Abstract

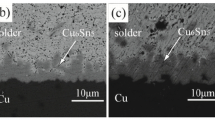

Reactions between zinc-aluminum-germanium solder and copper/nickel substrates were investigated after 30 min of soldering at 420°C that simulates a wafer-level bonding process, and the results were compared to a eutectic zinc–aluminum solder. The ZnAlGe system (81.4 at.% Zn, 13.1 at.% Al, 5.5 at.% Ge) was selected in order to decrease the eutectic temperature of the ZnAleut (88.7 at.% Zn, 11.3 at.% Al) for high-temperature lead-free solder applications. In addition, a standard high temperature storage test at 150°C was performed up to 3000 h in order to investigate the evolution of the interconnection microstructures. Extensive copper dissolution was discovered during the soldering process. Germanium did not participate in any of the interfacial reactions on a copper substrate. On a nickel substrate, rapid formation of intermetallic compounds was discovered with both solders, and all the aluminum from the 500 μm thick solder was consumed by the formation of the Al3Ni2 phase during bonding. Germanium was observed to dissolve in the Al3Ni2 phase, but the addition of germanium to the solder was not found to affect markedly the interfacial microstructure. Based on the results, isothermal sections at 150°C of Al-Cu–Zn and Al-Ni-Zn systems are presented with superimposed diffusion paths.

Similar content being viewed by others

References

European Parliament, Off. J. Eur. Union 54, 88 (2011).

A. Kroupa, D. Andersson, N. Hoo, J. Pearce, A. Watson, A. Dinsdale, and S. Mucklejohn, J. Mater. Eng. Perform. 21, 629 (2012).

V. Lindroos, T. Motooka, S. Franssila, M. Paulasto-Krockel, M. Tilli, and V.-M. Airaksinen, Handbook of Silicon Based MEMS Materials and Technologies, 2nd ed. (Amsterdam: Elsevier, 2015).

G. Zeng, S. McDonald, and K. Nogita, Microelectron. Reliab. 52, 1306 (2012).

K. Suganuma, S. Kim, and K. Kim, J. Miner. Met. Mater. Soc. 61, 64 (2009).

V.R. Manikam, and K.Y. Cheong, Components Packag. Manuf. Technol. IEEE Trans. 1, 457 (2011).

V. Chidambaram, J. Hattel, and J. Hald, Microelectron. Eng. 88, 981 (2011).

J. Bae, K. Shin, J. Lee, M. Kim, and C. Yang, Appl. Microsc. 45, 89 (2015).

R. Mahmudi, and M. Eslami, J. Electron. Mater. 39, 1168 (2011).

Y. Shi, W. Fang, Z. Xia, Y. Lei, F. Guo, and X. Li, J. Mater. Sci.: Mater. Electron. 21, 875 (2010).

H.G. Song, J.P. Ahn, and J.W. Morris, J. Electron. Mater. 30, 1083 (2001).

J.M. Song, H.Y. Chuang, and Z.M. Wu, J. Electron. Mater. 35, 1041 (2006).

J.N. Lalena, N.F. Dean, and M.W. Weiser, J. Electron. Mater. 31, 1244 (2002).

X. Yang, W. Hu, X. Yan, and Y. Lei, J. Electron. Mater. 44, 1128 (2015).

K.H. Jae-Ean Lee, K.-S. Kim, K. Suganuma, and J. Takenaka, Mater. Trans. 46, 2413 (2005).

