Abstract

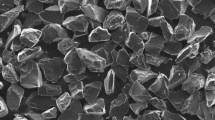

In this paper, we report for the first time, the synthesis and characterization of novel Ti3SiC2 reinforced Al-matrix composites. All the composites were cold pressed and sintered in the temperature range of 700–750 °C for 5–30 min in an inert Ar atmosphere. Microstructure analysis by scanning electron microscopy and phase analysis by x-ray diffraction confirmed that there was minimal interfacial reaction between Ti3SiC2 particles and Al. The addition of Ti3SiC2 enhanced the mechanical performance of the composites. For example, the pure Al samples had a yield strength of 97 ± 6 MPa, where as the volume fraction of Ti3SiC2 was increased to 5 and 10 vol.% in the composites, the yield strength increased significantly to 212 ± 27 and 273 ± 52 MPa, respectively. As the volume fraction of Ti3SiC2 was further increased to 20 and 35 vol.%, the yield strength mildly increased to 278 ± 48 MPa, and then decreased to 134 ± 20 MPa, respectively. The decrease in yield strength after 35 vol.% Ti3SiC2 addition in the Al matrix was attributed to the presence of higher amount of porosity in these samples. The addition of Ti3SiC2 particles also had a beneficial effect on the tribological performance of these composites against alumina substrates.

Similar content being viewed by others

References

M.W. Barsoum and M. Radovic, Elastic and Mechanical Properties of the MAX Phases, Annu. Rev. Mater. Res., 2011, 41, p 195–227

M.W. Barsoum and T. El-Raghy, Synthesis and Characterization of a Remarkable Ceramic: Ti3SiC2, J. Am. Ceram. Soc., 1996, 79, p 1953–1956

M.W. Barsoum, The Mn+1AXn Phases: A New Class of Solids; Thermodynamically Stable Nanolaminates, Prog. Solid State Chem., 2000, 28, p 201–281

S. Amini, M.W. Barsoum, and T. El-Raghy, Synthesis and Mechanical Properties of Fully Dense Ti2SC, J. Am. Ceram. Soc., 2007, 90(12), p 3953–3958

M. Radovic, M.W. Barsoum, T. El-Raghy, S.M. Wiederhorn, and W.E. Luecke, Effect of Temperature, Strain Rate and Grain Size on the Mechanical Response of Ti3SiC2 in Tension, Acta Mater., 2002, 50, p 1297–1306

T. El-Raghy, M.W. Barsoum, A. Zavaliangos, and S.R. Kalidindi, Processing and Mechanical Properties of Ti3SiC2. II. Effect of Grain Size and Deformation Temperature, J. Am. Ceram. Soc., 1999, 82, p 2855–2860

T. Zhen, M.W. Barsoum, S.R. Kalidindi, M. Radovic, Z.M. Sun, and T. El-Raghy, Compresive Creep of Fine and Coarse-Grained Ti3SiC2 in Air in the 1100-1300 °C Temperature Range, Acta Mater., 2005, 53, p 4963–4973

S.B. Li, L.F. Cheng, and L.T. Zhang, Oxidation Behavior of Ti3SiC2 at High Temperature in Air, Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process., 2003, 341, p 112–120

S. Gupta and M.W. Barsoum, Synthesis and Oxidation of V2AlC and (Ti0.5, V0.5)2AlC in Air, J. Electrochem. Soc., 2004, 151, p D24–D29

M.W. Barsoum, N. Tzenov, A. Procopio, T. El-Raghy, and M. Ali, Oxidation of Tin+1AlXn (n = 1–3 and X = C, N). II. Experimental Results, J. Electrochem. Soc., 2001, 148, p C551–C562

X.H. Wang and Y.C. Zhou, Oxidation Behavior of Ti3AlC2 Powders in Flowing Air, J. Mater. Chem., 2002, 12(9), p 2781–2785

S. Gupta, D. Filimonov, and M.W. Barsoum, Isothermal Oxidation of Ta2AlC in Air, J. Am. Ceram. Soc., 2006, 89, p 2974–2976

