Abstract

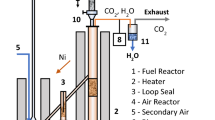

Coal slime is a kind of solid waste and inferior fuel, which is urgently needed to utilize. In this paper, a high-temperature thermal treatment of coal slime in a circulating fluidized bed (CFB) was attempted to achieve resource utilization. In the experiment, the combustion characteristics of dried coal slime during high-temperature thermal treatment were investigated in a 0.5 MW pilot-scale CFB. The stable fluidized combustion of dried coal slime was realized. When the excess air ratio was closer to 1.0, the furnace temperatures would be uniform. The ignition method of dried coal slime was changed correspondingly while the feeding position changed. However, feeding coal slime to the loop seal was instrumental in decreasing NOx emissions. Moreover, the NOx emissions were tried to further control by the post-combustion technology. Post-combustion technology could significantly reduce NOx emissions below 50 mg·Nm−3 while ensuring combustion efficiency. Besides, it was found that there was an optimum excess air ratio in CFB of about 0.9 resulting in minimum NOx emissions of coal slime. The experiment results could well guide the industrial-scale high temperature thermal treatment of coal slime.

Similar content being viewed by others

References

Guerrero L.A., Maas G., Hogland W., Solid waste management challenges for cities in developing countries. Waste Management, 2013, 33(1): 220–232.

Kelessidis A., Stasinakis A.S., Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Management, 2012, 32(6):1186–1195.

Gui X., Liu J., Cao Y., et al., Coal preparation technology: status and development in China. Energy and Environment, 2015, 26 (6–7): 997–1013.

Si Y., Du M., Research progress of slime utilization. Guangdong Chemical Industry, 2017, 44(4): 79–80.

Zhang Y., Zhao J., Ma Z., et al., Effect of oxygen concentration on oxy-fuel combustion characteristic and interactions of coal gangue and pine sawdust. Waste Management, 2019, 87: 288–294.

Wang H., Liu S., Li X., et al., Morphological and structural evolution of bituminous coal slime particles during the process of combustion. Fuel, 2018, 218: 49–58.

Song Z., Jing C., Yao L., et al., Microwave drying performance of single-particle coal slime and energy consumption analyses. Fuel Processing Technology, 2016, 143: 69–78.

Song Z., Jing C., Yao L., et al., Coal slime hot air/microwave combined drying characteristics and energy analysis. Fuel Processing Technology, 2016, 156: 491–499.

Song S., Yang Z., Na Y., et al., Investigation on the operating characteristics of a 350 MWe supercritical CFB boiler with a polygonal furnace. Applied Thermal Engineering, 2019, 156: 178–188.

Zhang W., Liu J., Gao M., et al., A novel operation cost optimization system for mix-burning coal slime circulating fluidized bed boiler unit. Applied Thermal Engineering, 2019, 148: 620–631.

Cliffe K.R., Patumsawad S., Co-combustion of waste from olive oil production with coal in a fluidised bed. Waste Management, 2001, 21(1): 49–53.

Gong Z., Liu Z., Zhou T., et al., Combustion and NO emission of shenmu char in a 2 MW circulating fluidized bed. Energy & Fuels, 2015, 29(2): 1219–1226.

Shi Y., Ma Y., The present conditions of circulating fluidized bed boiler for using coal slime in China. Applied Energy Technology, 2012, (06): 29–33.

Wu J., Wang B., Cheng F., Thermal and kinetic characteristics of combustion of coal sludge. Journal of Thermal Analysis & Calorimetry, 2017, 129(3): 1899–1909.

Zhou K., Lin Q., Hu H., et al., Ignition and combustion behaviors of single coal slime particles in CO2/O2 atmosphere. Combustion and Flame, 2018, 194: 250–263.

Zhou K., Lin Q., Hu H., et al., The ignition characteristics and combustion processes of the single coal slime particle under different hot-coflow conditions in N2/O2 atmosphere. Energy, 2017, 136: 173–184.

Wang H., Liu S., Wang X.Y., et al., Ignition and combustion behaviors of coal slime in air. Energy & Fuels, 2017, 31(10): 11439–11447.

Yin W., Li B., Wu Y., et al., Model of coal slime combustion behavior in CFB boiler. MeitanXuebao/Journal of the China Coal Society, 2015, 40(7): 1628–1633.

Ministry of Environmental Protection of People’s Republic of China Emission standard of air pollutants for thermal power plants (GB 13223-2011), 2011.

