Abstract

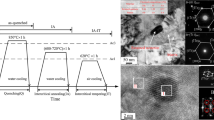

The effect of welding and postweld heat treatment on the microstructural characteristics and mechanical properties of a Cu-containing low-carbon low-alloy steel was studied. The obtained results indicated that ferrite, bainite, and coarse Cu-rich precipitates formed in the weld metal (WM) were responsible for its low impact energy of 57 J at − 40 °C. To obtain a good balance between strength and toughness in the WM, different heat treatments were employed. The obtained results demonstrated that direct tempering had a negligible effect on strength and toughness, but the addition of intercritical annealing to the conventional quenching and tempering process resulted in a significant increase in toughness and a slight decrease in tensile strength. The impact energy was increased to beyond 144 J, and the tensile strength was maintained at a high level of 958 MPa. The optimal microstructure benefiting both toughness and strength was found to primarily comprise intercritical ferrite, tempered martensite/bainite, reversed austenite, and fine Cu-rich precipitates. The toughening mechanism can be explained by the strain-induced martensitic transformation of reversed austenite and the retarding crack propagation effect of high-angle grain boundaries with a misorientation of more than 45 deg. The strengthening mechanism can be rationalized in terms of precipitation-strengthening and the strain-induced martensitic transformation of reversed austenite.

Similar content being viewed by others

References

H.J. Kong, C. Xu, C.C. Bu, C. Da, J.H. Luan, Z.B. Jiao, G. Chen, and C.T. Liu: Acta Mater., 2019, vol. 172, pp. 150–60.

S. Vaynman, M. Fine, G. Ghosh, and S. Bhat: Proc. Fourth Mater. Eng. Conf., 1996, pp. 1551–60.

S. Vaynman, D. Isheim, R. Prakash Kolli, S.P. Bhat, D.N. Seidman, and M.E. Fine: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 363–73.

J. Farren, A. Hunter, J. Dupont, C. Robino, E. Kozeschnik, and D. Seidman: Weld. J., 2013, vol. 92, pp. 140-s-47-s.

X. Yu, J.L. Caron, S.S. Babu, J.C. Lippold, D. Isheim, and D.N. Seidman: Acta Mater., 2010, vol. 58, pp. 5596–5609.

J.T. Bono, J.N. DuPont, D. Jain, S.-I. Baik, and D.N. Seidman: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 5158–70.

J.L. Caron, S.S. Babu, and J.C. Lippold: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 4032–44.

A.S.H. Mousavi, K.M. Aghaie, A.R. Khoshakhlagh, A.R. Eivani, N. Park, and H.R. Jafarian: J. Mater. Res. Technol., 2021, vol. 15, pp. 5776–86.

J.C.F. Jorge, L.F.G. de Souza, M.C. Mendes, I.S. Bott, L.S. Araújo, V.R. dos Santos, J.M.A. Rebello, and G.M. Evans: J. Mater. Res. Technol., 2021, vol. 10, pp. 471–501.

T. Kawakubo, K. Ushioda, and H. Fujii: Mater. Sci. Eng. A, 2021, vol. 832, p. 142350.

V.T.T. Miihkinen and D.V. Edmonds: in Fracture. S.R. Valluri, D.M.R. Taplin, P.R. Rao, J.F. Knott, and R. Dubey, eds., Pergamon, Oxford, 1984, pp. 1481–87.

Y. Zou, Y.B. Xu, Z.P. Hu, S.Q. Chen, D.T. Han, R.D.K. Misra, and G.Z. Wang: Mater. Sci. Eng. A, 2017, vol. 707, pp. 270–79.

X. Xi, J. Wang, L. Chen, and Z. Wang: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 5627–39.

J. Hu, L.-X. Du, W. Xu, J.-H. Zhai, Y. Dong, Y.-J. Liu, and R.D.K. Misra: Mater. Charact., 2018, vol. 136, pp. 20–28.

Z.J. Xie, S.F. Yuan, W.H. Zhou, J.R. Yang, H. Guo, and C.J. Shang: Mater. Des., 2014, vol. 59, pp. 193–98.

