Abstract

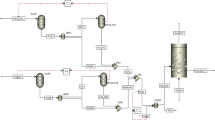

The co-combustion of low-rank coals through fluidized bed boiler (CFB) is an effective approach to enhance the level of resource utilization. To date, there has been a lack of investigation concerning the co-combustion kinetics and self-desulfurization characteristics of coal slime, coal gangue, and raw coal. In this study, we adopted multiple model-free and model-fitting methods to comparatively analyze co-combustion kinetics of blended coals on the basis of thermogravimetric data. Then, the sulfur balance and self-desulfurization of blended coals in the co-combustion were intensively investigated using a tube furnace set-up. The results reveal that in the presence of coal gangue in blended coals, the average activation energy (Ea) falls within the range of 65.7 kJ/mol to 100.4 kJ/mol, as determined by four model-free methods. Conversely, in the absence of coal gangue, only the Flynn-Wall-Ozawa (FWO) and Friedman (FM) methods are deemed appropriate for calculating the average Ea, yielding a value of 77.3 kJ/mol. The first order reaction model is confirmed to be reliable for analyzing the co-combustion kinetics of low-rank blended coals. Irrespective of the specific composition of the blended coal, a significant linear correlation exists between the Ea and the natural logarithm of the pre-exponential factor (lnA) within an extensive range of parameters. Moreover, the addition of coal gangue to the blended coal substantially enhances the self-desulfurization level, resulting in an increase from 25.7% to 60.7% at 1073 K. The self-desulfurization efficiency exhibits a good linear relationship with both the mass ratio of coal gangue to coal slime and the molar ratio of calcium to sulfur. In a practical implementation, the optimal addition ratio of coal gangue is a trade-off between the self-desulfurization efficiency and the ignition capacity.

Similar content being viewed by others

References

Zhang B., Zhu G., Lv B., Yan G., A novel and effective method for coal slime reduction of thermal coal processing. Journal of Cleaner Production, 2018, 198: 19–23.

Wang H., Liu S., Wang X., Shi Y., Qin X., Song C., Ignition and combustion behaviors of coal slime in air. Energy & Fuels, 2017, 31(10): 11439–11447.

Dai Z., Shi L., Wang L., Guo C., Rheological behaviors of coal slime produced by filter-pressing. International Journal of Mining Science and Technology, 2018, 28: 347–351.

Guo H., Zhao S., Xia D., Wang L., Lv J., Yu H., Jiao X., Efficient utilization of coal slime using anaerobic fermentation technology. Bioresource Technology, 2021, 332: 125072.

Guo X., Li K., Zhou P., Liang J., Gu J., Xue Y., Insight into the enhanced removal of water from coal slime via solar drying technology: dewatering performance, solar thermal efficiency, and economic analysis. ACS Omega, 2022, 7(8): 6710–6720.

Li J., Wang J., Comprehensive utilization and environmental risks of coal gangue: A review. Journal of Cleaner Production, 2019, 239: 117946.

Meng F., Yu J., Tahmasebi A., Tahmasebi A., Han Y., Pyrolysis and combustion behavior of coal gangue in O2/CO2 and O2/N2 mixtures using thermogravimetric analysis and a drop tube furnace. Energy & Fuels, 2013, 27(6): 2923–2932.

Song Z., Jing C., Yao L., Zhao X., Wang W., Mao Y., Ma C., Microwave drying performance of single-particle coal slime and energy consumption analyses. Fuel Processing Technology, 2016, 143: 69–78.

Czakiert T., Bis Z., Muskala W., Nowak W., Fuel conversion from oxy-fuel combustion in a circulating fluidized bed. Fuel Processing Technology, 2006, 87(6): 531–538.

Zhang Y., Guo Y., Cheng F., Yan K., Cao Y., Investigation of combustion characteristics and kinetics of coal gangue with different feedstock properties by thermogravimetric analysis. Thermochimica Acta, 2015, 614: 137–148.

Huang Z., Jiang J., Xu Z., Cao L., Research on CFB boiler large proportion coal slime co-combustion test. Proceeding of the CSEE, 2013, 33(s1): 112–116.

Wang F., Zhao J., Zhang Y., Zhang L., Yang Y., Zhang P., Guo Q., Cheng F., Investigation of agglomeration process of coal slime used in fluidized bed combustion. Clean Coal Technology, 2019, 25(4): 106–110.

Wang H., Yang D., Chen X., Liu H., Zhao K., Yang H., Wu J., Primary fragmentation characteristics in the process of coal Slime combustion. Combustion Science and Technology, 2023, 195(6): 1328–1345.

Fan H., Deng B., Shi J., Qin S., Feng Y., Huang Z., Fan B., Yang H., Jin Y., Zhang M., Experimental research on morphology and drying characteristics of coal slime dough injected into circulating fluidized bed boiler. Fuel Processing Technology, 2021, 222: 106981.

Wang H., Liu S., Li X., Yang D., Wang X., Song C., Morphological and structural evolution of bituminous coal slime particles during the process of combustion. Fuel, 2018, 218: 49–58.

Omar K.I., Hossain I., Begum J.A., Burning characteristics of high-ash bangladeshi peat. International Journal of Energy Research, 1995, 19(5): 391–396.

Wang C., Song G., Yang Z., Xiao Y., Yang X., Ji Z., Lyu Q., Influence of limestone addition on combustion and emission characteristics of coal slime in the 75 t/h CFB boiler with post-combustion chamber. Journal of Thermal Science, 2023, 32: 1849–1857.