Z.J. Lin, M.S. Li, J.Y. Wang, and Y.C. Zhou, High-Temperature Oxidation and Hot Corrosion of Cr2AlC, Acta Mater., 2007, 55, p 6182–6191

S. Gupta and M.W. Barsoum, On the Tribology of the MAX Phases and Their Composites During Dry Sliding: A Review, Wear, 2011, 271, p 1878–1894

Y. Zhang, Z.M. Sun, and Y.C. Zhou, Cu/Ti3SiC2 Composite: A New Electrofriction Material, Mater. Res. Innov., 1999, 3, p 80–84

S. Gupta, D. Filimonov, T. Palanisamy, T. El-Raghy, and M.W. Barsoum, Ta2AlC and Cr2AlC Ag-Based Composites: New Solid Lubricant Materials for Use Over a Wide Temperature Range Against Ni-Based Superalloys and Alumina, Wear, 2007, 262, p 1479–1489

B. Anasori, S. Amini, V. Presser, and M.W. Barsoum, Nanocrystalline M-Matrix Composites with Ultrahigh Damping Properties. Magnesium Technology, Wiley, Hoboken, 2011, p 463–468

W.J. Wang, V. Gauthier-Brunet, G.P. Bei, G. Laplanche, J. Bonneville, A. Joulain, and S. Dubois, Powder Metallurgy Processing and Compressive Properties of Ti3AlC2/Al Composites, Mater. Sci. Eng. A, 2011, 530, p 168–173

L. Hu, A. Kothalkar, M. O’Neil, I. Karaman, and M. Radovic, Current-Activated, Pressure-Assisted Infiltration: A Novel, Versatile Route for Producing Interpenetrating Ceramic-Metal Composites, Mater. Res. Lett., 2014, doi:10.1080/21663831.2013.873498

A. Kothalkar, R. Benitez, L. Hu, M. Radovic, and I. Karaman, Thermo-mechanical Response and Damping Behavior of Shape Memory Alloy/MAX Phase Composites, Metall. Mater. Trans. A., 2014, 45, p 2646–2658

K.G. Budinski and M.K. Budinski, Engineering Materials Properties and Selection, 9th ed., Prentice Hall, Upper Saddle River, 2010

D.B. Miracle, Metal Matrix Composites: From Science to Technological Significance, Compos. Sci. Technol., 2005, 65, p 2526–2540

Z. Chen, T. Takeda, and K. Ikeda, Microstructural Evolution of Reactive-Sintered Aluminum Matrix Composites, Compos. Sci. Technol., 2008, 68, p 2245–2253

A. Pramanik, L.C. Zhang, and J.A. Arsecularatne, Machining of Metal Matrix Composites: Effect of Ceramic Particles on Residual Stress, Surface Roughness and Chip Formation, Int. J. Mach. Tools Manuf., 2008, 48, p 1613–1625

M. El-Gallab and M. Sklad, Machining of Al/SiC Particulate Metal-Matrix Composites, Part I: Tool Performance, J. Mater. Process. Technol., 1998, 83, p 151–158

X. Ding, W.Y.H. Liew, and X.D. Liu, Evaluation of Machining Performance of MMC with PCBN and PCD Tools, Wear, 2005, 259, p 1225–1234

Acknowledgments

One of the authors (SG) would like to acknowledge the University of North Dakota start-up and seed grant funding for support. Authors would like to thank Kanthal Inc. for supplying the Ti3SiC2 powders. The XRD study in this work was supported in part by the MRSEC Program of the National Science Foundation under Award Number DMR-0819885. NDSU Electron Microscopy Center core facility is also acknowledged for the microscopy. This material is also based upon work supported by the National Science Foundation under Grant No. 0619098, and 1229417. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, S., Hammann, T., Johnson, R. et al. Synthesis and Characterization of Novel Al-Matrix Composites Reinforced with Ti3SiC2 Particulates. J. of Materi Eng and Perform 24, 1011–1017 (2015). https://doi.org/10.1007/s11665-014-1330-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1330-z