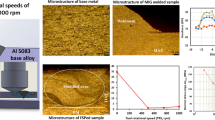

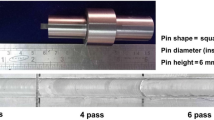

Aim of the present study is to investigate the effect of process parameters on microstructural evolution, mechanical properties and corrosion behavior of an age-hardenable Al 7075 alloy. The alloy plates (6 mm thickness) were friction stir processed (FSPed) at various traverse speed, namely 25, 45, 65, 85, 100 and 150 mm/min at 2 different rpm of 508 and 720. The optimized result in terms of defect-free processed zone with refined microstructure was obtained only at a rotational speed of 720 rpm for a traverse speed of 25, 45, 65 and 85 mm/min. The microstructural evolution was investigated using optical, scanning and transmission electron microscopy. The grain size of the nugget zone was found to decrease with increase in the traverse speed from 25 to 85 mm/min at a constant rpm of 720. The mechanical properties were evaluated by Vickers hardness measurements, tensile and wear testing. Yield strength was found to be the maximum (~366 MPa) for the FSPed sample processed at 85 mm/min. The hardness values also followed the similar increasing trend with increase in the traverse speed. The wear volume loss decreased by 38% for the sample processed at a traverse speed of 85 mm/min as compared to that of the sample processed at 25 mm/min. The friction coefficient was found to substantiate well with the wear track morphology. The improvement in mechanical properties is ascertained to the refinement of grain size at higher traverse speed (due to less heat input). The FSPed samples showed inferior corrosion resistance in contrast to that of the base metal. This is possibly due to the coarsening of precipitates and depletion of solutes in the matrix. The morphology of the corroded samples corroborated well with the corrosion behavior of the corresponding specimen.

Similar content being viewed by others

References

I.N. Fridlyander, A.V. Dobromyslov, E.A. Tkachenko, and O.G. Senatorova, Advanced High-Strength Aluminum-Base Materials, Met. Sci. Heat Treat., 2005, 47, p 269–275

ASM Handbook, Properties and Selection: Nonferrous Alloys and Special Purpose Materials, Vol 2, 10th ed., ASM International, USA, 1990

P.A. Rometsch, Y. Zhang, and S. Knight, Heat Treatment of 7xxx Series Aluminium Alloys—Some Recent Developments, Trans. Nonferrous Met. Soc. China, 2014, 24, p 2003–2017

E. Mohseni, E. Zalnezhad, A.A.D. Sarhan, and A.R. Bushroa, A Study on Surface Modification of Al 7075-T6 Alloy Against Fretting Fatigue Phenomenon, Adv. Mater. Sci. Eng., 2014, 2014, p 1–17

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, and Y.T. Zhu, Microstructures and Mechanical Properties of Ultrafine Grained 7075 Al Alloy Processed by ECAP and Their Evolutions During Annealing, Acta Mater., 2004, 52, p 4589–4599

S. Lee and Z. Horita, Superplasticity of Ultra-Fine Grained 7075 Alloy Processed by High Pressure Torsion, Mater. Sci. Forum, 2014, 794–796, p 807–810

H. Xie, M.P. Wang, W. Chen, and Y. Jia, Microstructure, Mechanical Properties, and Texture Evolution of Aluminum Alloy 7005 by Accumulative Roll Bonding, J. Mater. Eng. Perform., 2016, 25, p 1199–1210

A. Joshi, N. Kumar, K.K. Yogesha, R. Jayaganthan, and S.K. Nath, Mechanical properties and microstructural evolution in Al 2014 Alloy processed through multidirectional cryoforging, J. Mater. Eng. Perform., 2016, 25, p 3031–3045

P. Das, I.V. Singh, and R. Jayaganthan, An Experimental Evaluation of Material Properties and Fracture Simulation of Cryorolled 7075 Al Alloy, J. Mater. Eng. Perform., 2012, 21, p 1167–1181

R.S. Mishra and M.W. Mahoney, Friction Stir Processing: A New Grain Refinement Technique to Achieve High Strain Rate Superplasticity in Commercial Alloys, Mater. Sci. Forum, 2001, 357–359, p 507–514

R.S. Mishra, M.W. Mahoney, S.X. Mcfadden, N.A. Mara, and A.K. Mukherjee, High Strain Rate Superplasticity in a Friction Stir Processed 7075 Al Alloy, Scr. Mater., 1999, 42, p 163–168

Y.J. Kwon, I. Shigematsu, and N. Saito, Mechanical Properties of Fine-Grained Aluminum Alloy Produced by Friction Stir Process, Scr. Mater., 2003, 49, p 785–789

Z.Y. Ma, R.S. Mishra, and M.W. Mahoney, Superplastic Deformation Behaviour of Friction Stir Processed 7075Al Alloy, Acta Mater., 2002, 50, p 4419–4430

