Abstract

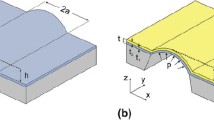

A new theoretical model considering the bending effect for the thick films (the ratio η of thickness to radius was larger than 1/80) using the bulge test method was established based on the energy method. The experiments of Ti films and PVDF films of different ratio η had validated the feasibility of the new theory. The universal applicability of the new theoretical model for different mechanical parameters (E and υ) was verified by FEM. The new expression of pressure-height could well predict the deformation of bulge test for the films with different thickness. As the ratio η increased, the competitive mechanism of bending energy gradually replacing stretching energy in the films was revealed. The modulus and the stress distribution of cross-section could be characterized correctly by the new theory for thick films using the bulge test technique. It will provide a powerful research tool to study the deformation mechanism of thick films in the bulge test.

Similar content being viewed by others

References

Small MK, Nix WD (1992) Analysis of the accuracy of the bulge test in determining the mechanical-properties of thin-films. J Mater Res 7:1553–1563

Sharpe WN, Yuan B, Edwards RL (1997) A new technique for measuring the mechanical properties of thin films. J Micro Electro Mech S 6:193–199

Kraft O, Volkert CA (2001) Mechanical testing of thin films and small structures. Adv Eng Mater 3:99–110

Edwards R, Coles G, Sharpe W Jr (2004) Comparison of tensile and bulge tests for thin-film silicon nitride. Exp Mech 44:49–54

Vlassak JJ, Nix WD (1992) A new bulge test technique for the determination of young modulus and poisson ratio of thin-films. J Mater Res 7:3242–3249

Huang HB, Spaepen F (2000) Tensile testing of free-standing Cu, Ag and Al thin films and Ag/Cu multilayers. Acta Mater 48:3261–3269

Mitchell JS, Zorman CA, Kicher T, Roy S, Mehregany M (2003) Examination of bulge test for determining residual stress, Young’s modulus, and Poisson’s ratio of 3C-SiC thin films. J Aerospace Eng 16:46–54

Nakladal A, Buchhold R, Kohler R, Gerlach G, Stavrev M, Wenzel C, Baumann K, Nowak B (1998) Bulge test investigation of the influence of moisture on mechanical properties of thin polymer layers. In: Brown SGJGHHRJGKP, Muhlstein C (Eds) Microelectromechanical Structures for Materials Research, vol. 518. pp. 105–110

Zheng DW, Xu YH, Tsai YP, Tu KN, Patterson P, Zhao B, Liu QZ, Brongo M (2000) Mechanical property measurement of thin polymeric-low dielectric-constant films using bulge testing method. Appl Phys Lett 76:2008–2010

Tonge TK, Atlan LS, Voo LM, Nguyen TD (2013) Full-field bulge test for planar anisotropic tissues: Part I - Experimental methods applied to human skin tissue. Acta Biomater 9:5913–5925

Small MK, Daniels BJ, Clemens BM, Nix WD (1994) The elastic biaxial modulus of Ag-Pd multilayered thin-films measured using the bulge test. J Mater Res 9:25–30

Nicola L, Xiang Y, Vlassak JJ et al (2006) Plastic deformation of freestanding thin films: experiments and modeling. J Mech Phys Solids 54:2089–2110

Merle B, Goeken M (2011) Fracture toughness of silicon nitride thin films of different thicknesses as measured by bulge tests. Acta Mater 59:1772–1779

Xu D, Liechti KM (2010) Bulge testing transparent thin films with Moir deflectometry. Exp Mech 50:217–225

Beams J (1959) The structure and properties of thin film. Wiley, New York, p 183

Hencky H (1915) On the stress state in circular plates with vanishing bending stiffness. Z Math Phys 63:311–317

Timoshenko S, Woinowsky-Krieger S (1959) Theory of plates and shells. Mc Graw-hill, New York

Tsuchiya T, Funabashi H (2003) Young’s modulus measurement for polysilicon thin film by tensile testing. Trans Inst Electr Eng Japan Part E 123-E

Kruglov A, Enikeev F, Lutfullin RY (2002) Superplastic forming of a spherical shell out a welded envelope. Mat Sci Eng: A 323:416–426

Nasser A, Yadav A, Pathak P, Altan T (2010) Determination of the flow stress of five AHSS sheet materials (DP 600, DP 780, DP 780-CR, DP 780-HY and TRIP 780) using the uniaxial tensile and the biaxial Viscous Pressure Bulge (VPB) tests. J Mater Process Technol 210:429–436

Koc M, Billur E, Cora ON (2011) An experimental study on the comparative assessment of hydraulic bulge test analysis methods. Mater Des 32:272–281

Vlassak JJ (1994) New experimental techniques and analysis methods for the study of the mechanical properties of materials in small volumes. Stanford University

Youssef H, Ferrand A, Calmon P, Pons P, Plana R (2010) Methods to improve reliability of bulge test technique to extract mechanical properties of thin films. Microelectron Reliab 50:1888–1893

Machado G, Favier D, Chagnon G (2012) Membrane curvatures and stress–strain full fields of axisymmetric bulge tests from 3D-DIC measurements. Theory and validation on virtual and experimental results. Exp Mech 52:865–880

Xiang Y, Chen X, Vlassak JJ (2005) Plane-strain bulge test for thin films. J Mater Res 20:2360–2370

Ziebart V, Paul O, Munch U, Schwizer J, Baltes H (1998) Mechanical properties of thin films from the load deflection of long clamped plates. J Microelectromech S 7:320–328

Yu Z, Mao W, Li F, Feng X, Pei Y, Fang D (2014) Magnetic and electric bulge-test instrument for the determination of coupling mechanical properties of functional free-standing films and flexible electronics. Rev Sci Instrum 85:065117

Wan KT, Mai YW (1995) Fracture-mechanics of a new blister test with stable crack-growth. Acta Metall Mater 43:4109–4115

Acknowledgments

The authors are grateful for the support by the National Natural Science Foundation of China (11090330, 11090331 and 11072003), the Chinese National Programs for Scientific Instruments Research and Development (2012YQ03007502) and the Beijing NOVA Program (No.Z151100000315041).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yu, Z., Xu, H., Chen, H. et al. Characterization Method of Thick Films Using the Bulge Test Technique. Exp Mech 56, 881–889 (2016). https://doi.org/10.1007/s11340-016-0139-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0139-0