Abstract

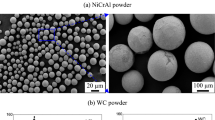

To enhance the tribological performance of ceramic coatings, the Ti2AlC phase was used as reinforcement to WC10Co4Cr coating by laser cladding. The microstructure and phases of obtained coatings were analyzed using a super-depth field microscope and X-ray diffraction, respectively. The effects of Ti2AlC mass fraction on the tribological properties of WC10Co4Cr-xTi2AlC coatings at 500 °C were investigated using a high-temperature wear tester, and the wear mechanism was also discussed in detail. The results demonstrate that the hardness of WC10Co4Cr-0, − 5, − 10 and − 15 pct Ti2AlC coatings is 1156 ± 57, 1514 ± 75, 1423 ± 71, and 1354 ± 67 HV0.5, respectively, showing that the WC10Co4Cr–5 pct Ti2AlC coating have the highest hardness among the four kinds of coatings. The average coefficients of friction of WC10Co4Cr-0, − 5, − 10, and − 15 pct Ti2AlC coatings is 0.828, 0.419, 0.591, and 0.738, respectively, and the corresponding wear rates are 55.85, 22.71, 34.05, and 39.33 μm3 N−1 mm−1, respectively. The wear mechanism of WC10Co4Cr–xTi2AlC coatings is abrasive wear, fatigue wear, adhesive wear, and oxidative wear, in which the appropriate Ti2AlC mass fraction plays the role of wear resistance in the friction process.

Similar content being viewed by others

References

J. Zhu, Z. Zhang, and J. Xie: Mater. Sci. Eng. A, 2019, vol. 752, pp. 101–14. https://doi.org/10.1016/j.msea.2019.02.085.

B. Breidenstein, B. Denkena, P. Wolters, M. Keitel, W. Tillmann, D. Stangier, and N.F. Lopes Dias: Mater. Today Sustain., 2023, vol. 24, p. 100507. https://doi.org/10.1016/j.mtsust.2023.100507.

H. Li, D. Xiang, Y. Cao, S. Zhao, and G. Tu: Ceram. Int., 2017, vol. 43(17), pp. 14726–31. https://doi.org/10.1016/j.ceramint.2017.07.204.

H. Yang, X. Wu, G. Cao, and Z. Yang: Surf. Coat. Technol., 2016, vol. 307, pp. 506–16. https://doi.org/10.1016/j.surfcoat.2016.09.029.

D. Wang, L. Zhang, X. Luo, and C. Li: Corros. Sci., 2022, vol. 209, p. 110800. https://doi.org/10.1016/j.corsci.2022.110800.

S. Sun, J. Wang, J. Xu, X. Cheng, C. Jing, Z. Chen, H. Ru, Y. Liu, and J. Jiao: Mater. Today Commun., 2023, vol. 37, p. 106939. https://doi.org/10.1016/j.mtcomm.2023.106939.

L. Kang, F. Chen, B. Wu, X. Liu, and H. Ge: J. Constr. Steel Res., 2022, vol. 199, p. 107603. https://doi.org/10.1016/j.jcsr.2022.107603.

J. Jiang, W. Hou, X. Feng, and Y. Shen: Surf. Coat. Technol., 2023, vol. 464, p. 129577. https://doi.org/10.1016/j.surfcoat.2023.129577.

C. Chen, A. Feng, Y. Wei, Y. Wang, X. Pan, and X. Song: Mater. Lett., 2023, vol. 337, p. 133939. https://doi.org/10.1016/j.matlet.2023.133939.

Y. Zhu, H. Zhou, Z. Chen, Z. Wang, F. He, and C. Xu: Micromachines, 2022, vol. 13(5), p. 653. https://doi.org/10.3390/mi13050653.

J. Ma, Y. Duan, W. Chen, Q. Li, J. Guo, X. Cao, H. Tan, J. Cheng, Q. Sun, and J. Yang: Wear, 2023, vol. 530–31, p. 205031. https://doi.org/10.1016/j.wear.2023.205031.

