Abstract

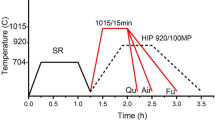

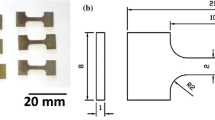

TIMETAL 54M is a newly developed (α + β) titanium alloy with nominal composition Ti-5Al-4V-0.6Mo-0.4Fe. The alloy can provide a cost benefit over Ti-6Al-4V due to improved machinability and formability. In the present work, evolution of mechanical properties in terms of tensile and hardness values is investigated as a function of deformation degrees imposed via rotary swaging (RS). Microstructure, mechanical properties, and fatigue performance of Ti-54M are investigated after severe plastic deformation by RS conducted at 850 °C and after being subjected to two different post-swaging annealing conditions. Optical microscopy and scanning electron microscopy using electron back scatter diffraction were utilized to document the evolution of the microstructure. Tensile tests were conducted to characterize mechanical properties. RS, to a true strain of 3.0, is found to lead to a marked ultrafine-grained structure of about 1 μm grain size with low content of high angle grain boundaries (HAGBs). Post-swaging heat treatment at 800 °C followed by air cooling did not change the grain size but exhibited high content of HAGBs. Post-swaging heat treatment at 940 °C followed by furnace cooling resulted in a grain size of about 5 μm and enhanced work-hardening capability and ductility, which resulted in less fatigue notch sensitivity, but at the same time lower fatigue strength at 107 cycles.

Similar content being viewed by others

References

T.S. Srivatsan and M. Kuruvilla, Lisa Park. An investigation of the cyclic fatigue and final behavior of titanium alloy, Key Eng. Mater., 2008, 378–379, p 271–298

V. Venkatesh, Y. Kosaka, J. Fanning, S. Nyakana, in Proceedings of the 11th International World Conference on Titanium (JIMICS5), ed. by M. Niinomi, S. Akiyama, M. Ikeda, M. Hagiwara, K. Maruyama (Kyoto, Japan, 2007), p. 713.

S.L. Nyakana, J.C. Fanning, D.W. Tripp, in Proceedings of the 11th International World Conference on Titanium (JIMICS5), ed. by M. Niinomi, S. Akiyama, M. Ikeda, M. Hagiwara, K. Maruyama (Kyoto, Japan, 2007), p. 749.

Image Taken From Torrington-Machinery, http://www.torrington-machinery.com/images/pic_rotary_swaging1.gifS. Accessed 26 April 2013.

M. Shahzad, Dr.-Ing. Influence of extrusion parameters on microstructure development and mechanical properties in wrought magnesium alloys AZ80 and ZK60 Thesis, TU Clausthal, 2007.

K. Zay, Considering mean stress and environmental effects in understanding the fatigue performance of mechanically surface treated Titanium alloys, Dr.-Ing. Thesis, TU Clausthal, 2011.

W. Wei, K.X. Wei, and Q.N. Shi, Grain refinement of copper sheets through accumulative roll-bonding process at room temperature, Ultrafine Grained Materials IV, Y.T. Zhu, T.G. Langdon, Z. Horita, M.J. Zehetbauer, S.L. Semiatin, and T.C. Lowe, Ed., TMS, Warrendale, 2006, p 209

A.P. Zhilyaev, K. Oh-ishi, G.I. Raab, and T.R. McNelley, Influence of processing parameters on texture and microstructure in ECAPed aluminum. Ultrafine Grained Materials IV, TMS, Warrendale, 2006, p 113

J. Müller, S. Yi, M. Janecek, J. Cizek, and L. Wagner, Effect of equal channel angular pressing on microstructure, texture and high-cycle fatigue performance of wrought magnesium alloys, Int. J. Mater. Res., 2009, 100, p 838

V. Randle and O. Engler, Introduction to texture analysis macrotexture, microtexture and orientation mapping, Gordon and Breach Science, The Netherlands, 2000

F.J. Humphreys and M. Hatherly, Recrystallization and related annealing phenomena, 1st ed., Elsevier, Oxford, 1995

J.I. Goldstein, D.E. Newbury, P.E. Echlin, D.C. Joy, C.E. Lyman, A.D. Romig, C.E. Fiori, and E. Lifshin, Scanning electron microscopy and x-ray microanalysis, Plenum Press, New York, 1992

C. Escher and G. Gottstein, Nucleation of recrystallization in boron doped Ni3Al, Acta Mater., 1998, 46, p 525–539

I.C. Hsiao, S.W. Su, and J.C. Huang, Evolution of texture and grain misorientation in an Al-Mg alloy exhibiting low temperature superplasticity, Metall. Mater. Trans., 2000, 31A, p 2169–2180

