Abstract

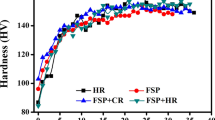

The evolution of microstructure and the preferred orientation during the two-step cross rolling at room (RT) and cryogenic temperatures (CTs) on Al-Mg-Sc alloy were investigated and compared with the unidirectional rolled Al-Mg-Sc alloy in this study. In addition, the effects of two-step cross rolling on tensile, forming and void coalescence behavior were analyzed. After the solution heat treatment, the two-step cross rolling was executed with an initial 25 pct reduction in the unidirectional path and the final 25 pct reduction in the transverse direction. The two-step cross-rolled (TSCR) Al-Mg-Sc alloy at CT showed a higher fraction of sub-micron grains. The TSCR Al-Mg-Sc alloy exhibited brass and copper and a strong S texture. The texture indices and in-plane anisotropy values indicated the highly anisotropic nature of the TSCR Al-Mg-Sc alloy. During tensile deformation, the TSCR Al-Mg-Sc alloy at CT exhibited a strength value of 423 MPa, whereas the TSCR Al-Mg-Sc alloy at RT revealed only 378 MPa. The TSCR Al-Mg-Sc alloy at CT exhibited inferior formability compared with the TSCR Al-Mg-Sc alloy at RT and the solution heat-treated base alloy. The formability of the TSCR Al-Mg-Sc alloy was evaluated through the combined forming and fracture limit diagram (CFFLD). The presence of higher Goss-oriented grains enhanced the fracture resistance of the TSCR Al-Mg-Sc alloy at CT. Furthermore, consistency was found between the evaluated void coalescence parameters and the CFFLD.

Similar content being viewed by others

References

[1] I.J.Polmear: Light Alloys, 4th ed., Butterworth-Heinemann, Oxford, 2006, pp. 205-35

The Strong Light Weight Aerospace Aluminium AA5028 AlMgSc, Aleris Corporation, USA, 2015, https://www.aleris.com/wp-content/uploads/2016/02/AL-2342_012-Aktualisierung-BR-AlMgSc-2015-06-03-WEB.pdf, accessed 20 Nov 2018.

[3] K.L. Kendig and D.B. Miracle: Acta Mater., 2002, vol. 50, pp. 4165–75.

[4] T. Dorin, M. Ramajayam, A. Vahid, T. Langan: Aluminium Scandium Alloys, in: Roger N. Lumley (Ed.), Fundamentals of Aluminium Metallurgy Recent Advances, Woodhead Publishing Series in Metals and Surface Engineering, UK, 2018, pp. 439-494.

[5] Y.A. Filatov, V.I. Yelagin and V. V Zakharov: Mater. Sci. Eng. A, 2000, vol. 280, pp. 97–101.

[6] Z. Yin, Q. Pan, Y. Zhang and F. Jiang: Mater. Sci. Eng. A, 2000, vol. 280, pp. 151–55.

[7] W. Yang, D. Yan and L. Rong: Scr. Mater., 2013, vol. 68, pp. 587–90.

[8] R. Roumina and C.W. Sinclair: Acta Mater., 2010, vol. 58, pp. 111–21.

[9] Y.W. Riddle and T.H. Sanders: Metall. Mater. Trans. A, 2004, vol. 35, pp. 341-50.

[10] V. Ocenasek and M. Slamova: Mater. Charct., 2001, vol. 47, pp. 157–62.

O.Roder, T. Wirtz, A. Gysler and G. Liitjering: Mater. Sci. Eng. A, 1997, vol. 234-236, pp. 181–84.

[12] A. Vinogradov, A. Washikita, K. Kitagawa and V.I. Kopylov: Mater. Sci. Eng. A, 2003, vol. 349, pp. 318–26.

[13] M. Li, Q. Pan, Y. Wang and Y. Shi: Mater. Sci. Eng. A, 2014, vol. 598, pp. 350–354.

[14] D. Zhemchuzhnikova, A. Mogucheva and R. Kaibyshev: Mater. Sci. Eng. A, 2013, vol. 565, pp. 132–41.

