Abstract

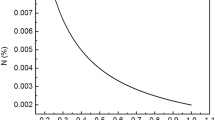

There are many types of non-metallic TiN-based inclusions observed in GCr15 bearing steel, including single-particle TiN, multi-particle polymerized TiN, and complex inclusions like TiN-MnS, TiN-MgO-MgAl2O4 (TiN-MgO-MA), and TiN-MgAl2O4-MnS (TiN-MA-MnS). Thermodynamic calculations suggest that single-particle TiN precipitates dominate the mushy zone of GCr15 bearing steel. Kinetic calculations regarding TiN growth suggest that the final size of the single-particle TiN ranges between 1 and 6 μm in the initial concentration range of [pct Ti] = 0.0060 to 0.0079 and [pct N] = 0.0049 to 0.0070, at 1620 to 1640 K and a local cooling rate of 0.5 to 10 K/s. The multi-particle polymerized TiN are formed by single TiN particles in three stages: single-particle TiN inclusions approach each other drawn by the cavity bridge force (CBF), local active angles consolidate, and neck region sintering occurs. Based on the thermodynamic calculations of TiN, MnS, and MgO precipitation, the formation behaviors of complex inclusions of TiN-MnS, TiN-MgO-MA, and TiN-MA-MnS were investigated.

Similar content being viewed by others

References

[1] T. Uesugi: Trans. ISIJ, 1986, vol. 26, pp. 614–20.

K. Tsubota and I. Fukumoto: IISC 6th Int. Iron and Steel Congress, 1990, vol. 3, pp. 637–43.

[3] T. Uesugi: Trans. ISIJ, 1988, vol. 28, pp. 893–99.

[4] T. Uesugi: Tetsu-To-Hagane, 1988, vol. 74, pp. 1889–94.

T. Lund and J. Akesson: Effect of Steel Manufacturing Processes on the Quality of Bearing Steel, ASTM Int. STP987, 1988, pp. 308–30.

M. Stone: Iron and Steel Engineer Year Book, Pittsburgh Association of Iron and Engineer Publisher, Pittsburgh, 1953, pp. 115–28.

[7] M. Zhou, and H. Yu, Int. J. Miner. Metall. Mater., 2012, vol. 19, pp. 805–11.

[8] J. Fu, J. Zhu, L. Di, F. Tong, D. Liu, and Y. Wang, Acta. Metall. Sin., 2000, vol. 36, pp. 801–04.

[9] S. Jonsson: Metall. Mater. Trans. B, 1998, vol. 29, pp. 371–84.

[10] J. Jong, W. Kim, C. Lee, and J.J. Pak: ISIJ Int., 2010, vol. 50, pp. 1373–79.

[11] J. Pak, Y. Jeong, and I. Hong: ISIJ Int., 2005, vol. 45, pp. 1106–11.

[12] D. Zhou, J. Fu, and X. Chen: J. Mater. Sci. Technol., 2003,vol. 19, pp. 184–86.

[13] X. Yang, G. Cheng, and M. Wang: J. Univ. Sci.Technol. Beijing, 2003, vol. 10, pp. 24–26.

[14] Y. Liu, L. Zhang, and H. Duan, Metall. Mater. Trans. A, 2016, vol. 47A, pp. 3015–25.

[15] K. Dirk, and A. Garbers-Craig: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 1514–32.

[16] K. Sasai: ISIJ Int., 2016, vol. 56, pp. 1013–22.

[17] K. Sasai: ISIJ Int., 2014, vol. 54, pp. 2780–89.

[18] X. Huang: Iron and Steel Metallurgy Principle, 4th ed., Metallurgical Industry Press, Beijing, 2014, pp. 181.

[19] G.M. Gulliver: Metallic Alloys, Griffen, London, 1922.

[20] E. Scheil: Zeitschrift Metallkunde, 1942, vol. 34, pp. 70–72.

[21] J. Chen: Manual of Chart and Data in Common Use of Steel Making, 2nd ed., The Metallurgical Industry Press, Beijing, 2010, pp. 510.

[22] P. Chen, C. Zhu, and G. Li: ISIJ Int., 2017, vol. 57, pp. 1019-28.

[23] E. Gao, G. Zou, W. Wang and F. Ma, and X. Luo: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 1014-23.

[24] W. Ma, Y. Bao, and L. Zhao: Int. J. Mine. Metall. Mater., 2014, vol. 21, pp. 234-39.

[25] H. Yin, H. Shibata, and T. Emi: ISIJ Int., 1997, vol. 37, pp. 936-45.

[26] H. Yin, H. Shibata, and T. Emi: ISIJ Int., 1997, vol. 37, pp. 946-55.