K.V. Jata, K.K. Sankaran, and J.J. Ruschau, Friction-Stir Welding Effects on Microstructure and Fatigue of Aluminum Alloy 7050-T7451, Metall. Mater. Trans. A, 2000, 31, p 2181–2192

K. Surekha, B.S. Murty, and K. Prasad Rao, Effect of Processing Parameters on the Corrosion Behaviour of Friction Stir Processed AA 2219 Aluminum Alloy, Solid State Sci., 2009, 11, p 907–917

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R Rep., 2005, 50, p 1–78

C.G. Rhodes, M.W. Mahoney, W.H. Bingel, and M. Calabrese, Fine-Grain Evolution in Friction-Stir Processed 7050 Aluminum, Scr. Mater., 2003, 48, p 1451–1455

V. Buchibabu, G.M. Reddy, D. Kulkarni, and A. De, Friction Stir Welding of a Thick Al-Zn-Mg Alloy Plate, J. Mater. Eng. Perform., 2016, 25, p 1163–1171

S. Jana, R.S. Mishra, J.B. Baumann, and G. Grant, Effect of Friction Stir Processing on Fatigue Behavior of an Investment Cast Al-7Si-0.6 Mg Alloy, Acta Mater., 2010, 58, p 989–1003

W. Woo and H. Choo, Softening Behaviour of Friction Stir Welded Al 6061-T6 and Mg AZ31B Alloys, Sci. Technol. Weld. Join., 2011, 16, p 267–272

H.K. Rafi, G.D.J. Ram, G. Phanikumar, and K.P. Rao, Microstructure and Tensile Properties of Friction Welded Aluminum Alloy AA7075-T6, Mater. Des., 2010, 31, p 2375–2380

J.Q. Su, T.W. Nelson, and C.J. Sterling, Friction Stir Processing of Large-Area Bulk UFG Aluminum Alloys, Scr. Mater., 2005, 52, p 135–140

H.J. Zhang, H.J. Liu, and L. Yu, Effect of Water Cooling on the Performances of Friction Stir Welding Heat-Affected Zone, J. Mater. Eng. Perform., 2012, 21, p 1182–1187

K. Elangovan and V. Balasubramanian, Influences of Post-Weld Heat Treatment on Tensile Properties of Friction Stir-Welded AA6061 Aluminum Alloy Joints, Mater. Charact., 2008, 59, p 1168–1177

H.J. Liu, H.J. Zhang, and L. Yu, Effect of Welding Speed on Microstructures and Mechanical Properties of Underwater Friction Stir Welded 2219 Aluminum Alloy, Mater. Des., 2011, 32, p 1548–1553

T. Azimzadegan and S. Serajzadeh, An Investigation into Microstructures and Mechanical Properties of AA7075-T6 During Friction Stir Welding at Relatively High Rotational Speeds, J. Mater. Eng. Perform., 2010, 19, p 1256–1263

P. Cavaliere, G. Campanile, F. Panella, A. Squillace, Effect of Welding Parameters on Mechanical and Microstructural Properties of AA6056 Joints Produced by Friction Stir Welding, J. Mater. Process. Technol., 2006, 180, p 263–270

C. Sharma, D.K. Dwivedi, and P. Kumar, Effect of Welding Parameters on Microstructure and Mechanical Properties of Friction Stir Welded Joints of AA7039 Aluminum Alloy, Mater. Des., 2012, 36, p 379–390

F. Zhang, X. Su, Z. Chen, and Z. Nie, Effect of Welding Parameters on Microstructure and Mechanical Properties of Friction Stir Welded Joints of a Super High Strength Al-Zn-Mg-Cu Aluminum Alloy, Mater. Des., 2015, 67, p 483–491

Z.Y. Ma, S.R. Sharma, and R.S. Mishra, Effect of Friction Stir Processing on the Microstructure of Cast A356 Aluminum, Mater. Sci. Eng., A, 2006, 433, p 269–278

J.Q. Su, T.W. Nelson, and C.J. Sterling, Microstructure Evolution During FSW/FSP of High Strength Aluminum Alloys, Mater. Sci. Eng., A, 2005, 405, p 277–286

A.S. Golezani, R.V. Barenji, A. Heidarzadeh, and H. Pouraliakbar, Elucidating of Tool Rotational Speed in Friction Stir Welding of 7020-T6 Aluminum Alloy, Int. J. Adv. Manuf. Technol., 2015, 81, p 1155–1164

Y.G. Kim, H. Fujii, T. Tsumura, T. Komazaki, and K. Nakata, Three Defect Types in Friction Stir Welding of Aluminum Die Casting Alloy, Mater. Sci. Eng., A, 2006, 415, p 250–254

J.Q. Su, T.W. Nelson, R. Mishra, and M. Mahoney, Microstructural Investigation of Friction Stir Welded 7050-T651 Aluminium, Acta Mater., 2003, 51, p 713–729

M.W. Mahoney, C.G. Rhodes, J.G. Flintoff, W.H. Bingel, and R.A. Spurling, Properties of Friction-Stir-Welded 7075 T651 Aluminum, Metall. Mater. Trans. A, 1998, 29, p 1955–1964