X. Xi, J. Wang, X. Li, L. Chen, and Z. Wang: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 2912–21.

J. Hu, J.-M. Zhang, G.-S. Sun, L.-X. Du, Y. Liu, Y. Dong, and R.D.K. Misra: J. Mater. Sci., 2019, vol. 54, pp. 6565–78.

Y.Y. Song, X.Y. Li, L.J. Rong, D.H. Ping, F.X. Yin, and Y.Y. Li: Mater. Lett., 2010, vol. 64, pp. 1411–14.

S.R.F. Lala, A. Gupta, and C. Srivastava: Metall. Mater. Trans. A, 2021, vol. 53, pp. 679–88.

B. Cui, Y. Peng, L. Zhao, M. Peng, T. An, and C. Ma: ISIJ Int., 2016, vol. 56, pp. 132–39.

Y. You, C. Shang, W. Nie, and S. Subramanian: Mater. Sci. Eng. A, 2012, vol. 558, pp. 692–701.

Z.J. Xie, G. Han, W.H. Zhou, X.L. Wang, C.J. Shang, and R.D.K. Misra: Scripta Mater., 2018, vol. 155, pp. 164–68.

M. Wang, Z.Y. Liu, and C.G. Li: Acta Metall. Sin., 2017, vol. 30, pp. 238–337.

S. Zhou, Y. Zuo, Z. Li, X. Wang, and Q. Yong: Mater. Charact., 2016, vol. 119, pp. 110–13.

G.R. Lehnhoff and K.O. Findley: JOM, 2014, vol. 66, pp. 756–64.

P. Ren, X.P. Chen, L. Mei, Y.Y. Nie, and Q. Liu: Mater. Sci. Eng. A, 2020, vol. 775, p. 138984-.

J. Hu, L.-X. Du, Y. Dong, Q.-W. Meng, and R.D.K. Misra: Mater. Charact., 2019, vol. 152, pp. 21–35.

N. Nakada, T. Yamashita, J. Syarif, T. Tsuchiyama, and S. Takaki: Tetsu-to-Hagane, 2003, vol. 89, pp. 1050–56.

X. Pan, G. Qian, and Y. Hong: Scripta Mater., 2021, vol. 194, p. 113631.

W.D. Mu, Y. Cai, and M. Wang: Mater. Sci. Eng. A, 2021, vol. 819, p. 141418.

M.I. Pascuet, E. Martínez, G. Monnet, and L. Malerba: J. Nucl. Mater., 2017, vol. 494, pp. 311–21.

T. Zhou, H. Yu, and S. Wang: Mater. Sci. Eng. A, 2016, vol. 658, pp. 150–58.

Y. You, C. Shang, L. Chen, and S. Subramanian: Mater. Sci. Eng. A, 2012, vol. 546, pp. 111–18.

H. Qiu, L.N. Wang, J.G. Qi, H. Zuo, and K. Hiraoka: Mater. Sci. Eng. A, 2013, vol. 579, pp. 71–76.

C. Wang, H. Ding, J. Zhang, and H.Y. Wu: Acta Metall. Sin., 2014, vol. 27, pp. 457–63.

S.S. Xu, Y. Zhao, X. Tong, H. Guo, L. Chen, L.W. Sun, M. Peng, M.J. Chen, D. Chen, Y. Cui, G.A. Sun, S.M. Peng, and Z.W. Zhang: J. Alloys Compd., 2017, vol. 712, pp. 573–78.

M.J. Yao, E. Welsch, D. Ponge, S.M.H. Haghighat, S. Sandlöbes, P. Choi, M. Herbig, I. Bleskov, T. Hickel, M. Lipinska-Chwalek, P. Shanthraj, C. Scheu, S. Zaefferer, B. Gault, and D. Raabe: Acta Mater., 2017, vol. 140, pp. 258–73.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant No. 52101133) and the Science and Technology Projects of Zhanjiang with the Contract Nos. 2021E05003 and 2021B01039.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Dong, G., Li, Y. et al. Crucial Microstructural Features to Determine the Mechanical Properties of Welded Joints in a Cu-Containing Low-Carbon Low-Alloy Steel After Postweld Heat Treatment. Metall Mater Trans A 53, 3493–3505 (2022). https://doi.org/10.1007/s11661-022-06768-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06768-1