T.R. McNelley, D.L. Swisher, and M.T. Perez-Prado, Deformation bands and the formation of grain boundaries in a superplastic aluminum alloy, Metall. Mater. Trans., 2002, 33, p 279–290

X. Huang, Grain orientation effect on microstructure in tensile strained copper, Scr. Mater., 1998, 38, p 1697–1703

K. Sztwertnia and F. Haessner, Orientational aspects of the morphological elements of the microstructure in highly cold rolled pure copper and phosphorous copper, Mater. Sci. Forum, 1994, 157–162, p 1291

G.C. Kaschner and G.T. Gray, III, The influence of crystallographic texture and interstitial impurities on the mechanical behavior of zirconium, Metall. Mater. Trans., 2000, 31A, p 1997–2003

J.J. Fundenberger, M.J. Philippe, F. Wanger, C. Esling, Modelling and prediction of mechanical properties for materials with hexagonal symmetry (zinc, titanium and zirconium alloys, Acta Mater., 1997, 45, p 4041–4055

N. Gey and M. Humbert, Characterization of the variant selection occurring during the α → β → α phase transformations of a cold rolled titanium sheet, Acta Mater., 2002, 50, p 277–287

S.L. Semiatin and T.R. Bieler, Effect of texture and slip mode on the anisotropy of plastic flow and flow softening during hot working of Ti-6Al-4V, Metall. Mater. Trans, 2001, 32A, p 1787–1799

F. Wanger, N. Bozzolo, O. Van Landuyt, and T. Grosdidier, Evolution of recrystallisation texture and microstructure in low alloyed titanium sheets, Acta. Mater., 2002, 50, p 1245–1259

S. Suwas, R.K. Ray, A.K. Singh, and S. Bhargava, Evolution of hot rolling textures in a two-phase (α2 + β) Ti3Al base alloy, Acta Mater., 1999, 47, p 4585–4598

S. Suwas and R.K. Ray, Effect of rolling on textures of primary and secondary alpha(2) produced by thermomechanical processing of the intermetallic alloy Ti-24Al-11Nb, Scr. Mater., 2001, 44, p 275–280

S. Suwas and R.K. Ray, Evolution of texture in the beta(B2) phase of a two phase titanium aluminide intermetallic alloy Ti-24Al-11Nb, Metall. Mater. Trans., 2000, 31A, p 2339–2350

S.L. Seniatin, P.N. Fagin, M.G. Glavicic, I.M. Sukonnik, and O.M. Ivasishin, Influence on texture on beta grain growth during continuous annealing of Ti-6Al-4V Mater, Sci. Eng. A, 2001, 299, p 225–234

S.V. Divinski, V.N. Dnieprenko, and O.M. Ivasishin, Effect of phase transformation on texture formation in Ti-base alloys, Mater. Sci. Eng. A, 1998, 243, p 201–205

Y.N. Wang and J.C. Huang, Texture analysis in hexagonal materials, Mater. Chem. Phys., 2003, 81, p 11–26

E.A. El-Danaf, M.S. Soliman, A.A. Almajid, and M.M. El-Rayes, Enhancement of mechanical properties and grain size refinement of commercial purity aluminum 1050 processed by ECAP, Mater. Sci. Eng. A, 2007, 458, p 226–234

F.H. DallaTorre, E.V. Pereloma, and C.H.J. Davies, Acta Mater., 2006, 54, p 1135

Z.J. Zhang, X.H. An, P. Zhang, M.X. Yang, G. Yang, S.D. Wu, and Z.F. Zhang, Effects of dislocation slip mode on high-cycle fatigue behaviors of ultrafine-grained Cu-Zn alloy processed by equal-channel angular pressing, Scr. Mater., 2013, 68, p 389–392

H. ALkhazraji, M.Z. Salih, Z. Zhong, M. Mhaede, H.-G. Brokmeier, L. Wagner, and N. Schell, Estimation of dislocation density in cold-rolled commercially pure titanium by using synchrotron diffraction, Metall. Mater. Trans. B, 2014, 45, p 1557–1564

Acknowledgments

The first author would like to thank the Ministry of Higher Education & Scientific Research, Iraq (MoHESR) and the German academic exchange service (DAAD) for supporting his stay at TU Clausthal. The second author would like to acknowledge the partial support by King Saud University, Deanship of Scientific Research, College of Engineering, Research Centre.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Khazraji, H., El-Danaf, E., Wollmann, M. et al. Microstructure, Mechanical, and Fatigue Strength of Ti-54M Processed by Rotary Swaging. J. of Materi Eng and Perform 24, 2074–2084 (2015). https://doi.org/10.1007/s11665-014-1283-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1283-2