Abstract

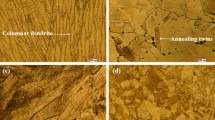

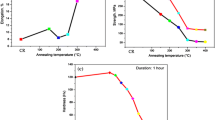

In this investigation, annealed Cu–0.13Sn alloys i.e., as-received samples were subjected to room-temperature rolling (RTR) at reduction ratios (RR) of 40 and 75 pct. Electron backscattered diffraction (EBSD) and transmission electron microscopy (TEM) was used to discuss the microstructure evolution in the as-received and RTR samples. RTR deformation resulted in the formation of Copper-type shear bands (SBs). An unusual phenomenon of static recrystallization (SRX) at room-temperature (RT)/self-annealing was observed in the severely deformed Cu–0.13Sn alloy. SBs and deformed grain boundaries (GBs) were the main sites with high levels of stored energy (SE), and new grains were nucleated in those regions via discontinuous SRX (DSRX) in the RTR samples. Continuous SRX (CSRX) was observed in grains nucleated inside the deformed grains. The fraction of SBs was increased with increases in the RR, and visco-plastic self-consistent (VPSC) modelling was used to predict the texture of the SBs in the severely deformed Cu–0.13Sn alloy. Microstructural heterogeneities had a significant effect on the evolution of the crystallographic texture in as-received and RTR samples. Under low strain (40 pct RR), a Copper-type texture was observed, whereas the severely deformed sample (75 pct RR) showed strong Copper and S components, but weak Brass component. Self-annealed grains in the SB regions and in the deformed GB regions led to the evolution of strong Copper and Rotated Cube components, but weak Brass component.

Similar content being viewed by others

Abbreviations

- C:

-

Center region in RD-ND plane

- CR:

-

Cryogenically rolled

- CSRX:

-

Continuous static recrystallization

- CT:

-

Cryogenic temperature

- DSRX:

-

Discontinuous static recrystallization

- EBSD:

-

Electron backscattered diffraction

- EDS:

-

Energy-dispersive spectroscopy

- GBs:

-

Grain boundaries

- GOS:

-

Grain orientation spread

- GS:

-

Grain size

- GSAvg :

-

Average grain size

- HR-TEM:

-

High-resolution transmission electron microscopy

- IACS:

-

International Annealed Copper Standard (IACS)

- IQ:

-

Image quality

- IPF:

-

Inverse pole figure

- KAM:

-

Kernel average misorientation

- HAGBs:

-

High angle grain boundaries (> 15 deg)

- LAGBs:

-

Low angle grain boundaries (3–15 deg)

- LAB-I:

-

Low angle boundaries of type 1 (3–10 deg)

- LAB-II:

-

Low angle boundaries of type 2 (10–15 deg)

- ND:

-

Normal direction

- ODF:

-

Orientation distribution function

- Q:

-

Quarter region in RD-ND plane

- RD:

-

Rolling direction

- RR:

-

Reduction ratio

- RT:

-

Room temperature

- RTR:

-

Room-temperature rolling

- RTR40:

-

Cu–0.13Sn samples rolled to 40 pct thickness reduction

- RTR75:

-

Cu–0.13Sn samples rolled to 75 pct thickness reduction

- S:

-

Surface region in RD-ND plane

- SBs:

-

Shear bands

- SE:

-

Stored energy

- SFE:

-

Stacking fault energy

- SLs:

-

Strain localizations

- STEM:

-

Scanning transmission electron microscopy

- ST1-ST4:

-

Slip traces of {111} plane

- SRX:

-

Static recrystallization

- SRV:

-

Static recovery

- SEavg :

-

Average stored energy

- TMP:

-

Thermomechanical processing

- TD:

-

Transverse direction

- VPSC:

-

Visco-plastic self-consistent

References

M. Karthik, J. Abhinav, and K.V. Shankar: Met. Mater. Int., 2021, vol. 27, pp. 1915–46.

J. Zhang, X. Cui, Y. Wang, Y. Yang, and J. Lin: Mater. Sci. Technol., 2014, vol. 30, pp. 506–509.

K. Maki, Y. Ito, H. Matsunaga, and H. Mori: Scr. Mater., 2013, vol. 68, pp. 777–80.

J. Zhang, X. Cui, J. Ma, and Y. Wang: Mater. Sci. Pol., 2016, vol. 34, pp. 142–47.

W. Fan, J. Hui, Z. Xinfeng, W. Gao, and C. Xue: Mater. Res. Express, 2018, vol. 5, 106520.

L. Han, J. Liu, H. Tang, X. Ma, and W. Zhao: Mater. Chem. Phys., 2019, vol. 221, pp. 322–31.

X. Zhang, X. Yang, W. Chen, J. Qin, and J. Fouse: Mater. Charact., 2015, vol. 106, pp. 100–107.

Z. Guo, J. Jie, S. Liu, J. Liu, S. Yue, Y. Zhang, and T. Li: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 1229–41.

