Abstract

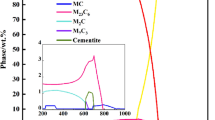

In the present study, Ti and B were added to lightweight Fe–Mn–Al–C steels matrix with 0, 0.1, and 0.4 wt pct C in order to evaluate the in-situ formation of reinforcing particles and their influence on the properties. The compositions were tailored by thermodynamic calculations and experimentally validated. Both titanium and boron were introduced in stoichiometry proportions for TiB2 formation. The composites were processed by arc-melting followed by hot rolling and annealing. The experimental results showed that carbon plays a key role in the system since it leads to TiC and (Fe,Mn)2B formation and, consequently, reduction of the TiB2 fraction. The composite with the highest Ti, B, and C contents achieved the highest specific modulus value (29.5 GPa cm3 g−1), with a density and modulus of elasticity of 7.09 g cm−3 and 209.3 GPa, respectively.

Similar content being viewed by others

References

H. Springer, C. Baron, A. Szczepaniak, V. Uhlenwinkel, and D. Raabe: Sci. Rep., 2017, vol. 7, p. 2757.

A.L. Vidilli, L.B. Otani, W. Wolf, C.S. Kiminami, W.J. Botta, F.G. Coury, and C. Bolfarini: J. Alloys Compd., 2020, vol. 831, p. 154806.

L. Otani, A. Vidilli, F. Coury, C. Kiminami, W. Botta, G. Zepon, and C. Bolfarini: Metals (Basel), 2020, vol. 10, p. 352.

J.K. Kim, L. Chen, H.S. Kim, S.K. Kim, Y. Estrin, and B.C. De Cooman: Metall. Mater. Trans. A, 2009, vol. 40, pp. 3147–58.

G.R. Lehnhoff, K.O. Findley, and B.C. De Cooman: Scr. Mater., 2014, vol. 92, pp. 19–22.

S. Chen, R. Rana, A. Haldar, and R.K. Ray: Prog. Mater. Sci., 2017, vol. 89, pp. 345–91.

A. Latapie and D. Farkas: Scr. Mater., 2003, vol. 48, pp. 611–15.

R. Rana and C. Liu: Can. Metall. Q., 2014, vol. 53, pp. 300–16.

S.A. Kim and W.L. Johnson: Mater. Sci. Eng. A, 2007, vol. 452–453, pp. 633–39.

F. Bonnet, V. Daeschler, and G. Petitgand: Can. Metall. Q., 2014, vol. 53, pp. 243–52.

H. Springer, C. Baron, F. Mostaghimi, J. Poveleit, L. Mädler, and V. Uhlenwinkel: Addit. Manuf., 2020, vol. 32, p. 101033.

H. Zhang, H. Springer, R. Aparicio-Fernández, and D. Raabe: Acta Mater., 2016, vol. 118, pp. 187–95.

C. Baron, H. Springer, and D. Raabe: Mater. Des., 2016, vol. 97, pp. 357–63.

B.B. He and J.Q. Zhang: Metall. Mater. Trans. A, 2021, vol. 52, pp. 4311–16.

N. Yang and I. Sinclair: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2017–24.

C.C. Degnan and P.H. Shipway: Metall. Mater. Trans. A, 2002, vol. 33, pp. 2973–83.

Z.C. Luo, B.B. He, Y.Z. Li, and M.X. Huang: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1981–89.

H. Springer, R.A. Fernandez, M.J. Duarte, A. Kostka, and D. Raabe: Acta Mater., 2015, vol. 96, pp. 47–56.

Y.Z. Li and M.X. Huang: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 2144–48.

F. Akhtar: J. Alloys Compd., 2008, vol. 459, pp. 491–97.

I. Gutierrez-Urrutia and D. Raabe: Scr. Mater., 2013, vol. 68, pp. 343–47.

J.B. Seol, D. Raabe, P. Choi, H.S. Park, J.H. Kwak, and C.G. Park: Scr. Mater., 2013, vol. 68, pp. 348–53.

