Abstract

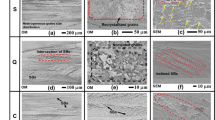

This study investigated the texture, mechanical properties, and fracture behavior during cold working of cryorolled (CR) Al-Mg-Si alloys. An x-ray texture goniometer was used to examine the crystallographic texture, and tensile tests were performed to understand the deformation behavior in more detail. SEM/EBSD/TEM was used to observe the microstructures and fracture morphology of the alloy during cryorolling. The microstructures indicated that a large number of ultrafine grains and dislocations formed after cryorolled. The recrystallization was prohibited due to low temperature during deformation. The ultrafine grains and dislocation strength improved the tensile strength from 279.38 MPa for the room-rolled alloy to 313.98 MPa for the cryorolled alloy; better plasticity (4.6%) was observed in the CR sheet. Ductile and intergranular fractures were observed in the CR sheet deformation from 20 to 90%.

Similar content being viewed by others

References

Y. Aruga, M. Kozuka, Y. Takaki, and T. Sato, Effects of Natural Aging After Pre-aging on Clustering and Bake-Hardening Behavior in an Al-Mg-Si Alloy, Scripta Mater., 2016, 116, p 82–86

A. Serizawa, S. Hirosawa, and T. Sato, Three-Dimensional Atom Probe Characterization of Nanoclusters Responsible for Multistep Aging, Metall. Mater. Trans. A, 2008, 39, p 243–251

V. Fallah, B. Langelier, and N. Ofori-Opoku, Cluster Evolution Mechanisms During Aging in Al-Mg-Si Alloys, Acta Mater., 2016, 103, p 290–300

M. Torsæter, H.S. Hasting, and W. Lefebvre, The Influence of Composition and Natural Aging on Clustering During Preaging in Al–Mg–Si Alloys, J. Appl. Phys., 2010, 108, p 3893–3896

G. Burger, A. Gupta, P. Jeffrey, and D. Lloyd, Microstructural Control of Aluminum Sheet Used in Automotive Applications, Mater. Charact., 1995, 35, p 23–39

X. Wang, M. Guo, Y. Zhang, H. Xing, Y. Li, J. Luo, J. Zhang, and L. Zhuang, The Dependence of Microstructure, Texture Evolution and Mechanical Properties of Al-Mg-Si-Cu Alloy Sheet on Final Cold Rolling Deformation, J. Alloy. Compd., 2016, 657, p 906–916

G. Dan Sathiaraj, P.P. Bhattacharjee, C.-W. Tsai, and J.-W. Yeh, Effect of Heavy Cryo-rolling on the Evolution of Microstructure and Texture During Annealing of Equiatomic CoCrFeMnNi high Entropy Alloy, Intermetallics, 2016, 69, p 1–9

T. Bhattacharjee, I.S. Wani, S. Sheikh, I.T. Clark, and T. Okawa, Simultaneous Strength-Ductility Enhancement of a Nano-Lamellar AlCoCrFeNi 2.1 Eutectic High Entropy Alloy by Cryo-Rolling and Annealing, Sci Rep, 2018, 8, p 3276

M. Yadollahpour, H. Hosseini-Toudeshky, and F. Karimzadeh, The Use of Response Surface Methodology in Cryrolling of Ultrafine Grained Al6061 to Improve the Mechanical Properties, Proc. Inst. Mech. Eng. L J. Mater. Des. Appl., 2015, 230, p 2

M. Yadollahpour, H. Hosseini-Toudeshky, and F. Karimzadeh, Effect of Cryorolling and Aging on Fatigue Behavior of Ultrafine-Grained Al6061, J. Met., 2016, 68, p 1446–1455

S.K. Panigrahi, D. Devanand, and R. Jayaganthan, A Comparative Study on Mechanical Properties of Ultrafine-Grained Al 6061 and Al 6063 Alloys Processed by Cryorolling, Trans. Indian Inst. Met., 2008, 61, p 159–163

H. Yu, L. Su, C. Lu, and K. Tieu, Enhanced Mechanical Properties of ARB-Processed Aluminum Alloy 6061 Sheets by Subsequent Asymmetric Cryorolling and Ageing, Mater. Sci. Eng. A, 2016, 674, p 256

H.-L. Yu, A. KietTieu, C. Lua, and X.-H. Liu, Mechanical Properties of Al-Mg-Si Alloy Sheets Produced Using Asymmetric Cryorolling and Ageing Treatment, Mater. Sci. Eng. A, 2013, 568, p 212

P. Nageswara Rao, D. Singh, and R. Jayaganthan, Effect of Post Cryorolling Treatments on Microstructural and Mechanical Behaviour of Ultrafine Grained Al-Mg-Si Alloy, J. Mater. Sci. Technol., 2014, 30, p 998–1005