L. Zhang, X. Guo, Z. Li, D. Zhang, and E. Wang: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 6727–39.

L. Jiang, H. Fu, C. Wang, W. Li, and J. Xie: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 331–41.

S.H. Choi, J.K. Choi, H.W. Kim, and S.B. Kang: Mater. Sci. Eng. A, 2009, vol. 519, pp. 77–87.

A. Gupta, T.-H. Yoo, L. Kaushik, J.W. Lee, Y.-K. Kim, and S.-H. Choi: Int. J. Plast., 2022, vol. 156, 103340.

A. Gupta, R.K. Khatirkar, A. Kumar, K. Thool, N. Bibhanshu, and S. Suwas: Mater. Charact., 2019, vol. 156, 109884.

Y. Geng, Y. Ban, B. Wang, X. Li, K. Song, Y. Zhang, Y. Jia, B. Tian, Y. Liu, and A.A. Volinsky: J. Mater. Res. Technol., 2020, vol. 9, pp. 11918–34.

A. Gupta, R.K. Khatirkar, A. Kumar, K.S. Thool, N. Bhibhanshu, and S. Suwas: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 1031–43.

X.W. Li, X.M. Wu, Z.G. Wang, and Y. Umakoshi: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 307–18.

J. Hui, Z. Feng, C. Xue, and W. Gao: J. Mater. Sci., 2018, vol. 53, pp. 15308–18.

D. Xu, M. Zhou, Y. Zhang, S. Tang, Z. Zhang, Y. Liu, B. Tian, X. Li, Y. Jia, A.A. Volinsky, D. Li, and Q. Liu: Mater. Charact., 2023, vol. 196, 112559https://doi.org/10.1016/j.matchar.2022.112559.

J. Zhao, L. Zhang, F. Du, X. Yuan, and P. Wang: Materials, 2022, vol. 15, p. 4501. https://doi.org/10.3390/ma15134501.

S. Semboshi, Y. Kaneno, T. Takasugi, S.Z. Han, and N. Masahashi: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 1389–96.

M. Fatmi, T. Chihi, M.A. Ghebouli, B. Ghebouli, A. Derafa, F. Sahnoune, H. Belhouchet, and A. Gamoura: Am. J. Mech. Appl., 2013, vol. 1, pp. 1–4.

Z.J. Wang and T.J. Konno: Mater. Trans., 2012, vol. 53, pp. 1590–97.

J.S. Huang, J. Zhang, A. Cuevas, and K.N. Tu: Mater. Chem. Phys., 1997, vol. 49, pp. 33–41.

L. Lapeire, J. Sidor, P. Verleysen, K. Verbeken, I. De Graeve, H. Terryn, and L.A.I. Kestens: Acta Mater., 2015, vol. 95, pp. 224–35.

I.F. Mohamed, Y. Yonenaga, S. Lee, K. Edalati, and Z. Horita: Mater. Sci. Eng. A, 2015, vol. 627, pp. 111–18.

C.-H. Yang, Y.-W. Lee, C.-Y. Lee, P.-T. Lee, and C.-E. Ho: J. Electrochem. Soc., 2020, vol. 167, 082514.

C.H. Yang, S.P. Yang, B.C. Huang, C.Y. Lee, H.C. Liu, and C.E. Ho: Surf. Coat. Technol., 2019, vol. 364, pp. 383–91.

A. Gupta, L. Kaushik, T.-H. Yoo, J.W. Lee, Y.-K. Kim, D. Lee, Y.-U. Heo, and S.-H. Choi: Int. J. Plast., 2022, vol. 159, 103473.

M.Y. Maeda, J.J.H. Quintero, M.T. Izumi, M.F. Hupalo, and O.M. Cintho: Mater. Res., 2017, vol. 20, pp. 716–21.

C.T. Wang, Y. He, and T.G. Langdon: Acta Mater., 2020, vol. 185, pp. 245–56.

N.X. Zhang, M. Kawasaki, Y. Huang, and T.G. Langdon: Mater. Sci. Eng. A, 2021, vol. 802, 140653.

H.D. Meingelberg, M. Meixner, and K. Lucke: Acta Met., 1965, vol. 13, pp. 835–44.

J.W. Patten, E.D. McClanahan, and J.W. Johnston: J. Appl. Phys., 1971, vol. 42, pp. 4371–77.

T. Konkova, S. Mironov, A. Korznikov, and S.L. Semiatin: Scr. Mater., 2010, vol. 63, pp. 921–24.

K. Edalati, Y. Hashiguchi, H. Iwaoka, H. Matsunaga, R.Z. Valiev, and Z. Horita: Mater. Sci. Eng. A, 2018, vol. 729, pp. 340–48.

T. Konkova, S. Mironov, A. Korznikov, and S.L. Semiatin: Mater. Sci. Eng. A, 2011, vol. 528, pp. 7432–43.

J.S. Carpenter, R.J. McCabe, S.J. Zheng, T.A. Wynn, N.A. Mara, and I.J. Beyerlein: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 2192–3008.

N. Jia, F. Roters, P. Eisenlohr, C. Kords, and D. Raabe: Acta Mater., 2012, vol. 60, pp. 1099–115.

N.P. Gurao and S. Suwas: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 809–27.

