Abstract

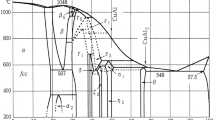

The interfacial reactions between Cu and Al during ultrasonic welding were investigated, focusing on the effect of Pd in Pd-coated Cu and Pd-alloyed Cu (0.3 wt% and 2 wt% PdCu). For Pd-coated Cu–Al bonding, it is found that Pd layer would act as diffusion barrier layer at the interface, and intermetallic compounds (IMCs) formed at Pd-free location for as-welded condition. As annealing time increases, Cu atoms and Al atoms bypassed the fractured Pd layer to form IMCs at the interface. Combining experimental observations, a model of Pd diffusion barrier effect was first proposed at the Pd-coated Cu–Al interface. For Pd-alloyed Cu–Al bonding, Pd can promote the atomic diffusion of active elements and accelerate the formation of IMCs, and excessive 2 wt% Pd addition can lead to the appearance of voids and cracks at interface, which is destructive for reliable interconnection structure. The thickness of the interfacial IMCs for pure Cu and 0.3 wt% PdCu at different heat treatment conditions has a linear relationship with the square root of time, which means that the growth of IMCs is controlled by volume diffusion. The diffusion activation energy of IMCs for 0.3 wt% PdCu (46.08 kJ/mol, 52.88 kJ/mol, and 65.35 kJ/mol for Cu9Al4, CuAl and CuAl2 respectively) was smaller than that for pure Cu (60.24 kJ/mol, 58.12 kJ/mol, and 82.94 kJ/mol for Cu9Al4, CuAl and CuAl2 respectively). Furthermore, the percentage of Cu9Al4 in the whole IMC decreased for 0.3 wt% PdCu, which can reduce the halogen corrosion from epoxy molding compound (EMC) during the reliability test of highly accelerated temperature and humidity stress testing (HAST).

Similar content being viewed by others

References

Preeti S. Chauhan, Anupam Choubey, ZhaoWei Zhong, Michael G. Pecht, Copper Wire Bonding (Springer, New York, 2014)

Martin Schneider-Ramelow, Christian Ehrhardt, Microelectron. Reliab. 63, 336 (2016)

H. Clauberg, P. Backus, B. Chylak, Microelectron. Reliab. 51, 75 (2011)

F.Y. Hung, Y.T. Wang, L.H. Chen, T.S. Lui, Mater. Trans. 47, 1776 (2006)

Z.W. Zhong, Microelectron. Reliab. 51, 4 (2011)

T. Uno, Microelectron. Reliab. 51, 148 (2011)

H. Xu, C. Liu, V. Silberschmidt, Z. Chen, J. Electron. Mater. 39, 124 (2010)

H. Xu, C. Liu, V.V. Silberschmidt, S.S. Pramana, T.J. White, Z. Chen, V.L. Acoff, Acta Mater. 59, 5661 (2011)

Y.-W. Lin, R.-Y. Wang, W.-B. Ke, I.S. Wang, Y.-T. Chiu, K.-C. Lu, K.-L. Lin, Y.-S. Lai, Mater. Sci. Eng. A 543, 152 (2012)

Y.H. Du, Z.Q. Liu, H.J. Ji, M.Y. Li, M. Wen, J. Mater. Sci.-Mater. Electron. 29, 13774 (2018)

V.K. Patel, S.D. Bhole, D.L. Chen, Sci. Technol. Weld. Join. 17, 202 (2012)

J. Robson, A. Panteli, P.B. Prangnell, Sci. Technol. Weld. Join. 17, 447 (2012)

M. Santella, E. Brown, M. Pozuelo, T.-Y. Pan, J.-M. Yang, Sci. Technol. Weld. Join. 17, 219 (2012)

Y.Y. Zhao, D. Li, Y.S. Zhang, Sci. Technol. Weld. Join. 18, 354 (2013)

S. Matsuoka, H. Imai, J. Mater. Process. Technol. 209, 954 (2009)

J.W. Yang, B. Cao, X.C. He, H.S. Luo, Sci. Technol. Weld. Join. 19, 500 (2014)

M. Petzold, L. Berthold, D. Katzer, H. Knoll, D. Memhard, P. Meier, K.-D. Lang, Microelectron. Reliab. 40, 1515 (2000)

H. Xu, C. Liu, V.V. Silberschmidt, S.S. Pramana, T.J. White, Z. Chen, Scr. Mater. 61, 165 (2009)

H. Xu, C. Liu, V.V. Silberschmidt, S.S. Pramana, T.J. White, Z. Chen, M. Sivakumar, V.L. Acoff, J. Appl. Phys. 108, 113517 (2010)

T.T. Mattila, J.K. Kivilahti, J. Electron. Mater. 34, 969 (2005)

X.J. Liu, I. Ohnuma, R. Kainuma, K. Ishida, J. Alloy Compd. 264, 201 (1998)

M.P. Shearer, S.K. Sen, C.L. Bauer, Phys. Status Solidi A 69, 139 (1982)

M. Kajihara, Acta Mater. 52, 1193 (2004)

T. Uno, T. Yamada, In Electronic Components and Technology Conference (ECTC), 1725 (2010)

T.M. Wang, F. Cao, P. Zhou, H.J. Kang, Z.N. Chen, Y.N. Fu, T.Q. Xiao, W.X. Huang, Q.X. Yuan, J. Alloy Compd. 616, 550 (2014)

Acknowledgements

This work was financially supported by the National Key R&D Program of China (Grant No. 2017YFB0305700), the National Natural Science Foundation of China (Grant No. 51564025), the National and Local Joint Engineering Laboratory of Advanced Electronic Packaging Materials (Shenzhen Development and Reform Commission 2017-934), and the Fund of the State Key Laboratory of Advanced Technologies for Comprehensive Utilization of Platinum Metals (Grant No. SKL-SPM-201803).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Du, Y., Wen, M., Ji, H. et al. Effects of Pd addition on the interfacial reactions between Cu and Al during ultrasonic welding. J Mater Sci: Mater Electron 30, 12840–12850 (2019). https://doi.org/10.1007/s10854-019-01729-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01729-8