Abstract

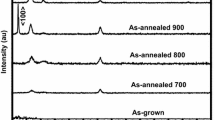

Single-crystalline ZnO films with good crystal quality were grown by plasma-assisted molecular beam epitaxy (MBE) technique on c-plane sapphire substrates and implanted with fixed energy of 180-keV P and 100-keV O ions at 460°C. The implanted single-crystalline ZnO films exhibit p-Type characteristics with hole concentration in the range of 5.3 × 1017–1.5 × 1018 cm−3, hole mobilities between 1.4 cm2V−1 s−1 and 2.1 cm2V−1 s−1, and resistivities in the range of 0.672–1.832 Ωcm, as confirmed by Hall-effect measurements. The x-ray diffraction pattern of the implanted single-crystalline ZnO films exhibits (002) orientation (c-plane), with no other secondary phase appearing after ion implantation and dynamic annealing. It is deduced from x-ray photoelectron spectroscopy (XPS) and secondary ion mass spectroscopy results that P ions were effectively implanted and formed acceptor complex PZn–2VZn, acting predominantly in all acceptors and achieving the goal of increasing the density of acceptors. Raman spectra and XPS results reflect that the enhanced solubility and stability of acceptor complexes in implanted single-crystalline ZnO films are related to the reduction of the concentration of oxygen vacancies by O ion implantation, achieving the goal of restraining the density of oxygen vacancies. It is concluded that the method of combining the increased density of acceptors and the restrained density of oxygen vacancies is meaningful and feasible, and afforded excellent p-type characteristics.

Similar content being viewed by others

References

D.-C. Perng, M.-H. Hong, K.-H. Chen, and K.-H. Chen, J. Alloys Compd. 695, 549 (2017).

M. Kumar, S. Otari, H. Jeong, and D. Lee, J. Alloys Compd. 725, 1115 (2017).

S.-H. Kim, G.-I. Shim, and S.-Y. Choi, J. Alloys Compd. 698, 77 (2017).

C.L. Jia, K.M. Wang, X.L. Wang, X.J. Zhang, and F. Lu, Opt. Express 13, 5093 (2005).

Z.Y. Zhang, J.Y. Huang, S.S. Chen, X.H. Pan, L.X. Chen, and Z.Z. Ye, J. Cryst. Growth 483, 236 (2018).

W. Yang, S.S. Hullavarad, B. Nagaraj, I. Takeuchi, R.P. Sharma, T. Venkatesan, R.D. Vispute, and H. Shen, Appl. Phys. Lett. 82, 3424 (2003).

S.O. Kucheyev, C. Jagadish, J.S. Williams, P.N.K. Deenapanray, M. Yano, K. Koike, S. Sasa, M. Inoue, and K. Ogata, J. Appl. Phys. 93, 2972 (2003).

Y.J. Zeng, Z.Z. Ye, and W.Z. Xue, Appl. Phys. Lett. 88, 062107 (2006).

L.Q. Zhang, Y.Z. Zhang, Z.Z. Ye, S.S. Lin, B. Lu, H.P. He, L.X. Chen, J.G. Lu, J. Jiang, K.W. Wu, J.Y. Huang, and L.P. Zhu, Appl. Phys. A 106, 191 (2012).

B.W.-C. Au and K.-Y. Chan, Appl. Phys. A 123, 485 (2007).

J. Huang, L.J. Wang, R. Xu, K. Tang, W.M. Shi, and Y.B. Xia, Semicond. Sci. Technol. 24, 075025 (2009).

G.-T. Du, W. Zhao, and G.-G. Wu, Appl. Phys. Lett. 101, 053503 (2012).

Z. Shi, Y. Zhang, and B. Wu, Appl. Phys. Lett. 102, 161101 (2013).

J. Huang, Z. Li, S. Chu, and J. Liu, Appl. Phys. Lett. 23, 232102 (2012).

L.J. Mandalapu, Z. Yang, F.X. Xiu, D.T. Zhao, and J.L. Liu, Appl. Phys. Lett. 88, 092103 (2006).

T.M. Barnes, K. Olson, and C.A. Wolden, Appl. Phys. Lett. 86, 112112 (2005).

