Abstract

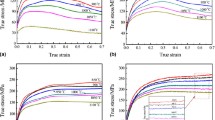

A modified Johnson-Cook constitutive equation of Ti-6Al-4V alloy is proposed based on hot compression tests performed in the temperature range of 1073-1323 K and strain rate 0.001-1 s−1. The experimental stress-strain data were employed to develop the modified Johnson-Cook constitutive equation of different phase regimes (α + β and β phase). The predicted flow stresses using the developed equation were compared with experimental data. Correlation coefficient (R) and average absolute relative error (AARE) were introduced to verify the validity of the constitutive equation. The values of R and AARE for α + β phase were 0.990 and 7.81%, respectively. And in β phase region, the values of R and AARE were 0.985 and 10.36%, respectively. Meanwhile, the accuracy, the number of material constants involved, and the computational time required of the constitutive equation were evaluated by comparing with a strain-compensated Arrhenius-type constitutive equation. The results indicate that accuracy of modified Johnson-Cook constitutive equation is higher than that of compensated Arrhenius-type model at α + β phase, while lower at single β phase region. Meanwhile, the time required for evaluating the material constants of modified Johnson-Cook constitutive equation is much shorter than that of the strain-compensated Arrhenius type ones.

Similar content being viewed by others

References

A. H, G.L. Xie, H.L. Zhang, and X.T. Wang, A Modified Zerilli-Armstrong Constitutive Model to Predict Hot Deformation Behavior of 20CrMo Alloy Steel, Mater. Des., 2014, 56, p 122–127

Y.C. Lin, M.S. Chen, and J. Zhong, Prediction of 42CrMo Steel Flow Stress at High Temperature and Strain Rate, Mech. Res. Commun., 2008, 35(3), p 142–150

K.P. Rao, Y.V.R.K. Prasad, and K. Suresh, Simulation Materials Modeling and Simulation of Isothermal Forging of Rolled AZ31B Magnesium Alloy: Anisotropy of Flow, Mater. Des., 2011, 32(5), p 2545–2553

Y. Han, G.J. Qiao, J.P. Sun, and D.N. Zou, A Comparative Study on Constitutive Relationship of As-cast 904L Austenitic Stainless Steel During Hot Deformation Based on Arrhenius-Type and Artificial Neural Network Models, Comput. Mater. Sci., 2013, 67, p 93–103

H.Y. Li, X.F. Wang, D.D. Wei, J.D. Hu, and Y.H. Li, A Comparative Study on Modified Zerilli-Armstrong, Arrhenius-Type and Artificial Neural Network Models to Predict High-Temperature Deformation Behavior in T24 Steel, Mater. Sci. Eng., A, 2012, 536, p 216–222

X. Xiao, G.Q. Liu, B.F. Hu, X. Zheng, L.N. Wang, S.J. Chen, and A. Ullah, A Comparative Study on Arrhenius-Type Constitutive Equations and Artificial Neural Network Model to Predict High-Temperature Deformation Behaviour in 12Cr3WV Steel, Comput. Mater. Sci., 2012, 62, p 227–234

J. Ding, G.Z. Kang, and Q.H. Kan, Constitutive Model for Uniaxial Time-Dependent Ratcheting of 6061-T6 Aluminum Alloy, Comput. Mater. Sci., 2012, 57, p 67–72

H.J. Jun, K.S. Lee, H. Kato, H.S. Kim, and Y.W. Chang, Constitutive Model for High Temperature Deformation Behavior of Ti-Zr-Ni-Be Bulk Metallic Glass in Supercooled liquid Region, Comput. Mater. Sci., 2012, 61, p 213–223

M. Vural, D. Rittel, and G. Ravichandran, Large Strain Mechanical Behavior of 1018 Cold-Rolled Steel Over a Wide Range of Strain Rates, Metall Mat Trans A Phys Metall Mat Sci., 2003, 34(12), p 2873–2885

Y.C. Lin and X.M. Chen, A Modified Johnson-Cook Model for Tensile Behaviors of Typical High-Strength Alloy Steel, Mater. Sci. Eng., A, 2010, 527(26), p 6980–6986

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32(4), p 1733–1759

G.R. Johnson and W.H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures, In: Proceedings of the 7th International Symposium on Ballistics (Den Haag, The Netherlands), 1983, p 541-547

P.J. Zerilli and R.W. Armstrong, Dislocation-mechanics-Based Constitutive Relations for Material Dynamics Calculations, J. Appl. Phys., 1987, 61, p 1816–1825

Y.Q. Cheng, H. Zhang, Z.H. Chen, and K.F. Xian, Flow Stress Equation of AZ31 Magnesium Alloy Sheet During Warm Tensile Deformation, J. Mater. Process. Technol., 2008, 208(1-3), p 29–34

C.M. Sellars and W.J. McTegart, On the mechanism of hot deformation, Acta Metall., 1966, 14, p 1136–1138

