Abstract

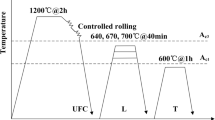

The effects of variation in the intercritical quench temperature of quench, intercritical quench, and temper (QLT) heat treatments on the microstructure and cryogenic mechanical properties of a 7 pct Ni steel are presented. The intercritical temperatures were in the range of 923 K to 983 K (650 °C to 710 °C) and were followed by quenching. The microstructures as determined by optical microscope, scanning electron microscope, and transmission electron microscopy, and X-ray diffraction are presented, and the results of low-temperature mechanical property tests are given. It is shown that both the grain size and the martensite lath width increased as the intercritical quench temperature increased, while the measured amount of reversed austenite decreased with increasing temperature. Higher amounts of stabilizing elements, such as Ni and Mn, which can improve the stability of reversed austenite, were absorbed by intercritical quenching from 963 K and 983 K (690 °C and 710 °C) than from 923 K and 943 K (650 °C and 670 °C). Both the stability and the amount of reversed austenite had critical effects on the cryogenic mechanical properties of the steel. An excellent combination of cryogenic strength and toughness was achieved by intercritical quenching from 963 K (690 °C), indicating that based on the cryogenic mechanical properties, 7 pct Ni-QLT steel could be used in place of 9 pct Ni steel for liquefied natural gas projects.

Similar content being viewed by others

References

Anzhong Gu: Nat. Gas Ind., 2011, vol. 31, pp. 1–11.

Dovid A. Wood: J. Nat. Gas Sci. Eng., 2012, vol. 9, pp. 16–27.

M. Yamashita, D. Knowels, M. Mitsumoto, and T. Kawabata: in Proceedings of the ASME Pressure Vessels and Piping Conference, 2011, ed. A.J. Duncan, New York, 2011, vol. 6, pp. 37–46.

I.V. Khomskaya: Phys. Met. Metallogr., 2010, vol. 110, pp. 188–98.

J.R. Strife and D.E. Passoja: Metall. Trans. A, 1980, vol. 11, pp. 1341–50.

S.J. Wu, G.J. Sun, Q.S. Ma, Q.Y. Shen, and L. Xu: J. Mater. Process. Technol., 2013, vol. 213, pp. 120–28.

J.M. Zhang, H. Li, F. Yang, Q. Chi, L.K. Ji, and Y.R. Feng: J. Mater. Eng. Perform., 2013, vol. 22, pp. 3867–71.

H. Furuya, T. Tagawa, and T. Ishikawa: Tetsu-to-Hagane, 2014, vol. 100, pp. 678–87.

Y.K. Lee, H.C. Shin, Y.C. Jang, S.H. Kim, and C.S. Choi: Scripta Mater., 2002, vol. 47, pp. 805–09.

Shigekazu Morito, Keiichiro Oh-ishi, Kazuhiro Hono, and Takuya Ohba: ISIJ Int., 2011, vol. 51, pp. 1200–02.

L.M. Wang, Z.B. Wang, and K. Lu: Acta Mater., 2011, vol. 59, pp. 3710–19.

R.R. Mohanty, O.A. Girina, and N.M. Fonstein: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3680–90.

J. Huan, W.J. Poole, and M. Militzer: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3363–75.

J.I. Kim and J.W. Morris: Metall. Trans. A, 1981, vol. 12, pp. 1957–63.

M.J. Carr, J.R. Strife, and G.S. Ansell: Metall. Trans. A, 1978, vol. 9, pp. 857–64.

Chol K. Syn, Sunguo Jin, and J.W. Morris: Metall. Trans. A, 1976, vol. 7, pp. 1827–32.

B. Fultz, J.I. Kim, Y.H. Kim, H.J. Kim, G.O. Fior, and J.W. Morris: Metall. Trans. A, 1985, vol. 16, pp. 2237–49.

J. Jang, Y. Yang, W. Kim, and D. Kwon: in Advances in Cryogenic Engineering Materials, U.B. Balachandran, D.G. Gubser, K.T. Hartwing, R.P. Reed, W.H. Warnes, and V.A. Bardos, eds., Springer, New York, 1998, pp. 41–8.

Acknowledgments

This work is sponsored and financially supported by WISCO. Thanks are also expressed to Dr. William R. Warke for his suggestive discussions and comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 28, 2016.

Rights and permissions

About this article

Cite this article

Cao, H., Luo, X., Zhan, G. et al. Effect of Intercritical Quenching on the Microstructure and Cryogenic Mechanical Properties of a 7 Pct Ni Steel. Metall Mater Trans A 48, 4403–4410 (2017). https://doi.org/10.1007/s11661-017-4200-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4200-0