Abstract

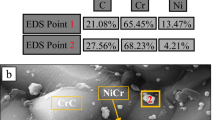

Corrosion in incinerators, power plants, and chemical industries are frequently encountered due to the presence of salts containing sodium, sulphur, and chlorine. To obviate this problem, bare and coated alloys were tested under environments simulating the conditions present inside incinerators and power plants. 0.2 wt.% zirconium powder was incorporated in the Cr3C2-(NiCr) coating powder. The original powder and Zr containing powder was sprayed on Superni 718 alloy by D-gun technique. The bare and coated alloys were tested under Na2SO4 + K2SO4 + NaCl + KCl and Na2SO4 + NaCl environment. The corrosion rate of specimens was monitored using weight change measurements. Characterization of the corrosion products has been done using FE-SEM/EDS and XRD techniques. Bare and coated alloys showed very good corrosion resistance under given molten salt environments. Addition of 0.2wt.%Zr in Cr3C2-25%(NiCr) coating further greatly reduced the oxidation rate as well as improved the adherence of oxide scale to the coating surface during the time of corrosion.

Similar content being viewed by others

References

R. Ademar, J.G. Gonzalez-Rodriguez, J. Uruchurtu, J. Porcayo-Calderon, V.M. Salinas-Bravo, G. Dominguez-Patiño, and A. Bedolla-Jacuinde, Corrosion Behavior of Fe40Al Alloy with Additions of Ti, Ag, and Cr in Molten KCl + ZnCl2, Int. J. Corros., 2012, 2012, art. id. 146486. doi:10.1155/2012/146486

Melanie. Montgomery, Ole Biede and Ole Hede Larsen, Experiences with Inconel 625 in Biomass and Waste Incineration Plants, Mater. Sci. Forum, 2006, 522-523, p 523–530

A. Jegede, V. Vasantasree, and M.G. Hocking, Corrosion of Ultimet and 310SS in a Simulated Waste Incineration Environment at 750 °C, J. Mater. Sci. Lett., 1995, 14, p 1089–1091

D.C. Agarwal and G.K. Grossmann, Case Histories on the Use of Nickel Alloys in Municipal and Hazardous Waste Fueled Facilities, Krupp VDM GmbH, Corrosion 2001, NACE International, 11-16 March, 2001, Houston, TX

S. Kamal, R. Jayaganthan, and S. Prakash, Mechanical and Microstructural Characteristics of Detonation Gun Sprayed NiCrAlY + 0.4% CeO2 Coatings on Superalloys, Mater. Chem. Phys., 2010, 12, p 262–268

K. Yamada, Y. Tomonoer, J. Morimoto, Y. Sasaki, and A. Ohmori, Hot Corrosion Behaviour of Boiler Tube Materials in Refuse Incineration Environment, Vacuum, 2002, 65, p 533–540

S. Paul, M.D.F. Harvey, Corrosion Testing of Ni Alloy HVOF Coatings in High Temperature Environments for Biomass Applications, Paper presented at ITSC 2012 International Thermal Spray Conference, Houston USA, 21-24 May 2012, and published in J. Therm. Spray Technol.

M. Suarez, S. Bellayer, M. Traisnel, W. Gonzalez, D. Chicot, J. Lesage, E.S. Puchi-Cabrera, and M.H. Staia, Corrosion Behaviour of Cr3C2-(NiCr) Vaccum Plasma Sprayed Coatings, Surf. Coat. Technol., 2008, 202, p 4566–4571

J.M. Guilemany, J.M. Miguel, S. Vizcaino, C. Lorenzana, J. Delgado, and J. Sanchez, Role of Heat Treatments in the Improvement of the Sliding Wear Properties of Cr3C2-NiCr Coatings, Surf. Coat. Technol., 2002, 157, p 207–213

S. Matthews, B. James, and M. Hyland, Erosion of Oxide Scales Formed on Cr3C2-NiCr Thermal Spray Coatings, Corros. Sci., 2008, 50, p 3087–3094

N. Espallargas, J. Berget, J.M. Guilemany, A.V. Benedetti, and P.H. Suegama, Cr3C2-NiCr and WC-Ni Thermal Spray Coatings as Alternatives to Hard Chromium for Erosion-Corrosion Resistance, Surf. Coat. Technol., 2008, 202, p 1405–1417

J.M. Guilemany, N. Eapallargas, P.H. Suegama, and A.V. Benedetti, Comparative Study of Cr3C2-NiCr Coatings Obtained by HVOF and Hard Chromium Coatings, Corros. Sci., 2006, 48, p 2998–3013