[15] D. Zhemchuzhnikova, S. Malopheyev, S. Mironov and R. Kaibyshev: Mater. Sci. Eng. A, 2014, vol. 598, pp. 387–95.

[16] S.K. Panigrahi, D. Devanand and R. Jayaganthan: Trans. Indian Inst. Met., 2008, vol. 61, pp. 159–63.

[17] B. Wang, X. Chen, F. Pan, J. Mao and Y. Fang: Trans. Nonferrous Met. Soc. China., 2015, vol. 25, pp. 2481–89.

[18] D. Singh, P.N. Rao and R. Jayaganthan: Mater. Sci. Technol., 2014, vol. 30, pp. 1835–42.

[19] R.J. Immanuel and S.K. Panigrahi: Mater. Sci. Eng. A, 2015, vol. 640, pp. 424-35.

[20] P. Das, R. Jayaganthan, T. Chowdhury and I. V Singh: Mater. Sci. Eng. A, 2011, vol. 528, pp. 7124-32.

P.L.M. Kanta, V.C. Srivastava, K. Venkateswarlu, S. Paswan, B. Mahato,G.Das, K.Sivaprasad and K.Gopala Krishna: Int. J. Miner. Metall. Mater., 2017, vol. 24, pp. 1293-05.

K.S.V.B.R. Krishna, S. Vigneshwaran, K.Chandra Sekhar, S.S.R. Akella, K. Sivaprasad, R. Narayanasamy and K. Venkateswarlu: Int. J. Adv. Manuf. Technol., 2017, vol. 93, pp. 253–59.

[23] R. Jayaganthan, H.G. Brokmeier, B. Schwebke and S.K. Panigrahi: J. Alloys Compd., 2010, vol. 496, pp. 183–88.

[24] Y. Wang, M. Chen, F. Zhou and E. Ma: Nature, 2002, vol. 419,pp. 912–15.

J. Zheng, C. Li, S. He, B. Ma andY. Song: Mater. Sci. Technol., 2017, vol. 33, 1681-87.

G.S. D’yakonov, S. V Zherebtsov, M. V Klimova and G.A. Salishchev: Phys. Met. Metallogr., 2015, vol. 116, pp. 182–88.

[27] Y.D. Shi, D.F. Guo, M. Li, Z.B. Zhang, T.Y. Ma and X.Y. Zhang: Mater. Sci. Technol., 2013, vol. 29, pp. 921–924.

[28] S. Vigneshwaran, K. Sivaprasad, R. Narayanasamy and K. Venkateswarlu: Mater. Sci. Eng. A, 2019, vol. 740–741, pp. 49–62.

[29] S. Vigneshwaran, K. Sivaprasad, R. Narayanasamy and K. Venkateswarlu: Mater. Sci. Eng. A, 2018, vol. 72, pp. 14–21.

[30] T. Konkova, S. Mironov, A. Korznikov, G. Korznikova, M.M. Myshlyaev and S.L. Semiatin: Mater. Des., 2015, vol. 86, pp. 913–21.

C. Xing Pin, S. Du, X. Rui, H.Guang Jie and L. Qing: Trans. Nonferrous Met. Soc. China., 2010, vol. 20, pp. 589–93.

[32] S. Suwas, A.K. Singh, K.N. Rao and T. Singh: Z. Metallkd., 2002, vol. 93, pp. 928-37.

[33] W. Liu, X. Kong, M. Chen, J. Li, H. Yuan and Q. Yang: Mater. Sci. Eng, 2009, vol. 516, pp. 263–69.

[34] W. Liu, X. Li and X. Meng: Scr. Mater., 2009, vol. 60, pp. 768–71.

[35] N. Nayan, S. Mishra, A. Prakash, S.V.S.N. Murty, M.J.N. V Prasad and I. Samajdar: Mater. Sci. Eng. A, 2019, vol. 740–741, pp. 252–61.

