Abstract

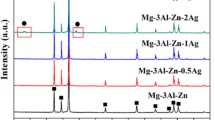

A series of coupled eutectic growths along the univariant eutectic groove in the ternary Al-Cu-Ag alloy was studied to investigate the effect of Ag on the microstructure and crystallization of directionally solidified Al-Cu-Ag alloys. The results indicated that the eutectic morphology and orientation relationship (OR) between eutectic phases were modified as the Ag content in the Al-Cu-Ag alloys increased. At a lower growth velocity (R ≤ 1 μm/s), a banded structure formed and the interlamellar spacing decreased with the increasing Ag content. At a higher growth velocity (R ≥ 3 μm/s), the eutectic cell spacing decreased with increasing Ag content. Increasing the Ag content in the Al-Cu-Ag alloys enhanced the enrichment of the Ag solute in the liquid ahead of the quenched liquid/solid interface. In addition, increasing the Ag content in the Al-Cu-Ag alloys promoted the transformation from a “Beta 6” OR to an “Alpha 4” OR between eutectic phases. Modifications of the eutectic morphology and the OR during directional solidification were attributed to the enrichment of Ag content at the solid/liquid interface and the changes in the interfacial energy due to the increase in Ag solubility in the α-Al phase.

Similar content being viewed by others

References

JD Wilde, L Froyen. Microgravity Sci. Tec., 2005, vol.16(1), pp. 40-44.

M Plapp, A Karma. Phys. Rev. E, 1999, vol. 60(6), pp. 6865-89.

JD Wilde, L Froyen, S Rex. Scripta Mater., 2004, vol. 51(6), pp: 533-38.

Wilde JD, Froyen L, Witusiewicz VT, Hecht U. J. Appl. Phys., 2005, 97(11), 113515.

Hecht U, Witusiewicz V, Drevermann A. IOP Conf. Series: Mater. Sci. Eng., 2012, 27(1), 012029.

HQ Bao, FCL Durand. J.Cryst. Growth, 1972, vol. 15(4), pp: 291-95.

JD Holder, BF Oliver. Metall. Trans., 1974, 5(11), 2423-37.

G Garmong. Metall. Mater. Trans. B, 1971, vol. 2(8), pp: 2025-30.

PJ Fehrenbach, HW Kerr, P Niessen. J.Cryst. Growth, 1972, vol. 16(3), pp: 209-14.

FW Schnake, GA Varschavsky. Mater.Charact., 1997, vol. 39(2), pp: 345-59.

WW Mullins, RF Sekerka. . Appl. Phys., 1964, vol. 35(2), pp: 444-51.

U Böyük, N Maraşlı, H Kaya, E Çadırlı, K Keşlioğlu. Appl. Phys. A, 2009, vol. 95(3), pp: 923-32.

A Dennstedt, L Ratke. Trans. Indian Inst. Met., 2012, vol. 65(6), pp: 777-82.

B Zhou, L Froyen. Trans. Indian Inst. Met., 2014, vol. 67(1), pp: 57-65.

AL Genau, L Ratke. IOP Conf. Series: Mater. Sci. Eng., 2012, 27(1), 012032.

J Hötzer, M Jainta, P Steinmetz, B Nestler, A Dennstedt, A Genau, et al.Acta Mater.,2015, vol. 93, pp: 194-204.

P Steinmetz, YC Yabansu, J Hötzer,MJainta, B Nestler, SR Kalidindi. Acta Mater.,2016, vol. 103, pp: 192-203.

V Kokotin, U Hecht. Comput. Mater. Sci., 2014, vol. 86, pp: 30-37.

VT Witusiewicz, U Hecht, SG Fries, S Rex. J. Alloys Compd., 2005, vol. 387(1), pp: 217-27.

R. Bonnet, F. Durand: Confer. on in situ composites., 1973. pp. 209–23.

MD Rinaldi, RM Sharp, MC Flemings. Metall. Trans., 1972, 3(12), 3139-48.

A Drevermann, U Hecht, V Witusiewicz, B Böttger, S Rex. Microgravity Sci. Tec., 2005, vol. 16(1), pp: 45-49.

KA Jackson, JD Hunt. Metall. Soc. AIME, 1966, vol. 236, pp: 1129-42.

VT Witusiewicz, U Hecht, S Rex. J. Cryst. Growth, 2013, vol. 372, pp: 57-64.

O Senninger, PW Voorhees, Acta Mater., 2016, vol. 116 pp: 308-20.

O Senninger, M Peters, PW Voorhees, Metall. Mat. Trans. A, 2018, https://doi.org/10.1007/s11661-018-4488-4.

A Genau, L Ratke. Inter. J. Mater. Res., 2012, vol. 103(4), pp: 469-75.

JD Wilde, E Nagels, F Lemoisson, Froyen L. Mater. Sci. Eng. A, 2005, 413, 514-20.

S Akamatsu, S Bottin-Rousseau, M Şerefoğlu, G Faivre. Acta Mater., 2012, vol. 60(6–7), pp: 3206-14.

T Haxhimali, AKarma, F Gonzales, M Rappaz. Nature Mater., 2006, vol. 5, pp: 660.

N Maraşli, JD Hunt. Acta Mater., 1996, vol. 44(3), pp: 1085-96.

JAV Butler. Proc. R. Soc. Lond. A 1932, vol. 135(827), pp: 348-75.

WR Tyson, WA Miller. Surf. Sci., 1977, vol. 62(1), pp: 267-76.

S Guldberg, N Ryum, Mater. Sci. Eng. A, 2000, vol. 289, pp: 143-50.

Acknowledgements

This work was supported by the National Key Technology R&D Program of China (No. 2016YFB0701405), the European Space Agency through the Bl-inter 09_473220, National Natural Science Foundation of China (Nos. 51271109 and 51171106), Aeronautical Science Foundation of China (2015ZE57011), Shanghai Science and Technology Committee Grant (Nos. 13DZ1108200, 13521101102 and 16DZ2260600), the Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning, the China Postdoctoral Science Foundation (2017M620154), and the fund of the State Key Laboratory of Solidification Processing in NWPU (SKLSP201732).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted January 1, 2018.

Rights and permissions

About this article

Cite this article

Du, D., Fautrelle, Y., Dong, A. et al. Effect of Ag Content on the Microstructure and Crystallization of Coupled Eutectic Growth in Directionally Solidified Al-Cu-Ag Alloys. Metall Mater Trans A 49, 4735–4747 (2018). https://doi.org/10.1007/s11661-018-4799-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4799-5