[27] H. Shibata, H. Yin, and S. Yoshinaga: ISIJ Int., 1998, vol. 38, pp. 149-56.

[28] J. Chen: Manual of Chart and Data in Common Use of Steel Making, 2nd ed., The Metallurgical Industry Press, Beijing, 2010, pp. 421.

[29] D. Bratko, R. A. Curtis, H. W. Blanch, and J. M. Prausnitz: J. Chem.Phys., 2001, vol. 115, pp. 3873-77.

[30] S. Singh, J. Houston, F. van Swol, and C. J. Brinker: Nature, 2006, vol. 442, pp. 526.

[31] N. Ishida, M. Sakamoto, M. Miyahara, and K. Higashitani: Langmuir, 2000, vol. 16, pp. 5681-87.

[32] J.L. Parker, P.M.Claesson, and P. Attard: J. Phys. Chem., 1994, vol. 98, pp. 8468-80.

[33] A. Carambassis, L. C. Jonker, P. Attard, and M. W. Rutland: Phys.Rev. Lett., 1998, vol. 80, pp. 5357-60.

[34] R. Podgornik: J. Chem. Phys., 1989, vol. 91, pp. 5840-49.

[35] M. Kiviö, and L. Holappa: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 233–40.

D.R. Poirier, H. Yin, and M. Suzuk, T. Emi.: ISIJ Int., 1998, vol. 38, pp. 229–38.

[37] D. Shangguan, S. Ahuja and D. M. Stefanescu: Metall. Mater. Trans. B, 1992, vol. 23A, pp. 669-80.

[38] K. Wu: Principles of Metallurgical Transport, 1th ed., Metallurgical Industry Press, Beijing, 2011, pp. 7.

[39] Y. Lu, S. Song, X. Shen, Z. Song, L. Wu, G. Wang, and S. Dai: Appl. Phy. A, 2014, 117, pp. 1933-40.

[40] W. D. Kingery: J. Appl. Phys., 1959, vol. 30, pp. 301-06.

J.L. Johnson and R. German: in Advances in Powder Metallurgy, vol. 4, A. Lawley and A. Swanson, eds., Metal Powder Industry Federation, Princeton, 1993, pp. 201–13.

J.L. Johnson, K. Hens, and R. German: In Tungsten and Refractory Metals-1994, 1995, Metal Powder Ind. Federation, Princeton, pp. 246–52.

[43] J.L. Johnson, and R. German: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 441-50.

[44] J.L. Johnson, and R. German: Metall. Mater. Trans. B, 1996, vol. 27, pp. 901-09.

[45] P. Yan, M. Guo, and B. Blanpain: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 903-13.

[46] G.V. Pervushin, and H. Suito: ISIJ Int., 2001, vol. 41, pp. 748-56.

[47] D. Turnbull, and B. Vonnegut: Ind. Eng. Chem., 1952, vol. 44, pp 1292-98.

[48] B.L. Bramfitt: Metall. Trans. 1970, vol. 1, pp. 1987-95.

[49] J. Park: Calphad, 2011, vol. 35, pp.455-62.

[50] H. Fujimura, S. Tsuge, Y. Komizo, and T. Nishizawa: Tetsu-to-Hagane, 2001, vol. 87, pp. 707-12.

[51] S. Zhang, N. Hattori, M. Enomoto, and T. Tarui: ISIJ Int.,1996, vol. 36, pp. 1301-09.

[52] R. Kohlhaas, P. Dunner, and P.N. Schmitz: Z Angew Physik, 1967, vol. 23, pp. 245-49.

[53] B. Morosin: Phys. Rev. B, 1970, vol. 1, pp. 236-43.

[54] S. Yang, Q. Wang, L. Zhang, J. Li, and K. Peaslee: Metall. Mater.Trans. B, 2012, vol. 43B, pp. 731-50

[55] S. Kimura, K. Nakajima, and S. Mizoguchi: Metall. Mater.Trans. B, 2001, vol. 32B, pp. 79-85.

[56] X. Huang: Iron and Steel Metallurgy Principle, 4th ed., Metallurgical Industry Press, Beijing, 2014, pp. 594.

Acknowledgments

The authors gratefully express their appreciation to Natural Science Foundation of China (51634004), Natural Science Foundation of Liaoning Province (2015020181), and Natural Science Foundation of China (51474125) for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 5, 2017.

Rights and permissions

About this article

Cite this article

Tian, Q., Wang, G., Zhao, Y. et al. Precipitation Behaviors of TiN Inclusion in GCr15 Bearing Steel Billet. Metall Mater Trans B 49, 1149–1164 (2018). https://doi.org/10.1007/s11663-018-1230-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1230-y