F.A. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman, Constitutive Analysis of Wrought Magnesium Alloy Mg-Al4-Zn1, Scr. Mater., 2007, 57(8), p 759–762

S. Mandal, V. Rakesh, P.V. Sivaprasad, S. Venugopal, and K.V. Kasiviswanathan, Constitutive Equations to Predict High Temperature Flow Stress In a Ti-Modified Austenitic Stainless Steel, Mater. Sci. Eng., A, 2009, 500(1-2), p 114–121

D. Samantaray, S. Mandal, A.K. Bhaduri, S. Venugopal, and P.V. Sivaprasad, Analysis and Mathematical Modelling of Elevated Temperature Flow Behaviour of Austenitic Stainless Steels, Mater. Sci. Eng., A, 2011, 528(4-5), p 1937–1943

H.J. Zhang, W.D. Wen, H.T. Cui, and Y. Xu, A Modified Zerilli-Armstrong Model for Alloy IC10 Over a Wide Range of Temperatures and Strain Rates, Mater. Sci. Eng., A, 2009, 527(1-2), p 328–333

D. Samantaray, S. Mandal, and A.K. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr-1Mo Steel, Comput. Mater. Sci., 2009, 47(2), p 568–576

H.Y. Li, X.F. Wang, J.Y. Duan, and J.J. Liu, A Modified Johnson Cook Model for Elevated Temperature Flow Behavior of T24 Steel, Mater. Sci. Eng., A, 2013, 577, p 138–146

A.K. Gupta, V.K. Anirudh, and S.K. Singh, Constitutive Models to Predict Flow Stress in Austenitic Stainless Steel 316 at Elevated Temperatures, Mater. Des., 2013, 43, p 410–418

Q.Y. Hou and J.T. Wang, A Modified Johnson-Cook Constitutive Model for Mg-Gd-Y Alloy Extended to a Wide Range of Temperatures, Comput. Mater. Sci., 2010, 50(1), p 147–152

Y.P. Wang, C.J. Han, C. Wang, and S.K. Li, A Modified Johnson-Cook Model for 30Cr2Ni4MoV Rotor Steel Over a Wide Range of Temperature and Strain Rate, J. Mater. Sci., 2011, 46(9), p 2922–2927

W.D. Song, J.G. Ning, X.N. Mao, and H.P. Tang, A Modified Johnson-Cook Model for Titanium Matrix Composites Reinforced with Titanium Carbide Particles at Elevated Temperatures, Mater. Sci. Eng., A, 2013, 576, p 280–289

P.D. Nicolaou and S.L. Semiatin, An Analysis of Cavity Growth During Open-Die Hot Forging of Ti-6Al-4V, Metall. Mater. Trans. A, 2005, 36(6), p 1567–1574

R.G. Guan, Y.T. Je, Y. Zhan, and C.S. Lee, Effect of Microstructure on Deformation Behavior of Ti-6Al-4V Alloy During Compressing Process, Mater. Des., 2012, 36, p 796–803

W.X. Yu, M.Q. Li, and J. Luo, Variation Effect of Strain Rate on Microstructure in Isothermal Compression of Ti-6Al-4V Alloy, Rare Met., 2012, 31(1), p 7–11

S.H. Huang, Y.Y. Zong, and D.B. Shan, Application of Thermohydrogen Processing to Ti6Al4V Alloy Blade Isothermal Forging, Mater. Sci. Eng. A, 2013, 561, p 17–25

G.A. Salishchev, R.M. Galeyev, O.R. Valiakhmetov, R.V. Safiullin, R.Y. Lutfullin, O.N. Senkov, and O.A. Kaibyshev, Development of Ti-6Al-4V Sheet with Low Temperature Superplastic Properties, J. Mater. Process. Technol., 2001, 116(2-3), p 265–268

P. Comley, Multi-Rate Superplastic Forming of Fine Grain Ti-6Al-4V Titanium Alloy, J. Mater. Eng. Perform., 2007, 16(2), p 150–154

X.M. Li and S. Soo, Numerical Simulation and Superplastic Forming of Ti-6Al-4V Alloy for a Dental Prosthesis, J. Mater. Eng. Perform., 2011, 20(3), p 341–347

Acknowledgments

The authors gratefully acknowledge the financial support received from Province Natural Science Foundation of Shaanxi (2014JM6230), Innovation Team Project of “Processing and Preparation for High-performance Non-ferrous Metal Materials” of Xi’an University of Architecture and Technology, Fundamental Science Funds of Xi’an University of Architecture and Technology (JC1308), and Talents Science Fund of Xi’an University of Architecture and Technology (RC1369).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, J., Wang, K., Zhai, P. et al. A Modified Johnson-Cook Constitutive Equation to Predict Hot Deformation Behavior of Ti-6Al-4V Alloy. J. of Materi Eng and Perform 24, 32–44 (2015). https://doi.org/10.1007/s11665-014-1243-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1243-x