L. Zhou, T. Wang, W.L. Zhou, Z.Y. Li, Y.X. Huang, and J.C. Feng, Microstructural Characteristics and Mechanical Properties of 7050-T7451 Aluminum Alloy Friction Stir-Welded Joints, J. Mater. Eng. Perform., 2016, 25, p 2542–2550

C.G. Rhodes, M.W. Mahoney, W.H. Bingel, R.A. Spurling, and C.C. Bampton, Effects of Friction Stir Welding on Microstructure of 7075 Aluminum, Scr. Mater., 1997, 36, p 69–75

W. Woo, L. Balogh, T. Ungár, H. Choo, and Z. Feng, Grain Structure and Dislocation Density Measurements in a Friction-Stir Welded Aluminum Alloy Using X-Ray Peak Profile Analysis, Mater. Sci. Eng., A, 2008, 498, p 308–313

M.Z. Huq and L.B. Celis, Reproducibility of Friction and Wear Results Is ball-on-Disc Unidirectional Sliding Tests of TiN-Alumina Pairings, Wear, 1997, 1648, p 151–159

M. Barmouz, M.K. Besharati Givi, and J. Seyfi, On the Role of Processing Parameters in Producing Cu/SiC Metal Matrix Composites via Friction Stir Processing: Investigating Microstructure, Microhardness, Wear and Tensile Behavior, Mater. Charact., 2011, 62, p 108–117

E.R.I. Mahmoud, M. Takahashi, T. Shibayanagi, and K. Ikeuchi, Wear Characteristics of Surface-Hybrid-MMCs Layer Fabricated on Aluminum Plate by Friction Stir Processing, Wear, 2010, 268, p 1111–1121

R.L. Deuis, C. Subramanian, and J.M. Yellup, Abrasive Wear of Aluminium Composites—A Review, Wear, 1996, 201, p 132–144

Y. Mazaheri, F. Karimzadeh, and M.H. Enayati, Tribological Behavior of A356/Al2O3 Surface Nanocomposite Prepared by Friction Stir Processing, Metall. Mater. Trans. A, 2013, 45, p 2250–2259

A. Thangarasu, N. Murugan, I. Dinaharan, and S.J. Vijay, Influence of Traverse Speed on Microstructure and Mechanical Properties of AA6082-TiC Surface Composite Fabricated by Friction Stir Processing, Procedia Mater. Sci., 2014, 5, p 2115–2121

A. Sert and O.N. Celik, Wear Behavior of SiC-Reinforced Surface Composite Al7075-T651 Aluminum Alloy Produced Using Friction Stir Processing, Indian J. Eng. Mater. Sci., 2014, 21, p 35–43

M.G. Fontena, Corrosion Engineering, 3rd ed., 12th reprint, Tata McGraw-Hill Edition, New Delhi, 2005

V. Proton, J. Alexis, E. Andrieu, J. Delfosse, M.C. Lafont, and C. Blanc, Characterisation and Understanding of the Corrosion Behaviour of the Nugget in a 2050 Aluminium Alloy Friction Stir Welding Joint, Corros. Sci., 2013, 73, p 130–142

S. Kim, U. Erb, K. Aust, and G. Palumbo, Grain Boundary Character Distribution and Intergranular Corrosion Behavior in High Purity Aluminum, Scr. Mater., 2001, 44, p 835–839

M. Jariyaboon, A.J. Davenport, R. Ambat, B.J. Connolly, S.W. Williams, and D.A. Price, Effect of Cryogenic Cooling on Corrosion of Friction Stir Welded AA7010-T651, Anti Corros. Methods Mater., 2010, 57, p 83–89

C. Sharma, D.K. Dwivedi, and P. Kumar, Friction Stir Welding of Al-Zn-Mg Alloy AA7039, Light Met., 2012, 2012, p 503–507

M.K. Cavanaugh, J.C. Li, N. Birbilis, and R.G. Buchheit, Electrochemical Characterization of Intermetallic Phases Common to Aluminum Alloys as a Function of Solution Temperature, J. Electrochem. Soc., 2014, 161, p C535–C543

S.D. Liu, B. Chen, C.B. Li, Y. Dai, Y.L. Deng, and X.M. Zhang, Mechanism of Low Exfoliation Corrosion Resistance Due to Slow Quenching in High Strength Aluminium Alloy, Corros. Sci., 2015, 91, p 203–212

Acknowledgments

The authors highly acknowledged the Department of Metallurgical and Materials Engineering and Institute Instrumentation Centre, IIT Roorkee, for providing the facilities and support to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, A., Sharma, S.K., Pal, K. et al. Effect of Process Parameters on Microstructural Evolution, Mechanical Properties and Corrosion Behavior of Friction Stir Processed Al 7075 Alloy. J. of Materi Eng and Perform 26, 1122–1134 (2017). https://doi.org/10.1007/s11665-017-2572-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2572-3