Abstract

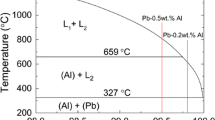

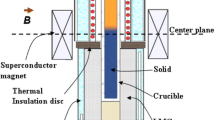

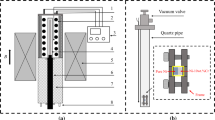

A theoretical model was built to describe the microstructure evolution during the solidification of a liquid–solid phase separation alloy under the effect of electric current pulses (ECPs). Solidification experiments were performed with Pb–0.15 wt pct Al alloy and the microstructure evolution was simulated. The simulation results are consistent with the experimental ones. They show that the Joule heating effect of ECPs can enhance the melt convection; the electromagnetic force induced by ECPs leads to a migration of minority phase particles (MPPs) from the surface to the center; the electromagnetic energy induced by ECPs can effectively promote the nucleation of MPPs, resulting in the refinement of MPPs. The peak current density \(\left( {j_{{{\text{max}}}} } \right)\) of ECPs and the temperature drop of the melt in the nucleation region during one pulse cycle \(\left( {\Delta T_{{F,{\text{Nuc}}}} = F^{ - 1} \cdot \left( {\partial T/\partial t} \right)_{{{\text{Nuc}}}} } \right)\) dominate the refinement extent of MPPs. When the peak current density is lower than a critical value, the size of MPPs is almost unchanged. While when the peak current density is higher, the size of MPPs decrease rapidly. For a fixed value of \(j_{{{\text{max}}}}\), there is an optimal value of \(\Delta T_{{F,{\text{Nuc}}}}\) to achieve the best refinement extent of MPPs.

Similar content being viewed by others

References

J.F. Cole and F.E. Goodwin: JOM J. Miner. Met. Mater. Soc., 1990, vol. 42, pp. 41–3.

Z.C. Lu, Z.L. Liu, Y.L. Li, D. Wu, and F.M. Wang: IOP Conf. Ser. Mater. Sci. Eng., 2017, vol. 201, 012045.

S.K. Yu, F. Sommer, and B. Predel: Z. Fuer Met., 1996, vol. 87, pp. 574–80.

T. Ahmed, H.X. Jiang, W. Li, and J.Z. Zhao: Acta Metall. Sin. Engl. Lett., 2018, vol. 31, pp. 842–52.

M. Nakada, Y. Shiohara, and M.C. Flemings: ISIJ Int., 1990, vol. 30, pp. 27–33.

N. Balasubramani, Y.Y. Xu, Y.H. Zhang, Q.J. Zhai, G. Wang, D. StJohn, and M. Dargusch: JOM J. Miner. Met. Mater. Soc., 2021, vol. 73, pp. 3873–82.

L.M. Zhang, H.N. Liu, N. Li, J. Wang, R. Zhang, H. Xing, and K.K. Song: J. Mater. Res., 2016, vol. 31, pp. 396–404.

Z. Xu, X. Wang, D. Liang, H. Zhong, N. Pei, Y. Gong, and Q. Zhai: Mater. Sci. Technol., 2015, vol. 31, pp. 1595–600.

Y.H. Zhang, C.J. Song, L. Zhu, H.X. Zheng, H.G. Zhong, Q.Y. Han, and Q.J. Zhai: Metall. Mater. Trans. B, 2011, vol. 42, pp. 604–11.

N. Li, L.M. Zhang, R. Zhang, P.F. Yin, H. Xing, and H.J. Wu: Metals, 2019, vol. 9, p. 571.

W.J. Wang, T.C. Yuan, R.D. Li, X.Y. Zhu, H.H. Li, W.J. Lin, L.B. Li, and D. Zheng: J. Electroanal. Chem., 2019, vol. 847, 113250.

J. Zhu, T.M. Wang, F. Cao, H.W. Fu, Y.N. Fu, H.L. Xie, and T.Q. Xiao: J. Mater. Eng. Perform., 2013, vol. 22, pp. 1319–23.