[36] W.Y. Yeung and B.J. Duggan: Acta Mater., 1986, vol. 34, pp. 653–60.

[37] N.P. Gurao, S. Sethuraman and S. Suwas: Mater. Sci. Eng. A, 2011, vol. 528, pp. 7739–50.

[38] S. Suwas, N.P. Gurao: Development of Microstructures and Textures by Cross Rolling, in: M.S.J. Hashmi (Ed.), Comprehensive materials processing, Elsevier, Oxford, 2014, pp. 81-106.

[39] T. Ungár: Scr. Mater., 2004, vol. 51, pp. 777–781.

[40] A.K. Zak, W.H.A. Majid, M.E. Abrishami and R. Youse: Solid State Sci., 2011, vol. 13, pp. 251-56.

[41] R.R. Smallman and K.H. Westmacott: Philos Mag., 1957, vol. 2, pp. 669–83.

K.S.V.B.R. Krishna, K. Chandra Sekhar, R. Tejas, N. Naga Krishna, K. Sivaprasad, R. Narayanasamy and K. Venkateswarlu: Mater. Des., 2015, vol. 67, pp. 107–17.

[43] R.E. Smallman and D. Green: Acta. Mater., 1964, vol. 12, pp. 145-54.

[44] H. Bunge: Texture Analysis in Materials Science – Mathematical Methods, Butterworth & Co., UK, 1982. pp. 88-89.

[45] M.Y. Huh, S.Y. Cho and O. Engler: Mater. Sci. Eng. A, 2001, vol. 315, pp. 35–46.

[46] T. Ozturk: Scr. Mater., 1988, vol. 22, pp. 1611-16.

[47] A. Bocker, H. Klein and H.J. Bunge: Textures and Microstruct., 1990, vol. 12, pp. 155–74.

[48] P.P. Bhattacharjee, M. Joshi, V.P. Chaudhary and M. Zaid: Mater. Charact., 2012, vol. 76, 21–27.

K. Chandra Sekhar, R. Narayanasamy and K. Velmanirajan: Mater. Des., 2014, vol. 53, pp. 1064–70.

[50] G.E. Dieter, Mechanical Metallurgy, McGraw-Hill Book Company limited, UK, 1988, pp. 35-37.

[51] I.Samajdar and R.D. Doherty: Scr. Mater., 1995, vol. 32, pp. 845–50.

[52] K. Velmanirajan, K. Anuradha, A.S. Abu, R. Narayanasamy, R. Madhavan and S. Suwas: Arch. Civ. Mech. Eng., 2013, vol. 14, pp. 398–16.

[53] Y. Zhang and Z. Chen: Int. J. Fract., 2007, vol. 143, pp. 105–12.

[54] S.C. Tang and L.B. Chappius: J. Mater. Manuf. Process, 1988, vol. 8, pp. 19–26.

[55] X. Gao, T. Wang and J. Kim: Int. J. Sol. Struct., 2005, vol. 42, pp. 5097–17.

[56] Q. Zhao, Z. Liu, T. Huang, P. Xia and F. Li: Mater. Charact., 2016, vol.119, pp. 47-54.

[57] F. Goli and R. Jamaati: Mater. Letters, 2018, vol. 219, pp. 229–32.

Acknowledgments

The authors thank Professor I. Samajdar, Department of Metallurgical Engineering and Materials Science, National Facility, OIM and Texture Laboratory, IIT-Bombay, India, for providing the EBSD and bulk texture facilities. The authors also extend their thanks to Dr. S. Sankaran, Professor, Department of Metallurgical and Materials Engineering, IIT-Madras, India, for providing the cryorolling facilities.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 7, 2019.

Rights and permissions

About this article

Cite this article

Vigneshwaran, S., Sivaprasad, K., Narayanasamy, R. et al. Superior Strength with Enhanced Fracture Resistance of Al-Mg-Sc Alloy Through Two-Step Cryo Cross Rolling. Metall Mater Trans A 50, 3265–3281 (2019). https://doi.org/10.1007/s11661-019-05253-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05253-6