S.S. Chatha, H.S. Sidhu, and B.S. Sidhu, High Temperature Hot Corrosion Behaviour of NiCr and Cr3C2-NiCr Coatings on T91 Boiler Steel in an Aggressive Environment at 750 °C, Surf. Coat. Technol., 2012, 206(19-20), p 3839–3850

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Hot Corrosion Studies of HVOF Sprayed Cr3C2-NiCr and Ni-20Cr Coatings on Nickel-Based Superalloy at 900 °C, Surf. Coat. Technol., 2006, 201(3-4), p 792–800

S. Kamal, R. Jayaganthan, and S. Prakash, Evaluation of Cyclic Hot Corrosion Behaviour of Detonation Gun Sprayed Cr3C2-25%NiCr Coatings on Nickel- and Iron-Based Superalloys, Surf. Coat. Technol., 2009, 203, p 1004–1013

S. Kamal, R. Jayaganthan, S. Prakash, and S. Kumar, Hot Corrosion Behavior of Detonation Gun Sprayed Cr3C2-NiCr Coatings on Ni and Fe-Based Superalloys in Na2SO4-60% V2O5 Environment at 900 °C, J. Alloys Compd., 2008, 463, p 358–372

Y. Wang, R. Kovacevic, and J. Liu, Mechanism of Surface Modification of CeO in Laser Remelted Alloy Spray Coatings, Wear, 1998, 221, p 47–53

Y.B. Zhou, H.-J. Zhang, and Z.-T. Wang, Effect of Y2O3 on Microstructure and Oxidation of γ-Ni + γ′-Ni3Al Coatings Transformed from Electrodeposited Ni-Al Films at 1000 °C, Trans. Nonferr. Met. Soc. China, 2008, 18, p 297–302

Z. Zhang, X. Lu, B. Han, and J. Luo, Rare Earth Effect on the Microstructure and Wear Resistance of Ni-Based Coatings, Mater. Sci. Eng. A, 2007, 454-455, p 194–202

Xiu. Song and Lei. Wang, Yang Liu and Huiping Ma,) Study on the Mechanical Performance of a Ni-Based Superalloy with Trace Rare Earth Element La Additions, Adv. Mater. Res., 2012, 509, p 177–181

Tetsuo. Ishitsuko and Koichi. Nose, Stability of Protective Oxide Films in Waste Incineration Environment-Solubility Measurement of Oxides in Molten Chlorides, Corros. Sci., 2002, 22, p 247–263

D.K. Goyal, H. Singh, H. Kumar, and V. Sahni, Erosive Wear Study of HVOF Spray Cr3C2-NiCr Coated CA6NM Turbine Steel, J. Tribol., 2014, 136(4), p 041602

H.T. Wang, G.C. Ji, Q.Y. Chen, X.F. Du, and W. Fe, The Microstructure and Erosion Wear Performance of HVOF-Sprayed Cr3C2-NiCr Coatings with Different Feedstock Powder, Adv. Mater. Res., 2011, 228-229, p 809–812

C.A.D. Cunha, N.B.D. Lima, J.R. Martinelli, A.H.D.A. Bressiani, A.G.F. Padial, and L.V. Ramanathan, Microstructure and Mechanical Properties of Thermal Sprayed Nanostructured Cr3C2-Ni20Cr Coatings, Mater. Res., 2008, 11(2), p 137–143

M.W. Richert, M. Książek, P. Pałka, S. Wawrzyniak, R. Grzelka, and K. Płońska-Niżnik, Microstructure Characterization of Chromium Carbides Coatings Deposited by Thermal Spraying Processes, JAMME, 2012, 55(1), p 108–112

G. Kaushal, N. Bala, N. Kaur, H. Singh, and S. Prakash, Comparative High-Temperature Corrosion Behavior of Ni-20Cr Coatings on T22 Boiler Steel Produced by HVOF, D-Gun, and Cold Spraying, Metall. Mater. Trans. A, 2014, 45, p 395–410. doi:10.1007/s11661-013-1984-4

H.P. Nielsena, F.J. Frandsena, K. Dam-Johansena, and L.L. Baxter, The Implications of Chlorine-Associated Corrosion on the Operation of Biomass-Fired Boilers, Prog. Energy Combust. Sci., 2000, 26, p 283–298

A. Zahs, M. Spiegel, and H.J. Grabke, Chloridation and Oxidation of Iron, Chromium, Nickel and Their Alloys in Chloridizing and Oxidizing Atmospheres at 400 ± 700 °C, Corros. Sci., 2000, 42, p 1093–1122

