Abstract

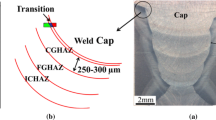

An experimental steel with the composition Fe-1.39Cu-2.70Ni-0.58Al-0.48Mn-0.48Si-0.065Nb-0.05C (wt pct) or alternatively Fe-1.43Cu-2.61Ni-1.21Al-0.48Mn-0.98Si-0.039Nb-0.23C (at. pct) has been developed at Northwestern University, which has both high toughness and high strength after quenching and aging treatments. Simulated heat-affected zone (HAZ) samples are utilized to analyze the microstructures typically obtained after gas metal arc welding (GMAW). Dissolution within the HAZ of cementite (Fe3C) and NbC (F.C.C.) is revealed using synchrotron X-ray diffraction, while dissolution of Cu precipitates is measured employing local electrode atom probe tomography. The results are compared to Thermo-Calc equilibrium calculations. Comparison of measured Cu precipitate radii, number density, and volume fraction with similar measurements from a GMAW sample suggests that the cooling rate in the simulations is faster than in the experimental GMAW sample, resulting in significantly less Cu precipitate nucleation and growth during the cooling part of the weld thermal cycle. The few Cu precipitates detected in the simulated samples are primarily located on grain boundaries resulting from heterogeneous nucleation. The dissolution of NbC precipitates and the resultant austenite coarsening in the highest-temperature sample, coupled with a rapid cooling rate, results in the growth of bainite, and an increase in the strength of the matrix in the absence of significant Cu precipitation.

Similar content being viewed by others

References

P.J. Konkol, K.M. Stefanick, and G.S. Pike: Weld. J., 2011, vol. 90(2), pp 34–41.

M.D. Mulholland and D.N. Seidman: Scipta Mater., 2009, Vol. 60(11), pp 992-995.

M.D. Mulholland and D.N. Seidman: Acta Mater, 2011, Iss. 5, Vol. 59, pp 1881-1897.

M.D. Mulholland and D.N. Seidman: Microsc Microanal, 2011, Iss. 6, Vol. 17, pp 950-962.

A. Saha and G.B. Olson: J. Comput-Aided Mater. Des., 2007, Iss. 2, Vol. 14, pp 177-200.

A. Saha, J. Jung and G.B. Olson: J. Comput-Aided Mater. Des., 2007, Iss. 2, Vol. 14, pp 201-233.

D. Isheim, A.H. Hunter, X.J. Zhang and D.N. Seidman: Metall. Mat. Trans. A, 2013, Iss. 7, Vol. 44, pp 3046-3059.

R.P. Kolli, R.M. Wojes, S. Zaucha and D.N. Seidman: Int. J. Mater. Res., 2008, Iss. 5, Vol. 99, pp 513-527.

S. Vaynman, D. Isheim, R.P. Kolli, S.P. Bhat, D.N. Seidman, and M.E. Fine: Metall. Mater. Trans. A, 2008, Vol. 39A, pp 363-373.

D. Isheim, R.P. Kolli, M.E. Fine and D.N. Seidman: Scripta Mater., 2006, Vol. 55(1), pp 35–40.

M.S. Gagliano and M.E. Fine: CALPHAD, 2001, Vol. 25(2), pp 207–16.

M.S. Gagliano and M.E. Fine: CALPHAD, 2004, Vol. 35A(8), pp 2323–29.

S. Vaynman, M.E. Fine, and S.P. Bhat: Proceedings from the Materials Science & Technology 2004 Conference, AIST and TMS, Warrendale, PA, 2004, pp. 417–21.

S. Vaynman, M.E. Fine, C. Hahin, N. Biondolillo and C. Crosby: Modern Steel Construction, 2007, vol. 47, p. 50.

S. Vaynman, M.E. Fine, R.I. Asfahani, D.M. Bormet, and C. Hahin: Proceedings from the Materials Solutions Conference 2002, ASM International, Columbus, OH, 2002, pp. 43–48.

S. Vaynman and M.E. Fine: International Symposium on Steel for Fabricated Structures, 1999, pp. 59–66.

S. Vaynman, I.J. Uslander, and M.E. Fine: 39th Mechanical Working and Steel Processing Conference Proceedings, ISS, Indianapolis, IN, 1997, pp. 1183–19.

S. Vaynman, M.E. Fine, G. Ghosh, and S.P. Bhat: Proceedings of the Fourth Materials Engineering Conference, ASCE, New York, NY, 1996, pp. 1551–60.

