2002, 408, p 136-147

D. Rostislav and Musil, J. Novel Nanocomposite Coatings Advances and Industrial Applications. (Pan Stanford Publishing Pte. Ltd., 2015).

F. Magalhaes and Teixeira, M. Introduçao A Tecnica De Espectroscopia Por Raios X: (XPS). (Synergia, 2011).

W. Qingxiang, L. Shuhua, W. Xianhui, and F. Zhikang, Diffusion Barrier Performance of Amorphous W-Ti-N Films in Cu Metallization, Vacuum, 2010, 84, p 1270-1274

U. Meier and C. Pettenkofer, Morphology of the Si-ZnO Interface, Appl. Surf. Sci., 2005, 252, p 1139-1146

S. Kac̆iulis, G. Mattogno, A. Galdikas, A. Mironas, and A. S̆etkus, Influence of Surface Oxygen on Chemoresistance of tin Oxide Film, J. Vac. Sci. Technol. A Vacuum, Surfaces, Film. 1996, 14, p 3164.

M.A. Stranick and A. Moskwa, SnO2 by XPS, Surf. Sci. Spectra, 1993, 2, p 50-54

D.K. Kim et al., Controlling the Defects and Transition Layer in SiO2 Films Grown on 4H-SiC via Direct Plasma-Assisted Oxidation, Sci. Rep., 2016, 6, 1-11

C. Wagner, Handbook of x-ray photoelectron spectroscopy : a reference book of standard data for use in x-ray photoelectron spectroscopy (Physical Electronics Division Perkin-Elmer Corp., 1979).

H.A. Castillo, E. Restrepo-Parra, and P.J. Arango-Arango, Chemical and Morphological Difference Between TiN/DLC and a-C:H/DLC Grown by Pulsed Vacuum Arc Techniques, Appl. Surf. Sci., 2011, 257, 2665-2668

S.M. Rossnagel, I. Yang, and J.J. Cuomo, Compositional Changes During Magnetron Sputtering of Alloys, Thin Solid Films, 1991, 199, p 59-69

T. Nakano, I. Mori, S. Baba, The Effect of ‘warm’ Gas Scattering on the Deceleration of Energetic Atoms: Monte Carlo Study of the Sputter-Deposition of Compounds, Appl. Surf. Sci., 1997, 113-114, p 642-646

J.M. García-Martín, R. Alvarez, P. Romero-Gómez, A. Cebollada, and A. Palmero, Tilt Angle Control of Nanocolumns Grown by Glancing Angle Sputtering at Variable Argon Pressures, Appl. Phys. Lett,. 2010, 97, p 173103

H. Toku, R.S. Pessoa, H.S. Maciel, M. Massi, and U.A. Mengui, Influence of Process Parameters on the Growth of Pure-Phase Anatase and Rutile TiO2 Thin Films Deposited by Low Temperature Reactive Magnetron Sputtering.

R. Chandra, A.K. Chawla, and P. Ayyub, Optical and Structural Properties of Sputter-Deposited Nanocrystalline Cu2O Films: Effect of Sputtering Gas, J. Nanosci. Nanotechnol., 2006, 6, p 1119-1123

H.N. Shah, V. Chawla, R. Jayaganthan, and D. Kaur, Microstructural Characterizations and Hardness Evaluation of d.c. Reactive Magnetron Sputtered CrN Thin Films on Stainless Steel Substrate, Bull. Mater. Sci., 2010, 33, 103-110

L. Ling, X. Tao, S. Zhongxiao, L. Chunliang, and M. Fei, Effect of Sputtering Pressure on Surface Roughness, Oxygen Vacancy and Electrical Properties of a-IGZO Thin Films, Rare Met. Mater. Eng., 2016, 45, 1992-1996

J. Yu et al., Tribochemical Wear of Phosphate Laser Glass Against Silica Ball in Water, Tribol. Int., 2016, 104, p 10-18

S. Kuiry, Advanced Scratch Testing for Evaluation of Coatings. www.bruker-axs.com (2012).

J. Stallard and S. Poulat, D.G. Teer, The Study of the Adhesion of a TiN Coating on Steel and Titanium Alloy Substrates Using a Multi-mode Scratch Tester, Tribol. Int. 2006, 39, p 159-166

S.J. Bull, Failure Mode Maps in the Thin Film Scratch Adhesion Test, Tribol. Int., 1997, 30, 491-498

F. Svahn, Å. Kassman-Rudolphi, E. Wallén, The Influence of Surface Roughness on Friction and Wear of Machine Element Coatings, Wear, 2003, 254, p 1092-1098

M. Ali, E. Hamzah, and M. Radzi Toff, Friction Coefficient and Surface Roughness of TiN-Coated HSS Deposited Using Cathodic Arc Evaporation PVD Technique, Ind. Lubr. Tribol., 2008, 60, p 121-130

F. Di Puccio and L. Mattei, A Novel Approach to the Estimation and Application of the Wear Coefficient of Metal-on-Metal Hip Implants, Tribol. Int. 2015, 83, p 69-76

M. Federici, C. Menapace, A. Moscatelli, S. Gialanella, and G. Straffelini, Effect of Roughness on the Wear Behavior of HVOF Coatings Dry Sliding Against a Friction Material, Wear, 2016, 368-369, p 326-334

Acknowledgments

The authors gratefully acknowledge the financial support provided by Dirección Nacional de Investigaciones of the Universidad Nacional de Colombia (DIMA) under the project 34567. We have also been able to pursue this research with the help of Laboratorio de Superfícies e Nanoestruturas—Centro Brasilero de Pesquisas Físicas and Laboratorio de Materiales y Procesos—Universidad Nacional de Colombia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Londoño-Menjura, R.F., Ospina, R., Escobar, D. et al. Influence of Microstructure, Composition and Morphology on Tribological Performance of WTiN Coatings Obtained by DC Magnetron Sputtering at Various Working Pressures. J. of Materi Eng and Perform 29, 5203–5213 (2020). https://doi.org/10.1007/s11665-020-05031-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05031-1