Y.-C. Huang, X.-Y. Yan, and T. Qiu, Microstructure and Mechanical Properties of Cryo-rolled AA6061 Al Alloy, Trans. Nonferrous Met. Soc. China, 2016, 26, p 12–18

Y.-C. Huang, X.-Y. Yan, Z.-B. Xiao, Z.-Y. Du, Y.-T. Huang, and T. Qiu, Texture Evolution and Fracture Mechanism of Cold Rolled AA6061 Alloy, Mater. Sci. Eng. Powder Metall., 2015, 20, p 585

T. Shanmugasundaram, B.S. Murty, and V. Subramanya Sarma, Development of Ultrafine Grained High Strength Al-Cu Alloy by Cryorolling, Scripta Mater., 2006, 54, p 2013–2016

V.L. Niranjani, K.C. Hari Kumar, and V. Subramanya Sarma, Development of High Strength Al–Mg–Si AA6061 Alloy Through Cold Rolling and Ageing, Mater. Sci. Eng. A, 2009, 515, p 169–174

M. Murayama, Z. Horita, and K. Hono, Microstructure of Two-Phase Al-1.7 at% Cu Alloy Deformed by Equal-Channel Angular Pressing, Acta Mater., 2001, 49, p 21–29

K. Venkateswarlu, M. Chakraborty, and B.S. Murty, Influence of Thermo-Mechanical Processing of Al-5Ti-1B Master Alloy on its Grain Refining Efficiency, Mater. Sci. Eng. A, 2004, 364, p 75–83

Y.C. Huang, Y. Liu, Q. Li, X. Liu, and C.G. Yang, Relevance Between Microstructure and Texture During Cold Rolling of AA3104 Aluminum Alloy, J. Alloys Compd., 2016, 673, p 383–389

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Pergamon, Oxford, 1996, p 16

O. Engler and K. Lucke, Mechanisms of Recrystallization Texture Formation in Aluminium Alloys, Scr. Metall. Mater., 1992, 27, p 1527–1532

R.Z. Valiev, R.K. Islamgliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater. Sci., 2000, 45, p 103–189

Y. Huang and P.B. Prangnell, Continuous Frictional Angular Extrusion and Its Application in the Production of Ultrafine-Grained Sheet Metals, Scripta Mater., 2007, 56, p 333–336

A.P. Zhilyaev, G.V. Nurislamove, B.K. Kim, M.D. Baro, J.A. Szpunar, and T.G. Langdon, Experimental Parameters Influencing Grain Refinement and Microstructural Evolution During High-Pressure Torsion, Acta Mater., 2003, 51, p 753–765

P.P. Bhattacharjee and R.K. Ray, Effect of Processing Variables on Cube Texture Formation in Powder Metallurgically Prepared Ni and Ni-W Alloy Tapes for use as Substrates for Coated Conductor Applications, Mater. Sci. Eng. A, 2007, 459, p 309–323

P.P. Bhattacharjee, M. Joshi, V.P. Chaudhary, and M. Zaid, The Effect of Starting Grain Size on the Evolution of Microstructure and Texture in Nickel During Processing by Cross-rolling, Mater. Charact., 2013, 76, p 21–27

P.P. Bhattacharjee, M. Joshi, V.P. Chaudhary, J.R. Gatti, and M. Zaid, Texture Evolution During Cross Rolling and Annealing of High-Purity Nickel, Metall Mater Trans A, 2013, 44, p 2707–2716

J.R. Gatti and P.P. Bhattacharjee, Annealing Textures of Severely Cold and Warm-Rolled Al-2.5 wt% Mg Alloy, J. Alloys Compd., 2014, 615, p 950–961

N. Rangaraju, T. Raghuram, B.V. Krishna, K.P. Rao, and P. Venugopal, Effect of Cryo-Rolling and Annealing on Microstructure and Properties of Commercially Pure Aluminium, Mater. Sci. Eng. A, 2005, 398, p 246–251

S.K. Panigrahi, K. Sushanta, and R. Jayaganthan, A Study on the Mechanical Properties of Cryorolled Al-Mg-Si Alloy, Mater. Sci. Eng. A, 2008, 480, p 299–305

W.J. Kim and J.Y. Wang, Microstructure of the Post-ECAP Aging Processed 6061 Al Alloys, Mater. Sci. Eng. A, 2007, 464, p 23–27

Acknowledgments

The project was supported by the program for the 973 Program (No. 2014CB046702). We are grateful M. A. Y. Li acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, X., Huang, Y. & Liu, Y. Cryorolling-Induced Texture, Mechanical Properties and Fracture Behavior of Al-Mg-Si Alloys During Cold Deformation. J. of Materi Eng and Perform 27, 3932–3939 (2018). https://doi.org/10.1007/s11665-018-3486-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3486-4