H.L. Bernstein, High Temperature Coatings for Industrial Gas Turbine Users, Proceedings of the 28th Turbomachinery Symposium, Texas A&M University, 1999, p 179-188

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Characterizations and Hot Corrosion Resistance of Cr3C2-NiCr Coating on Ni-Base Superalloys in an Aggressive Environment, J. Therm. Spray Technol., 2006, 15(4), p 811–816

S.J. Matthews, B.J. James, and M.M. Hyland, The Role of Microstructure in the Mechanism of High Velocity Erosion of Cr3C2-NiCr Thermal Spray Coatings: Part 2-Heat Treated Coatings, Surf. Coat. Technol., 2009, 203, p 1094–1100

C.A. Barrett, A.S. Khan, and C.E. Lowell, The Effect of Zirconium on the Cyclic Oxidation of NiCrAl Alloys, Electrochem. Sci. Technol., 1981, 128(1), p 25–32

I. Gurrappa, Hot Corrosion Behaviour of CM 247 LC Alloy in Na2SO4 and NaCl Environments, Oxid. Met., 1999, 51(5/6), p 353–382

H.P. Nielsen, F.J. Frandsen, K. Dam-Johansen, and L.L. Baxter, The Implications of Chlorine-Associated Corrosion on the Operation of Biomass-Fired Boilers, Prog Energy Combust. Sci., 2000, 26, p 283–298

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Hot Corrosion Studies of HVOF Sprayed Cr3C2-NiCr and Ni-20Cr Coatings on Nickel-Based Superalloy at 900 °C, Surf. Coat. Technol., 2006, 201, p 792–800

Y.-J. Zhang, X.-F. Sun, H.-R. Guan, and Z.-Q. Hu, Effect of Sprayed Powder Particle Size on the Oxidation Behavior of MCrAlY Materials during High Velocity Oxygen-Fuel Deposition, Surf. Coat. Technol., 2002, 161, p 302–305

R.A. Neiser, M.F. Smith, and R.C. Dykhuizen, Oxidation in Wire HVOF-Sprayed Steel, J. Therm. Spray Technol., 1998, 7(4), p 537–545

Christian. Brunner, Herbert. Hutter, Peter. Wilhartitz, and Manfred. Grasserbauer, Investigation of the Formation and Properties of Protective Oxide Layers on High Purity Chromium with SIMS Imaging Techniques, Mikrochim. Acta, 1997, 125, p 69–72

S. Matthews, B. James, and M. Hyland, The Effect of Heat Treatment on the Oxidation Mechanism of Blended Powder Cr3C2-NiCr Coatings, J. Therm. Spray Technol., 2010, 19(1-2), p 119–127

M. Kaur, H. Singh, and S. Prakash, High-Temperature Corrosion Studies of HVOF-Sprayed Cr3C2-NiCr Coating on SAE-347H Boiler Steel, J. Therm. Spray Technol., 2009, 18(4), p 619–632

E.M. Lehockey, G. Palumbo, and P. Lin, Improving the Weldability and Service Performance of Nickel and Iron-Based Superalloys by Grain Boundary Engineering, Metall. Mater. Trans. A, 1998, 29, p 3069–3079

W. Kai, C.T. Leu, and P.Y. Lee, Effects of Sulfur Pressure on the Sulfidation Behavior of 310 Stainless Steel, Oxid. Met., 1996, 46(3/4), p 185–211

A.C.S. Sabioni, A.M. Huntz, F. Silva, and F. Jomard, Diffusion of Iron in Cr2O3: Polycrystals and Thin Films, Mater. Sci. Eng. A, 2005, 392, p 254–261

D.M. Johnson, D. Whittle, and J. Stringer, Mechanisms of Na2SO4-Induced Accelerated Oxidation, Corros. Sci., 1975, 15, p 721–739

M.F. Pillis, E.G. Araújo, and L.V. Ramanathan, Effect of Rare Earth Oxide Additions on Oxidation Behavior of AISI, 304L Stainless Steel, Mater. Res., 2006, 9(4), p 375–379

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mudgal, D., Singh, S. & Prakash, S. Hot Corrosion Behavior of Bare, Cr3C2-(NiCr) and Cr3C2-(NiCr) + 0.2wt.%Zr Coated SuperNi 718 at 900 °C. J. of Materi Eng and Perform 24, 1–15 (2015). https://doi.org/10.1007/s11665-014-1279-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1279-y