L.G. Wang and A. Zunger, Phys. Rev. Lett. 90, 256401 (2003).

L. Gong, Z.Z. Ye, and J.G. Lu, Vacuum 85, 365 (2010).

D.C. Look, D.C. Reynolds, C.W. Litton, R.L. Jones, D.B. Eason, and G. Cantwell, Appl. Phys. Lett. 81, 1830 (2002).

M.S. Oh and R. Navamathavan, RSC Adv. 7, 16119 (2017).

P. Sharma, R. Bhardwaj, R. Singh, S. Kumar, and S. Mukherjee, Appl. Phys. Lett. 111, 091604 (2017).

P. Sharma, R. Bhardwaj, A. Kumar, and S. Mukherjee, J. Phys. D Appl. Phys. 51, 015103 (2018).

R. Bhardwaj, P. Sharma, R. Singh, S. Mukherjee, and I.E.E.E. Photo, Technol. Lett. 29, 1215 (2017).

J.S. Williams, Mater. Sci. Eng. A 253, 8 (1998).

D.G. Armour, Vacuum 37, 423 (1987).

S.J. Pearton, D.P. Norton, K. Ip, Y.W. Heo, and T. Steiner, Prog. Mater. Sci. 50, 293 (2005).

M.A. Myers, M.T. Myers, M.J. General, J.H. Lee, L. Shao, and H. Wang, Appl. Phys. Lett. 101, 112201 (2012).

C.O. Kim, D.H. Shin, S. Kim, S. Choi, and K. Belay, J. Appl. Phys. 110, 103708 (2011).

T. Prasada Rao and M.C. Santhosh Kumar, J. Alloy. Compd. 509, 8676 (2011).

J.D. Pedersen, H.J. Esposito, and K.S. The, Nanoscale Res. Lett. 6, 568 (2011).

N. Fujimura, T. Nishihara, S. Goto, J.F. Xu, and T. Ito, J. Cryst. Growth 130, 269 (1993).

M.-J. Kim, J.-T. Yeon, K. Hong, S.-I. Lee, N.-S. Choi, and S.-S. Kim, Bull. Korean Chem. Soc. 34, 2029 (2013).

M.A. Carrillo Solano, M. Dussauze, P. Vinatier, L. Croguennec, E.I. Kamitsos, R. Hausbrand, and W. Jaegermann, Ionics 22, 471 (2016).

W.-J. Lee, J. Kang, and K.J. Chang, Phys. Rev. B 73, 024117 (2006).

M. Yuan, H. Yuan, Q. Jia, Y. Chen, X. Jiang, and H.-H. Wang, J. Phys. D Appl. Phys. 45, 085103 (2012).

J.C.C. Fan and J.B. Goodenough, J. Appl. Phys. 48, 3524 (1977).

L. Jing, Z. Xu, X. Sun, J. Shang, and W. Cai, Appl. Surf. Sci. 180, 308 (2001).

F. Li, X.C. Liu, R.W. Zhou, H.M. Chen, S.Y. Zhuo, and E.W. Shi, J. Appl. Phys. 116, 243910 (2014).

C.J. Youn, T.S. Jeong, M.S. Han, and J.H. Kim, J. Cryst. Growth 261, 526 (2004).

C. Bundesmann, N. Ashkenov, M. Schubert, D. Spemann, T. Butz, E.M. Kaidashev, M. Lorenz, and M. Grundmann, Appl. Phys. Lett. 83, 1974 (2003).

Z.Z. Zhi, Y.C. Liu, B.S. Li, X.T. Zhang, Y.M. Lu, D.Z. Shen, and X.W. Fan, J. Phys. D. 36, 719 (2003).

Acknowledgments

This work was financially supported by Zhejiang Provincial Public Technology Research (LGG18E020001) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Z., Huang, J., Chen, S. et al. A Method of Combining the Increased Density of Acceptors with Restrained Density of Oxygen Vacancies to Fabricate p-Type Single-Crystalline ZnO Films. J. Electron. Mater. 48, 780–786 (2019). https://doi.org/10.1007/s11664-018-6784-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6784-6