T. Ma, X.S. Sun, Y.A. Ning, and W.X. Hao: High Temp. Mater. Process., 2021, vol. 40, pp. 382–88.

H.X. Jiang, J.Z. Zhao, C.P. Wang, and X.J. Liu: Mater. Lett., 2014, vol. 132, pp. 66–9.

B.Y. Gao, X.R. Meng, Z.Q. Cao, and F. Mao: Mater. Today Commun., 2021, vol. 29, 102825.

B.Y. Geng, R.F. Zhou, Y.K. Li, Q.P. Wang, and Y.H. Jiang: Mater. Res. Express, 2020, vol. 7, 096506.

H.Y. Lv, R.F. Zhou, L. Li, H.T. Ni, J. Zhu, and T. Feng: Materials, 2018, vol. 11, p. 2220.

H.X. Jiang, J. He, and J.Z. Zhao: Sci. Rep., 2015, vol. 5, p. 12680.

G.M. Ying, W.L. Wang, H.H. Zhang, and J. Zeng: Metall. Mater. Trans. B, 2019, vol. 50, pp. 1608–16.

J.Z. Zhao, L. Ratke, J. Jia, and Q.C. Li: J. Mater. Sci. Technol., 2002, vol. 18, pp. 197–205.

L. Gránásy and L. Ratke: Scr. Metall. Mater., 1993, vol. 28, pp. 1329–34.

T. Iida and R.I.L. Guthrie: The Thermophysical Properties of Metallic Liquids: Fundamentals, 1st ed. Oxford University Press, Oxford, 2015, p. 285.

Y.Q. Li, J.Z. Zhao, H.X. Jiang, and J. He: Acta Metall. Sin., 2022, vol. 58, pp. 1072–82.

R.S. Qin and B.L. Zhou: Int. J. Non-Equilib. Process., 1998, vol. 11, pp. 77–86.

J. Zhao and L. Ratke: Scr. Mater., 1998, vol. 39, pp. 181–88.

D. Shangguan, S. Ahuja, and D.M. Stefanescu: Metall. Trans. A, 1992, vol. 23A, pp. 669–80.

H.X. Jiang and J.Z. Zhao: Chin. Phys. Lett., 2012, vol. 29, 088104.

H.L. Li and J.Z. Zhao: Appl. Phys. Lett., 2008, vol. 92, 241902.

C.K. Deng, H.X. Jiang, J.Z. Zhao, J. He, and L. Zhao: Acta Metall. Sin., 2020, vol. 56, pp. 212–20.

A.T. Dinsdale: Calphad, 1991, vol. 15, pp. 317–425.

J. He, J.Z. Zhao, and L. Ratke: Acta Mater., 2006, vol. 54, pp. 1749–57.

H.L. Li, J.Z. Zhao, Q.X. Zhang, and J. He: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 3308–16.

Acknowledgments

The authors acknowledge the financial supported from the National Key Research and Development Program of China [Grant Number 2021YFA0716303], the National Natural Science Foundation of China (Nos. 51971227, 51974288, 52174380), the China's Manned Space Station Project, the Science and Technology Project of Fujian Province [Grant Number 2020T3037], and the Space Utilization System of China Manned Space Engineering (Grant Number KJZ-YY-NCL06).

Author information

Authors and Affiliations

Contributions

HJ and JZ conceived the idea and designed the experiments. YL, HJ, HS, LZ and JH conducted the experiments, YL prepared the samples, conducted materials characterization and performed the numerical simulations. YL and HJ drafted the manuscript. HJ and JZ interpreted, discussed and edited the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Jiang, H., Sun, H. et al. Microstructure Evolution of the Pb–Al Alloy Solidified Under the Effect of Electric Current Pulses. Metall Mater Trans B 54, 2564–2574 (2023). https://doi.org/10.1007/s11663-023-02857-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02857-7