M.F. Sklate Boja and A.V. Druker: Metall. Mater. Trans. A, 2022, vol. 53A, pp. 3986–4003.

G.Z. Wassermann: Z. Met., 1963, vol. 54, p. 61.

E. El-Danaf, S.R. Kalidindi, R.D. Doherty, and C. Necker: Acta Mater., 2000, vol. 48, pp. 2665–73.

Z. Zheng, P. Guo, J. Li, T. Yang, Z. Song, C. Xu, and M. Zhou: J. Alloys Compd., 2020, vol. 831, 154842.

R. Kumar, A. Gupta, A. Kumar, R.N. Chouhan, and R.K. Khatirkar: J. Alloys Compd., 2018, vol. 742, pp. 369–82.

A. Paul, C. Ghosh, and W.J. Boettinger: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 952–63.

S.I. Wright and M.M. Nowell: Microsc. Microanal., 2006, vol. 12, pp. 72–84.

F. Bachmann, R. Hielscher, and H. Schaeben: Solid State Phenom., 2010, vol. 160, pp. 63–68.

S.H. Choi and Y.S. Jin: Mater. Sci. Eng. A, 2004, vol. 371, pp. 149–59.

J.S. Kim, S.I. Kim, and S.H. Choi: Mater Charact, 2014, vol. 92, pp. 159–70.

P. Wagner, O. Engler, and K. Lücke: Acta Metall. Mater., 1995, vol. 43, pp. 3799–812.

N. Jia, P. Eisenlohr, F. Roters, D. Raabe, and X. Zhao: Acta Mater., 2012, vol. 60, pp. 3415–34.

H. Paul, A. Morawiec, E. Bouzy, J.J. Fundenberger, and A. Piatkowski: Metall Mater. Trans. A, 2004, vol. 35A, pp. 3775–86.

D.P. Lu, J. Wang, W.J. Zeng, Y. Liu, L. Lu, and B. De Sun: Mater. Sci. Eng. A, 2006, vol. 421, pp. 254–59.

O. Engler, C.N. Tomé, and M.Y. Huh: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2299–315.

S. Han, K. Sohn, C. Kim, and S. Kim: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 465–69.

I.L. Dillamore, J.G. Roberts, and A.C. Bush: Met. Sci., 1979, vol. 13, pp. 73–77.

L. Kaushik, M.S. Kim, J. Singh, J.H. Kang, Y.U. Heo, J.Y. Suh, and S.H. Choi: Int. J. Plast., 2021, vol. 141, 102989.

A. Gupta, K.S. Park, T.H. Yoo, A.K. Singh, D. Lee, Y.U. Heo, and S.H. Choi: Int. J. Plast., 2023, vol. 167, 103672.

G. Wilde and H. Rösner: J. Mater. Sci., 2007, vol. 42, pp. 1772–81.

P.M. Anderson, J.P. Hirth, and J. Lothe: Theory of Dislocations, Cambridge University Press, Cambridge, 2017.

K. Okuda and A.D. Rollett: Comput. Mater. Sci., 2005, vol. 34, pp. 264–73.

H.T. Jeong and W.J. Kim: J. Mater. Sci. Technol., 2021, vol. 71, pp. 228–40.

J.G. Kim, A. Gupta, M.-S. Kim, and S.-H. Choi: Mater. Sci. Eng. A, 2022, vol. 858, p. 144162.

O. Engler: Mater. Sci. Eng. A, 2014, vol. 618, pp. 654–62.

C. Li, X. Wang, B. Li, J. Shi, Y. Liu, and P. Xiao: J. Alloys Compd., 2020, vol. 818, pp. 1–7.

R. Li, S. Zhang, H. Kang, Z. Chen, F. Yang, W. Wang, C. Zou, T. Li, and T. Wang: J. Alloys Compd., 2017, vol. 693, pp. 592–600.

Y. Lu, R. Ma, and Y.N. Wang: Trans. Nonferr. Met. Soc. China, 2015, vol. 25, pp. 2948–57.

H. Paul, J.H. Driver, and Z. Jasieński: Acta Mater., 2002, vol. 50, pp. 815–30.

P. Haasen: Scr. Metall. Mater., 1992, vol. 27, pp. 1477–84.

A.A. Ridha and W.B. Hutchinson: Acta Metall., 1982, vol. 30, pp. 1929–39.

H.T. Jeong and W.J. Kim: J. Mater. Sci. Technol., 2022, vol. 111, pp. 152–66.

Acknowledgments

This research was supported by the National Center for Materials Research Data (NCMRD) through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (NRF-2021M3A7C2089777).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gupta, A., Kaushik, L., Yoo, TH. et al. Unveiling the Room-Temperature Softening Phenomenon and Texture Evolution in Room-Temperature-Rolled Cu–0.13Sn Alloys. Metall Mater Trans A 55, 1516–1538 (2024). https://doi.org/10.1007/s11661-024-07341-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-024-07341-8