Abstract

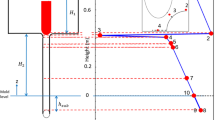

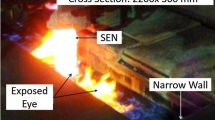

Quantifying the pressure distribution and flow rate in the metal delivery system from the tundish to the mold is important to understand nozzle clogging due to air aspiration, argon bubble size, and other important phenomena in continuous casting of steel. A one-dimensional pressure energy model, PFSG, is presented here to calculate pressure distribution and flow rate in slide-gate nozzle systems for argon-molten steel flow systems including argon gas expansion by solving a system of Bernoulli equations. PFSG is a user-friendly MATLAB-based software package with an intuitive Graphical User Interface capable of inverse solutions that enables users to conduct parametric studies in seconds. The model predictions is verified with computational fluid dynamics simulations and validated with plant measurements and water model measurements, with errors of less than 6 pct. The verified and validated PFSG model is then applied to investigate the effect of different casting conditions on the flow rate and pressure distribution. For a given slide gate opening, the flow rate increases with increasing distance from the tundish level to the mold level, increasing SEN diameter, and decreasing argon gas injection rate. The slide-gate opening fraction that produces the minimum pressure is almost independent of casting conditions, except for SEN bore diameter. This critical opening fraction, which is most detrimental for air aspiration, increases from 50 to 70 pct with increasing SEN diameter by 13 pct for the system studied. The minimum pressure worsens (decreases) with increasing tundish height and/or nozzle bore diameter.

Similar content being viewed by others

References

H. Bai and B.G. Thomas: Metall. Trans. B., 2001, vol. 32B(4), pp. 707–22.

H. Yang, H. Olia, and B.G. Thomas: Metals., 2021, https://doi.org/10.3390/met11010116).

L. Zhang, Y. Wang, and X. Zuo: Metall Trans. B., 2008, vol. 39B(4), pp. 534–50.

K.G. Rackers and B.G. Thomas: Proc. of 78th Steelmaking Conf., The Iron and Steel Society, Warrendale, PA, vol. 78, 1995, pp. 723–34.

S. Yokoya, S. Takagi, H. Souma, M. Iguchi, Y. Asako, and S. Hara: ISIJ Int., 1989, vol. 38, pp. 1346–52.

S.M. Cho, S.H. Kim, R. Chaudhary, B.G. Thomas, H.J. Shin, W.R. Choi, and S.K. Kim: Proc. AISTech, Indianapolis, IN, AIST, Warrendale, PA, vol. 2, 2011, pp. 669–79.

Y. Murakami, S. Kodama, and S. Konuma: Int. J. Fatigue., 1989, vol. 11(5), pp. 291–98.

A.D. Wilson: J. Eng. Mater. Technol., 1979, vol. 101 (3), p. 265.

L. Zhang, J. Aoki, and B.G. Thomas: Metall. Trans. B., 2006, vol. 37B(3), pp. 361–79.

POSCO: Korean Patent Application 10-2012-0026720, 2012.

J. Savolainen, A. Rousu, T. Fabritius, O. Mattila, and P. Sulasalmi: Steel Res. Int., 2010, vol. 81, pp. 980–86.

R. Liu, B.G. Thomas, J. Sengupta, S.D. Chung, and M. Trinh: ISIJ Int., 2014, vol. 54, pp. 2314–23.

M. Javurek, M. Thumfart, and R. Wincor: Steel Res. Int., 2010, vol. 81, pp. 668–74.

H. Yang, S.P. Vanka, and B.G. Thomas: JOM., 2018, vol. 70, pp. 2148–56.

R. Liu and B.G. Thomas: Metall. Trans. B., 2015, vol. 46(1), pp. 388–405.

L. Zhang, S. Yang, K. Cai, J. Li, X. Wan, and B.G. Thomas: Metall. Trans. B., 2007, vol. 38B, pp. 63–83.

Y. Wang and L. Zhang: Metall. Trans. B., 2011, vol. 42B, pp. 1319–51.

W. Chen, Y. Ren, and L. Zhang: Steel Res. Int., 2019, vol. 90, Article No. 1800287, https://doi.org/10.1002/srin.201800287.

B.G. Thomas: Steel Res. Int., 2018, vol. 89, pp. 1–21.

H. Yang, S.P. Vanka, and B.G. Thomas: ISIJ Int., 2019, vol. 59, pp. 956–72.

S.M. Cho, M. Liang, H. Olia, L. Das, and B.G. Thomas: TMS Annual Meeting, Pittsburgh, PA, TMS, Warrendale, PA, 2020, pp. 1161–73, https://doi.org/10.1007/978-3-030-36296-6_108.