Neuwahl F., Cusano G., Benavides J., et al., Best available techniques (BAT) reference document for waste incineration: industrial emissions directive 2010/75/EU (Integrated Pollution Prevention and Control). 2019.

Hou Z., Xiao K., Yu Z., et al., Study on NOx emission characteristics in coal slime circulating fluidized bed boiler. Journal of Engineering for Thermal Energy & Power, 2017, 2(11): 68–72.

Gong Z., Zhou T., Lu Q., et al., Combustion and NOx emission characteristics of shenmu char in a circulating fluidized bed with post-combustion. Energy & Fuels, 2016, 30(1): 31–38.

Zhou T., Gong Z., Lu Q., et al., Experimental study on enhanced control of NOx emission from circulating fluidized bed combustion. Energy & Fuels, 2015, 29(6): 3634–3639.

Zhou T., Lu Q., Cao Y., et al., Study on the combustion and NOx emission characteristics of low rank coal in a circulating fluidized bed with post-combustion. Canadian Journal of Chemical Engineering, 2017, 95(12): 2333–2340.

Song G., Xiao Y., Yang Z., et al., A comparative study on characteristics of ultra-low NOx emission and fly ash between Fugu bituminous and its semi-coke with post-combustion. Fuel Processing Technology, 2021, 211: 106618.

Ponzio A., Senthoorselvan S., Yang W., et al., Ignition of single coal particles in high-temperature oxidizers with various oxygen concentrations. Fuel, 2008, 87(6): 974–987.

Khatami R., Stivers C., Levendis Y., Ignition characteristics of single coal particles from three different ranks in O2/N2 and O2/CO2 atmospheres. Combustion & Flame, 2012, 159(12): 3554–3568.

Riaza J., Khatami R., Levendis Y., et al., Single particle ignition and combustion of anthracite, semi-anthracite and bituminous coals in air and simulated oxy-fuel conditions. Combustion & Flame, 2014, 161(4): 1096–1108.

Johnsson J.E., Formation and reduction of nitrogen oxides in fluidized-bed combustion. Fuel, 1994, 73: 1398–1415.

Furusawa T., Tsunoda M., Tsujimura M., et al., Nitric oxide reduction by char and carbon monoxide: fundamental kinetics of nitric oxide reduction in fluidized bed combustion of coal. Fuel, 1985, 64(9): 1306–1309.

Hayhurst A., Lawrence A., The amounts of NOx and N2O formed in a fluidized bed combustor during the burning of coal volatiles and also of char. Combustion & Flame, 1996, 105(3): 341–357

Schönenbeck C., Gadiou R., Schwartz D., A kinetic study of the high temperature NO-char reaction. Fuel, 2004, 83(4–5): 443–450.

He J., Song W., Gao S., et al., Experimental study of the reduction mechanisms of NO emission in decoupling combustion of coal. Fuel Processing Technology, 2006, 87(9): 803–810.

Xu M., Li S., Wu Y., et al., Reduction of recycled NO over char during oxy-fuel fluidized bed combustion: Effects of operating parameters. Applied Energy, 2017, 199: 310–322.

Xu M., Li S., Wu Y., et al., The characteristics of recycled NO reduction over char during oxy-fuelfluidized bed combustion. Applied Energy, 2017, 190: 553–562.

Marek W., Pels J., Moulijn J., The fate of nitrogen functionalities in coal during pyrolysis and combustion. Fuel, 1995, 74(4): 507–516.

Gong B., Buckley A., Lamb R., et al., XPS determination of the forms of nitrogen in coal pyrolysis chars. Surface and Interface Analysis, 1999, 28(1): 126–130.

Pietrzak R., XPS study and physico-chemical properties of nitrogen-enriched microporous activated carbon from high volatile bituminous coal. Fuel, 2009, 88(10): 1871–1877.

Acknowledgments

This work was financially supported by the National Key Research & Development Program of China (Grant No. 2018YFB0605002) and “Transformational Technologies for Clean Energy and Demonstration”, Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No. XDA21040100).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, G., Xiao, Y., Yang, Z. et al. Experiment Study on the High-Temperature Thermal Treatment and Ultra-Low NOx Control of Solid Waste Coal Slime in Circulating Fluidized Bed. J. Therm. Sci. 31, 2244–2251 (2022). https://doi.org/10.1007/s11630-022-1644-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-022-1644-3