R.P. Kolli and D.N. Seidman: Microsc. microanal., 2007, Iss. 4, Vol. 13, pp 272-284.

R.P. Kolli, Z. Mao, D.N. Seidman and D.T. Keane: Appl. Phys. Lett., 2007, Iss. 24, Vol. 91, pp 241903.

R.P. Kolli and D.N. Seidman: Acta Mater., 2008, Iss. 9, Vol. 56, pp 2073-2088.

J.D. Farren, A.H. Hunter, J.N. Dupont, D.N. Seidman, C.V. Robino and E. Kozeschnik: Metall Mater Trans A, 2012, Vol. 43A, pp 4155-4170.

A.H. Hunter, J.D. Farren, J.N. Dupont and D.N. Seidman: Metall Mater Trans A, 2013, Iss. 4, Vol. 44A, pp 1741-1759.

B.M. Leister and J.N. DuPont: Weld J, 2012, Iss. 2, Vol. 91, pp 53s-58s.

J.D. Farren, A.H. Hunter, J.N. DuPont, C.V. Robino, E. Kozeschnik and D.N. Seidman: Weld J, 2013, Iss. 5, Vol. 92, pp 140s-147s.

P.W. Fuershbach and G.R. Eisler: 6th Intl. Trends in Welding Research, Pine Mountain, GA, April 15–19, 2002.

R.P. Kolli: Ph.D. Thesis, Northwestern University, 2007.

B.D. Cullity and S.R. Stock: Elements of X-Ray Diffraction, 3rd Edition, Prentice Hall, Upper Saddle Rivery, NJ, 2001, pp. 351-361.

L.C.D. Fielding: Mater Sci Tech Ser, 2013, Iss. 4, Vol. 29, pp 383-399.

S.J. Lee, M.T. Lusk and Y.K. Lee: Acta Mater, 2007, Iss. 3, Vol. 55, pp 875-882.

C.S. Smith: Trans. Am. Inst. Min. Metall. Eng., 1948, Vol. 175, pp 15-51.

S. Takaki, K. Kawasaki and Y. Kimura: J Mater Process Tech, 2001, Iss. 3, Vol. 117, pp 359-363.

M. Perez, F. Perrard, V. Massardier, X. Kleber, A. Deschamps, H. De Monestrol, P. Pareige, and G. Covarel: Philos Mag, 2005, Iss. 20, Vol. 85, pp 2197-2210.

X.H. Yu, J.L. Caron, S.S. Babu, J.C. Lippold, D. Isheim and D.N. Seidman: Acta Mater, 2011, Iss. 6, Vol. 59, pp 2564-2564.

Acknowledgments

This research is funded by the Office of Naval Research under grants N00014-09-1-0361 and N00014-07-1-0331 (Dr. W.W. Mullins, grant monitor). LEAP tomographic measurements are performed at the Northwestern University Center for Atom Probe Tomography (NUCAPT). The LEAP tomography system was purchased with funding from NSF-MRI Grant DMR-0420532 and with initial funding from ONR-DURIP Grant N00014-0400798, and with funding for upgrades from N00014-0610539, N00014-0910781, and the Initiative for Sustainability and Energy at Northwestern (ISEN) for grants to upgrade the capabilities of NUCAPT. Portions of this work were performed at the DuPont-Northwestern-Dow Collaborative Access Team (DND-CAT) located at Sector 5 of the Advanced Photon Source (APS). DND-CAT is supported by E.I. DuPont de Nemours & Co., The Dow Chemical Company, and Northwestern University. Use of the APS, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science by Argonne National Laboratory, was supported by the U.S. DOE under Contract No. DE-AC02-06CH11357. The authors kindly thank Dr. Dieter Isheim for managing NUCAPT, helpful discussions, and assistance with this project, and Dr. Denis T. Keane for his generous assistance with the XRD measurements. DNS thanks Prof. Emeritus M. E. Fine for generously introducing him to the subject of NUCu steels, which he had developed over many years at Northwestern University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 9, 2013.

Rights and permissions

About this article

Cite this article

Hunter, A.H., Farren, J.D., DuPont, J.N. et al. Multi-component Cu-Strengthened Steel Welding Simulations: Atom Probe Tomography and Synchrotron X-ray Diffraction Analyses. Metall Mater Trans A 46, 3117–3131 (2015). https://doi.org/10.1007/s11661-015-2899-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2899-z