Song G., Xiao Y., Yang Z., Yang Q., Lyu Q., Experiment study on the high-temperature thermal treatment and ultra-low NOx control of solid waste coal slime in circulating fluidized bed. Journal of Thermal Science, 2022, 31(6): 2244–2251.

Ji Z., Song G., Yang Z., Xiao Y., Yang X., Wang C., Zhang X., Effect of post-combustion air distribution on NOx original emission and combustion characteristics of 75 t/h coal slime circulating fluidized bed boiler. Journal of the Energy Institute, 2021, 99: 154–160.

Ran J., Niu B., Zhang L., Pu G., Tang Q., Study on general combustion performance and kinetic characteristics of combustion of coal reside. Proceedings of the CSEE, 2006, 15: 58–62.

Shao S., Ma B., Wang C., Chen Y., Thermal behavior and chemical reactivity of coal gangue during pyrolysis and combustion. Fuel, 2023, 331: 125927.

Li B., Liu G., Gao W., Cong H., Bi M., Ma L., Deng J., Shu C., Study of combustion behaviour and kinetics modelling of Chinese Gongwusu coal gangue: Model-fitting and model-free approaches. Fuel, 2020, 268: 117284.

Ma Z., Cheng L., Li L., Luo G., Zhang W., Wu Y., Pollutant emission and attrition performance of low calorific blended coals during co-combustion in fluidized bed. Fuel, 2023, 331: 125782.

Zhang Y., Nakano J., Liu L., Wang X., Zhang Z., Co-combustion and emission characteristics of coal gangue and low-quality coal. Journal of Thermal Analysis and Calorimetry, 2015, 120: 1883–1892.

Bi H., Ni Z., Tian J., Wang C., Jiang C., Zhou W., Bao L., Sun H., Lin Q., Influence of biomass on multi-component reaction model and combustion products of coal gangue. Combustion and Flame, 2022, 240: 111999.

Zhang X., Zhu S., Zhu J., Lyu Q., Wei K., Huang Q., TG-MS study on co-combustion characteristics and coupling mechanism of coal gasification fly ash and coal gangue by ECSA®. Fuel, 2022, 314: 123086.

Peng H., Wang B., Li W., Yang F., Cheng F., Combustion characteristics and NO emissions during co-combustion of coal cangue and coal slime in O2/CO2 atmospheres. Journal of Thermal Science, 2023, 32(1): 457–467.

Ma Z., Cheng L., Wang Q., Li L., Luo G., Zhang W., Co-combustion characteristics and CO2 emissions of low-calorific multi-fuels by TG-FTIR analysis. Energy, 2022, 252: 123919.

Ping C., Zhou J., Cheng J., Yang W., Cen K., Research on the pyrolysis kinetics of blended coals. Proceedings of the CSEE, 2007, 27(17): 6–10.

Liu J., Liu M., Zhao W., Thermogravimetric study on combustion characteristics of lignite semicoke. Thermal Power Generation, 2013, 42(11): 86–92.

Kaur R., Gera P., Jha M.K., Bhaskar T., Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis. Bioresource Technology, 2018, 250: 422–428.

Morais L.C., Maia A.A.D., Guandique M.E.G., Rosa A.H., Pyrolysis and combustion of sugarcane bagasse. Journal of Thermal Analysis and Calorimetry, 2017, 129: 1813–1822.

Starink M.J., The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochimica Acta, 2003, 404(1–2): 163–176.

Friedman H.L., Kinetics of thermal degradation of char-forming plastics from thermogravimetry application to a phenolic plastic. Journal of Polymer Science Part C, 1964, 6(1): 183–195.

Wahab A., Sattar H., Ashraf A., Hussain S.N., Saleem M., Shahid M., Thermochemical, kinetic and ash characteristics behaviour of Thar lignite, agricultural residues and synthetic polymer waste (EVA). Fuel, 2020, 266: 117151.

Liu J., Feng Z., Zhang B., Zhou J., Cen K., Comparison of two methods for analyzing the activation energy of coal combustion. Journal of Power Engineering, 2006, 26(1): 121–124.

Zhou K., Lin Q., Hu H., Shan F., Fu W., Zhang P., Wang X., Wang C., Ignition and combustion behaviors of single coal slime particles in CO2/O2 atmosphere. Combustion and Flame, 2018, 194: 250–263.

Mei W., Jia T., Zhang Y., Wang T., Wang J., Pan W., Combustion and fragmentation characteristics of single wet coal slime particle. Combustion Science and Technology, 2022: 1–24.

Wang X., Xu J., Ling P., An X., Han H., Chen Y., Jiang L., Wang Y., Su S., Xiang J., A study on the release characteristics and formation mechanism of SO2 during co-combustion of sewage sludge and coal slime. Fuel, 2023, 333: 126511.

Funding

This work has been supported by the National Natural Science Foundation of China (52276110).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary materials

11630_2024_1987_MOESM1_ESM.pdf

Combustion and Self-Desulfurization Characterization of Blended Low-Rank Coals for Improved Resource Utilization in Fluidized Bed Boilers

Rights and permissions

About this article

Cite this article

Su, L., Zhang, C., Zhang, Y. et al. Combustion and Self-Desulfurization Characterization of Blended Low-Rank Coals for Improved Resource Utilization in Fluidized Bed Boilers. J. Therm. Sci. 33, 1242–1256 (2024). https://doi.org/10.1007/s11630-024-1987-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-024-1987-z