H.Y. Wang, Q.C. Jiang, Y. Wang, B.X. Ma, and F. Zhao: Mater. Lett., 2004, vol. 58, pp. 3509–13.

A. Slipenyuk, V. Kuprin, Y. Milman, V. Goncharuk, and J. Eckert: Acta Mater., 2006, vol. 54, pp. 157–66.

R. Aparicio-Fernández, H. Springer, A. Szczepaniak, H. Zhang, and D. Raabe: Acta Mater., 2016, vol. 107, pp. 38–48.

J. Han, S. Xiao, J. Tian, Y. Chen, L. Xu, X. Wang, Y. Jia, Z. Du, and S. Cao: Mater Charact, 2015, vol. 106, pp. 112–22.

B. Almangour, D. Grzesiak, and J.M. Yang: J. Alloys Compd., 2016, vol. 680, pp. 480–93.

B. AlMangour, Y.K. Kim, D. Grzesiak, and K.A. Lee: Compos. B, 2019, vol. 156, pp. 51–63.

L. Ma, T. Jia, G. Li, J. Hu, J.A. Jimenez, and X. Gao: Mater. Sci. Eng. A, 2020, vol. 784, p. 139333.

J. Lentz, A. Röttger, and W. Theisen: Mater Charact, 2018, vol. 135, pp. 192–202.

C. Baron, H. Springer, and D. Raabe: Mater. Des., 2016, vol. 111, pp. 185–91.

X. Wei, Z. Chen, J. Zhong, L. Wang, W. Yang, and Y. Wang: Comput. Mater. Sci., 2018, vol. 147, pp. 322–30.

B. Xiao, J. Feng, C.T. Zhou, J.D. Xing, X.J. Xie, Y.H. Cheng, and R. Zhou: Phys. B Condens. Matter, 2010, vol. 405, pp. 1274–78.

Y. Jian, Z. Huang, J. Xing, and Y. Gao: J. Mater. Sci., 2018, vol. 53, pp. 5329–38.

Y. Jian, H. Ning, Z. Huang, Y. Wang, and J. Xing: J. Mater. Res. Technol., 2021, vol. 14, pp. 1301–11.

R.G. Munro: J. Res. Natl. Inst. Stand. Technol., 2000, vol. 105, p. 709.

U. Pandey, R. Purohit, P. Agarwal, S.K. Dhakad, and R.S. Rana: Mater. Today Proc., 2017, vol. 4, pp. 5452–60.

Y. Jian, Z. Huang, X. Liu, J. Sun, and J. Xing: J. Mater. Sci. Technol., 2020, vol. 57, pp. 172–79.

R. Kalsar and S. Suwas: Scr. Mater., 2018, 154, vol. 154, pp. 207–11.

P.H.F. Oliveira, D.C.C. Magalhães, M.T. Izumi, O.M. Cintho, A.M. Kliauga, and V.L. Sordi: Mater. Sci. Eng. A, 2021, vol. 813, p. 141154.

Acknowledgments

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001. The authors thank the Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) and the Conselho Nacional de Desenvolvimento Científico e Tecnológico – Brasil (CNPq) for the financial support. The authors thank the Institute of Materials Technology (ITM/UPV) and Laboratory of Structural Characterization (LCE/DEMa/UFSCar) for the general facilities. GG acknowledges UNAM-DGAPA-PASPA program for supporting his sabbatical year at UPV.

Funding

This work was supported by the Fundação de Amparo à Pesquisa do Estado de São Paulos – FAPESP (Process Numbers: 2016/11309-0, 2020/05049-1, and 2021/11537-1); the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001; the Conselho Nacional de Desenvolvimento Científico e Tecnológico – Brasil - CNPq (Grant Number 141250/2020-8, and Process No. 403955/2021-1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vidilli, A.L., Coury, F.G., Gonzalez, G. et al. Tailoring the Microstructure and Properties of Reinforced FeMnAlC Composites by In-Situ TiB2–TiC–M2B Formation. Metall Mater Trans A 55, 101–117 (2024). https://doi.org/10.1007/s11661-023-07230-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07230-6