Abstract

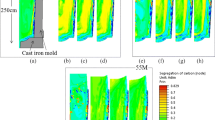

In order to cognize the macrosegregation formation with solidification conditions, a 36-ton steel ingot has been experimentally investigated. Temperature variations of fourteen specified positions, for both the mold and ingot, were monitored to acquire the thermal conditions during solidification. Calibrated heat transfer coefficients between the ingot and mold were determined based on the temperature measurements and the empirical formula. Besides, concentration distributions of both carbon and sulfur in the ingot longitudinal section were mapped by 1800 drilled samples. Macrosegregation patterns were obtained, and notable negative segregations along the side walls of hot-top as well as typical segregation characteristics were presented in the maps. Segregation extent of sulfur was greater than that of carbon, and the segregated sulfur was relevant to the segregated carbon in a certain extent on statistical analysis with a standard correlation coefficient r = 0.68872. Finally, a two-phase multiscale multicomponent solidification model was preliminarily utilized to predict the species segregation. General good agreements are exhibited for the comparisons between the prediction and measurement of concentration profiles of carbon and sulfur in ingot.

Similar content being viewed by others

References

C. Beckermann: Int. Mater. Rev., 2002, vol. 47, pp. 243-61.

E. J. Pickering: ISIJ Int., 2013, vol. 53, pp. 935-949.

D. Z. Li, X. Q. Chen, P. X. Fu, X. P. Ma, H. W. Liu, Y. Chen, Y. F. Cao, Y. K. Luan, and Y. Y. Li: Nat. Commun., 2014, vol. 5, pp.5572. doi:10.1038/ncomms6572.

M. C. Flemings and G. E. Nereo: Trans. Metall. Soc. AIME, 1967, vol. 239, pp. 1449-61.

W. D. Bennon and F. P. Incropera: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2161-70.

C. Beckermann and R. Viskanta: Physicochem. Hydrodyn., 1995, vol. 10, pp. 195-213.

J. Ni and C. Beckermann: Metall. Trans. B, 1991, vol. 22B, pp. 349-61.

C. Y. Wang and C. Beckermann: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2754-64.

M. Wu and A. Ludwig: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1613-31.

M. Bellet, H. Combeau, Y. Fautrelle, D. Gobin, M. Rady, E. Arquis, O. Budenkova, B. Dussoubs, Y. Duterrail, A. Kumar, C. A. Gandin, B. Goyeau, S. Mosbah, and M. Založnik: Int. J. Therm. Sci., 2009, vol. 48, pp. 2013–16.

G. Lesoult: Mater. Sci. Eng. A, 2005, vols. 413-414A, pp. 19–29.

J. Li, M. Wu, A. Ludwig, and A. Kharicha: Int. J. Heat Mass Transfer, 2014, vol. 72, pp. 668–79.

S. Hans, P.E. Richy, B. Lusson, and A. Grellier: in 1st Multidisciplinary Congress on Materials, Tours, France, 2002, AF16005.

H. Combeau, B. Rabia, S. Charmond, S. Hans, and P.E. Richy: in 2nd Multidisciplinary Conference on Materials, Dijon, France, 2006.

H. Combeau, M. Založnik, S. Hans, and P. E. Richy: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 289–304.

J.Pickering, C.Chhesman, S.Al-Bermani, M. Holland, P.Davies, and J. Talamantes-silva: Metall. Mater. Trans. B, 2015, vol.46B, pp.1860-1874.

P. Machovcak, A. Opler, Z. Carbol, A. Trefil, K. Merta, J. Zaoral, M. Tkadleckova, and K. Michalek: Arch. Mater. Sci. Eng., 2012, vol. 58, pp. 22–27.

K. Kajikawa, S. Suzuki, F. Takahashi, S. Yamamoto, T. Suzuki, S. Ueda, T. Shibata, and H. Yoshida: in 1st International Conference on Ingot Casting, Rolling and Forging, Aachen, Germany, 2012.

W. S. Li, H. F. Shen, X. Zhang and B. C. Liu: Metal. Mater. Trans. B, 2014, vol. 45B, pp. 464–71.

W. Tu, H. Shen, and B. Liu: ISIJ Int., 2014, vol. 54, pp. 351–55.

Z. Duan, H. Shen, and B. Liu: in The 14th Modelling of Casting, Welding and Advanced Solidification Process, Hyogo, Japan, 2015, p. 012048.

M. C. Schneider and C. Beckermann: Metal. Mater. Trans. A, 1995, vol. 9A, pp. 2373–88.

ProCAST software, version 2011, https://www.esi-group.com/software-services/virtual-manufacturing/casting/procast-quikcast.

W.S. Li, B.Z. Shen, H.F. Shen, and B.C. Liu: in The 69th World Foundry Congress, Hangzhou, P.R. China, 2010, pp. 0537–40.

Z. Liu, Y. Zhao, Y. Zhang, H. L. Zhao, Y. T. Yang: J. Iron.Steel.Res, 1993, vol.5, pp. 23-32.

Acknowledgments

This work was financially supported by the National Basic Research Program of China (No. 2011CB012900) and the National Science and Technology Major Project the Ministry of Science and Technology of China (No. 2012ZX04012011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 27, 2015.

Appendix

Appendix

The concentration solute transport equations[19,20] for the liquid and solid phase is improved as follows:

According to the interface solute balance, it can be derived as

Considering the fact that diffusion in solid is negligible compared with the diffusion in liquid (D s,1 ≪ D l,1), it can be simplified as

Similarly, the interfacial phase change rate can also be expressed as

Combining Eqs. [A4] and [A5], the constraint between the interface solute element evolutions is

Rights and permissions

About this article

Cite this article

Duan, Z., Tu, W., Shen, B. et al. Experimental Measurements for Numerical Simulation of Macrosegregation in a 36-Ton Steel Ingot. Metall Mater Trans A 47, 3597–3606 (2016). https://doi.org/10.1007/s11661-016-3531-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3531-6