H. Olia, H. Yang, S.M. Cho, M. Zappulla, and B.G. Thomas: Proc. AISTech, AIST, Warrendale, PA, 2020, pp. 1964–74, https://doi.org/10.33313/380/212.

R. Liu, B. Forman, H. Yin, and Y. Lee: Proc. AISTech, Philadelphia, PA, 2018, vol. 2, pp. 1793–1802.

H. Yang, S. Vanka, and B.G. Thomas: J. Fluids Eng., 2018, vol. 140, 101202 (1–12).

R. Liu and B.G. Thomas: Metall. Trans. B., 2014, vol. 4B, pp. 388–405.

Fsolve: Matlab subroutine from MathWorks Web Resource, https://www.mathworks.com/help/optim/ug/fsolve, accessed 25 July 2021.

E.W. Weisstein: Circle–Circle Intersection (From MathWorld—A Wolfram Web Resource), http://mathworld.wolfram.com/Circle-CircleIntersection.html, accessed 29 September 2021.

F.M. White: Fluid Mechanics, 7th. ed., McGraw Hill, New York, 2011, pp. 356–94.

Crane Co.: Flow of Fluids Through Valves Fittings and Pipes, Crane Co., New York, 1999, pp. 2-11–2-12.

H. Oertel: Prandtl-Essentials of Fluid Mechanics, 2nd ed. Springer, New York, 2004, p. 164.

G.J.O. Jameson: Math. Gaz., 2014, vol. 98, pp. 227–34.

B.G. Thomas and X. Huang: Metall. Trans. B., 1994, vol. 25B, pp. 527–47.

B.E. Launder and D.B. Spalding: Lectures in Mathematical Models of Turbulence, Academic Press, London, 1972, pp. 157–62.

D.K. Lilly: Phys. Fluids A., 1992, vol. 4, pp. 633–35.

ANSYS FLUENT 18.1-Theory Guide, ANSYS. Inc., Canonsburg, PA, USA, 2017.

S.-M. Cho, S.-H. Kim, and B.G. Thomas: ISIJ Int., 2014, vol. 54, pp. 845–54.

H. Werner and H. Wengle: 8th Symp. Turbulent Shear Flows, Munich, Germany, 1991, pp. 155–68.

L. Das and B.G. Thomas: CCC Annual Meeting, Continuous Casting Center, Colorado School of Mines, Golden, CO, USA, 15 August 2019.

S.-M. Cho and B.G. Thomas: CCC Annual Meeting, Continuous Casting Center, Colorado School of Mines, Golden, CO, USA, 15 August 2018.

Acknowledgments

The authors thank ArcelorMittal, Baosteel, and POSCO for their assistance in collecting and providing plant data, specifically Dr. Tatha Bhattacharya, ArcelorMittal, Dr. Xiaoming Ruan , Baosteel, and Dr. Shin-Eon Kang, POSCO for help with the plant measurements. Support from the Continuous Casting Center at Colorado School of Mines, and the National Science Foundation GOALI grant (Grant No. CMMI 18-08731) are gratefully acknowledged. Provision of FLUENT licenses through the ANSYS Inc. academic partnership program is also much appreciated. The authors specially thank Dr. Ken Morales, AK Steel, Dirk van der Plas, Tata Steel, Alexandre Dolabella Resende, RHI Magnesita, and Dr. Matthew Zappulla, Colorado School of Mines, for their kind comments and helpful feedback on PFSG.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Wall Friction Calculation for Tapered Pipe

Appendix: Wall Friction Calculation for Tapered Pipe

Wall friction equation for a pipe with constant diameter (i.e. not tapered), discussed in fluid mechanics reference book,[28] is defined as:

where h is pressure head loss due to wall friction [m], f friction factor, L pipe length [m], D pipe diameter [m], V fluid velocity [m/s], and g Earth’s gravitation acceleration [m/s2].

Now, consider a tapered pipe as shown in Figure A1.

For a very small portion of pipe with the length of dx, it is true to say:

Consider the continuity equation:

where V and D are velocity and diameter of the section [m/s] and [m], respectively.

Also from Figure A1:

where \(\theta\) is the taper angle [rad].

Therefore:

Substituting Eqs. [A3] and [A5] into Eq. [A2] gives:

Integrating Eq. [A6] over the whole domain (from \({D}_{1}\) to \({D}_{2}\)) and simplifying gives:

Insert into Figure A1:

Finally, substituting Eq. [A8] into Eq. [A7] gives the pressure loss in a tapered pipe due to wall friction:

Rights and permissions

About this article

Cite this article

Olia, H., Yang, H., Cho, SM. et al. Pressure Distribution and Flow Rate Behavior in Continuous-Casting Slide-Gate Systems: PFSG. Metall Mater Trans B 53, 1661–1680 (2022). https://doi.org/10.1007/s11663-022-02476-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02476-8