J. Liu, S. Yang, W. Xia, X. Jiang, and C. Gui: J. Alloy. Compd., 2016, vol. 654, pp. 63–70. https://doi.org/10.1016/j.jallcom.2015.09.130.

H. Wang, M. Gee, Q. Qiu, H. Zhang, X. Liu, H. Nie, X. Song, and Z. Nie: J. Mater. Sci. Technol., 2019, vol. 35(11), pp. 2435–46. https://doi.org/10.1016/j.jmst.2019.07.016.

Z. Wang, M. Tan, J. Wang, J. Zeng, F. Zhao, X. Xiao, S. Xu, B. Liu, L. Gong, Q. Sui, R. Zhang, B. Han, and J. Liu: J. Alloy. Compd., 2021, vol. 878, p. 160127. https://doi.org/10.1016/j.jallcom.2021.160127.

M.W. Barsoum: Prog. Solid State Ch., 2000, vol. 28(14), pp. 201–81. https://doi.org/10.1016/S0079-6786(00)00006-6.

E. Hugon, O. Rapaud, R. Lucas, and T. Chotard: Open Ceram., 2023, vol. 15, p. 100398. https://doi.org/10.1016/j.oceram.2023.100398.

H. Xiao, S. Zhao, Q. Liu, Y. Li, S. Zhao, F. Luo, Y. Wang, Q. Huang, and C. Wang: Acta Mater., 2023, vol. 248, p. 118783. https://doi.org/10.1016/j.actamat.2023.118783.

H. Chen, Y. Du, D. Wang, C. Zhang, G. Yang, B. Liu, Y. Gao, and S. Shi: Ceram. Int., 2018, vol. 44(18), pp. 22520–28. https://doi.org/10.1016/j.ceramint.2018.09.023.

G. Song, Y. Pei, W. Sloof, S. Li, J. Hosson, and S. Zwaag: Scripta Mater., 2008, vol. 58(1), pp. 13–16. https://doi.org/10.1016/j.scriptamat.2007.09.006.

S. Li, G. Song, K. Kwakernaak, S. Zwaag, and W. Sloof: J. Eur. Ceram. Soc., 2012, vol. 21(8), pp. 1813–20. https://doi.org/10.1016/j.jeurceramsoc.2012.01.017.

S. Hua, M. Pang, F. Ji, J. Chen, and G. Liu: Mater. Today Commun., 2023, vol. 34, p. 105165. https://doi.org/10.1016/j.mtcomm.2022.105165.

C. Jiang, J. Zhang, Y. Chen, Z. Hou, Q. Zhao, Y. Li, L. Zhu, F. Zhang, and Y. Zhao: Int. J. Refract Metal Hard Mater., 2022, vol. 107, p. 105902. https://doi.org/10.1016/j.ijrmhm.2022.105902.

P. Tatarko, M. Kašiarová, Z. Chlup, J. Dusza, P. Šajgalík, and I. Vávra: Wear, 2013, vol. 300(1–2), pp. 155–62. https://doi.org/10.1016/j.wear.2013.01.030.

W. Shao, Y. Zhou, L. Zhou, L. Rao, X. Xing, Z. Shi, and Q. Yang: Mater. Design, 2021, vol. 211, p. 110133. https://doi.org/10.1016/j.matdes.2021.110133.

L. Zhang, C. Wang, X. Huang, R. Nie, J. Zhu, and X. Yan: Int. J. Refract Metal Hard Mater., 2023, vol. 115, p. 106309. https://doi.org/10.1016/j.ijrmhm.2023.106309.

G. Lee, T. Kim, W. Sloof, and K. Lee: Ceram. Int., 2021, vol. 47(16), pp. 22478–86. https://doi.org/10.1016/j.ceramint.2021.04.257.

V. Katranidis, S. Gu, B. Allcock, and S. Kamnis: Surf. Coat. Technol., 2017, vol. 311, pp. 206–15. https://doi.org/10.1016/j.surfcoat.2017.01.015.

Z. Liu, J. Shi, C. He, F. Wang, and D. Kong: Int. J. Appl. Ceram. Technol., 2023, vol. 20(5), pp. 2847–59. https://doi.org/10.1111/ijac.14403.