S. Egelkraut, L. Frey, M. Knoerr, and A. Schletz, 2010 12th Electron. Packag. Technol. Conf. EPTC 2010 660 (2010).

M. Rettenmayr, P. Lambracht, B. Kempf, and C. Tschudin, J. Electron. Mater. 31, 278 (2002).

T. Yamaguchi, O. Ikeda, Y. Oda, S. Hata, K. Kuroki, H. Kuroda, and A. Hirose, J. Electron. Mater. 44, 751 (2015).

L. Liu, M. Mirgkizoudi, P. Zhang, L. Zhou, and C. Liu, Electron. Syst. Conf. ESTC 1 (2014).

T. Shimizu, H. Ishikawa, I. Ohnuma, and K. Ishida, J. Electron. Mater. 28, 1172 (1999).

A. Haque, B.H. Lim, A.S.M. Haseeb, and H.H. Masjuki, J. Mater. Sci.: Mater. Electron. 23, 115 (2012).

L. Li, Y. Liu, H. Gao, and Z. Gao, J. Mater. Sci.: Mater. Electron. 24, 336 (2013).

X. Yan, X. Yang, W. Hu, and Y. Lei, J. Mater. Sci.: Mater. Electron. 26, 7537 (2015).

T. Gancarz, J. Pstruś, P. Fima, and S. Mosińska, J. Mater. Eng. Perform. 21, 599 (2012).

N. Kang, H.S. Na, S.J. Kim, and C.Y. Kang, J. Alloys Compd. 467, 246 (2009).

S.-J. Kim, K.-S. Kim, S.-S. Kim, C.-Y. Kang, and K. Suganuma, Mater. Trans. 49, 1531 (2008).

P.W. Chih, B. Joseph, A. Mesa, X. Hong, and G.M. Hao, Electron. Packag. Technol. Conf. 463 (2014).

J. Li, I. Yaqub, M. Corfield, P. Agyakwa, and C.M. Johnson, Integr. Power Syst. 1, 1 (2014).

L. Balanović, D. Manasijević, D. Živković, A. Mitovski, N. Talijan, D. Minić, and Ž. Živković, J. Therm. Anal. Calorim. 110, 221 (2012).

A. Haque, Y.S. Won, A.S.M.A. Haseebl, and H.H. Masjukil, Electron. Syst. Technol. Conf. 1 (2010).

Y. Takaku, L. Felicia, I. Ohnuma, R. Kainuma, and K. Ishida, J. Electron. Mater. 37, 314 (2008).

L. Liu, L. Zhou, and C. Liu, Electron. Components Technol. Conf. 1348 (2014).

M. Prach, and R. Koleňák, Proc. Eng. 100, 1370 (2015).

T. Gancarz, J. Pstruś, P. Fima, and S. Mosińska, J. Alloys Compd. 582, 313 (2014).

V. Raghavan, J. Phase Equilibria Diffus. 28, 183 (2007).

J.D. Villegas-Cardenas, M.L. Saucedo-Muñoz, V.M. Lopez-Hirata, H.J. Dorantes-Rosales, and J.L. Gonzalez-Velazquez, Mater. Res.17, 1137 (2014)

Y.H. Zhu, W.B. Lee, and S. To, J. Mater. Sci. 38, 1945 (2003).

S.-M. Liang, and R. Schmid-Fetzer, Calphad 52, 21 (2016).

H. Chen, X. Xin, D.Y. Dong, Y.P. Ren, and S.M. Hao, Acta Metall. Sin. 17, 269 (2004).

Y. Takaku, K. Makino, K. Watanabe, I. Ohnuma, R. Kainuma, Y. Yamada, Y. Yagi, I. Nakagawa, T. Atsumi, and K. Ishida, J. Electron. Mater. 38, 54 (2009).

V. Raghavan, J. Phase Equilibria Diffus. 33, 478 (2012).

G. Ghosh, and J. Van Humbeeck, Light Met. Syst. 11A2, 1 (2005).

H. Xu, Y. Du, Y. Zhou, and F. Yin, Int. J. Mater. Res. 99, 644 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rautiainen, A., Vuorinen, V. & Paulasto-Kröckel, M. Interfacial Reactions Between ZnAl(Ge) Solders on Cu and Ni Substrates. J. Electron. Mater. 46, 2323–2333 (2017). https://doi.org/10.1007/s11664-016-5272-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-5272-0