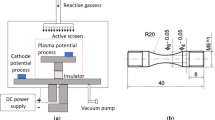

The effect of the temperature and duration of plasma nitriding on the microstructure and friction and wear parameters of Inconel 718 nickel alloy is investigated. The process of plasma nitriding is conducted in a nitrogen-hydrogen gaseous mixture at a temperature of 400, 500 and 600°C for 1 and 4 h. The modulus of elasticity of the nitrided layer, the micro- and nanohardness, the surface roughness, the friction factor and the wear resistance of the alloy are determined prior to and after the nitriding. The optimum nitriding regime providing the best tribological characteristics is determined.

Similar content being viewed by others

References

A. Altin, M. Nalbant, and A. Taskesen, “The effects of cutting speed on tool wear and tool life when machining Inconel 718 with ceramic tools,” Mater. Design, 28, 2518 – 2522 (2007).

A. Bhatt, H. Attia, R. Vargas, and V. Thomson, “Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718,” Tribology Int., 43, 1113 – 1121 (2010).

Y. Chen and Y. Liao, “Study on wear mechanisms in drilling of Inconel 718 superalloy,” J. Mater. Proc. Technol., 140, 269 – 273 (2003).

J. Costes, Y. Guillet, G. Poulachon, and M. Dessoly, “Tool-life and wear mechanisms of CBN tools in machining of Inconel 718,” Int. J. Mach. Tools Manuf., 47, 1081 – 1087 (2007).

W. F. Smith, Structure and Properties of Engineering Alloys (1993).

V. Singh and E. I. Meletis, “Synthesis, characterization and properties of intensified plasma-assisted nitrided superalloy Inconel 718,” Surf. Coat. Technol., 201, 1093 – 1101 (2006).

A. Houghton, R. Lewis, U. Olofsson, and J. Sundh, “Characterising and reducing seizure wear of inconel and incoloy superalloys in a sliding contact,” Wear, 271, 1671 – 1680 (2011).

B. Edenhofer, “Physical and metallurgical aspects of ionitriding,” Heat Treat. Met., Pt. 1, 23 – 28 (1974).

A. Alsaran and A. Celik, “Structural characterization of ion-nitrided AISI 5140 low-alloy steel,” Mater. Charact., 47, 207 – 213 (2001).

A. Çelik and S. Karadeniz, “Improvement of the fatigue strength of AISI 4140 steel by an ion nitriding process,” Surf. Coat. Technol., 72, 169 – 173 (1995).

A. Rizk and D. McCulloch, “Plasma nitriding of Inconel 625,” Surf. Technol., 9, 303 – 315 (1979).

C. Leroy, T. Czerwiec, C. Gabet, et al., “Plasma assisted nitriding of Inconel 690,” Surf. Coat. Technol., 142, 241 – 247 (2001).

T. Borowski, A. Brojanowska, M. Kost, et al., “Modifying the properties of the Inconel 625 nickel alloy by glow discharge assisted nitriding,” Vacuum, 83, 1489 – 1493 (2009).

Y. Sun, “Kinetics of layer growth during plasma nitriding of nickel based alloy Inconel 600,” J. Alloys Comp., 351, 241 – 247 (2003).

F. Kahraman and S. Karadeniz, “Characterization and wear behavior of plasma nitrided nickel based dental alloy,” Plasma Chem. Plasma Proc., 31, 595 – 604 (2011).

C. Sudha, R. Anand, Paul V. Thomas, et al., “Nitriding kinetics of Inconel 600,” Surf. Coat. Technol., 226, 92 – 99 (2013).

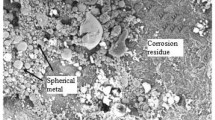

P. Aw, A. Batchelor, and N. Loh, “Structure and tribological properties of plasma nitrided surface films on Inconel 718,” Surf. Coat. Technol., 89, 70 – 76 (1997).

P. Aw, A. Batchelor, and N. Loh, “Failure mechanisms of plasma nitrided Inconel 718 film,” Wear, 208, 226 – 236 (1997).

F. Yildiz and A. Alsaran, “Multi-pass scratch test behavior of modified layer formed during plasma nitriding,” Tribology Int., 43, 1472 – 1478 (2010).

L. Cunha, M. Andritschky, K. Pischow, and Z. Wang, “Microstructure of CrN coatings produced by PVD technique,” Thin Solid Films, 355, 465 – 471 (1999).

H. Ichimura and I. Ando, “Mechanical properties of arc-evaporated CrN coatings. Part I. Nanoindentation hardness and elastic modulus,” Surf. Coat. Technol., 145, 88 – 93 (2001).

J. A. Sue, A. J. Perry, and J. Vetter, “Young’s modulus and stress of CrN deposited by cathodic vacuum arc evaporation,” Surf. Coat. Technol., 68, 126 – 130 (1994).

Preliminary results of this study have been reported at PSE 2012 (13th International Conference on Plasma Surface Engineering). The authors would like to thank Dr. Fatih Yildiz for the SEM analyses and Dr. Mustafa Toparlu for the nanoindentation tests. H. Ghahramanzadeh ASL would like to thank TUBITAK for the BIDEB 2215 Scholarship.

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 23 – 28, August, 2016.

Rights and permissions

About this article

Cite this article

Kovací, H., Ghahramanzadeh ASL, H., Albayrak, Ç. et al. Effect of Plasma Nitriding Parameters on the Wear Resistance of Alloy Inconel 718. Met Sci Heat Treat 58, 470–474 (2016). https://doi.org/10.1007/s11041-016-0037-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-016-0037-1