A. Khorram, A. Jamaloei, and R. Sepehrnia: Optik, 2022, vol. 264, p. 169407. https://doi.org/10.1016/j.ijleo.2022.169407.

G. Cui, B. Han, J. Zhao, and M. Li: Tribol. Int., 2019, vol. 134, pp. 36–49. https://doi.org/10.1016/j.triboint.2019.01.019.

A. Sharma and D. Gupta: Appl. Surf. Sci., 2012, vol. 258(15), pp. 5583–92. https://doi.org/10.1016/j.apsusc.2012.02.019.

D. Ravnikar, N. Dahotre, and J. Grum: Appl. Surf. Sci., 2013, vol. 282, pp. 914–22. https://doi.org/10.1016/j.apsusc.2013.06.089.

T. Sudaprasert, P. Shipway, and D. McCartney: Wear, 2003, vol. 255(7–12), pp. 943–49. https://doi.org/10.1016/S0043-1648(03)00293-X.

Y. Zhou, X. Liu, J. Kang, W. Yue, W. Qin, G. Ma, Z. Fu, L. Zhu, D. She, H. Wang, J. Liang, W. Weng, and C. Wang: Eng. Fail. Anal., 2020, vol. 109, p. 104338. https://doi.org/10.1016/j.engfailanal.2019.104338.

D. Stewart, P. Shipway, and D. McCartney: Acta Mater., 2000, vol. 48(7), pp. 1593–1604. https://doi.org/10.1016/S1359-6454(99)00440-1.

H. Jiang, F. Su, Y. Yang, D. Zhang, Y. Hong, H. Cui, F. Min, C. Wang, G. Li, and J. Zhang: Int. J. Refract Metal Hard Mater., 2023, vol. 115, p. 106303. https://doi.org/10.1016/j.ijrmhm.2023.106303.

M. Yin, Y. Shao, X. Kang, J. Long, and X. Zhang: Tribol. Int., 2023, vol. 177, p. 107975. https://doi.org/10.1016/j.triboint.2022.107975.

L. Zhao, Z. Zhang, B. Wang, S. Xu, and C. Si: Mater. Lett., 2022, vol. 328, p. 133203. https://doi.org/10.1016/j.matlet.2022.133203.

Y. Yu, Y. Wu, S. Hong, J. Cheng, S. Zhu, and H. Li: Ceram. Int., 2023, vol. 49(17–B), pp. 28560–70. https://doi.org/10.1016/j.ceramint.2023.06.148.

Y. Chen, D. Wang, W. Wang, Y. Liu, Y. Sato, T. Yamaguchi, Y. Chen, and C. Wang: Surf. Coat. Technol., 2021, vol. 422, pp. 127–493. https://doi.org/10.1016/j.surfcoat.2021.127493.

V. Kumar, R. Verma, and S. Shrivastava: Mater. Today Proc., 2023, https://doi.org/10.1016/j.matpr.2023.08.044.

H. Wang, H. Lu, X. Song, X. Yan, X. Liu, and Z. Nie: Corros. Sci., 2019, vol. 147, pp. 372–83. https://doi.org/10.1016/j.corsci.2018.11.028.

R. Khuengpukheiw, A. Wisitsoraat, and C. Saikaew: Wear, 2021, vol. 484–485, p. 203699. https://doi.org/10.1016/j.wear.2021.203699.

Q. Cao, L. Fan, H. Chen, Y. Hou, L. Dong, and Z. Ni: Tribol. Int., 2022, vol. 176, p. 107939. https://doi.org/10.1016/j.triboint.2022.107939.

G. Chen, X. Liu, F. Zhang, Q. Liu, H. Ou, and S. Zhang: Surf. Coat. Technol., 2023, vol. 472, p. 129930. https://doi.org/10.1016/j.surfcoat.2023.129930.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hui, X., Dejun, K. Microstructure and High-Temperature Tribological Properties of Laser-Cladded WC10Co4Cr–xTi2AlC Coatings. Metall Mater Trans A 55, 1976–1987 (2024). https://doi.org/10.1007/s11661-024-07373-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-024-07373-0